Patents

Literature

56 results about "Non-Evaporable Getter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

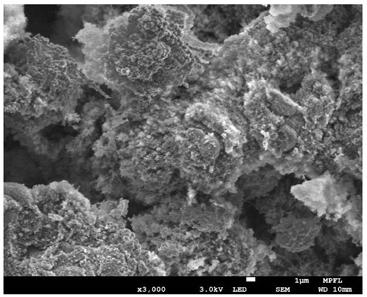

Non evaporable getters (NEG), based on the principle of metallic surface sorption of gas molecules, are mostly porous alloys or powder mixtures of Al, Zr, Ti, V and Fe. They help to establish and maintain vacuums by soaking up or bonding to gas molecules that remain within a partial vacuum. This is done through the use of materials that readily form stable compounds with active gases. They are important tools for improving the performance of many vacuum systems. Sintered onto the inner surface of high vacuum vessels, the NEG coating can be applied even to spaces that are narrow and hard to pump out, which makes it very popular in particle accelerators where this is an issue. The main sorption parameters of the kind of NEGs, like pumping speed and sorption capacity, have low limits. A different type of NEG, which is not coated, is the Tubegetter. The activation of these getters is accomplished mechanically or at a temperature from 550 K. The temperature range is from 0 to 800 K under HV/UHV conditions.

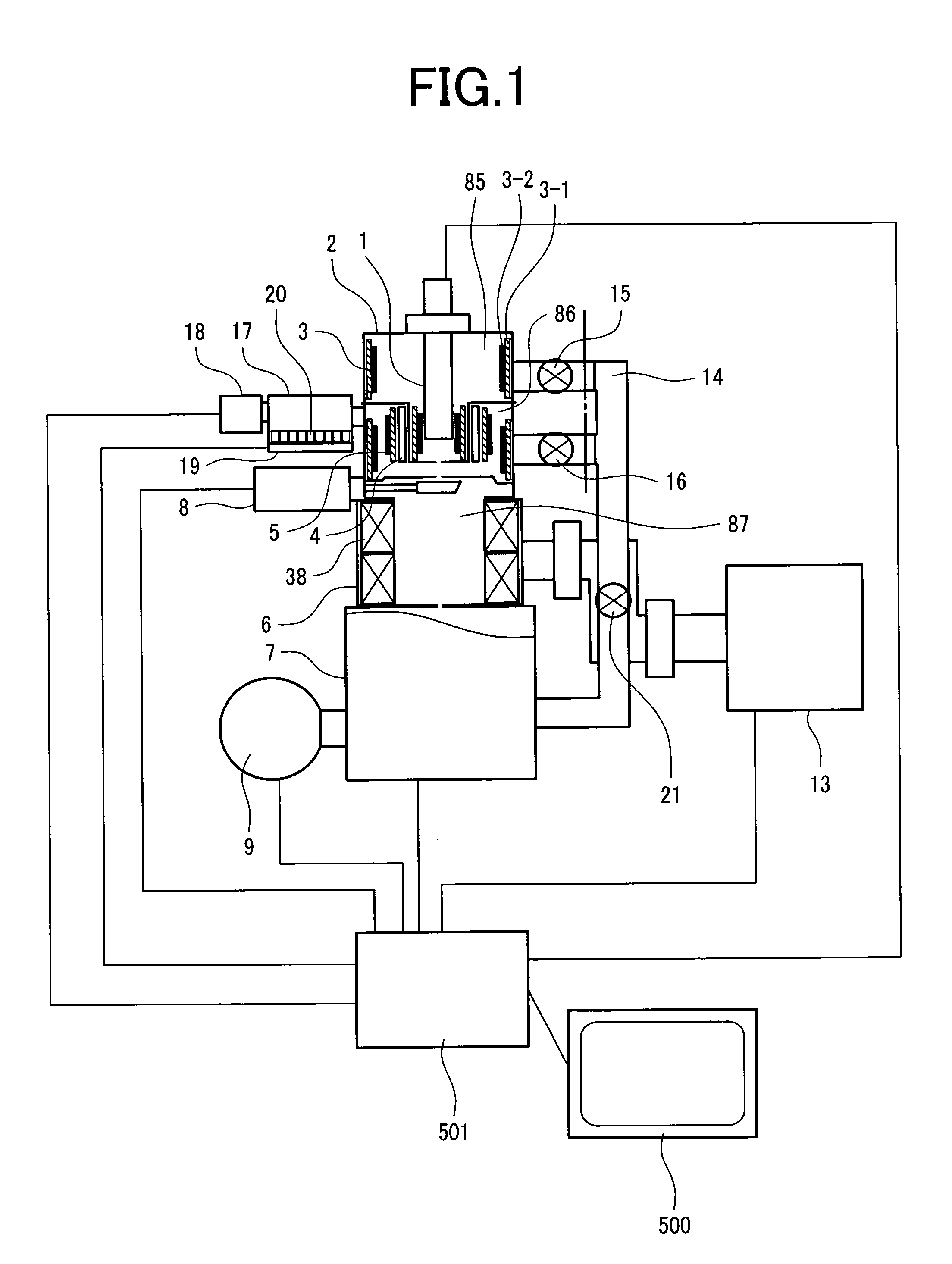

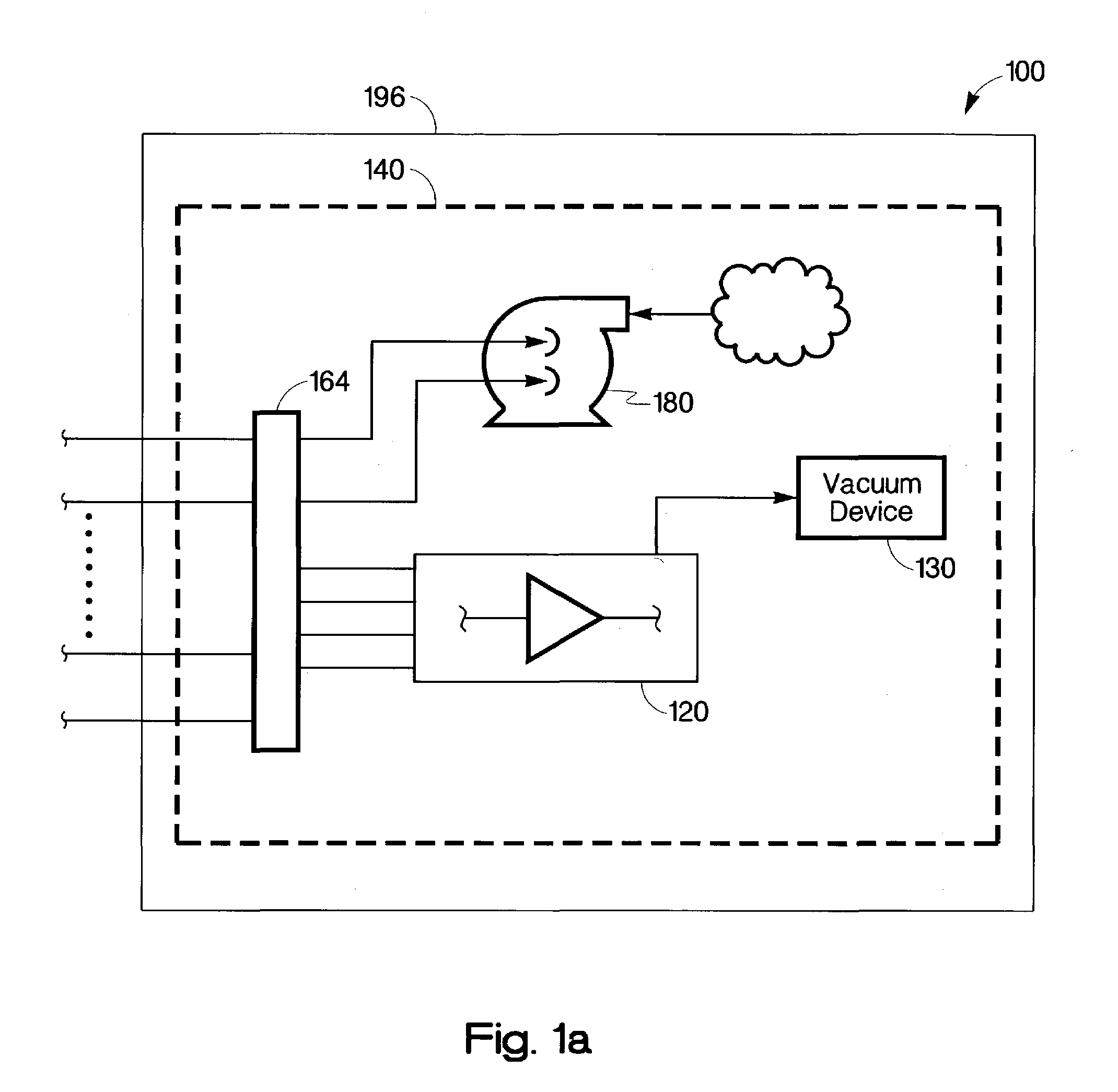

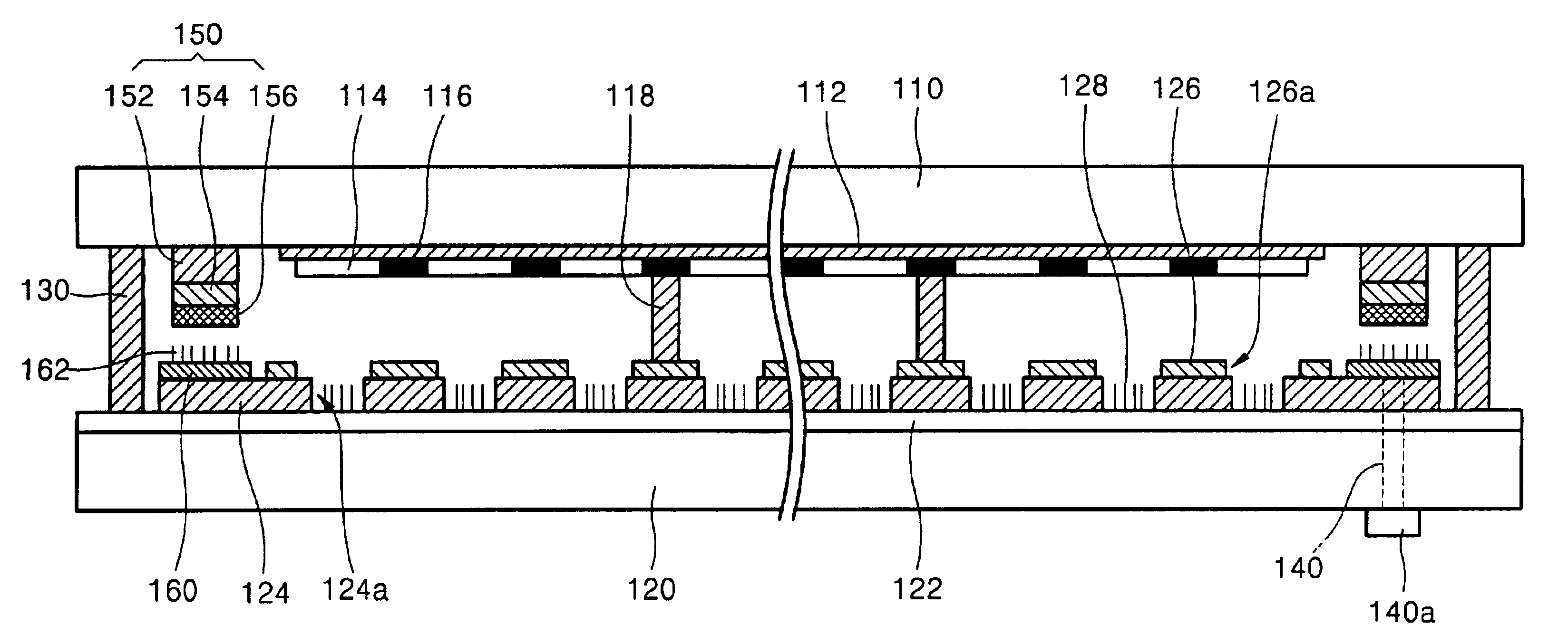

Charged particle beam apparatus

InactiveUS20070102650A1Increase vacuumImprove efficiencyPump componentsThermionic cathodesVacuum pumpingAlloy

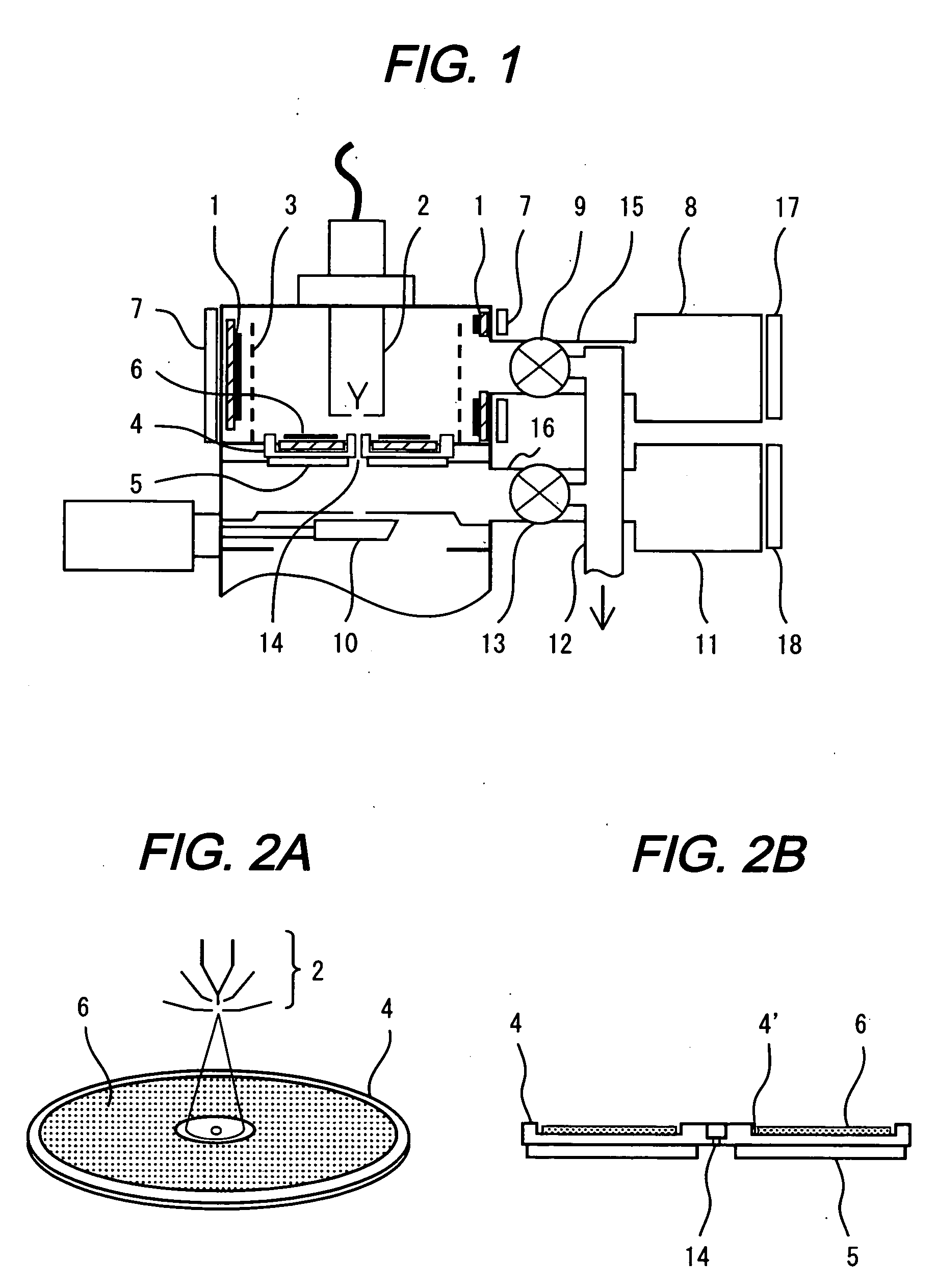

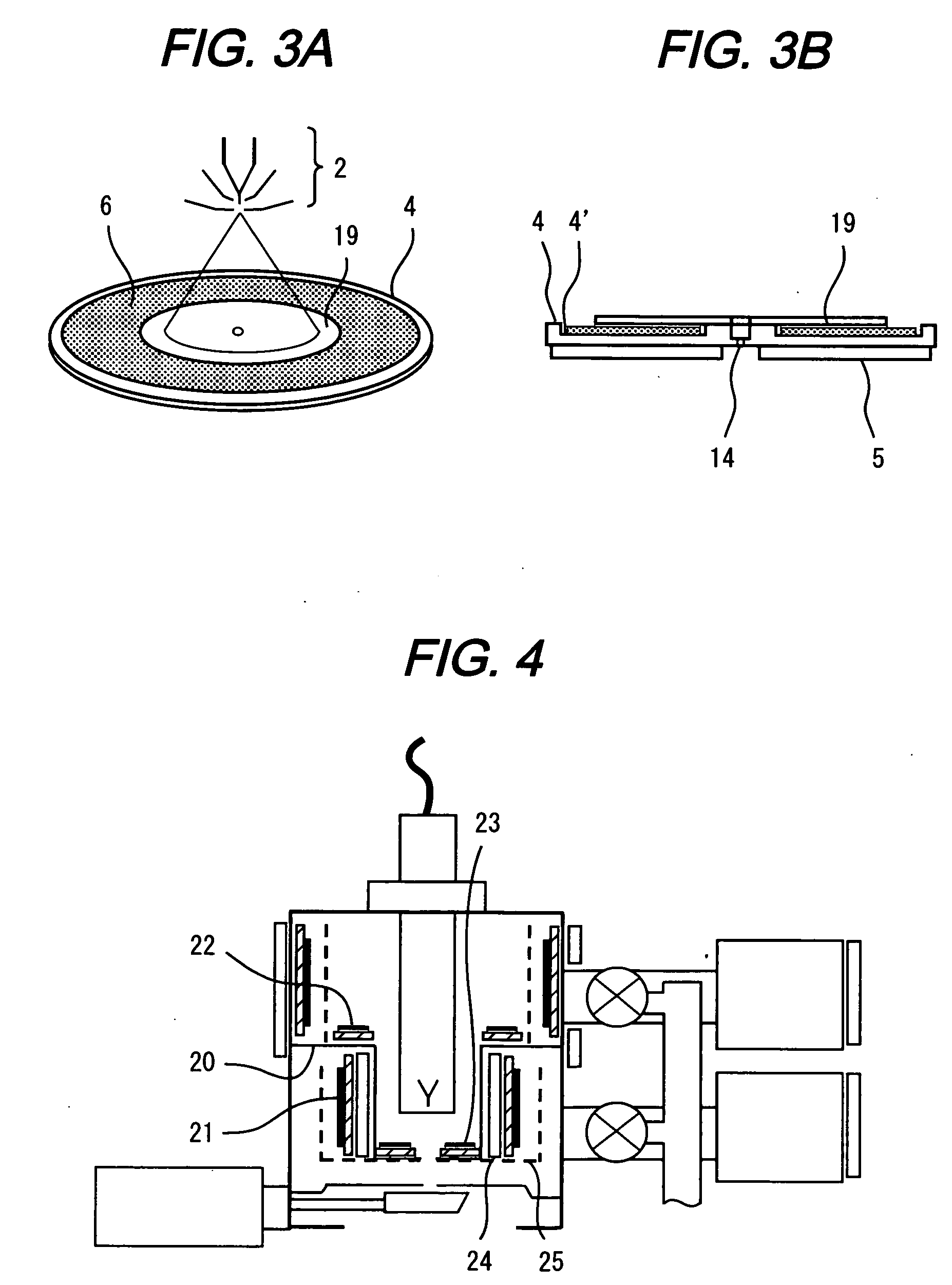

There is provided a compact charged particle beam apparatus with a non-evaporable getter pump which maintains high vacuum even during emission of an electron beam without generating foreign particles. The apparatus comprises: a charged particle source; a charged particle optics which focuses a charged particle beam emitted from the charged particle source on a sample and performs scanning; and means of vacuum pumping which evacuates the charged particle optics. The means of vacuum pumping has a differential pumping structure with two or more vacuum chambers connected through an opening in series. A pump made of non-evaporable getter alloy is placed in an upstream vacuum chamber with a high degree of vacuum, and a gas absorbing surface of the non-evaporable getter alloy is fixed without contact with another part.

Owner:HITACHI HIGH-TECH CORP

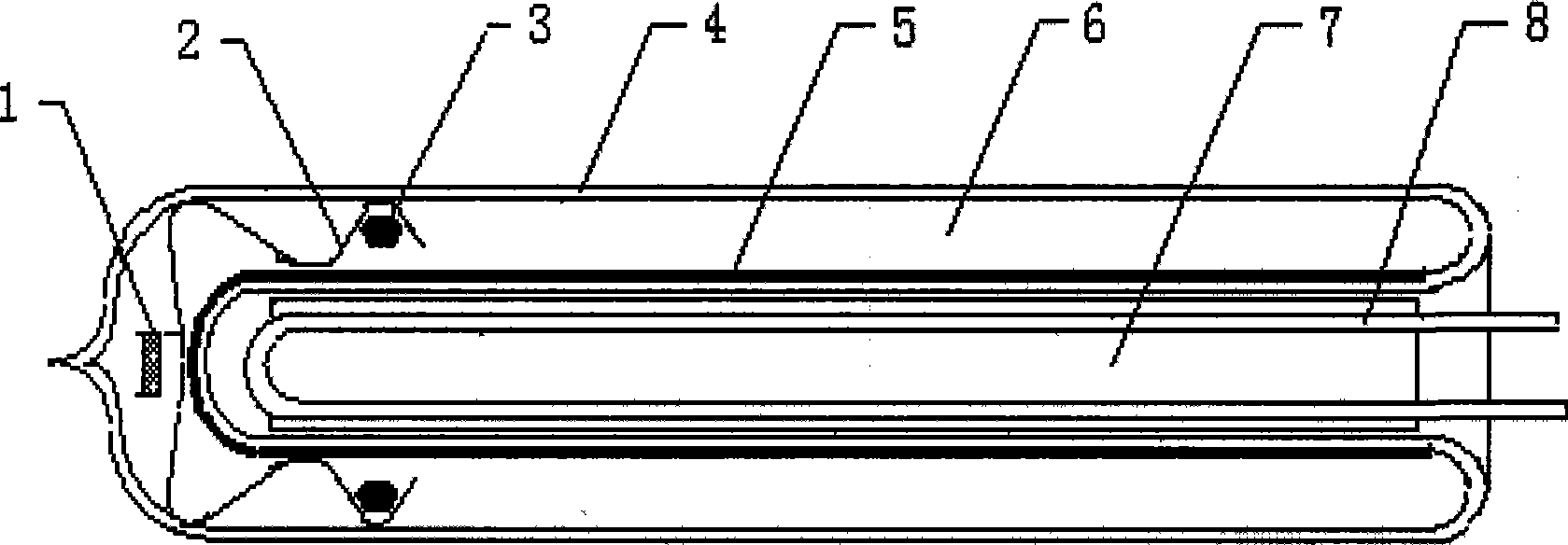

Medium temperature glass-metal structure solar vacuum thermal-collecting tube

InactiveCN101392965AMeet solar air conditioningFulfil requirementsSolar heating energySolar heat devicesMaterials scienceMetallic Nickel

The invention discloses an intermediate temperature glass-metallic structure solar vacuum thermal-collecting tube, which belongs to the technical field of solar utilization, wherein a layer of temperature-resistant anti-oxidation film is plated on the outer surface of a heat-transfer pipe provided with a heat-conductive wing in the intermediate temperature glass-metallic solar vacuum thermal-collecting tube, and the film layer is aluminum or zinc or nickel or chromium or stainless steel; the heat-conductive wing is a thin aluminum plate which is coiled into the shape of an opening cylinder or a semicircular cylinder, and is tightly connected or welded with a U-shaped copper tube or a copper heat pipe of the temperature-resistant anti-oxidation film; and a heat-conductive wing tube is arranged inside the all-glass solar vacuum thermal-collecting tube, and closely contacts the inner wall of the all-glass solar vacuum thermal-collecting tube. A non-evaporable getter can be arranged inside a vacuum interlayer of the all-glass solar vacuum thermal-collecting tube, thereby improving the vacuum service life of the all-glass solar vacuum thermal-collecting tube after the long-term operating temperature is extended to more than 140 DEG C. The invention is a novel intermediate temperature glass-metallic solar vacuum thermal-collecting tube with high cost performance, and can meet the requirements of solar air-conditioners and industrial heat.

Owner:TSINGHUA UNIV

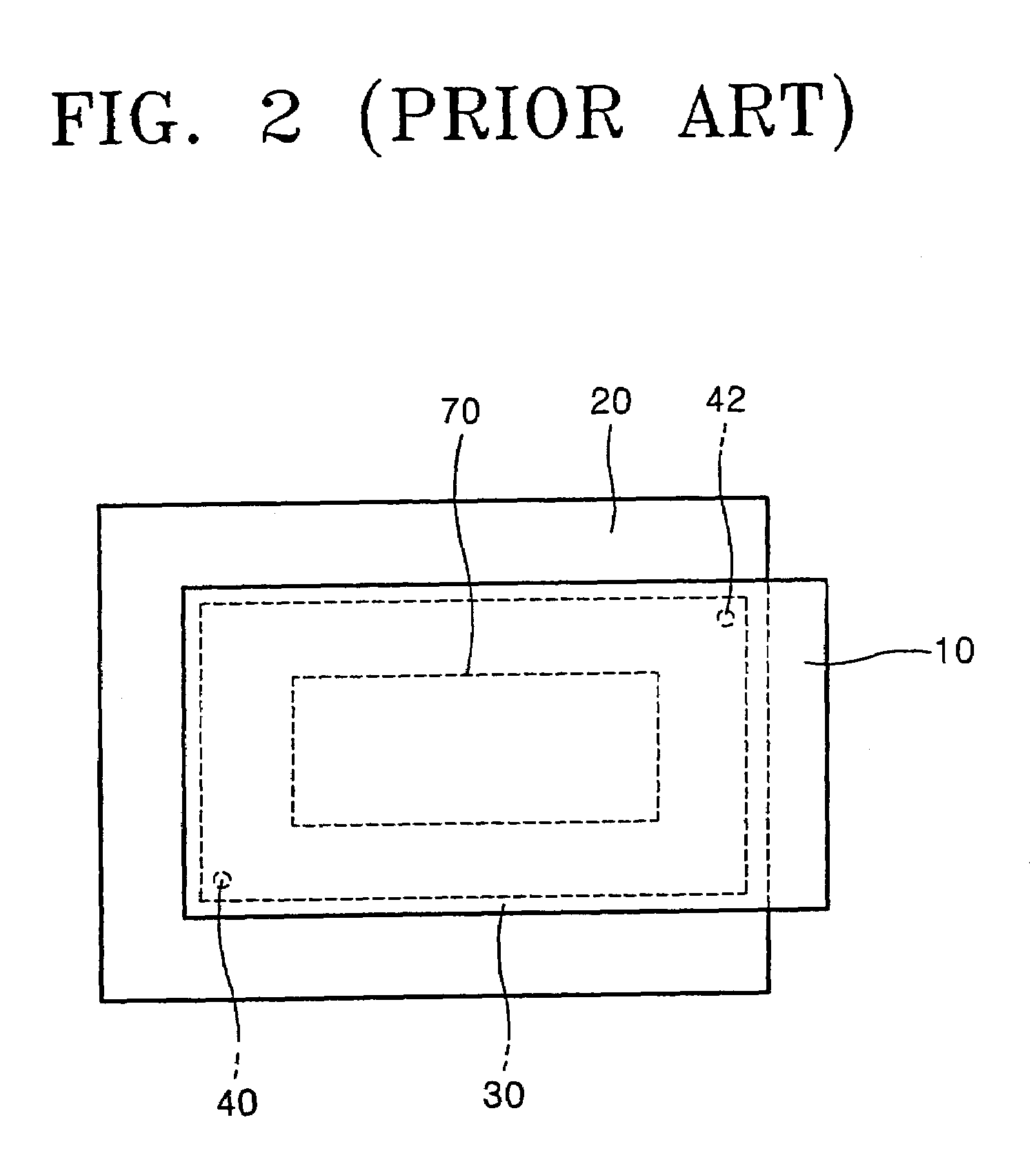

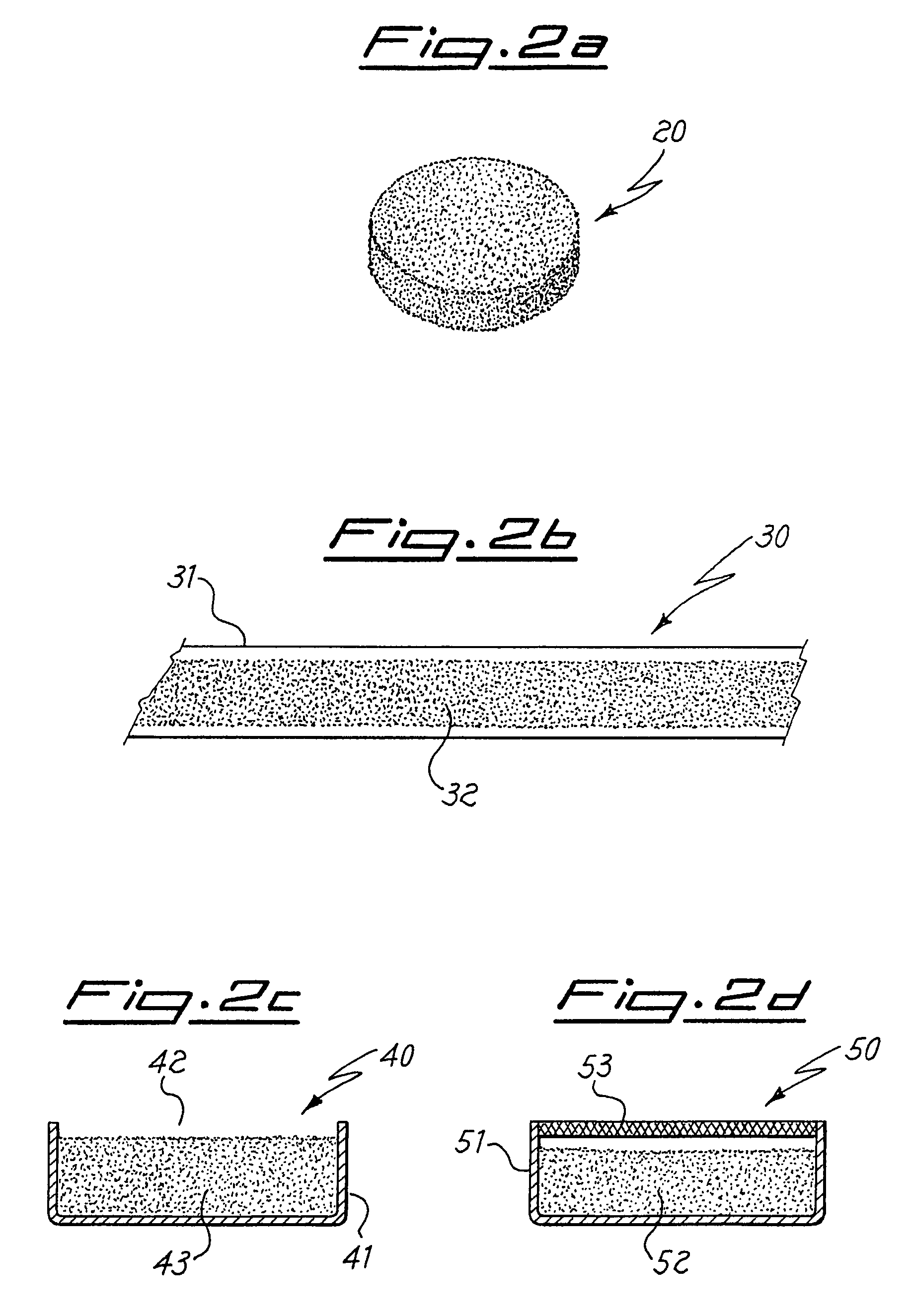

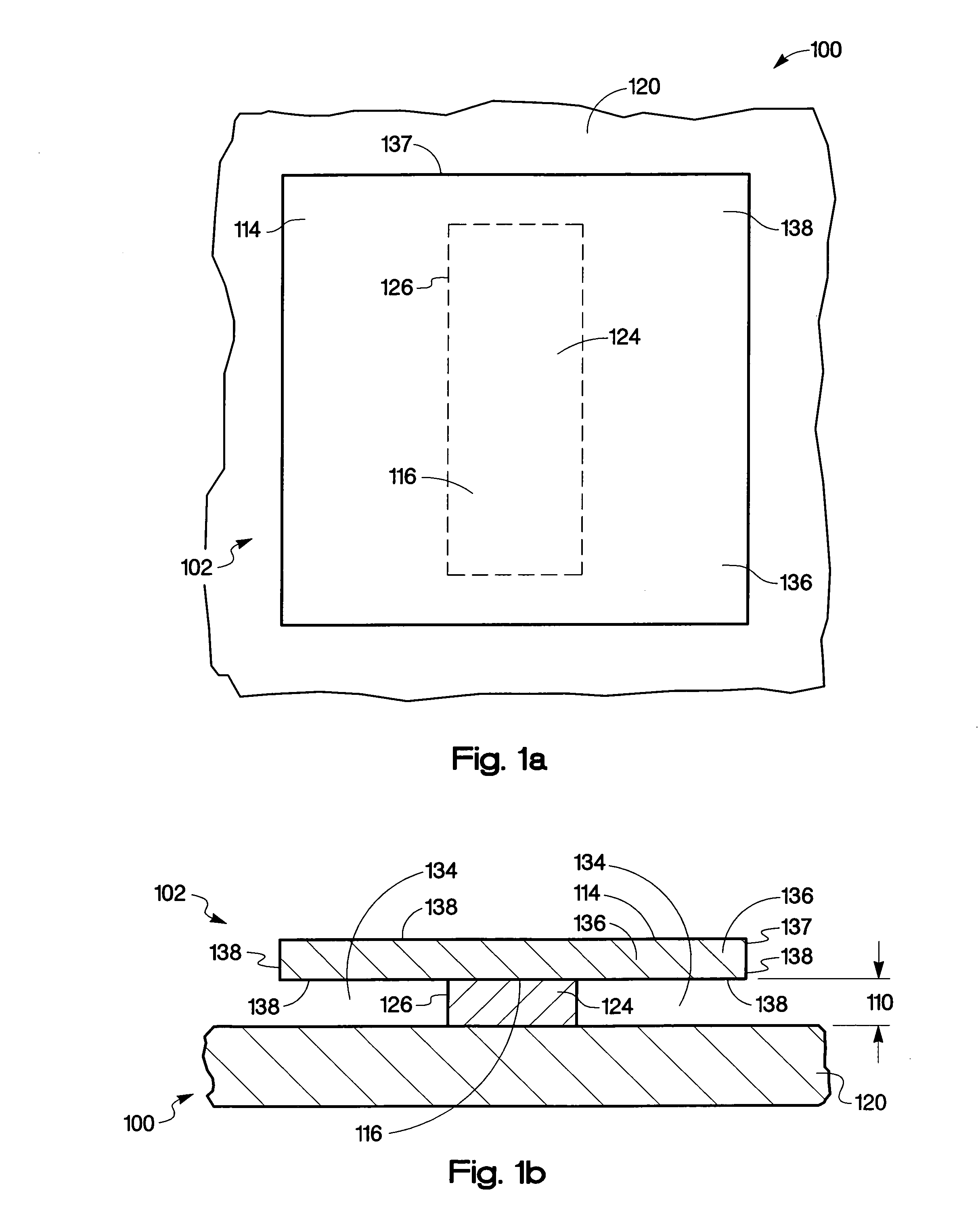

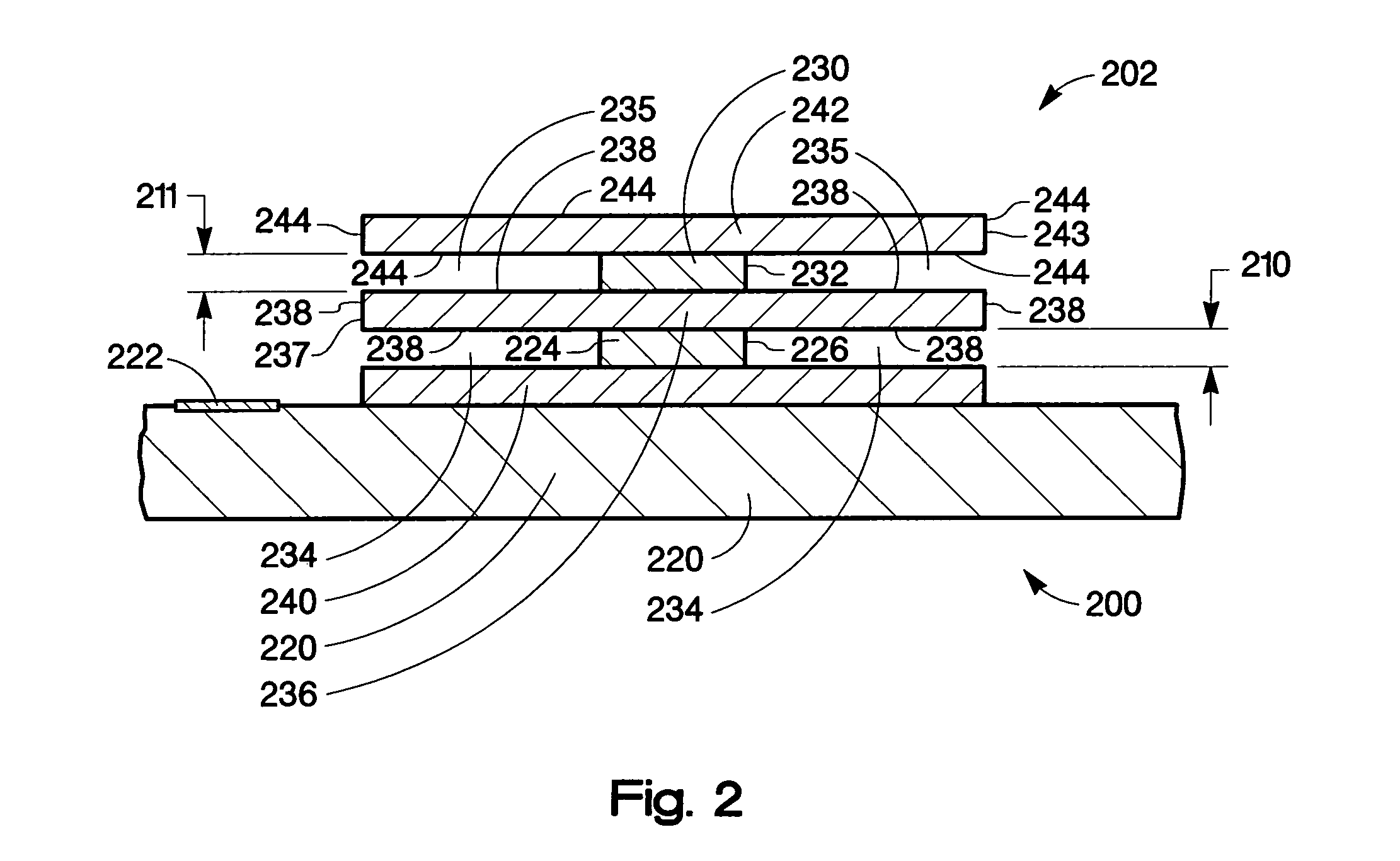

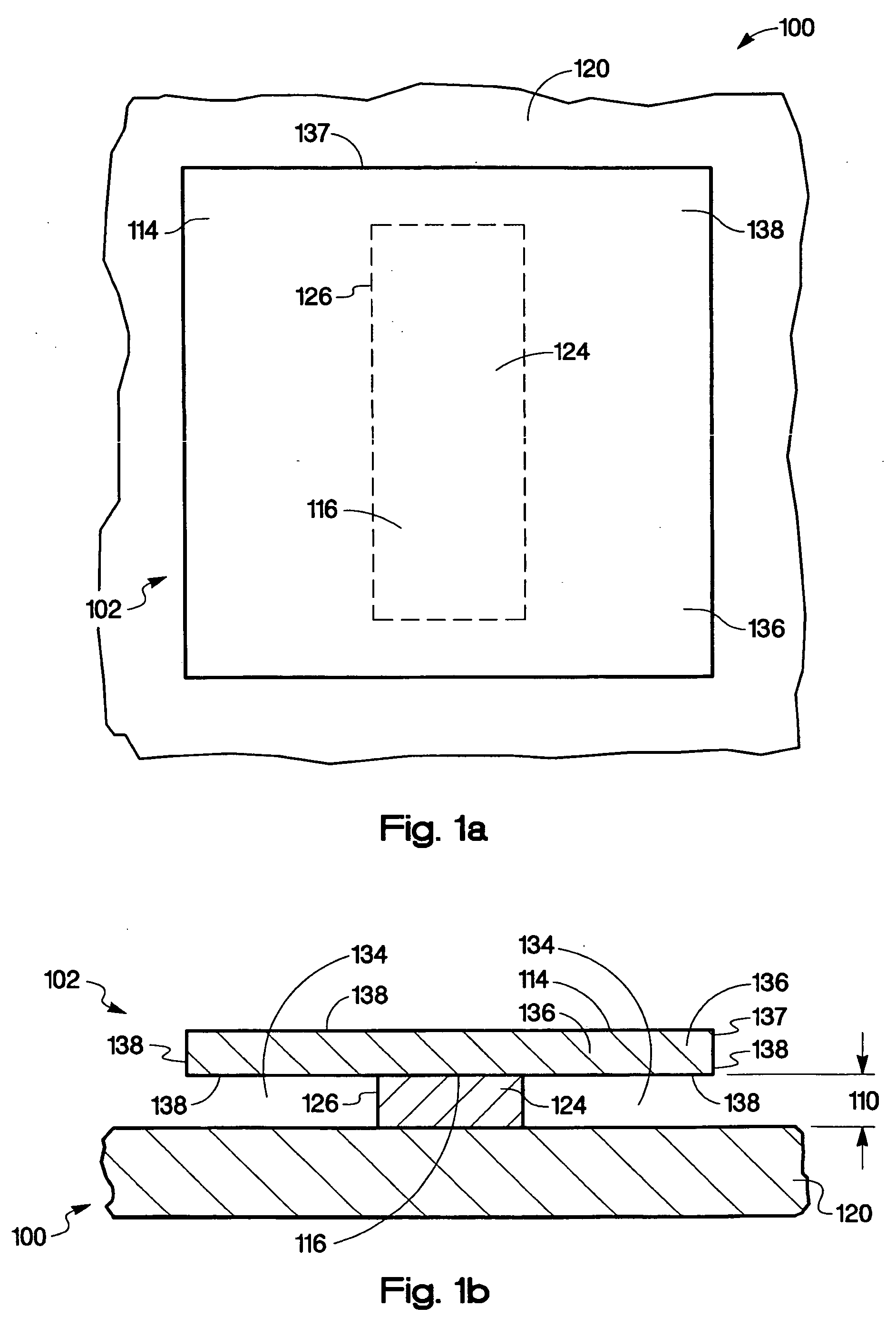

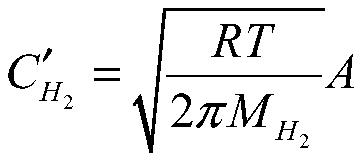

Field emission display manufacturing method having integrated getter arrangement

InactiveUS7131883B2Efficient removalGas filling substance selectionDischarge tube luminescnet screensField emission displayElectron

A field emission display (FED) and a manufacturing method thereof are provided. The FED includes a getter portion isolated outwardly from an active display region. This getter portion includes a non-evaporable getter layer for absorbing gas and an electron emission source for activating the getter layer. Accordingly, by activating the non-evaporable getter, the gas generated in the display is easily absorbed, and the FED is maintained in a high vacuum state.

Owner:SAMSUNG SDI CO LTD

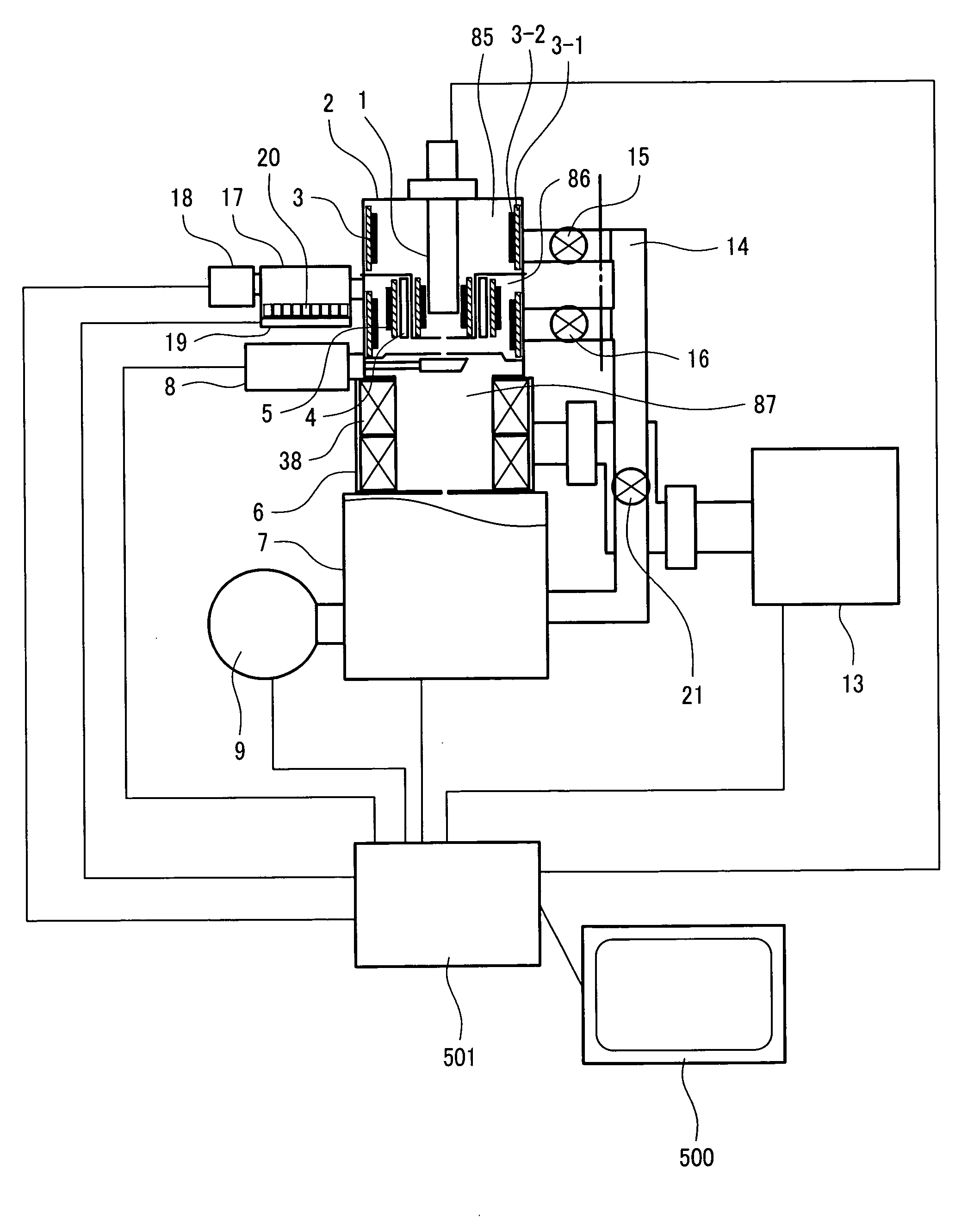

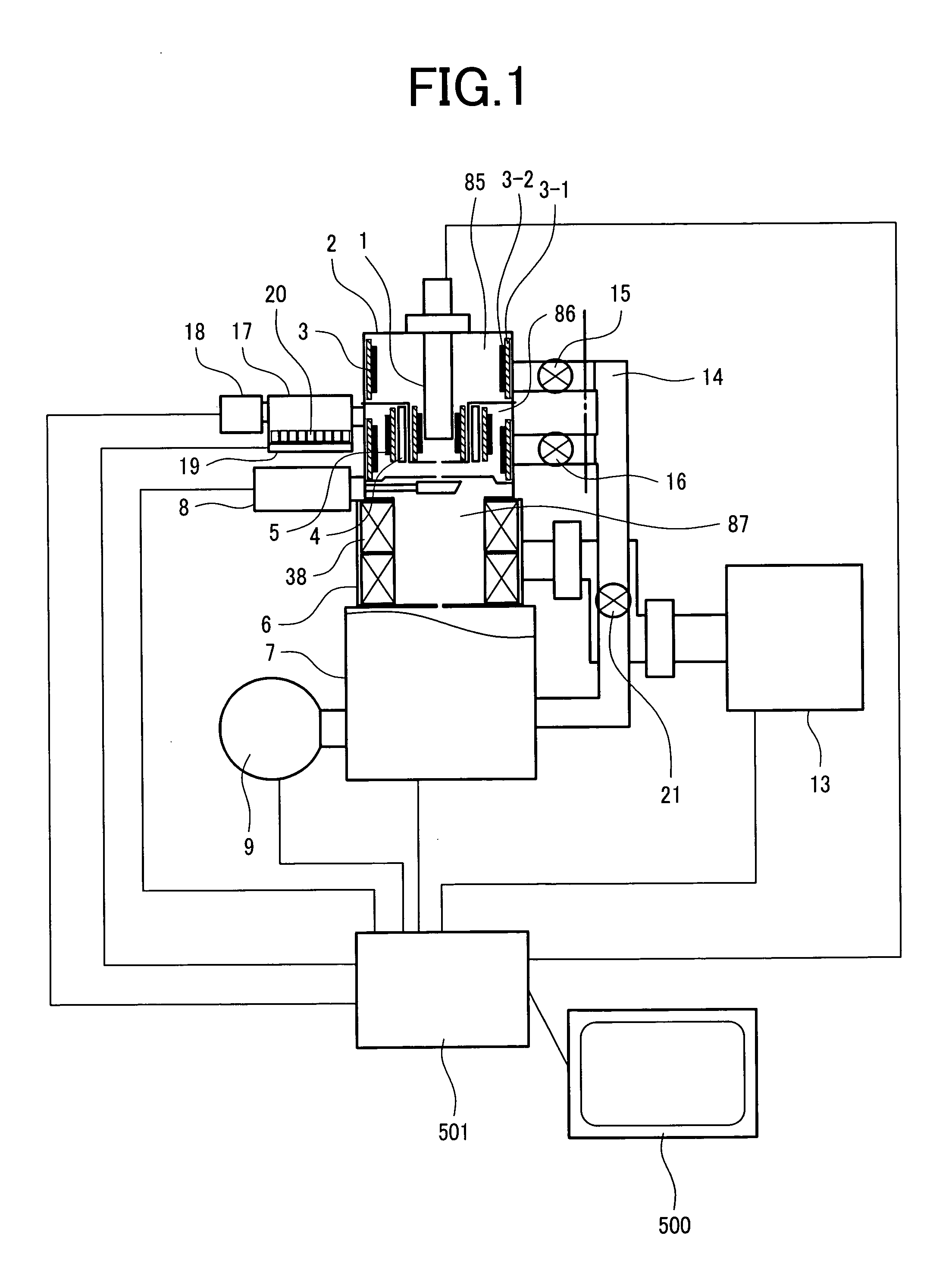

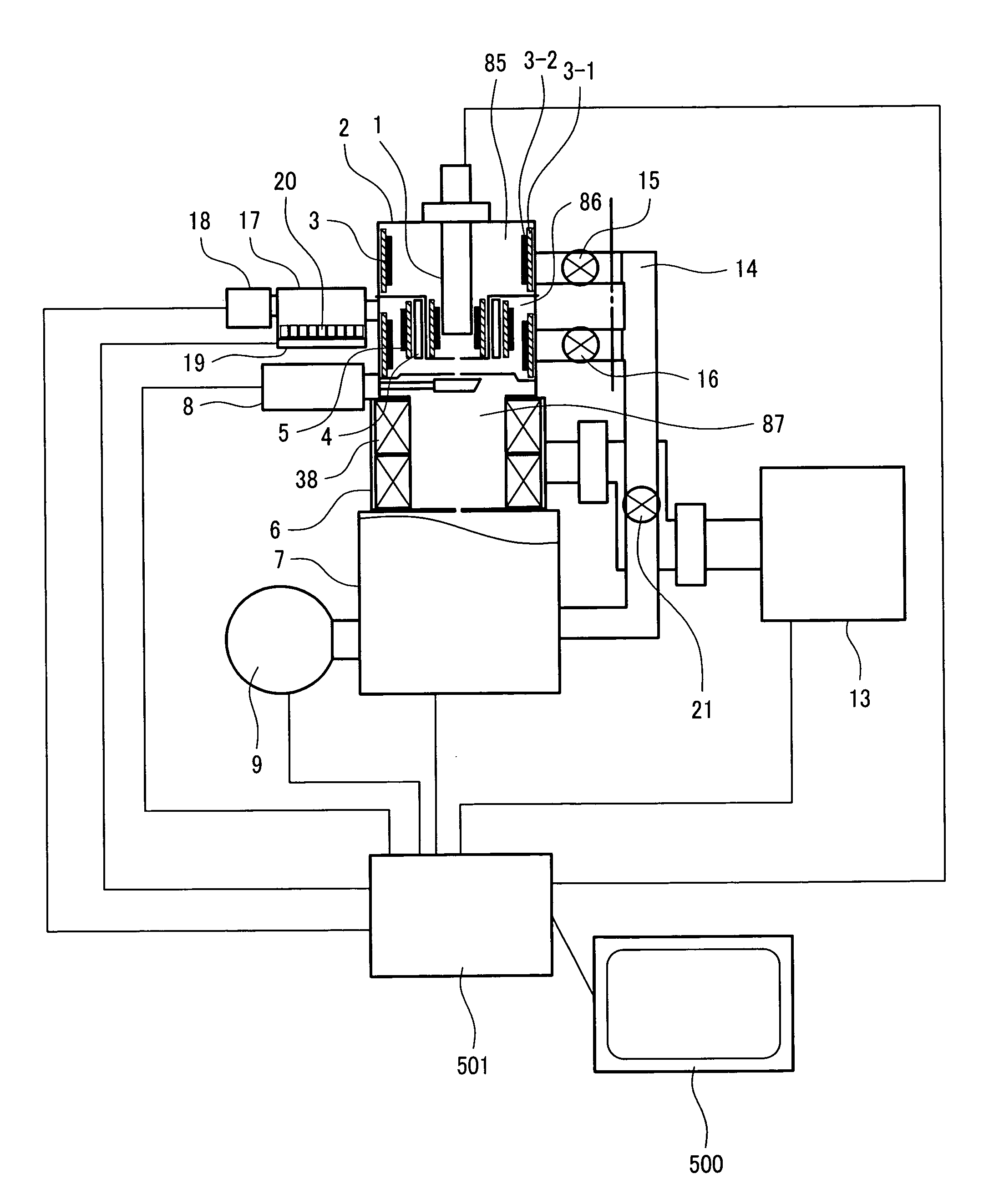

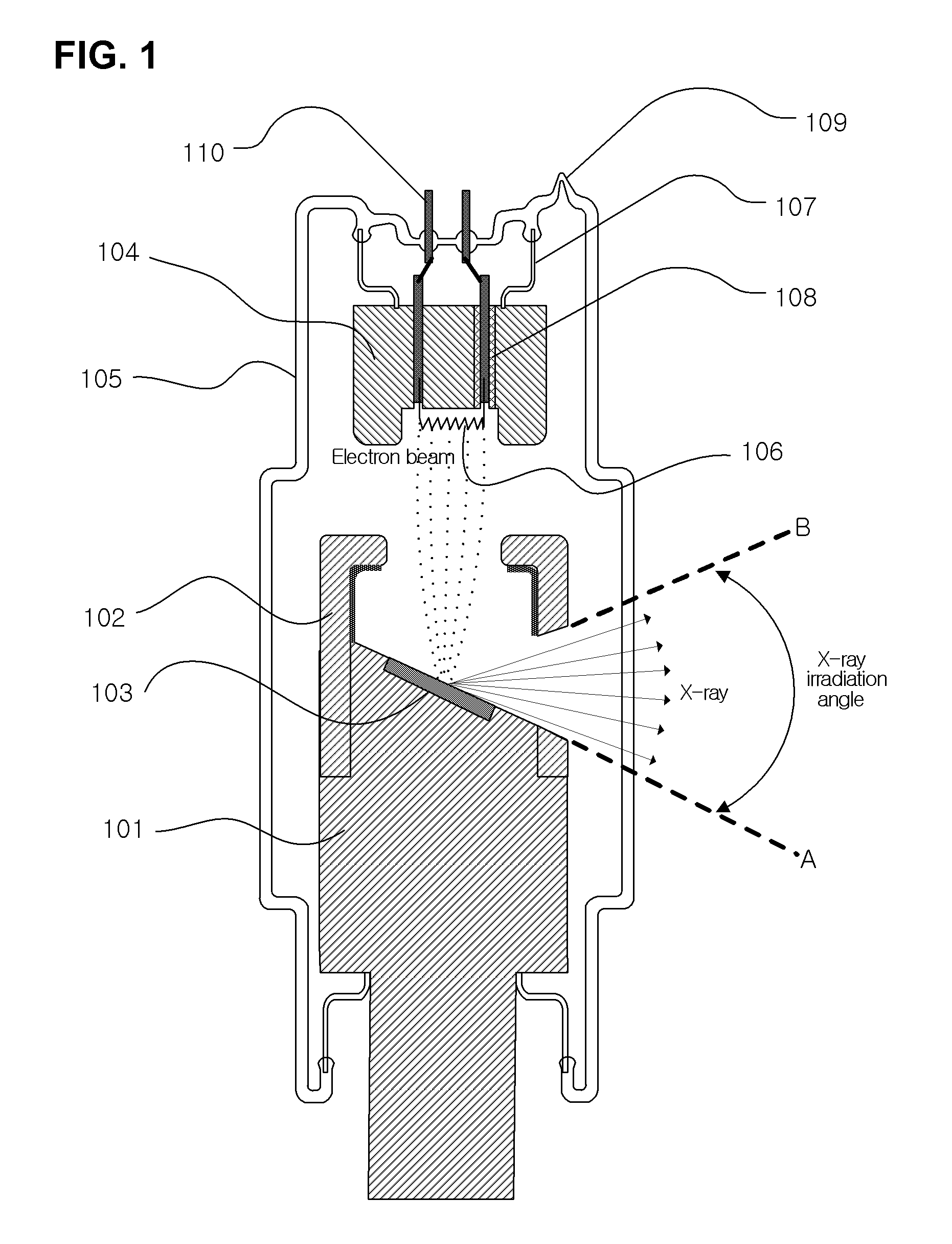

Charged particle beam apparatus

InactiveUS7615765B2Improve efficiencyExtension of timePump componentsThermionic cathodesVacuum pumpingAlloy

There is provided a compact charged particle beam apparatus with a non-evaporable getter pump which maintains high vacuum even during emission of an electron beam without generating foreign particles. The apparatus comprises: a charged particle source; a charged particle optics which focuses a charged particle beam emitted from the charged particle source on a sample and performs scanning; and means of vacuum pumping which evacuates the charged particle optics. The means of vacuum pumping has a differential pumping structure with two or more vacuum chambers connected through an opening in series. A pump made of non-evaporable getter alloy is placed in an upstream vacuum chamber with a high degree of vacuum, and a gas absorbing surface of the non-evaporable getter alloy is fixed without contact with another part.

Owner:HITACHI HIGH-TECH CORP

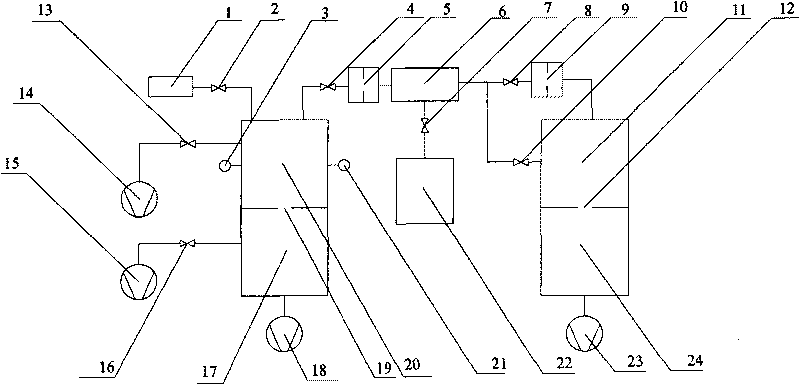

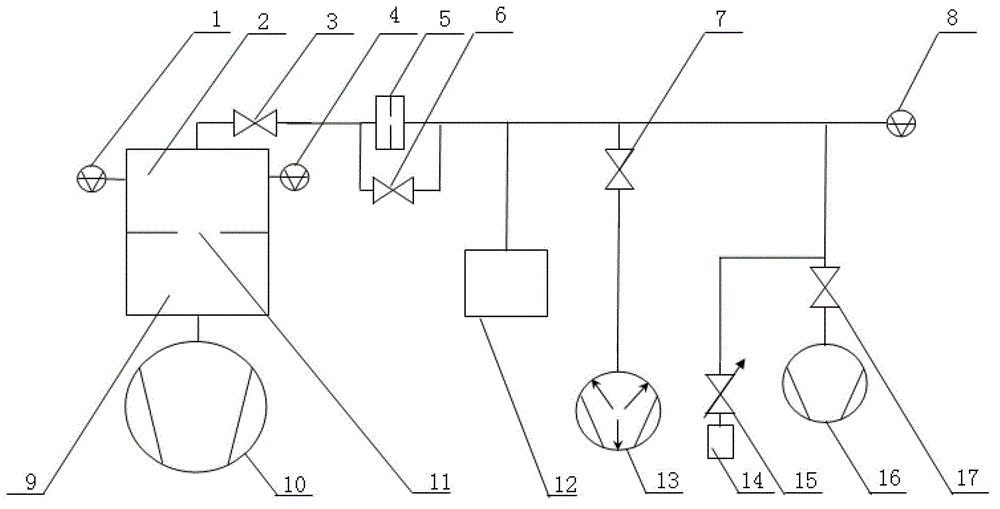

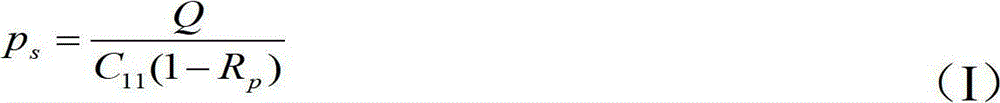

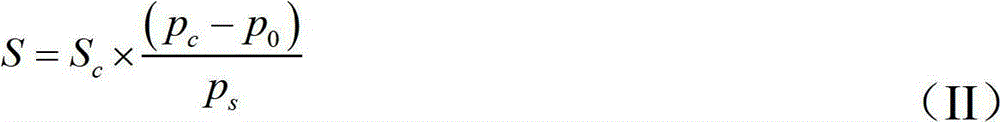

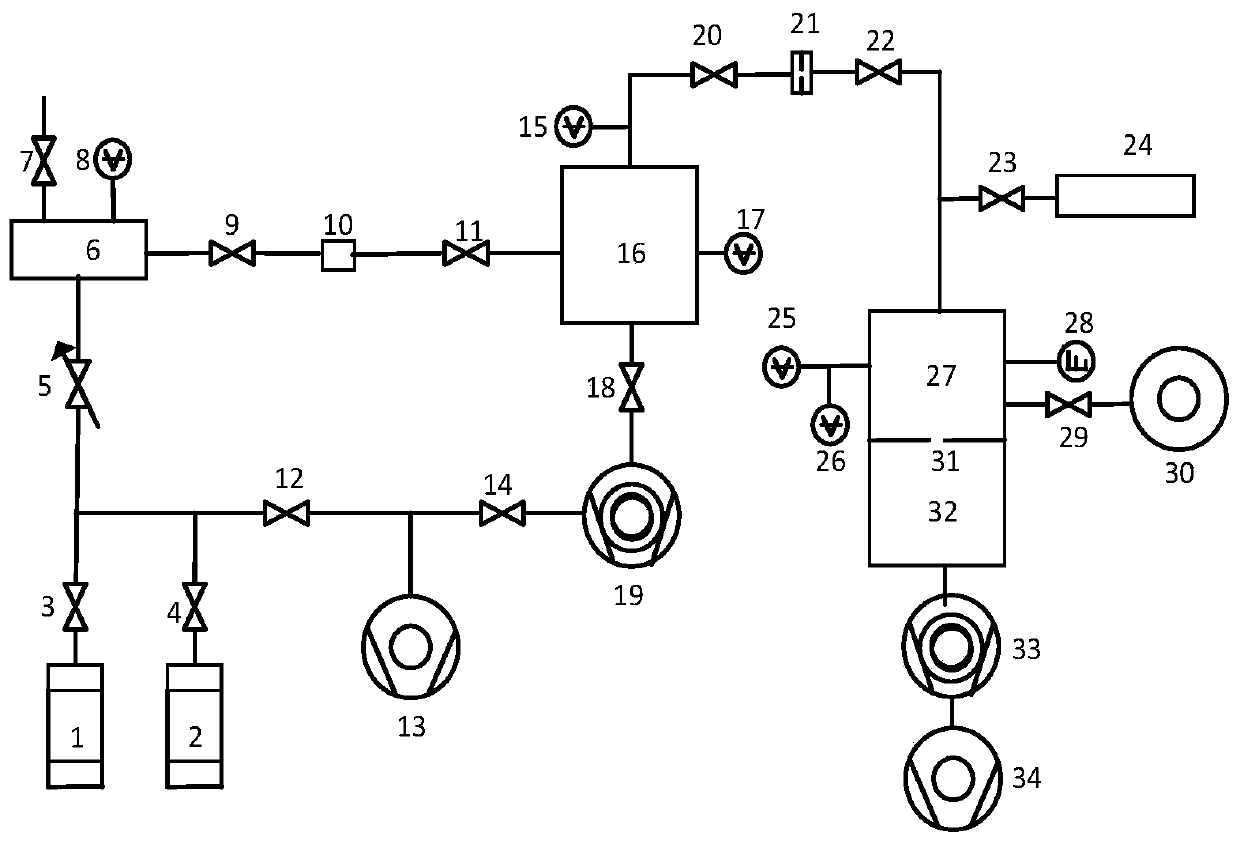

Device and method for calibrating flow-dividing vacuum leaking hole

ActiveCN101713696AWide measurement rangeReduce measurement uncertaintyDetection of fluid at leakage pointMeasurement of fluid loss/gain rateUltra-high vacuumEngineering

The invention relates to a device and a method for calibrating a flow-dividing vacuum leaking hole, in particular to the device and the method for calibrating the vacuum leaking hole, the leakage value of which is less than 1*10-8 Pa.m3 / s by adopting flow-dividing technology, and belongs to the field of measuring technology. The device consists of the calibrated leaking hole, a valve, an ionization gauge, a small hole, a flow-dividing chamber, a non-evaporable getter pump, an ultrahigh vacuum calibrating chamber, a metering hole, a very high vacuum pumping chamber, an oil-free bi-turbo molecular pump air exhauster set, a quadrupole mass spectrometer, a flow meter, a super-high vacuum calibrating chamber, the metering hole, a super-high vacuum pumping chamber and a common molecular pump air exhauster set. The method adopts a fixed flow method gas micro-flow meter to provide a known gas flow rate, so the measuring range of the flow rate is wide and uncertainty of the measurement is low; and by adopting a flow-dividing method to calibrate the vacuum leaking hole, the method of the invention completely avoids a nonlinear error of the quadrupole mass spectrometer and can precisely calibrate the vacuum leaking hole the leakage value of which is less than 1*10-8 Pa.m3 / s.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

Charged particle beam apparatus

ActiveUS20090294697A1Without their problemElectric discharge tubesPortable shielded containersElectron sourceUltra-high vacuum

The present invention provides a charged particle beam apparatus that keeps the degree of vacuum in the vicinity of the electron source to ultra-high vacuum such as 10−8 to 10−9 Pa even in the state where electron beams are emitted using a non-evaporable getter pump and is not affected by dropout foreign particles.The present invention includes a vacuum vessel in which a charged particle source (electron source, ion source, etc.) is disposed and a non-evaporable getter pump disposed at a position that does not directly face electron beams and includes a structure that makes the non-evaporable getter pump upward with respect to a horizontal direction to drop out foreign particles into a bottom in a groove, so that the foreign particles dropped out from the non-evaporable getter pump do not face an electron optical system. Or, the present invention includes a structure that is covered by a shield means, or a means that is disposed immediately on a surface of the non-evaporable getter pump but at a position where the electron beams are not seen and has a concave structure capable of trapping the dropout foreign particles on a lower portion of the non-evaporable getter pump.

Owner:HITACHI HIGH-TECH CORP

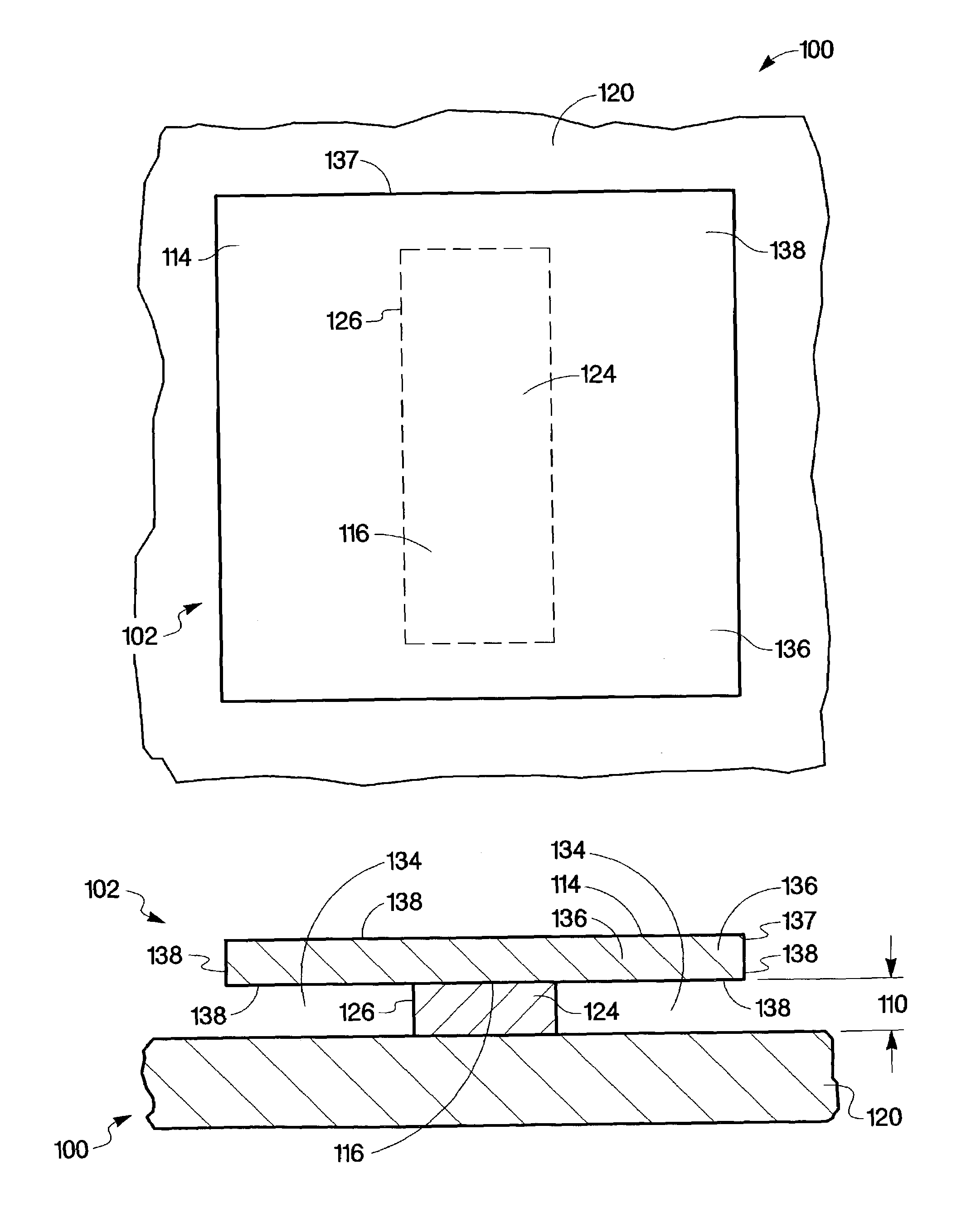

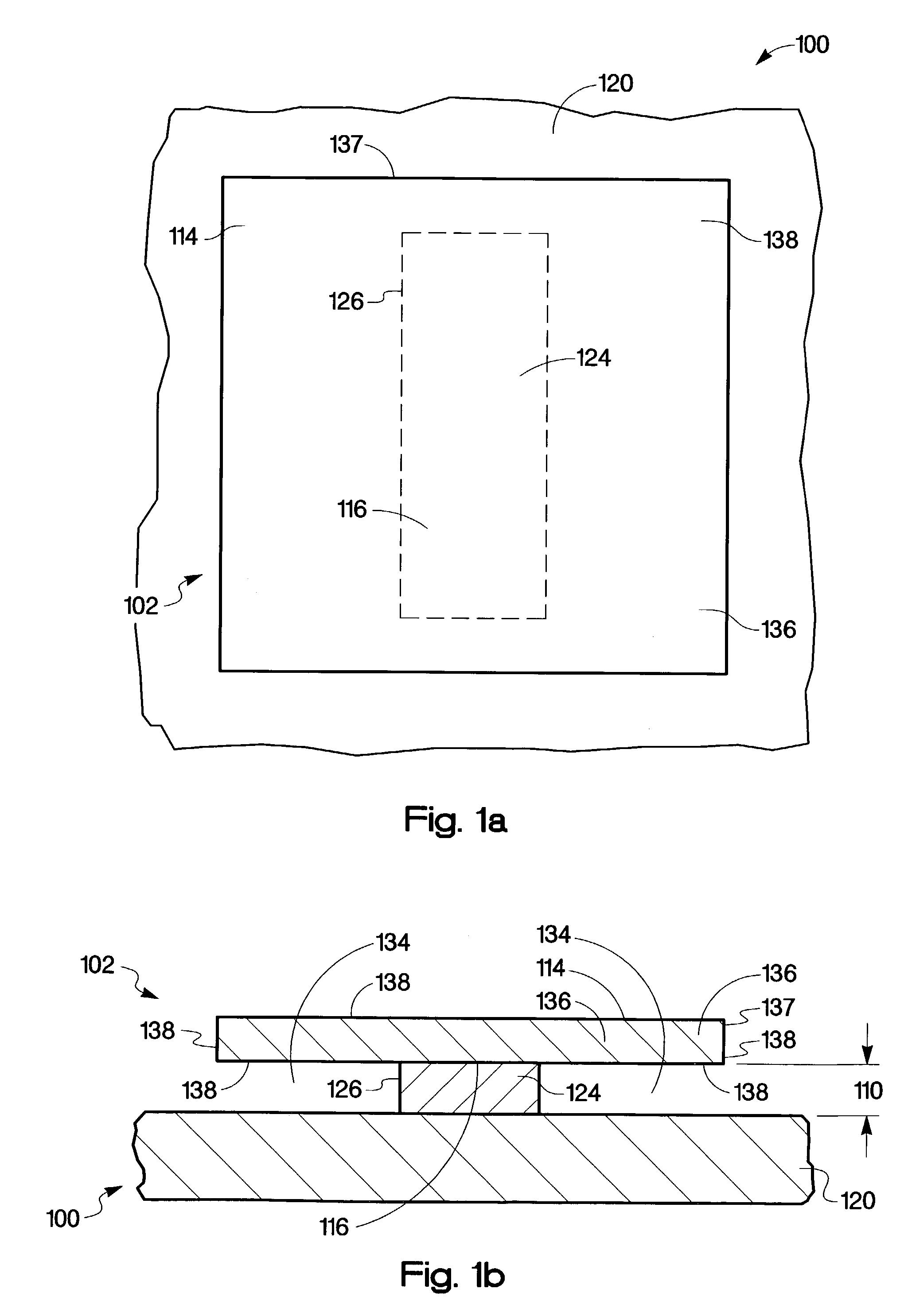

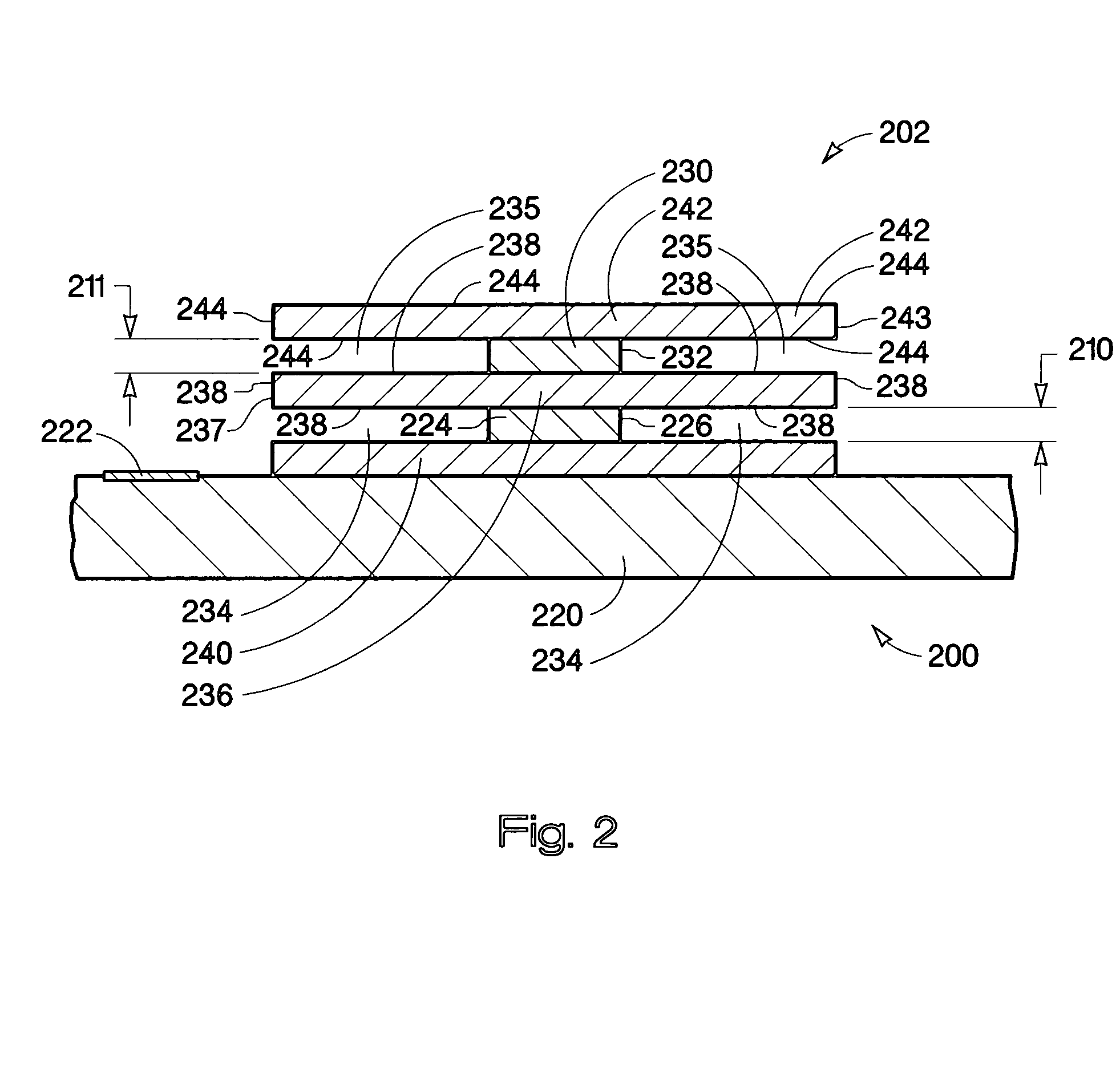

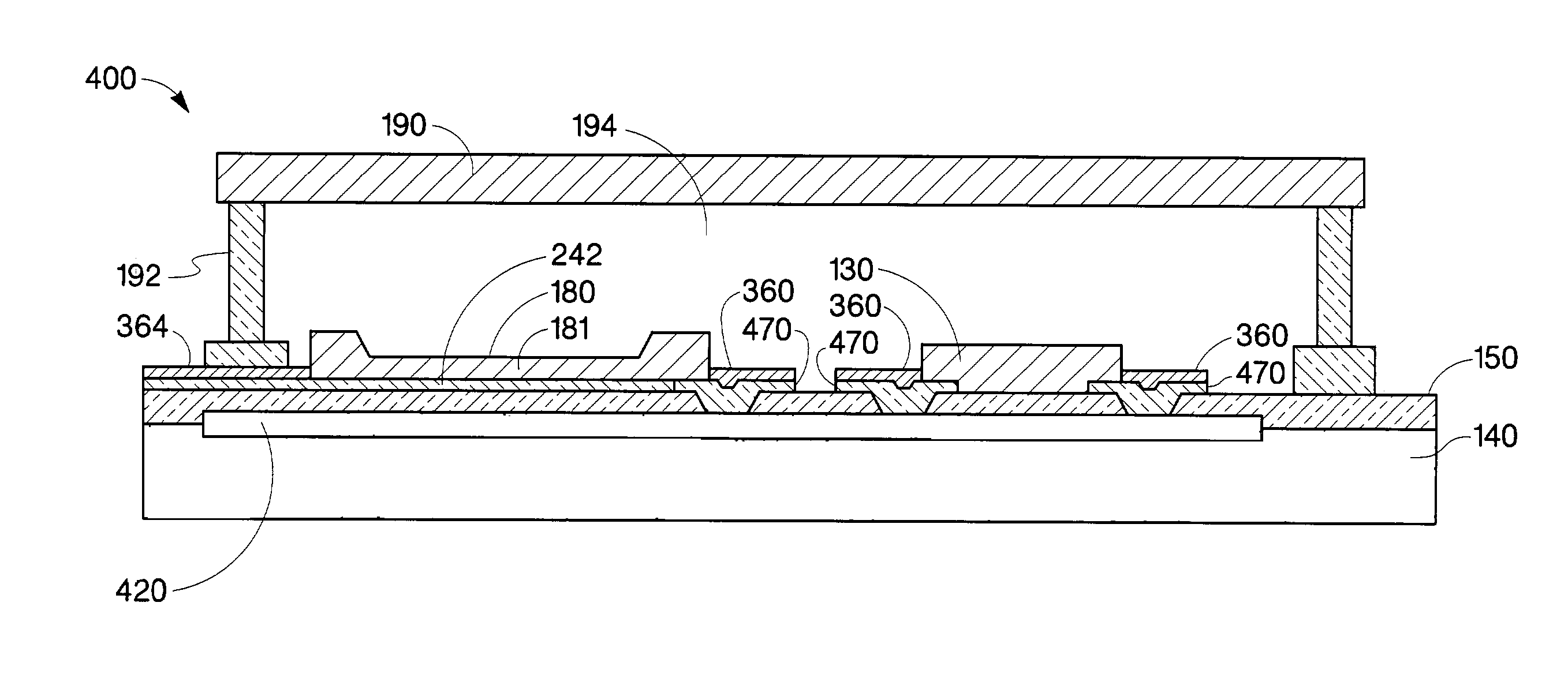

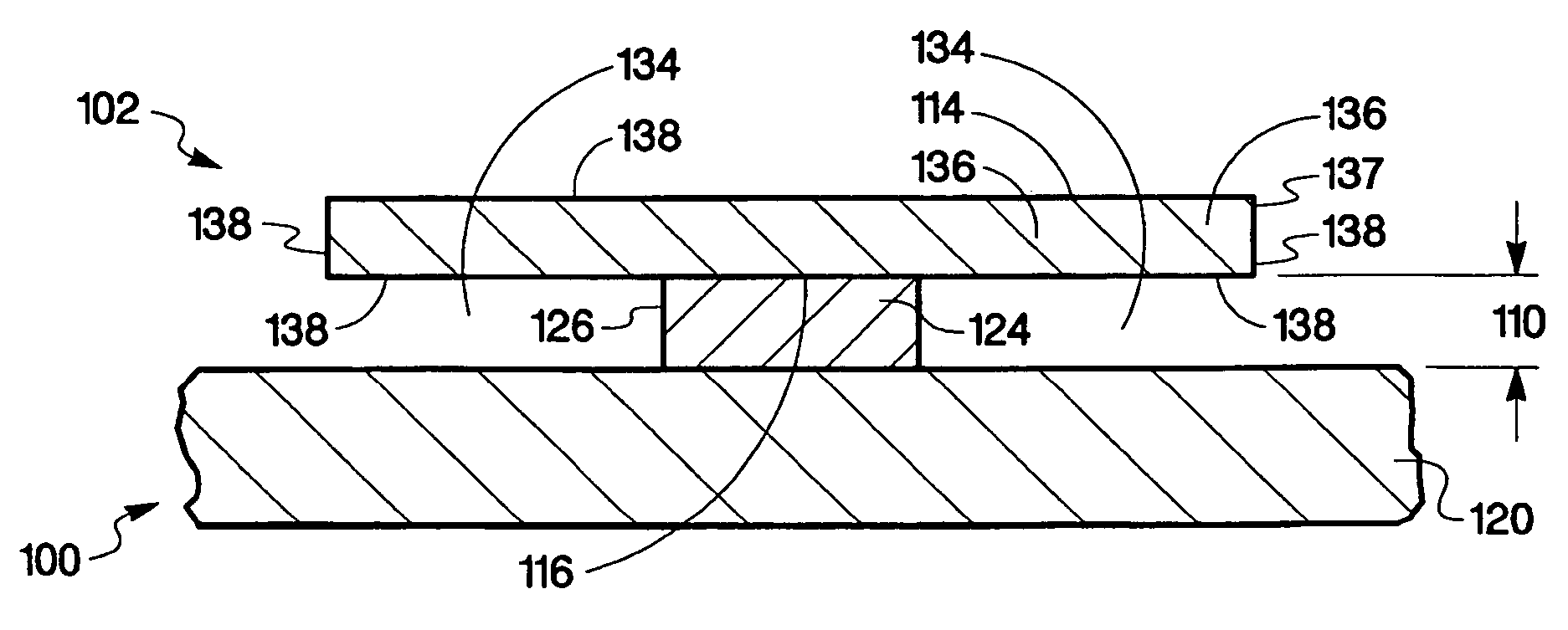

Vacuum device having a getter

A vacuum device, including a substrate and a support structure having a support perimeter, where the support structure is disposed over the substrate. In addition, the vacuum device also includes a non-evaporable getter layer having an exposed surface area. The non-evaporable getter layer is disposed over the support structure, and extends beyond the support perimeter, in at least one direction, of the support structure forming a vacuum gap between the substrate and the non-evaporable getter layer increasing the exposed surface area.

Owner:SAMSUNG ELECTRONICS CO LTD

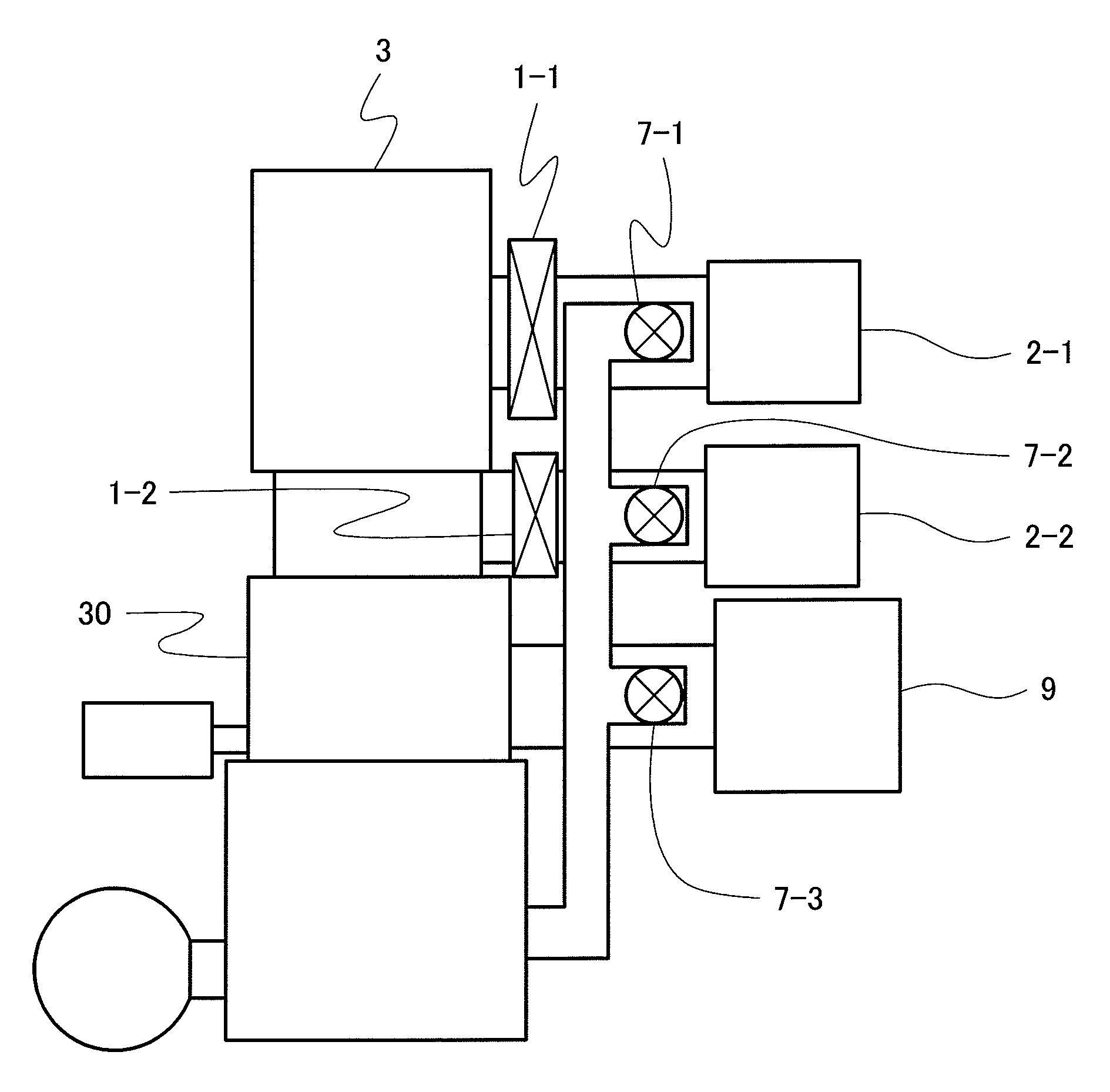

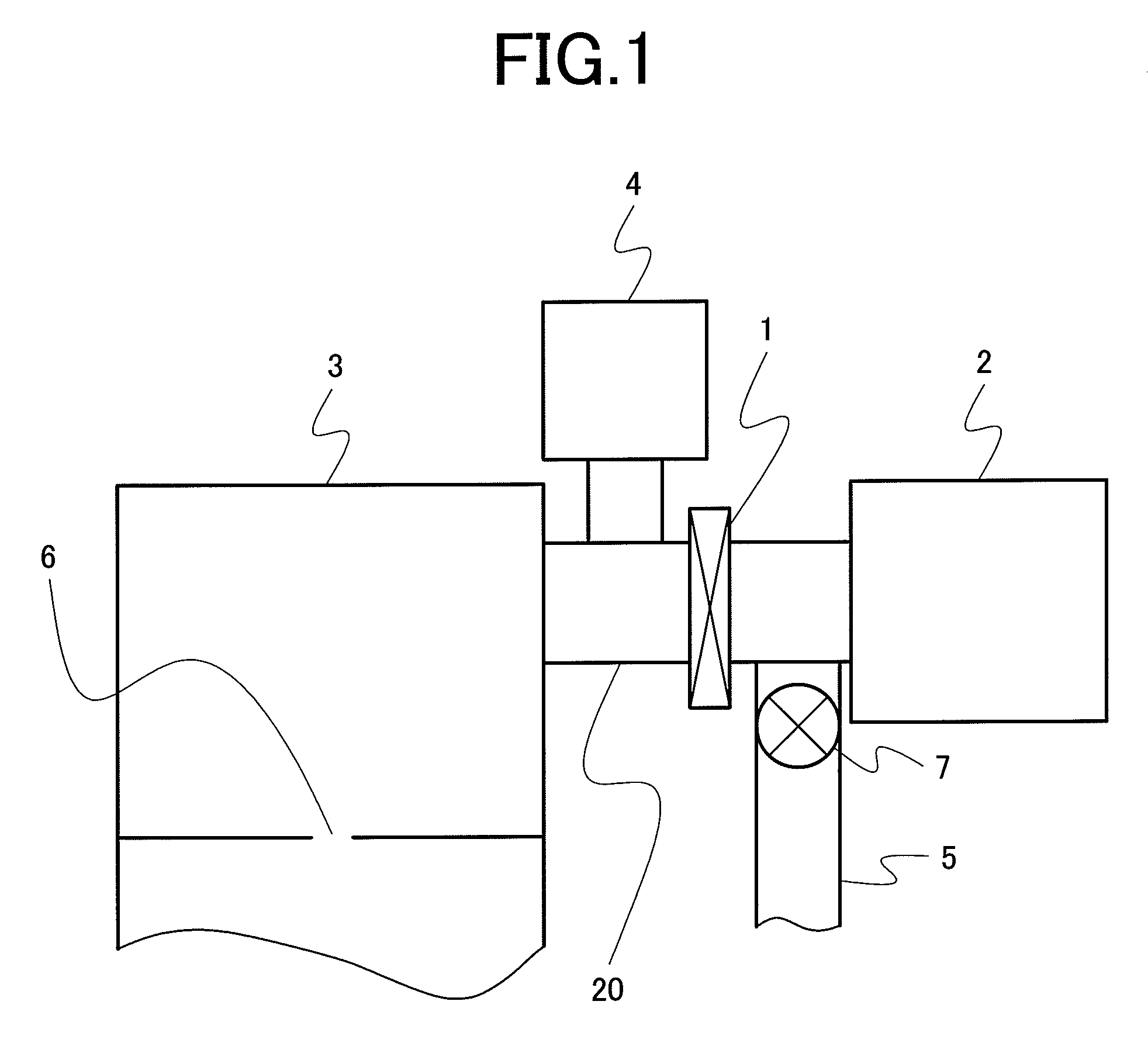

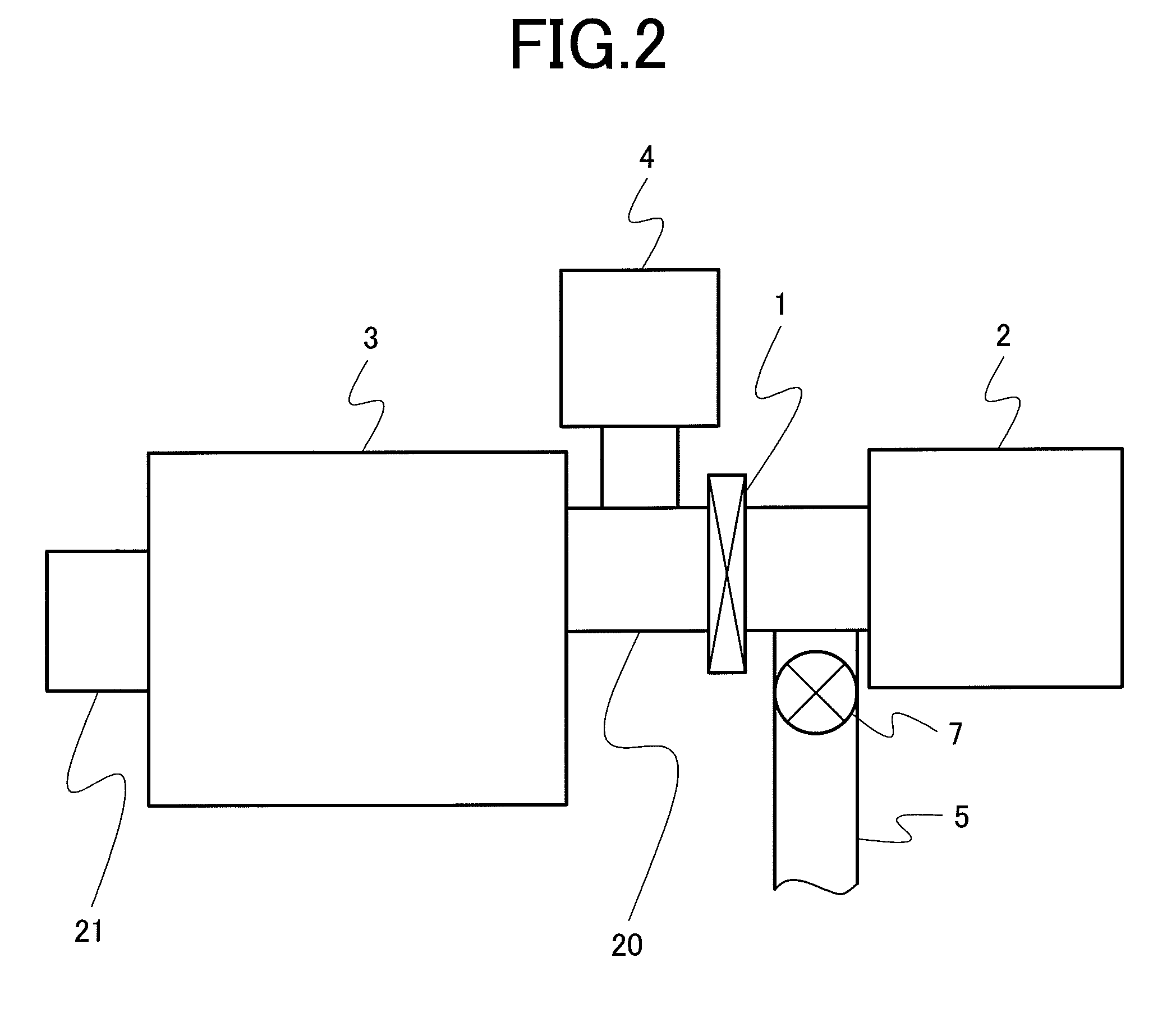

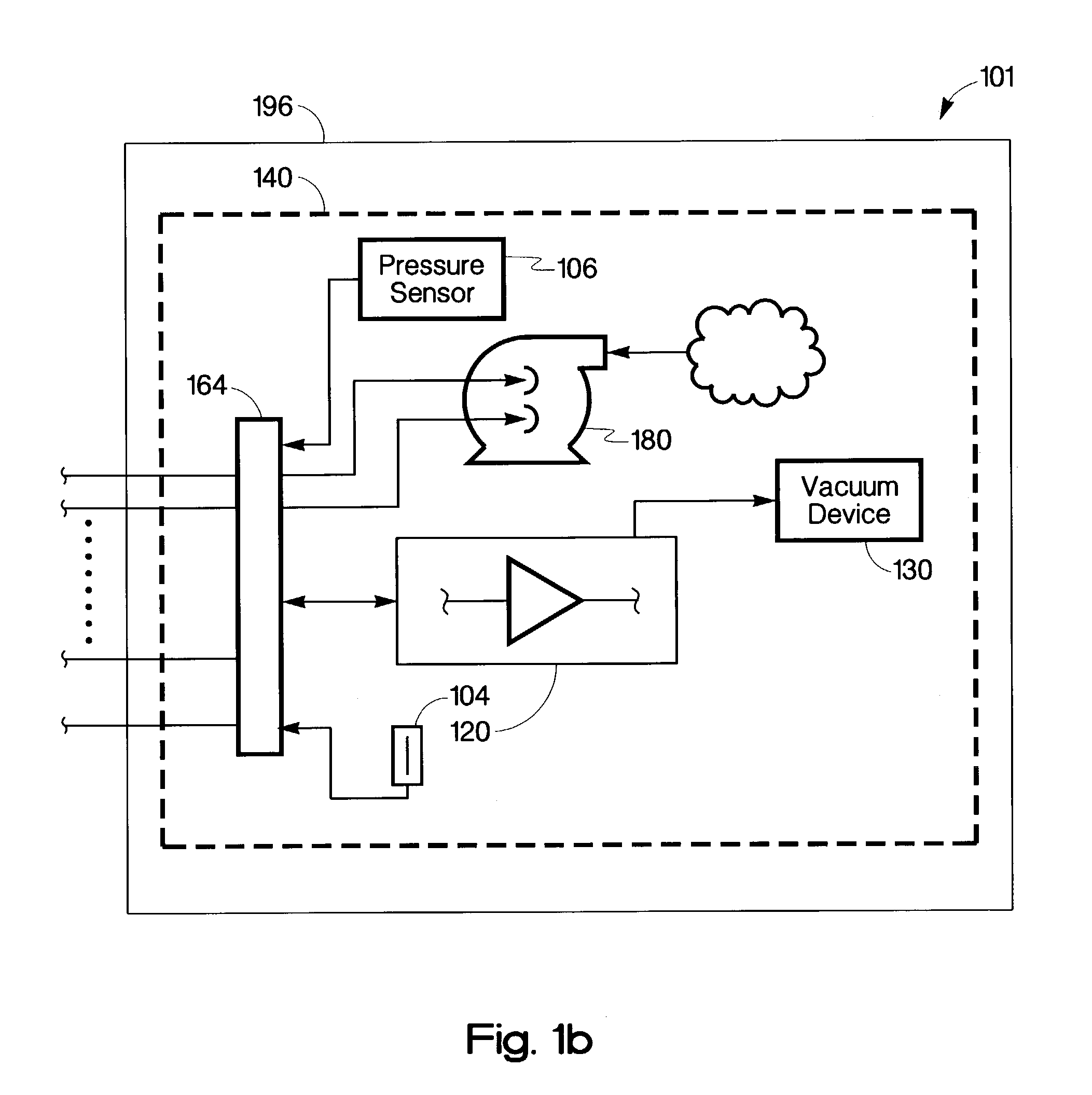

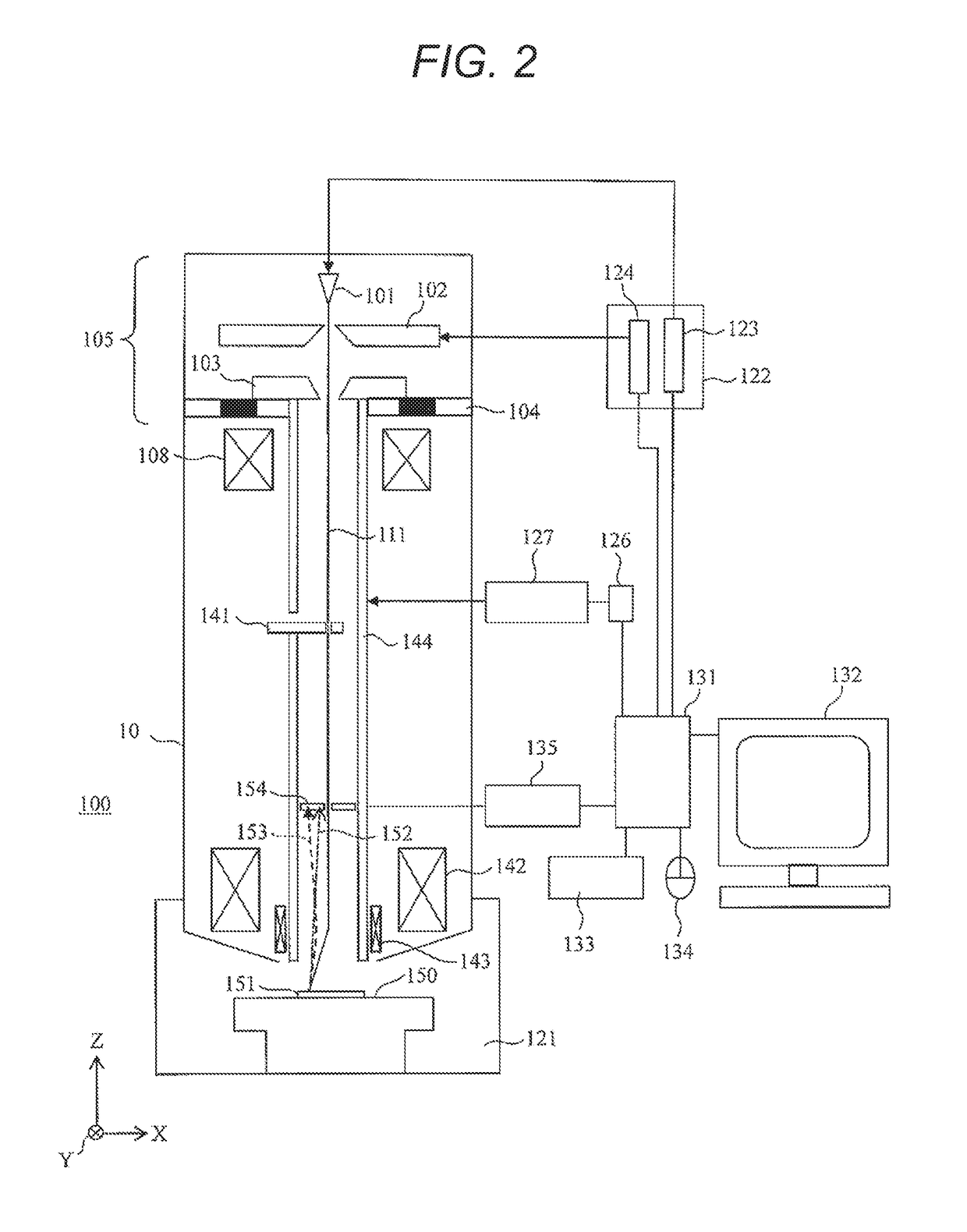

Charged particle beam system and method for evacuation of the system

InactiveUS7781743B2High degreeShort timePump componentsScattering properties measurementsUltra-high vacuumEvaporation

The present invention provides a charged particle beam system which can perform evacuation on an electron gun chamber or an ion-gun chamber having a non-evaporable getter pump in a short time and can maintain the ultra-high vacuum for a long time, and a technology of evacuation therefor. Provided is a charged particle beam system equipped with a charged particle optics which makes the charged particle beam emitted from a charged particle source incident on a sample and means of evacuation for evacuating the charged particle optics, characterized in that the evaporation means has: a vacuum vessel with a charged particle source disposed in the vessel; a non-evaporable getter pump which connects with the vacuum vessel through a vacuum pipe and evacuates the interior of the vacuum vessel as a subsidiary vacuum pump; a valve interposed in the vacuum pipe connecting between the vacuum vessel and the non-evaporable getter pump; a rough pumping port which is provided closer to the non-evaporable getter pump than the valve and performs rough pumping; an open and shut valve for opening and shutting the rough pumping port; and a main vacuum pump which is provided closer to the vacuum vessel than the valve and evacuates the interior of the vacuum vessel.

Owner:HITACHI HIGH-TECH CORP

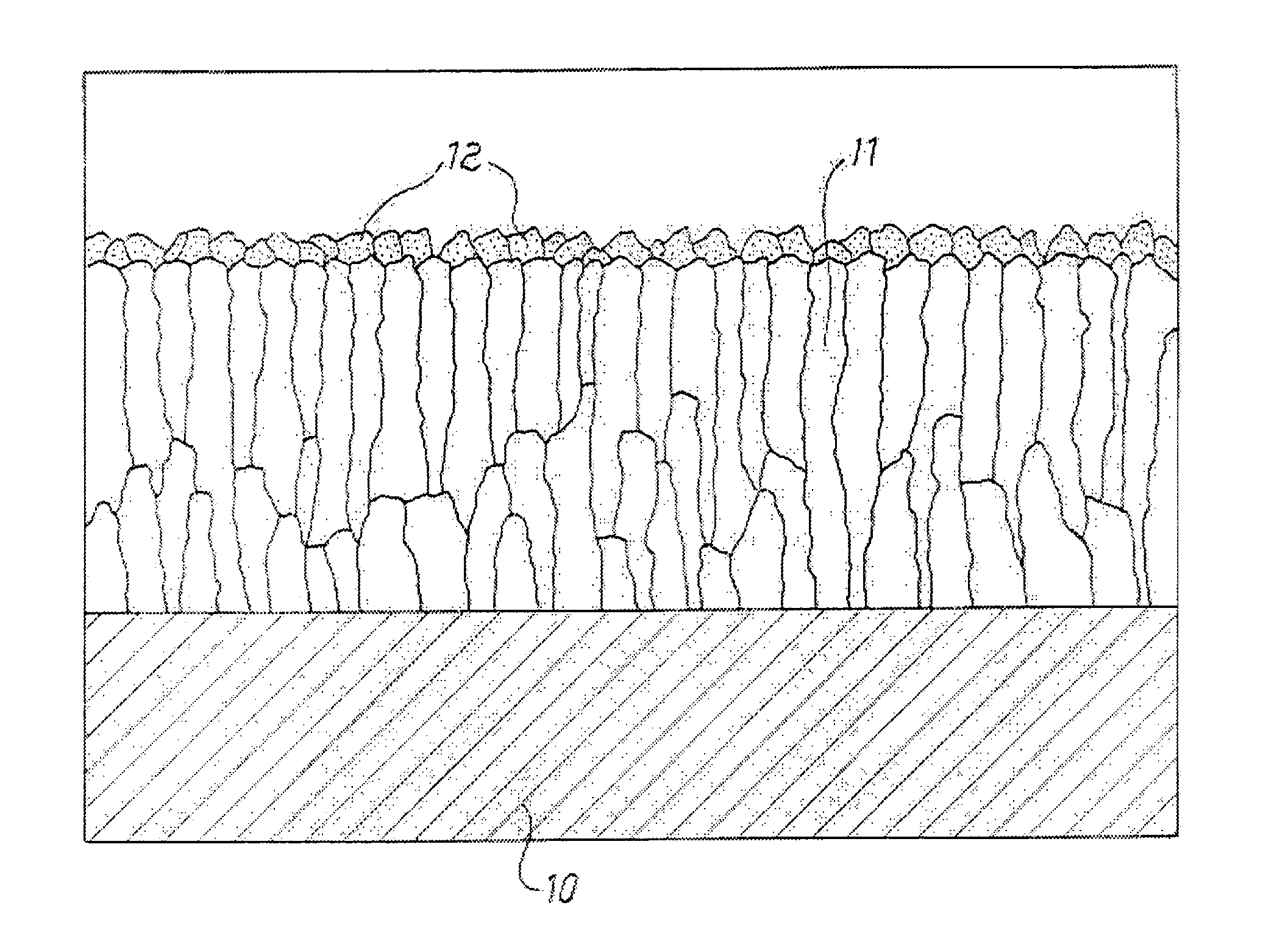

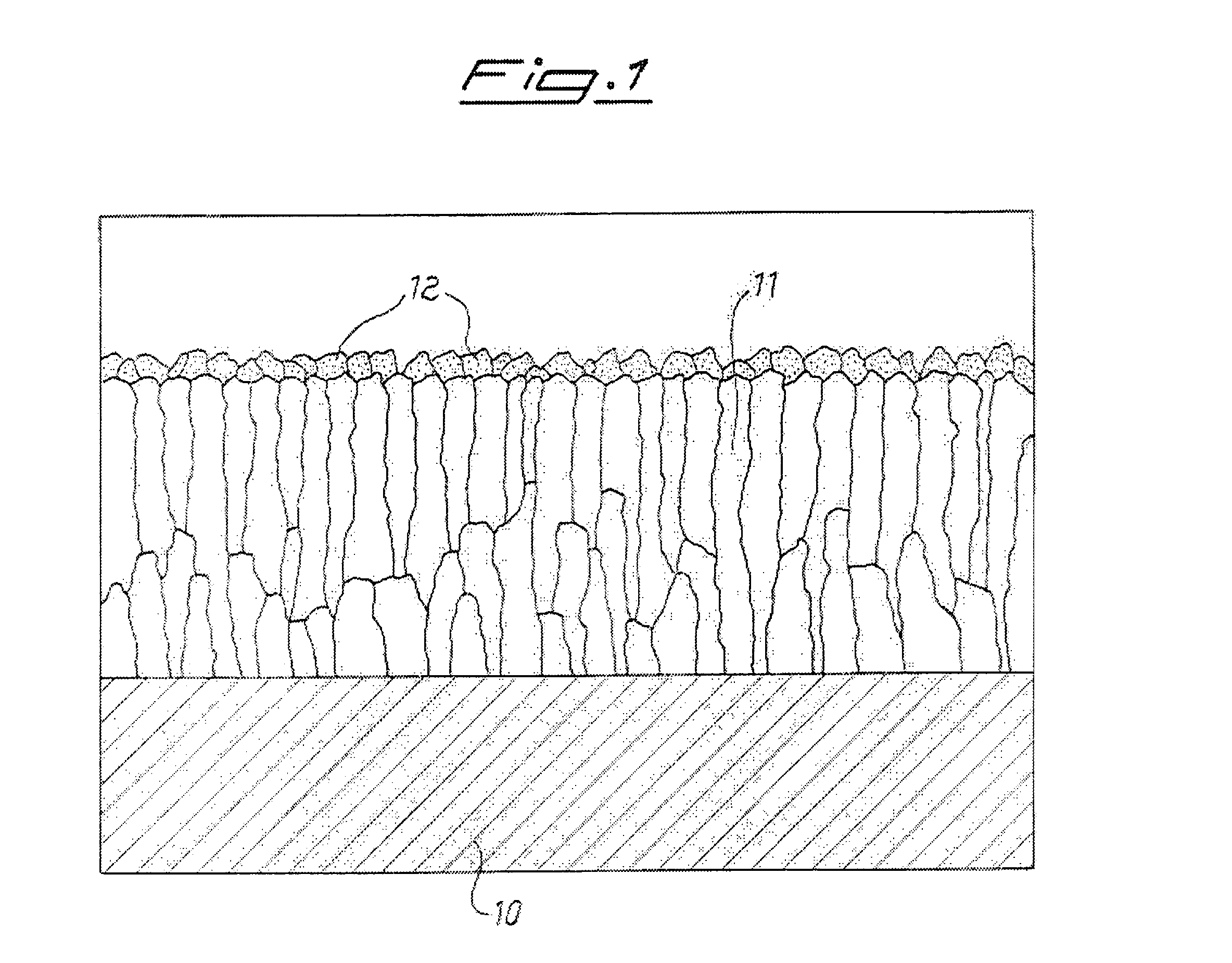

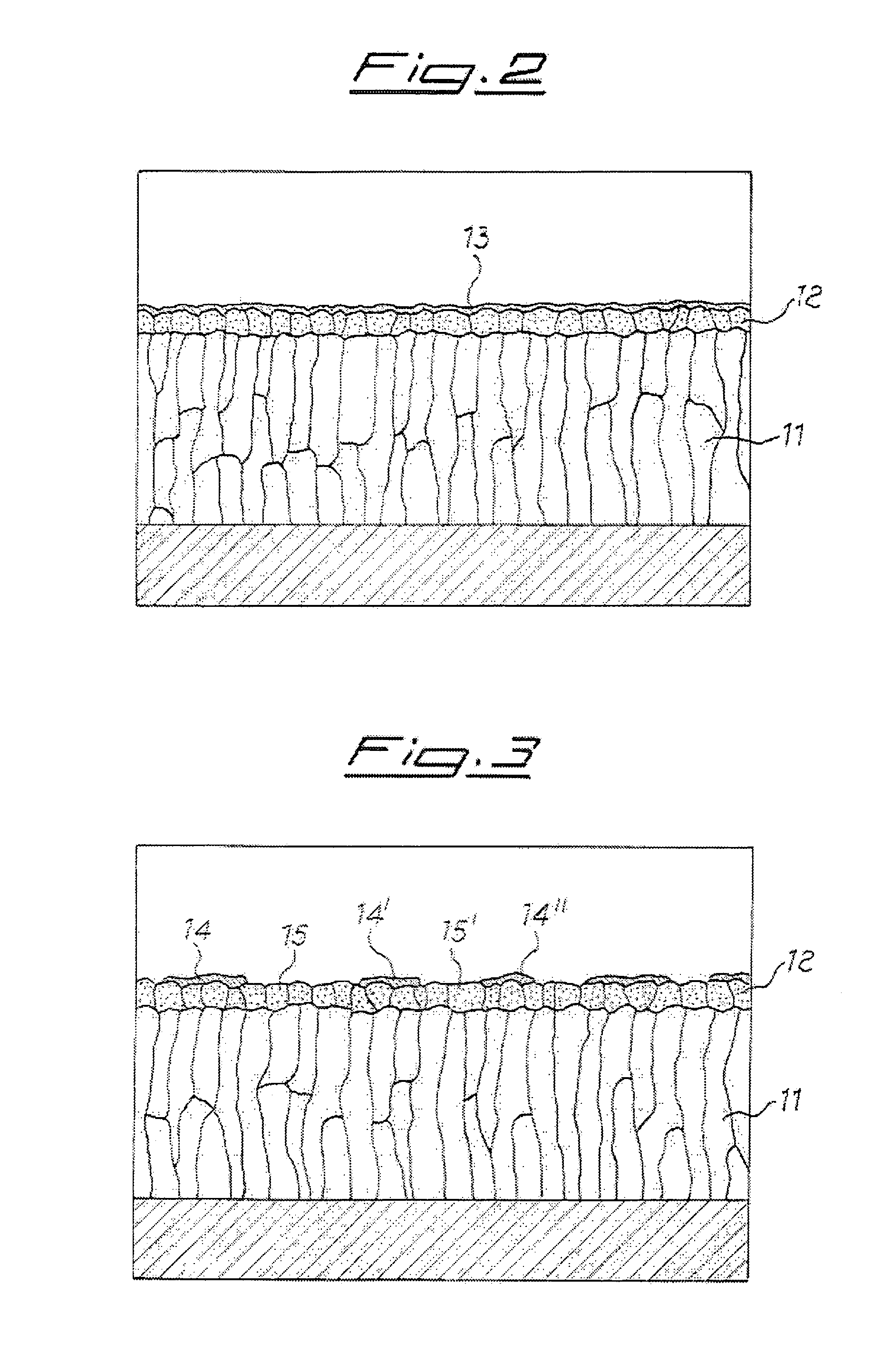

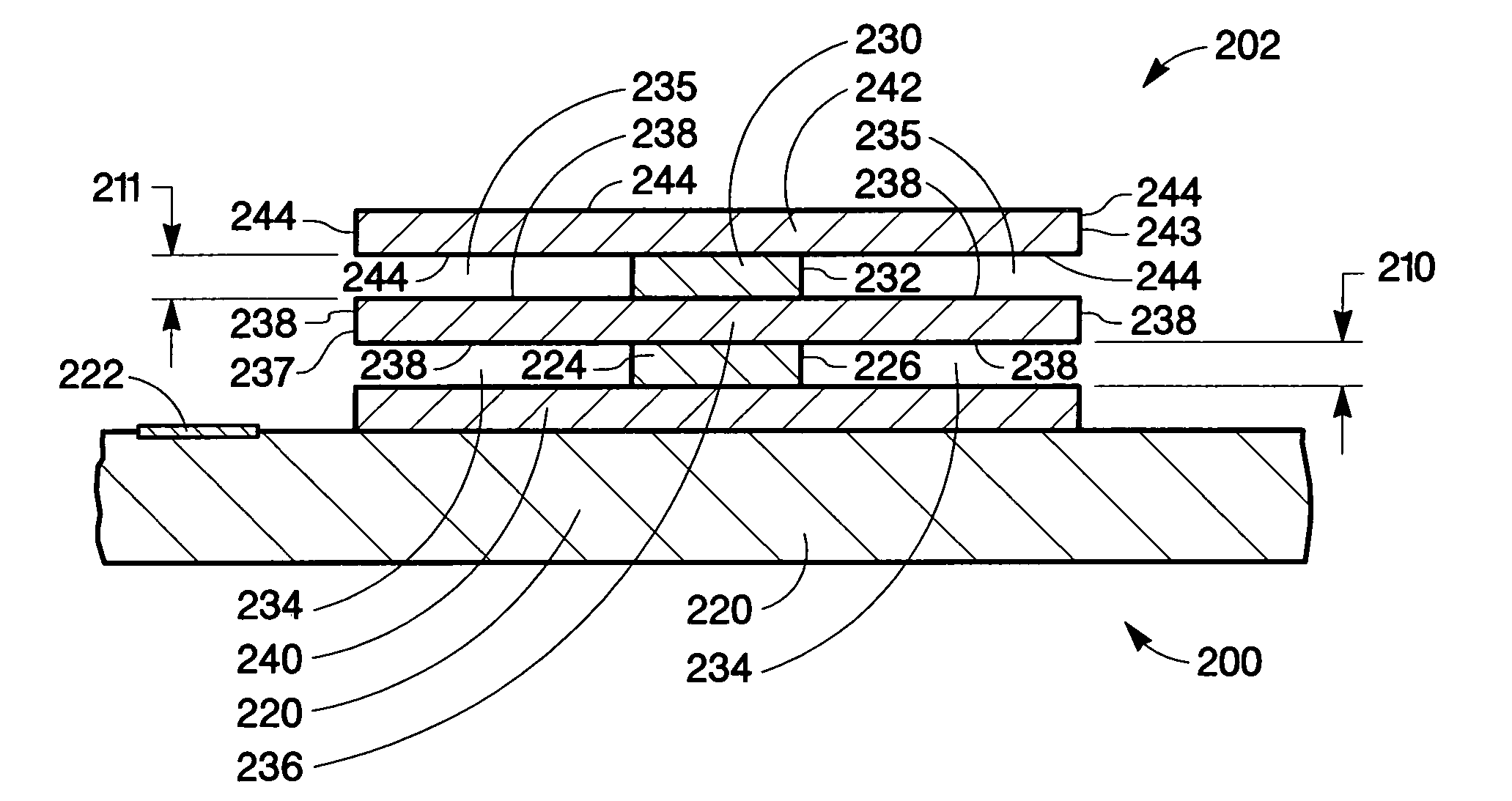

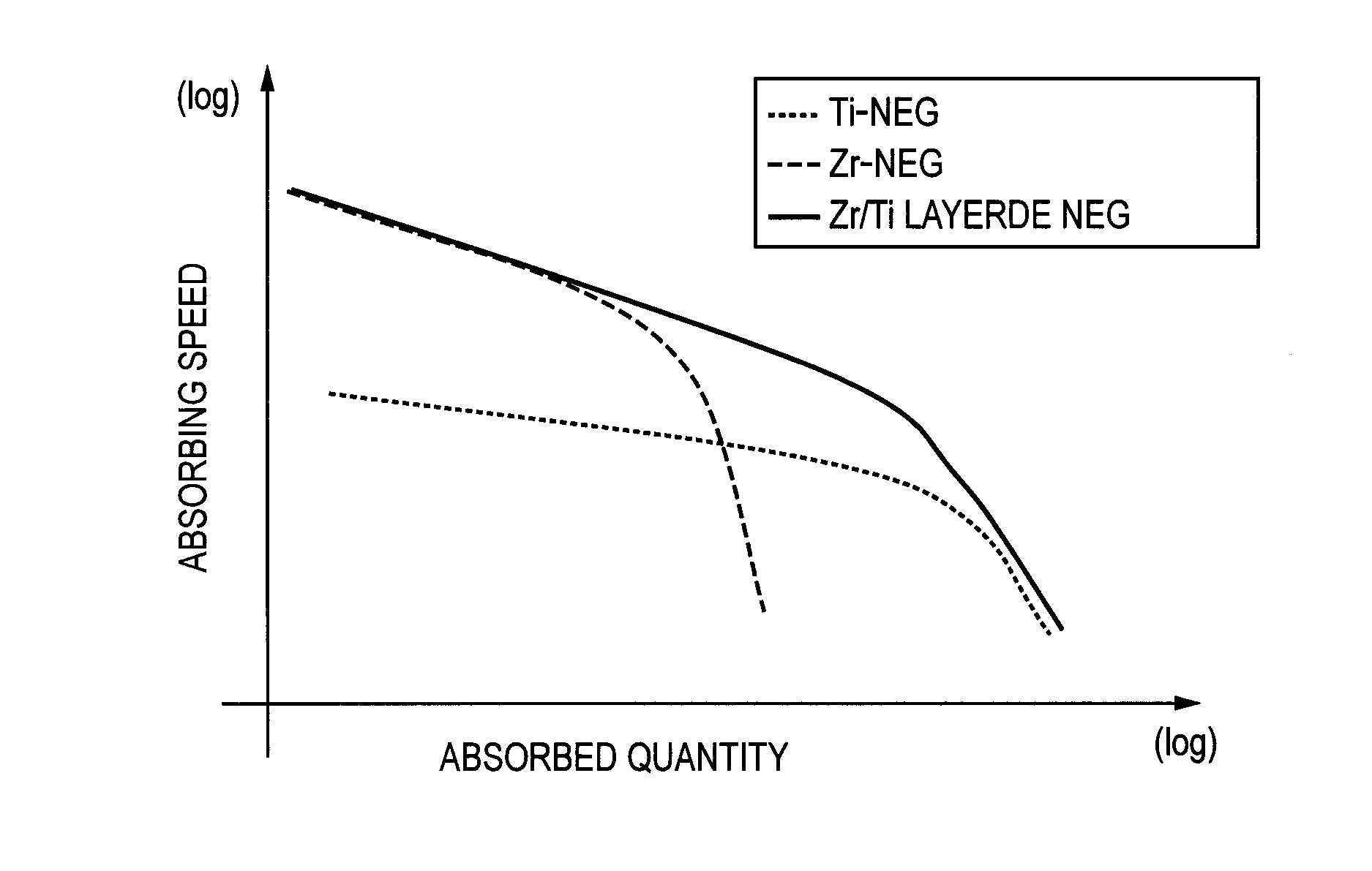

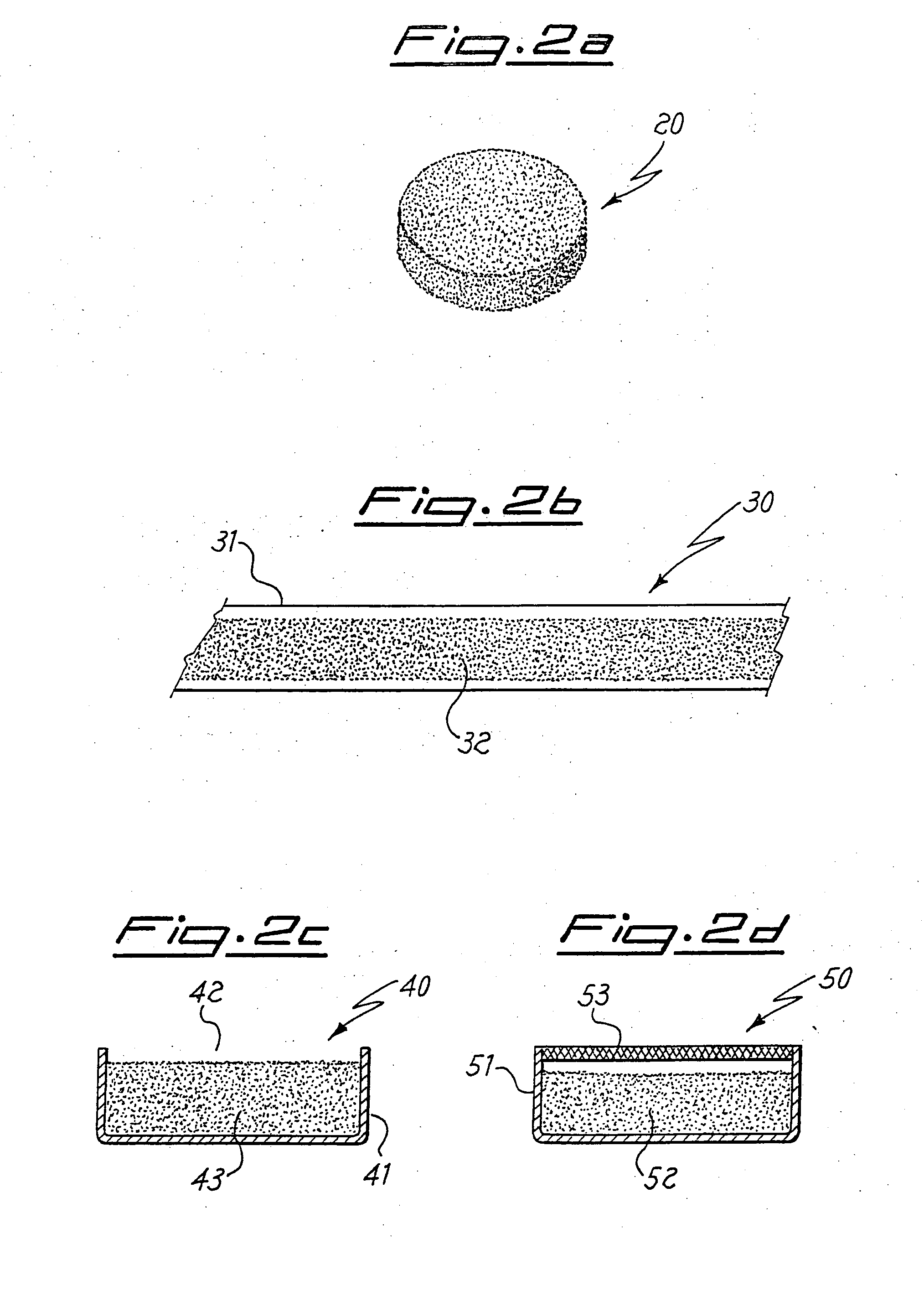

Multilayer getter structures and methods for making same

ActiveUS7413814B2Large specific surface areaLow activation temperatureVacuum evaporation coatingSoldering apparatusAlloyBiological activation

Getter multilayer structures are disclosed, embodiments of which include at least a layer of a non-evaporable getter alloy having a low activation temperature over a layer of a different non-evaporable getter material having high specific surface area, both preferably obtained by cathodic deposition. The multilayer NEG structures exhibit better gas sorbing characteristics and lower activation temperature lower than those of deposits made up of a single material. A process for manufacturing such structures includes depositing a first, high surface area NEG film on a support, and then depositing a thin over layer of low activation NEG film.

Owner:SAES GETTERS SPA

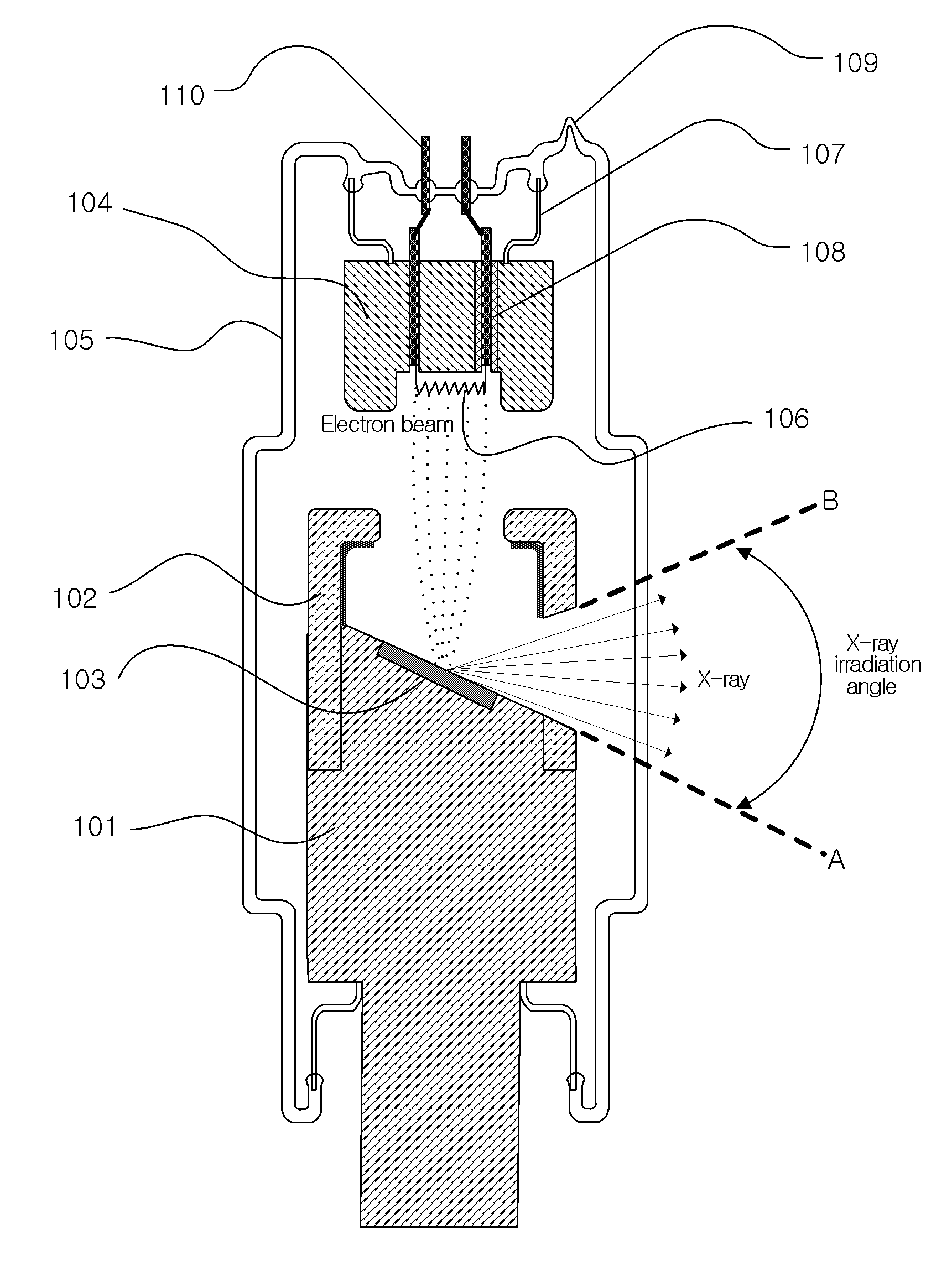

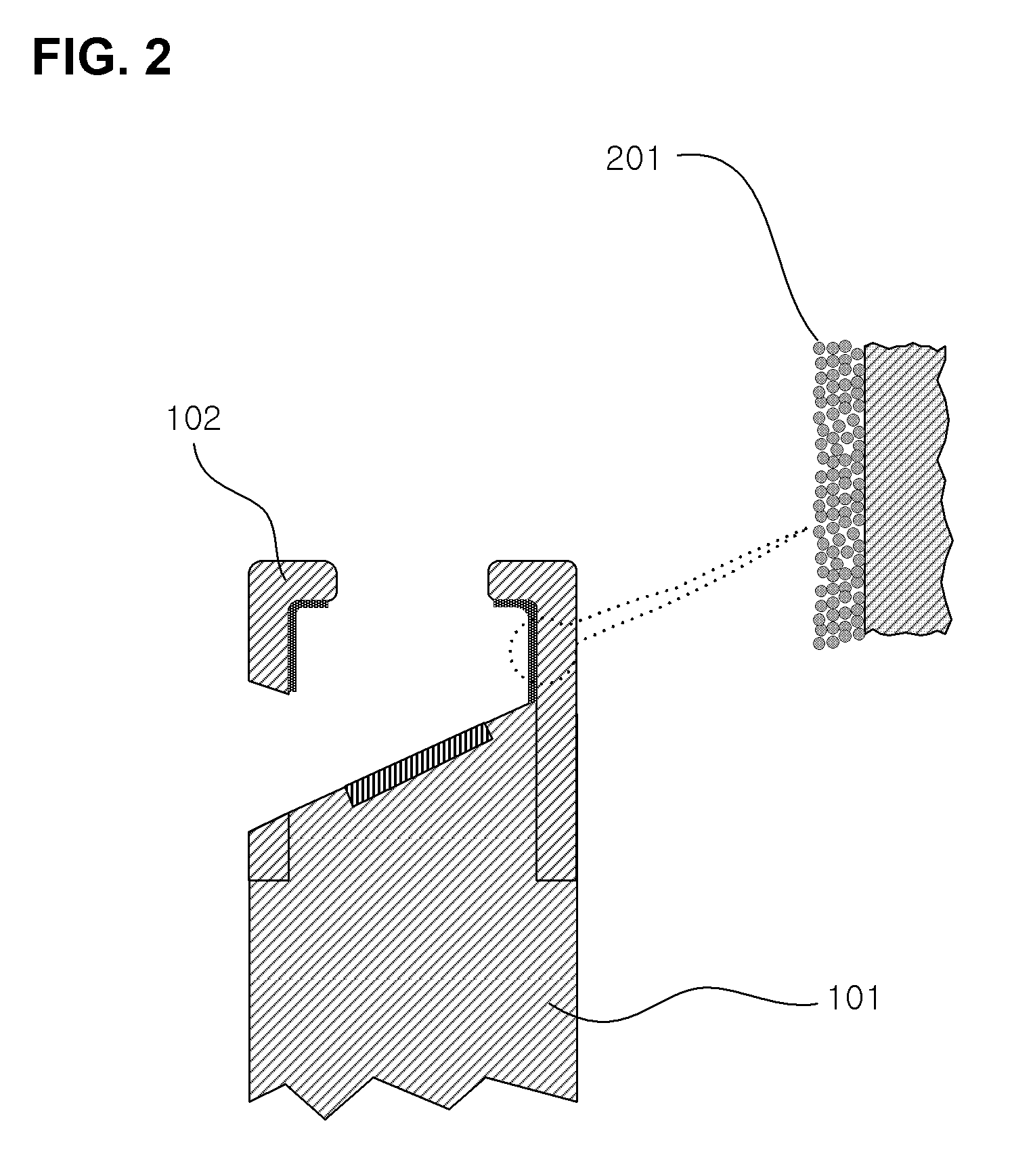

X-ray tube having non-evaporable getter

InactiveUS20120257721A1Prevent pressureIncrease vacuumX-ray tube electrodesCathode ray concentrating/focusing/directingX-rayPhysics

The present invention relates to an X-ray tube with non-evaporable getters disposed therein for maintaining a degree of vacuum sufficient to operate the X-ray tube. The present invention provides a fixed-anode X-ray tube and a rotating-anode X-ray tube in which non-evaporable getters are disposed. The X-ray tubes, even when rated power is introduced without an aging process, can perform gas adsorption sufficiently and stably during operation, despite gases that can be generated by the filament and the cathode focusing cap and gases that can be generated by the target.

Owner:XL CO LTD

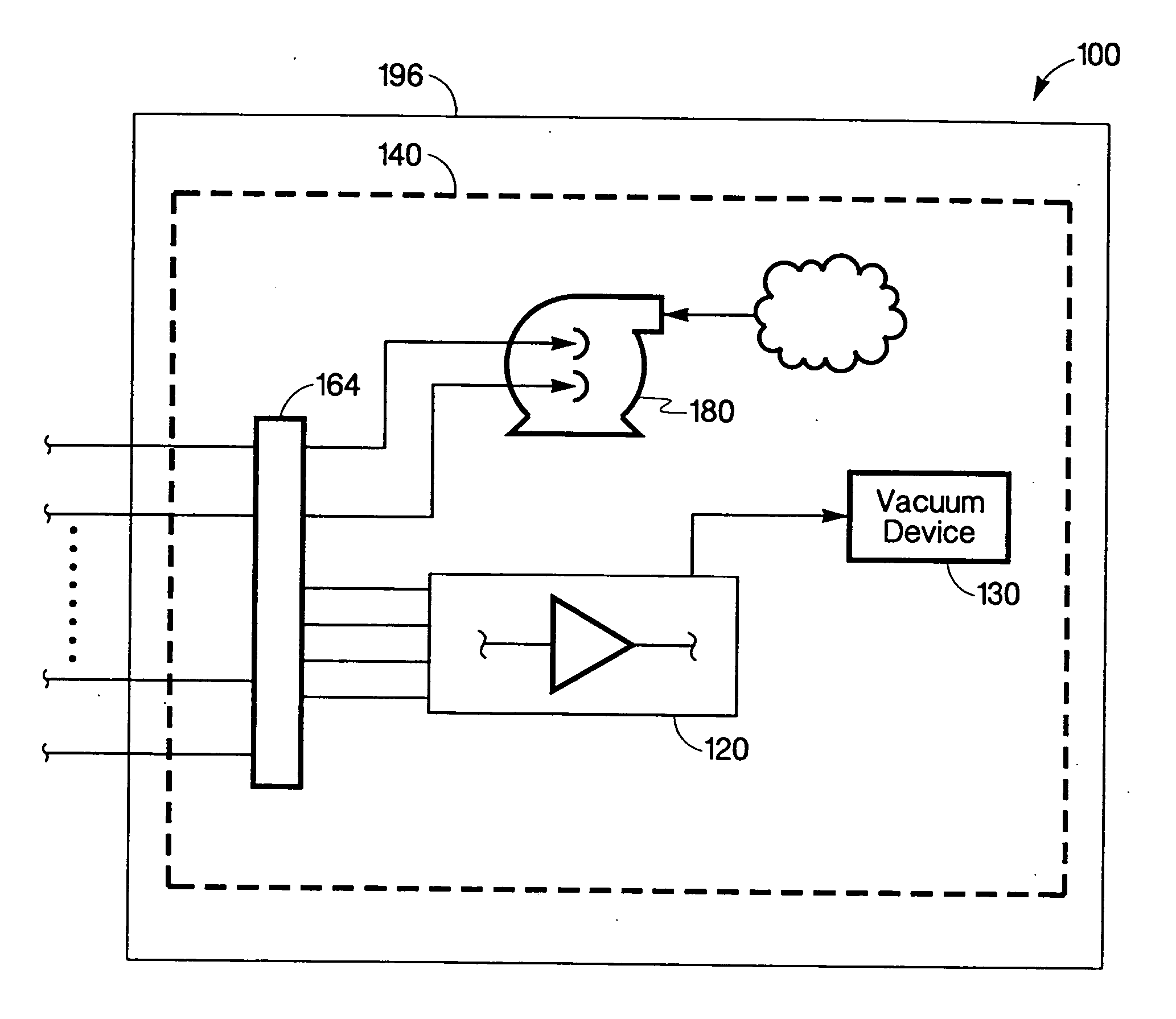

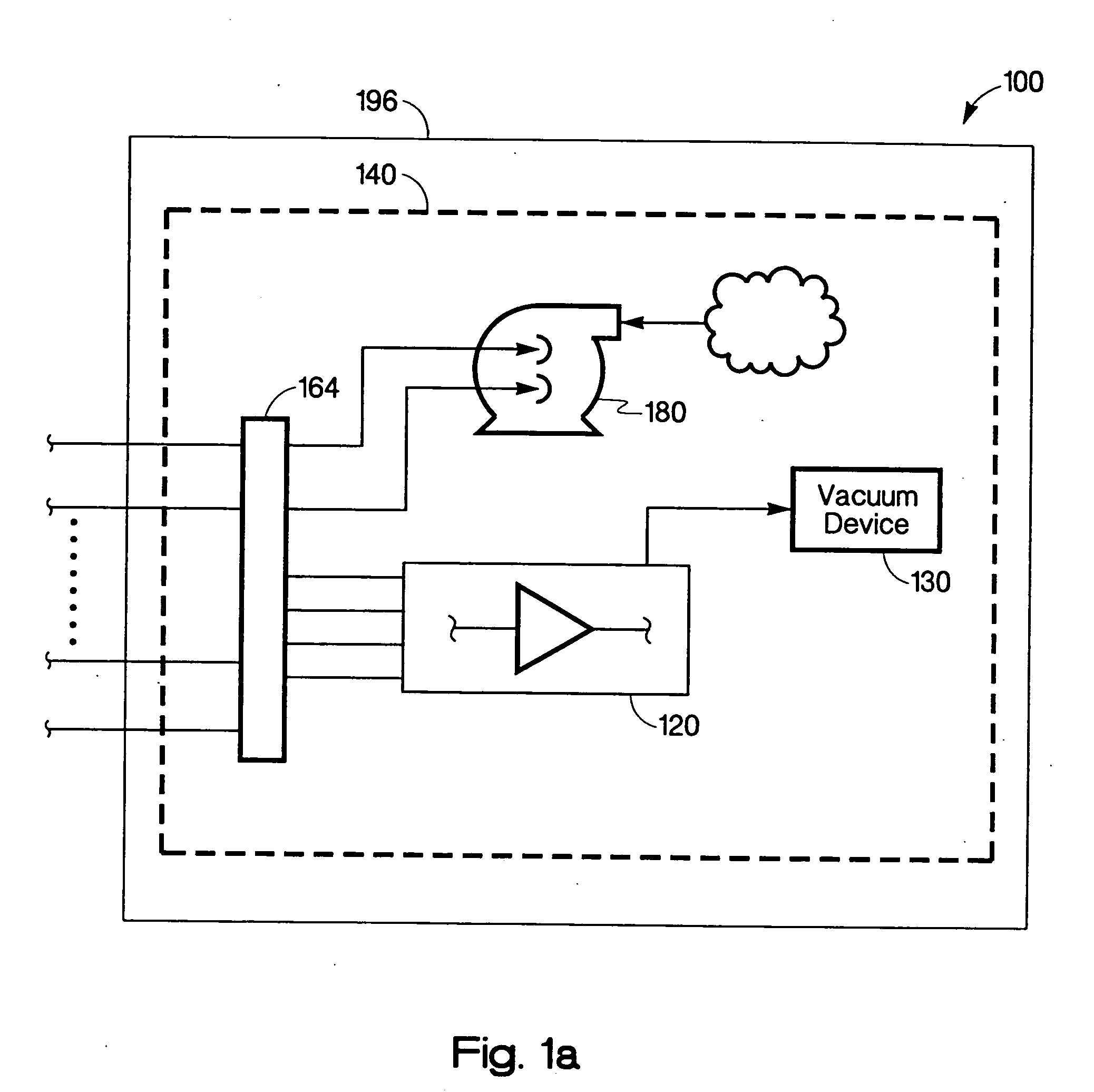

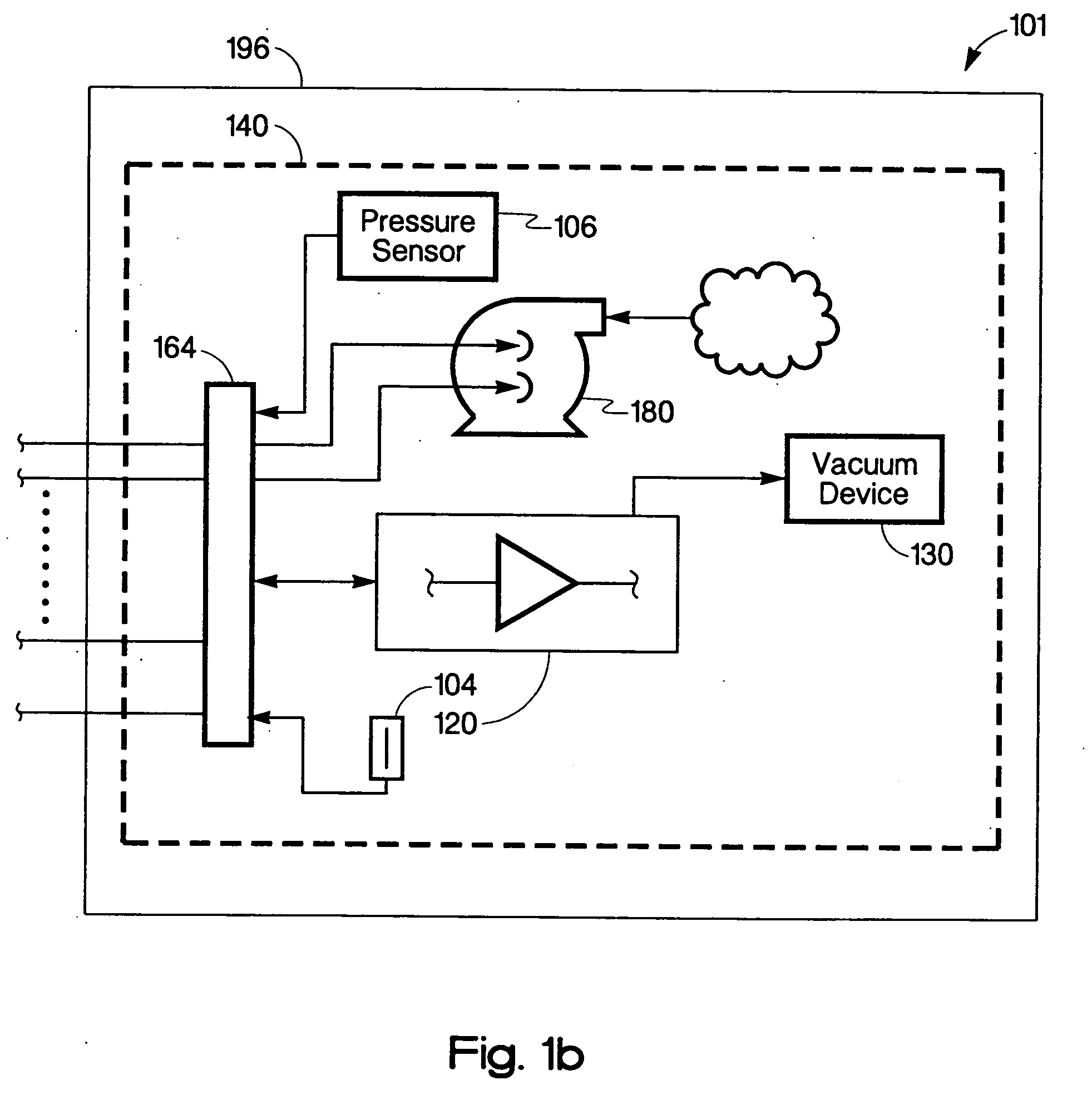

Electronic device sealed under vacuum containing a getter and method of operation

InactiveUS7042075B2Gas filling substance selectionSemiconductor/solid-state device detailsEngineeringDielectric layer

An electronic device that is sealed under vacuum includes a substrate, a transistor formed on the substrate, and a dielectric layer covering at least a portion of the transistor. The electronic device further includes a layer of non-evaporable getter material disposed on a portion of the dielectric layer; and a vacuum device disposed on a portion of the substrate. Electrical power pulses activate the non-evaporable getter material.

Owner:SAMSUNG ELECTRONICS CO LTD

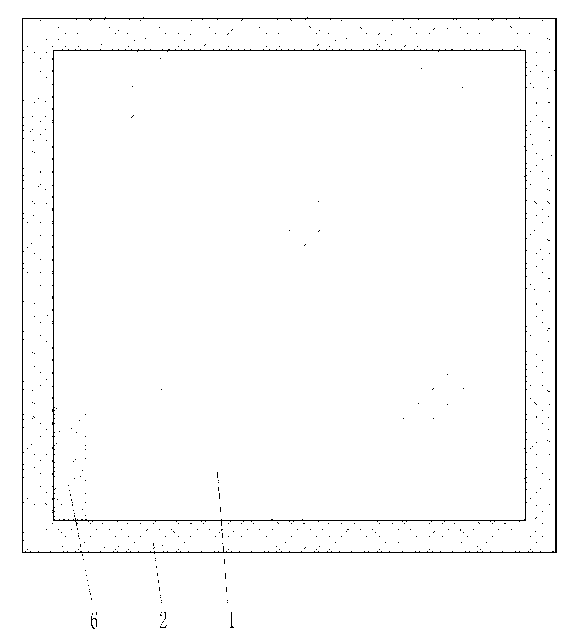

Vacuum glass with getter film

The invention discloses vacuum glass with a getter film. The vacuum glass is formed by compounding two or more glass plates; the getter film is arranged on the surface of the glass plate on at least one side of a vacuum space in the vacuum glass; and the getter film is composed of a non-evaporable getter. The getter is arranged on the surfaces of the glass plates in a getter film way so that the getter can be conveniently set and the setting quantity of the getter can be conveniently adjusted; and meanwhile, the getter is arranged at the corner of the vacuum space, so that the transparency of the vacuum glass cannot be affected, and a brand new technical approach is provided for the setting of the getter of the vacuum glass.

Owner:洛阳兰迪真空玻璃科技有限公司

Method of making a getter structure

A method of manufacturing a getter structure, including forming a support structure having a support perimeter, where the support structure is disposed over a substrate. In addition, the method includes forming a non-evaporable getter layer having an exposed surface area, where the non-evaporable getter layer is disposed over the support structure, and includes forming a vacuum gap between the substrate and the non-evaporable getter layer. The non-evaporable getter layer extends beyond the support perimeter of the support structure increasing the exposed surface area.

Owner:SAMSUNG ELECTRONICS CO LTD

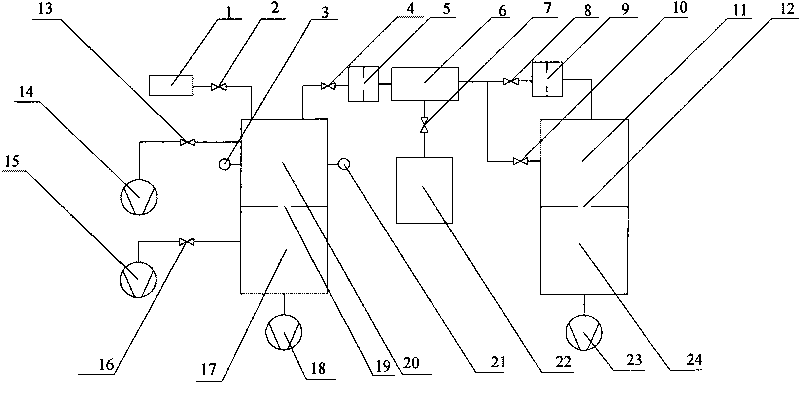

Extremely high vacuum gauge calibration device and method

ActiveCN102944356ALarge measuring rangeReduce measurement uncertaintyFluid pressure measurementVacuum extractorEngineering

The invention discloses an extremely high vacuum gauge calibration device and a method, belonging to measurement field. The device comprises an extremely high vacuum gauge, an extremely high vacuum calibration room, a first valve, a vacuum gauge to be calibrated, a small hole, a second valve, a third valve, a high-precision vacuum gauge, an extremely high vacuum aspirating chamber, an extremely high vacuum air-bleed set, a flow limiting hole, a pressure stabilizing chamber, a non-evaporable getter pump, an air source, a micrometering valve, a flowmeter air-bleed set and a fourth valve, and the peripheral equipment includes a heating device. With the device and the method disclosed by the invention, the measurement uncertainty is small, accurate calibration to the extremely high vacuum gauge within the pressure range smaller than 10<-9>Pa can be realized, and the flow measurement range is expanded.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

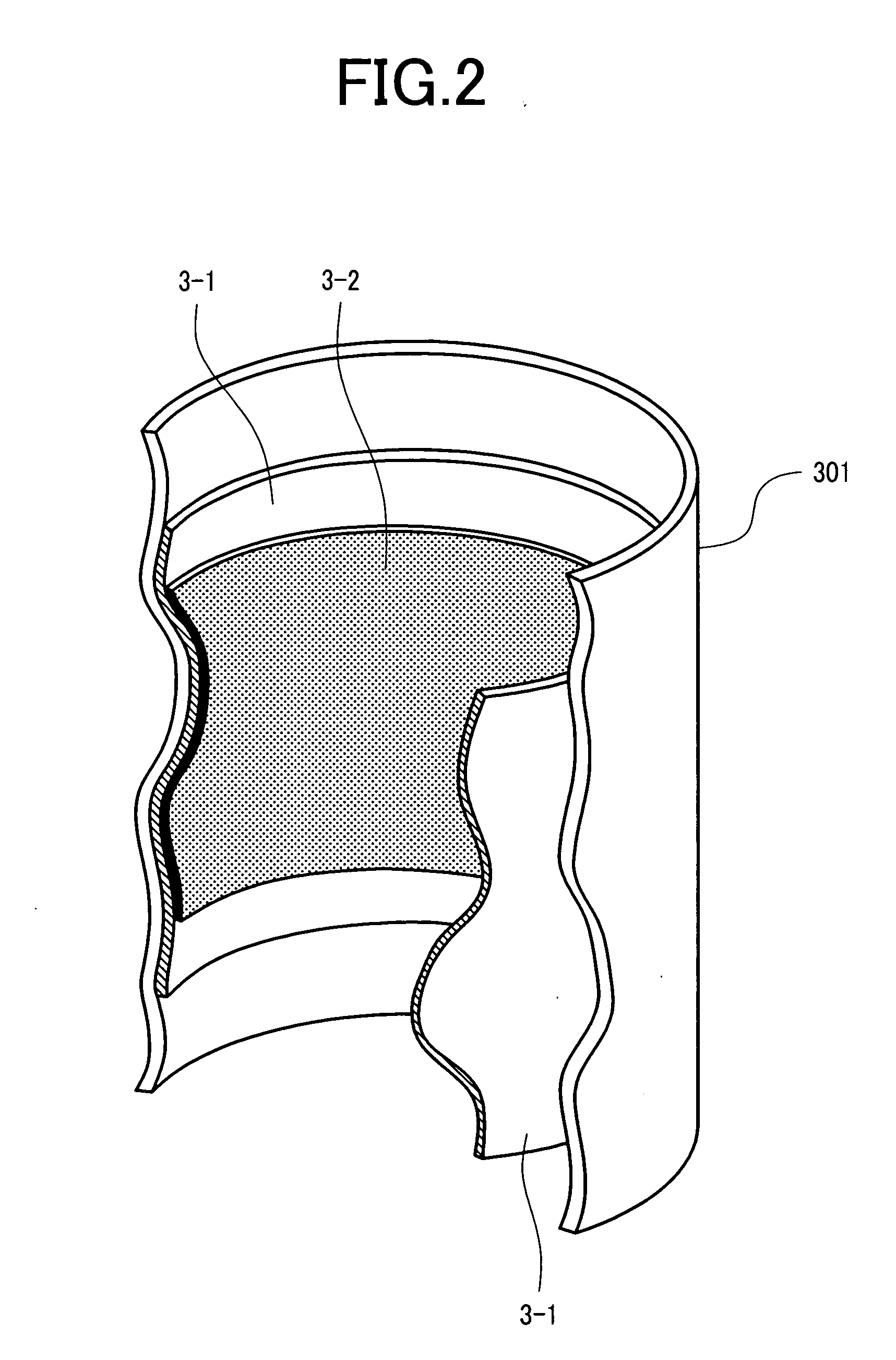

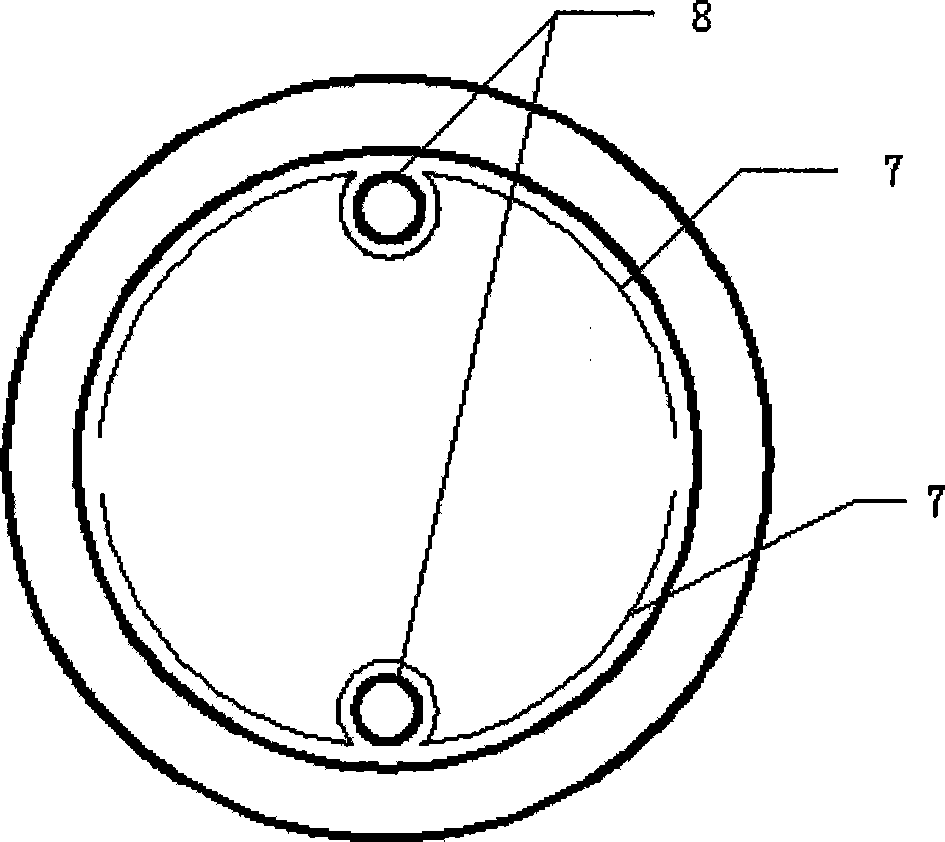

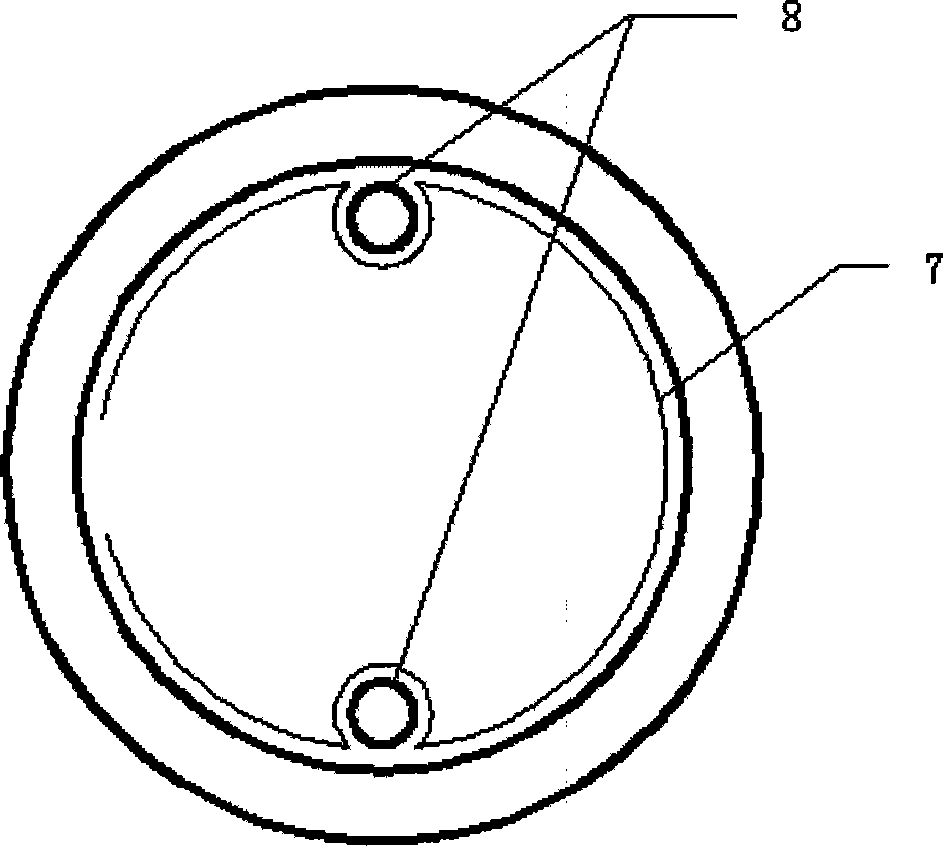

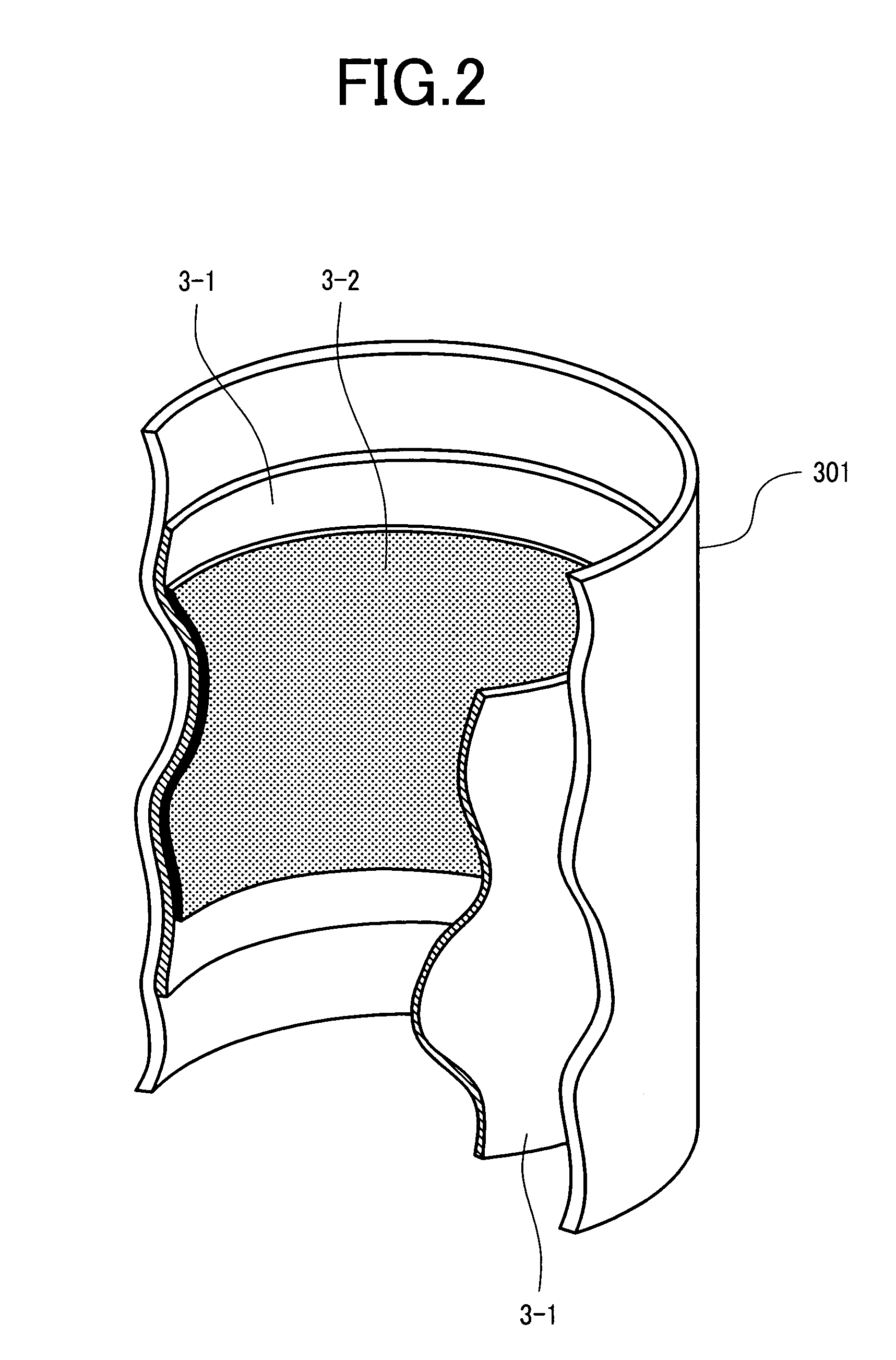

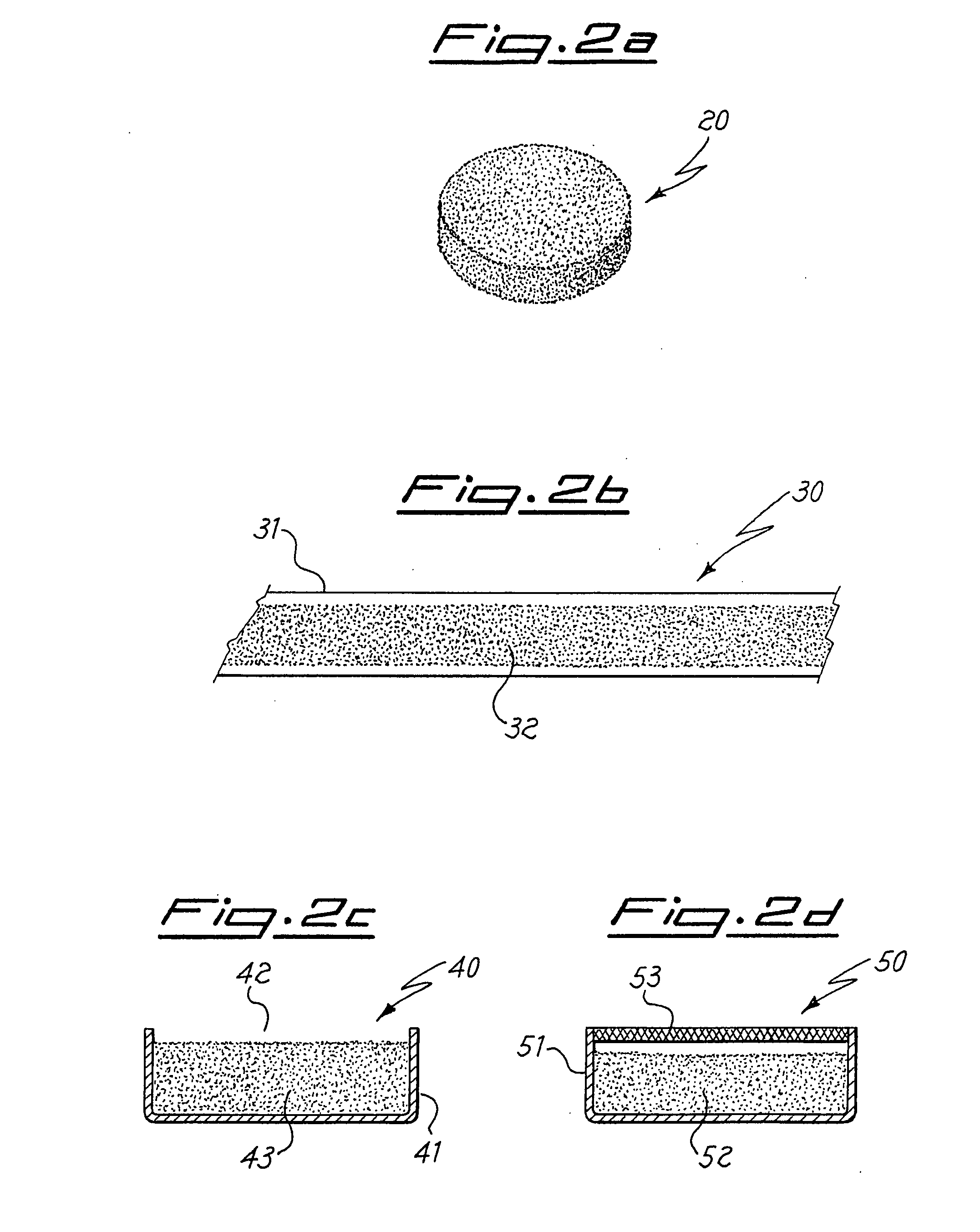

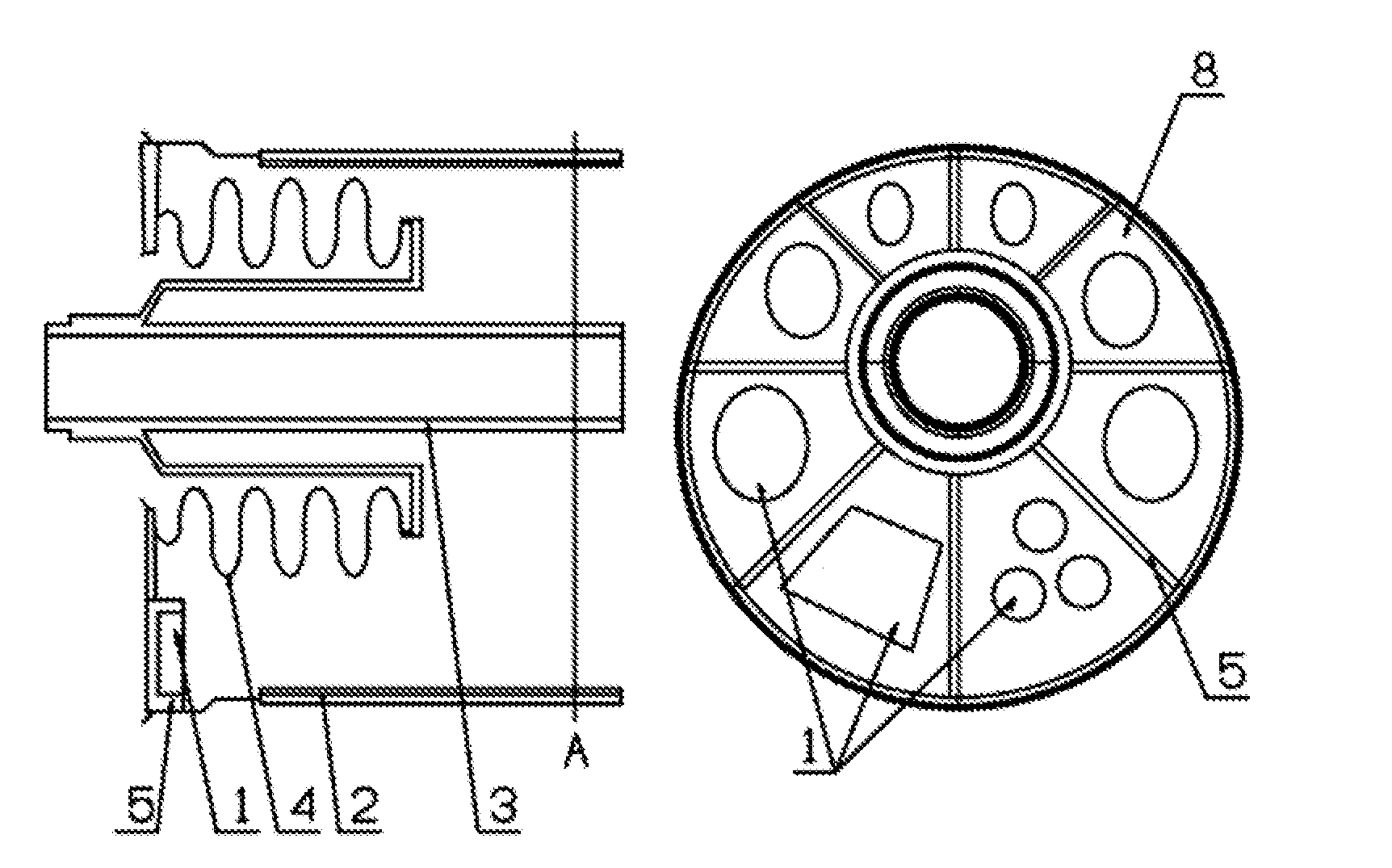

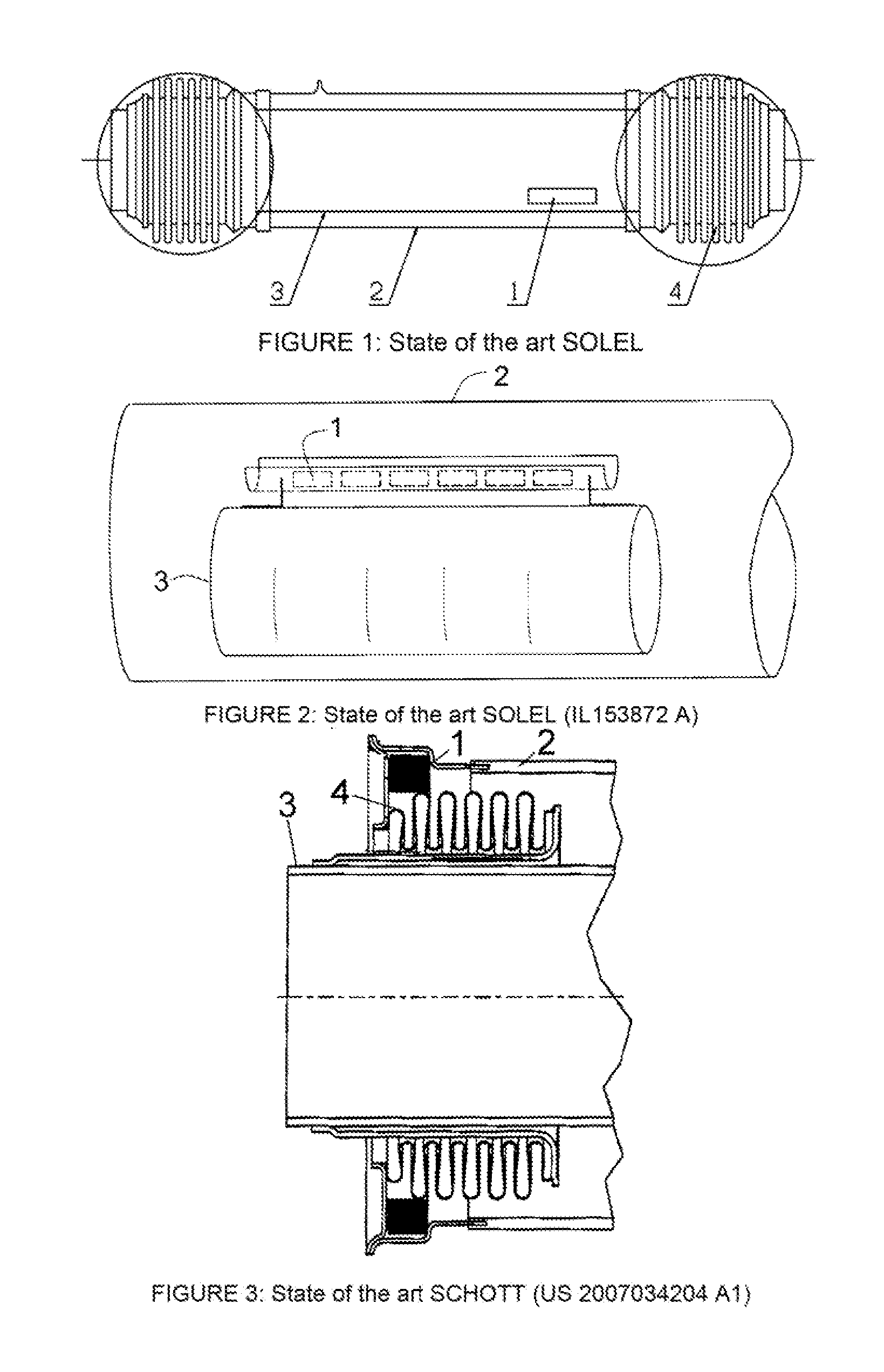

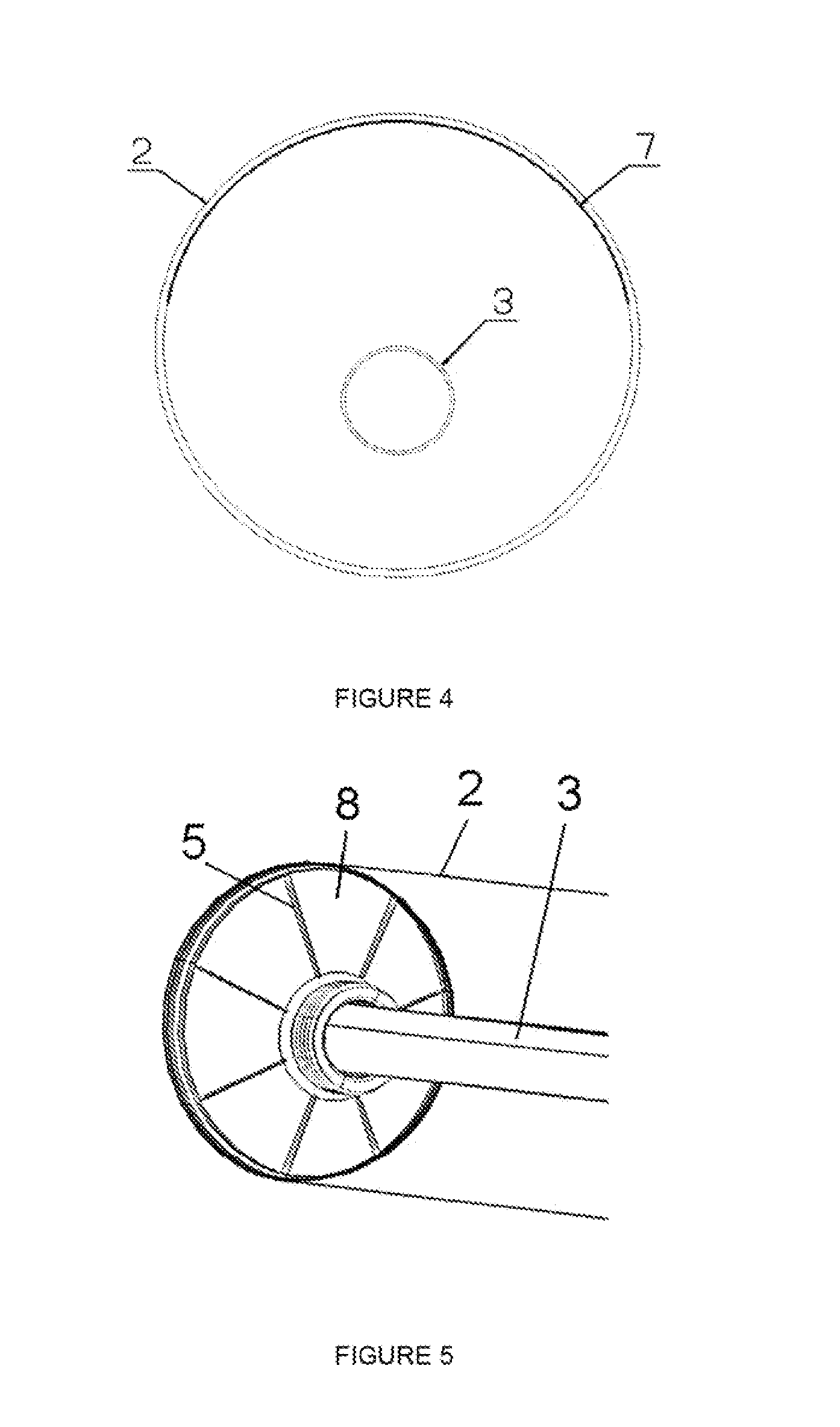

Novel arrangement of non-evaporable getters for a tube solar collector

InactiveUS20130220308A1Improving optical behaviorLarge diameterSolar heating energySolar heat devicesSolar energy harvestingHeat transfer fluid

The invention relates to a novel arrangement of non-evaporable getters for a tube solar collector, said tube collector being of the type that includes an outer glass tube (2); an inner metal tube (3) through which a heat-transfer fluid flows; a vacuum chamber between both tubes; and, at the ends, non-evaporable getter pellets (1) that absorb gas molecules that could produce a loss of vacuum between the inner tube (3) and the outer tube (2) and the covers (8) at which a bellows-type expansion compensating device (4) is positioned.The inner metal tube (3) and outer glass tube (2) are positioned eccentrically to one another, forming a thicker area and a narrower area in the cover (8), said narrower area being used for the positioning, by means of bonding, of the non-evaporable getter pellets (1).

Owner:ABENGOA SOLAR NEW TECH SA

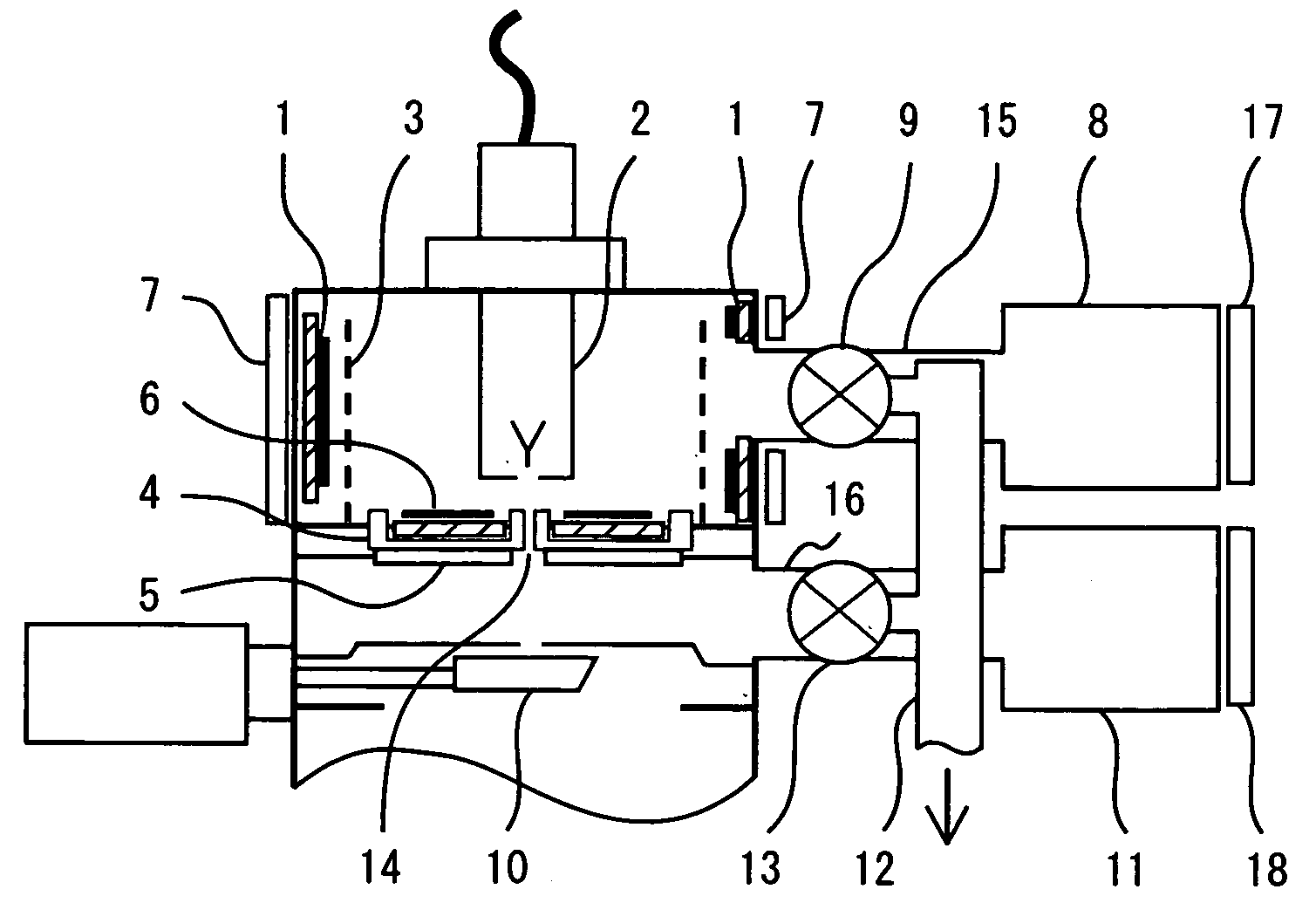

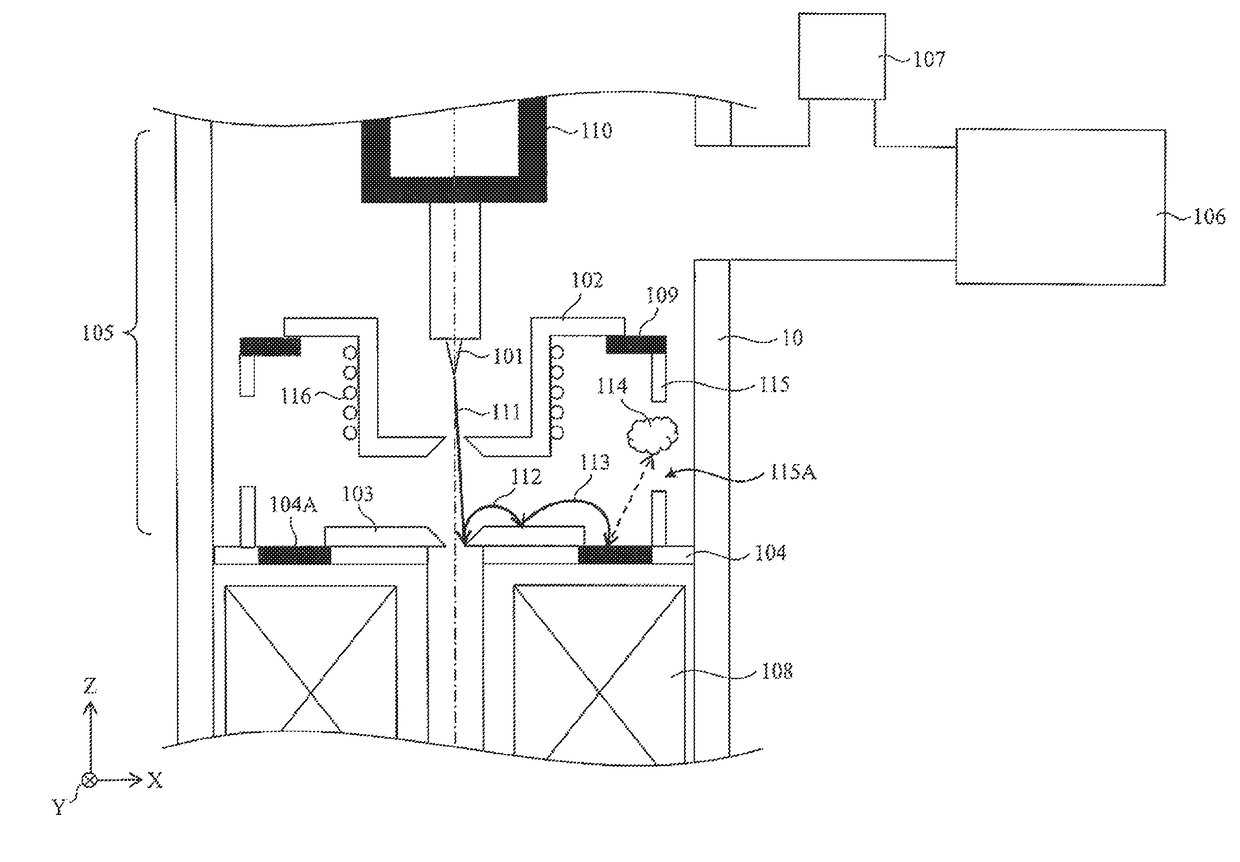

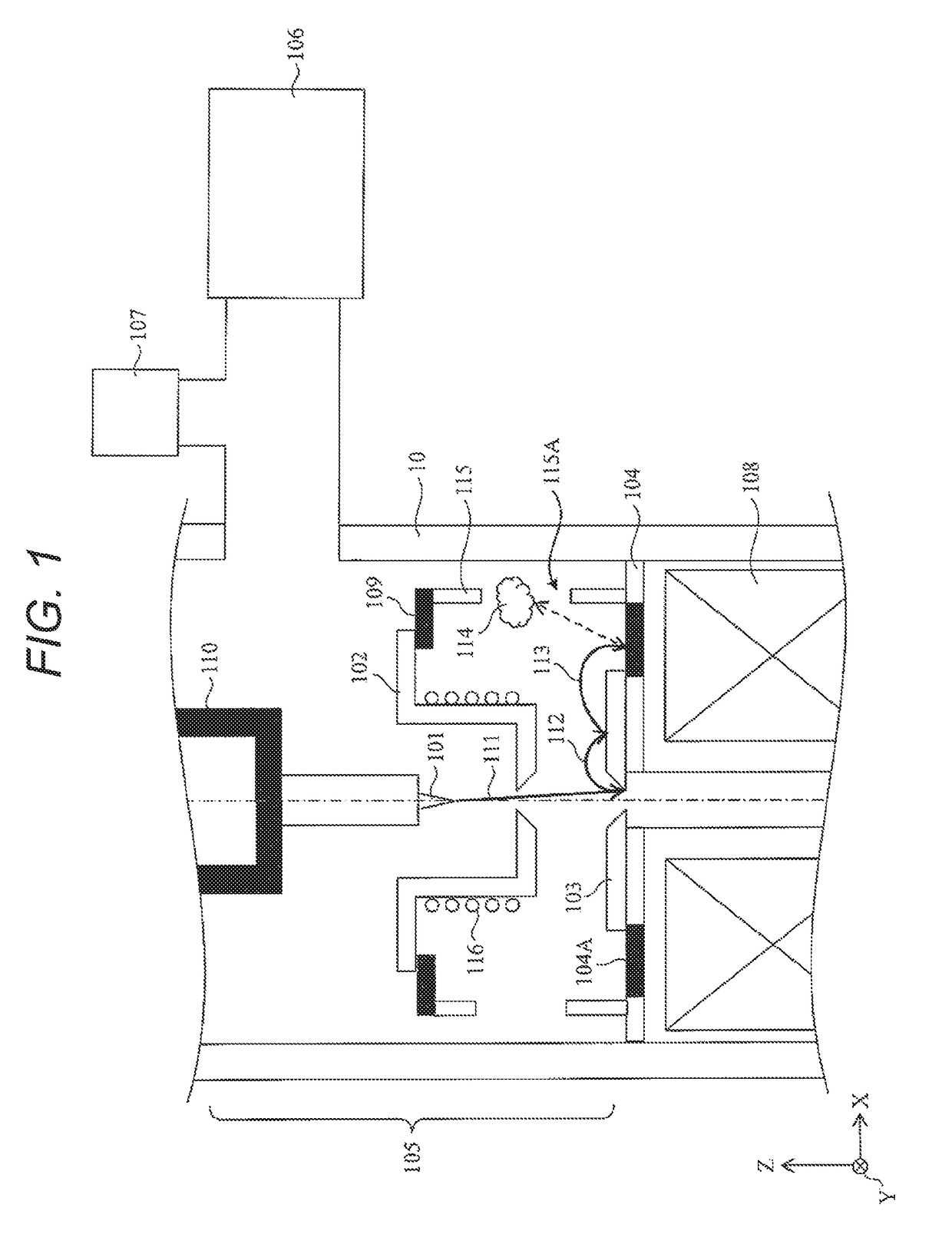

Scanning Electron Microscope

ActiveUS20170309437A1High resolutionIncrease currentElectric discharge tubesElectron sourceScanning tunneling microscope

The purpose of the present invention is to be able to acquire high-resolution images in a scanning electron microscope using a combination of a cold cathode (CFE) electron source and a boosting process, even at low accelerating voltage enhancing the current stability of the CFE electron source. A configuration in which a CFE electron source (101), an anode electrode (103) at positive (+) potential, and an insulator (104) for isolating the anode electrode (103) from ground potential are accommodated within a single vacuum chamber (105), and an ion pump (106) and a non-evaporable getter (NEG) pump (107) are connected to the vacuum chamber (105), is employed.

Owner:HITACHI HIGH-TECH CORP

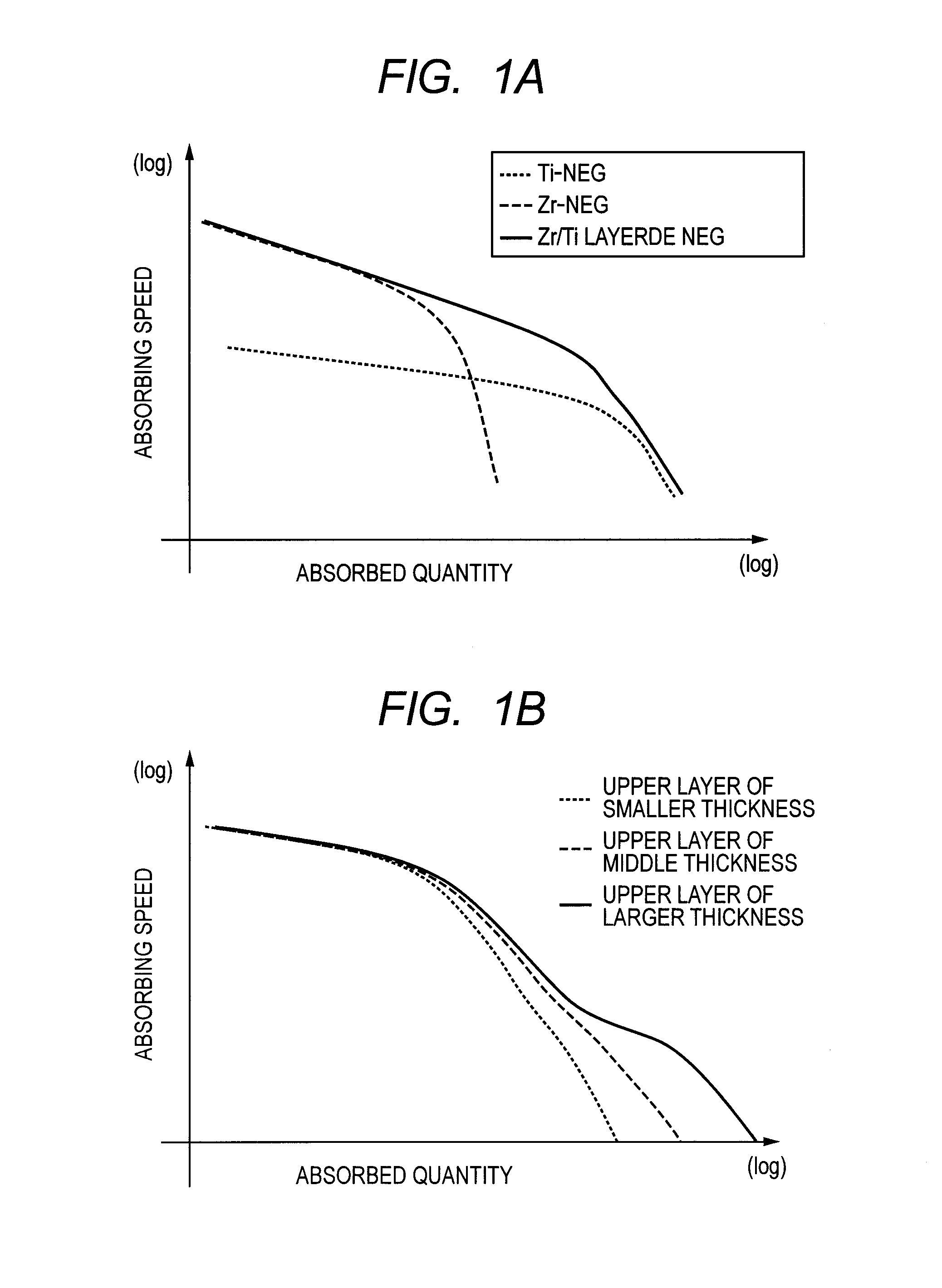

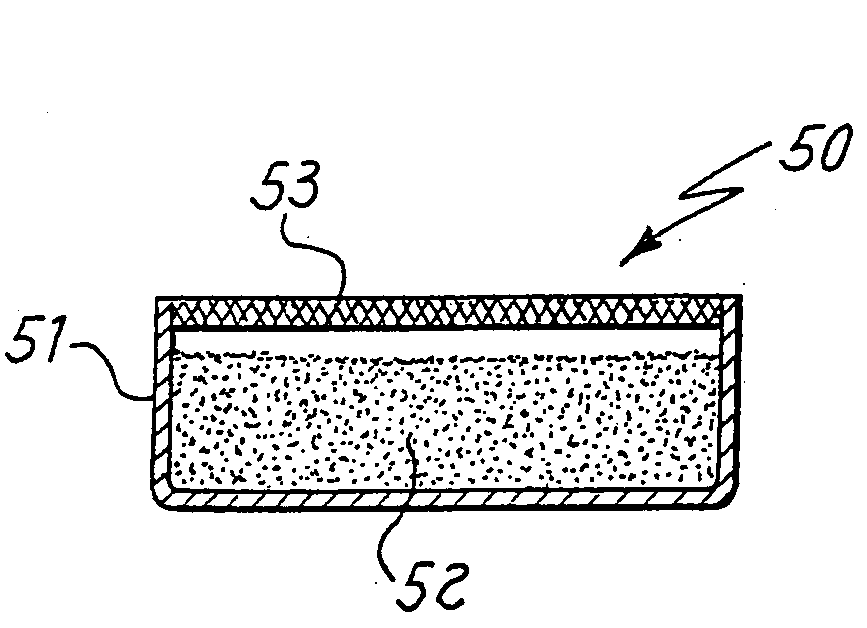

Non-evaporable getter for field-emission display

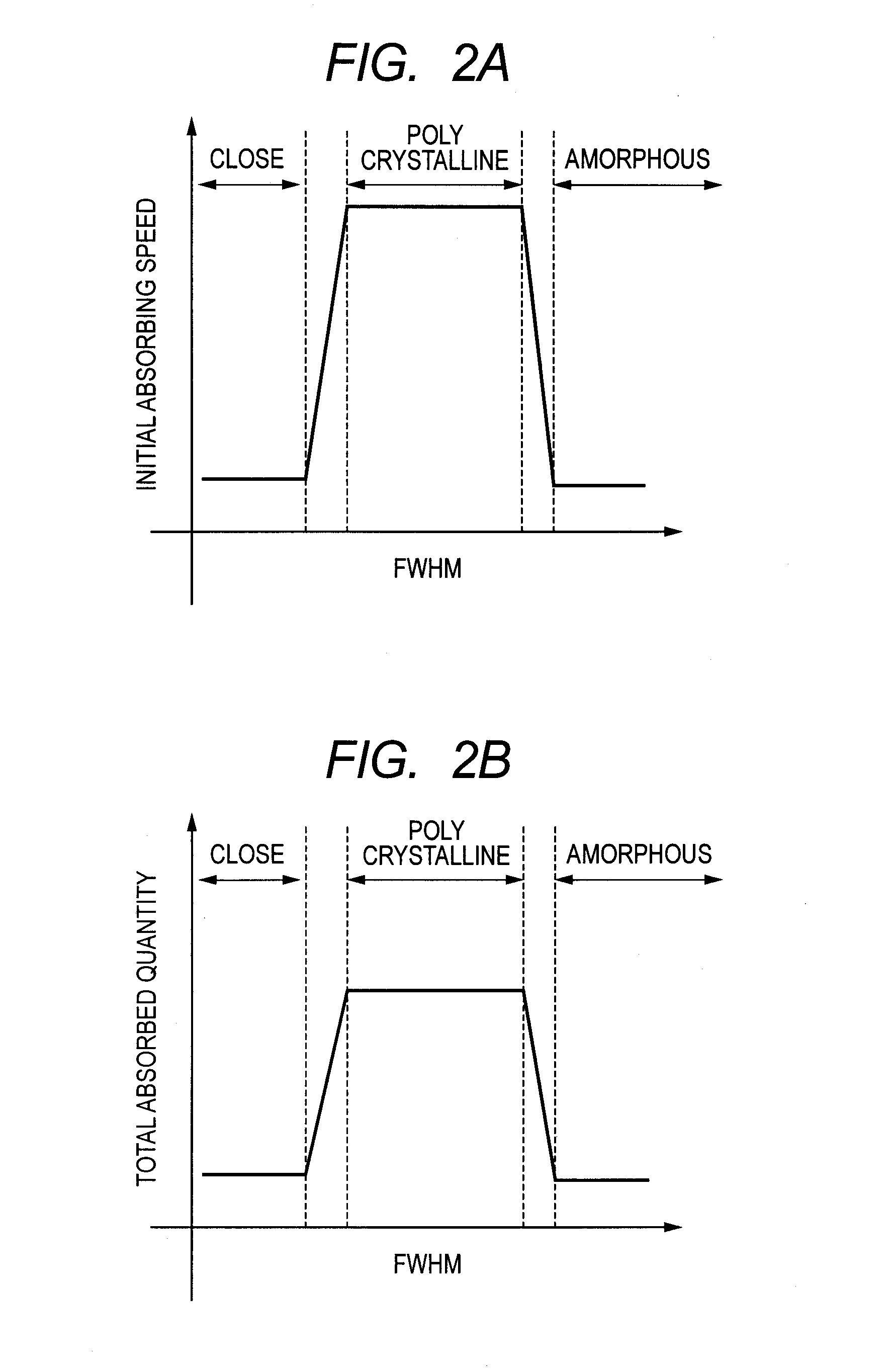

InactiveUS20110234091A1Fast absorptionLong period of timeLiquid surface applicatorsGas filling substance selectionField emission displayTitanium

The present invention provides a non-evaporable getter for an FED which can remove a plurality of types of gases. The non-evaporable getter for the FED has a first layer containing titanium, and a second layer containing crystalline zirconium layered on the first layer. The average value of crystalline grain sizes of the crystalline zirconium is 3 nm or more but 20 nm or less.

Owner:CANON KK

Vacuum device having a getter

A vacuum device, including a substrate and a support structure having a support perimeter, where the support structure is disposed over the substrate. In addition, the vacuum device also includes a non-evaporable getter layer having an exposed surface area. The non-evaporable getter layer is disposed over the support structure, and extends beyond the support perimeter, in at least one direction, of the support structure forming a vacuum gap between the substrate and the non-evaporable getter layer increasing the exposed surface area.

Owner:SAMSUNG ELECTRONICS CO LTD

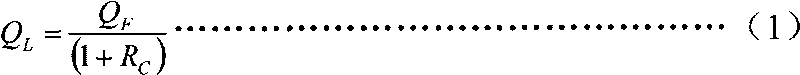

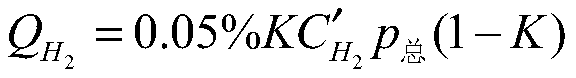

Nitrogen and hydrogen mixed gas vacuum leak hole calibration device and method

The invention discloses a nitrogen and hydrogen mixed gas vacuum leak hole calibration device. The device comprises a hydrogen gas and nitrogen gas supply system, a gas distribution chamber, a pressure gauge, a gas obtaining chamber, a low vacuum pump, a gas inlet chamber, a vacuum gauge, a high vacuum pump, a seepage device, a mass spectrometer, a non-evaporable getter pump, a calibration systemand a gas extracting system; the pressure gauge is arranged on the gas distribution chamber; the gas distribution chamber is divided into two paths; one path is connected with the gas obtaining chamber and the gas inlet chamber; the other path is connected with the high vacuum pump through a pipeline; the hydrogen gas and nitrogen gas supply system and the low vacuum pump are arranged between thegas distribution chamber and the high vacuum pump; the high vacuum pump is connected with the gas inlet chamber; the gas inlet chamber is sequentially connected with the seepage device, the calibration system and the gas extracting system through pipelines; the pressure gauge and the vacuum gauge are arranged on the gas inlet chamber; a stop valve is arranged between the seepage device and the calibration system; a nitrogen and hydrogen mixed gas vacuum leak hole is connected to the calibration system; the pressure gauge, the vacuum gauge and the mass spectrometer are arranged on the calibration system; and the non-evaporable getter pump is connected to the calibration system.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

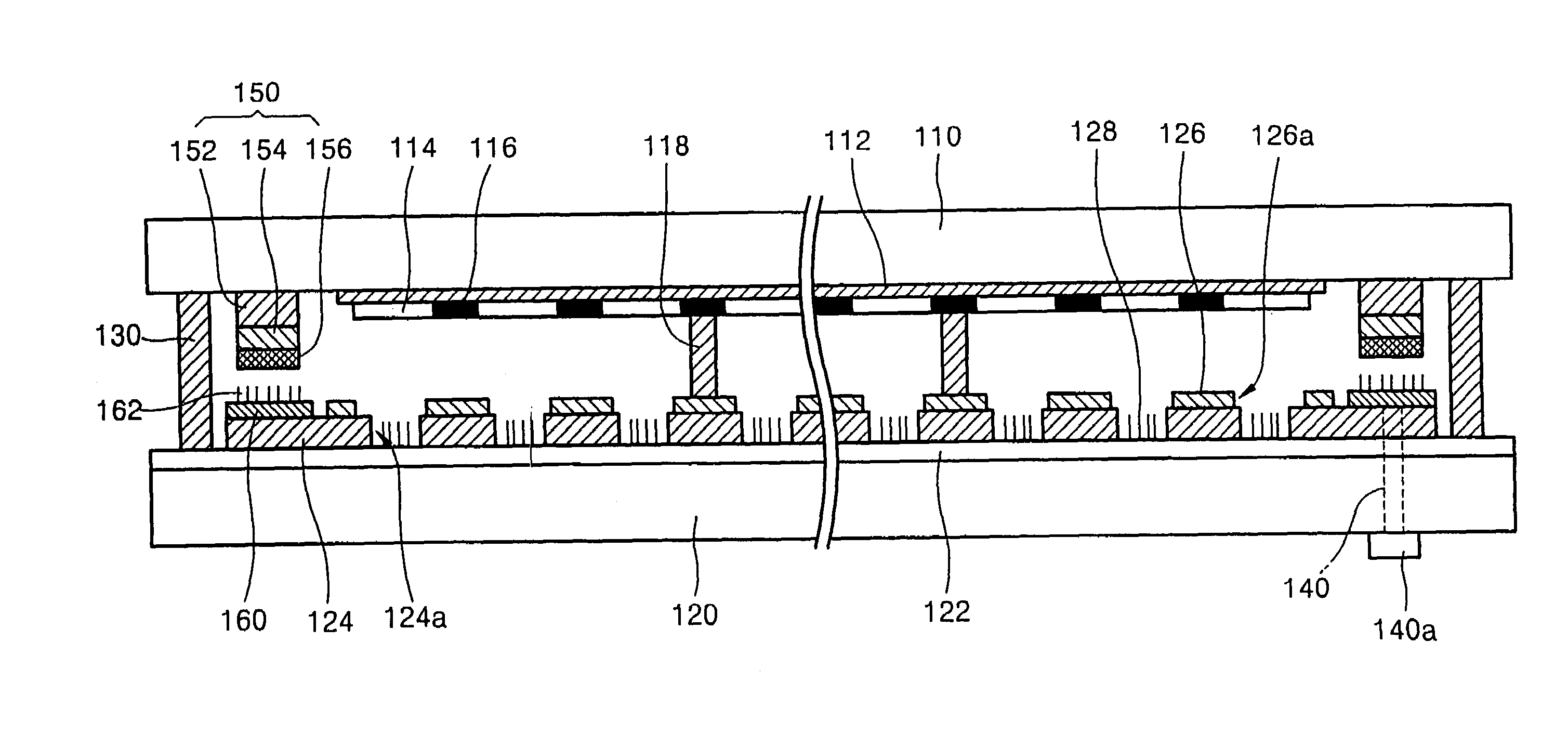

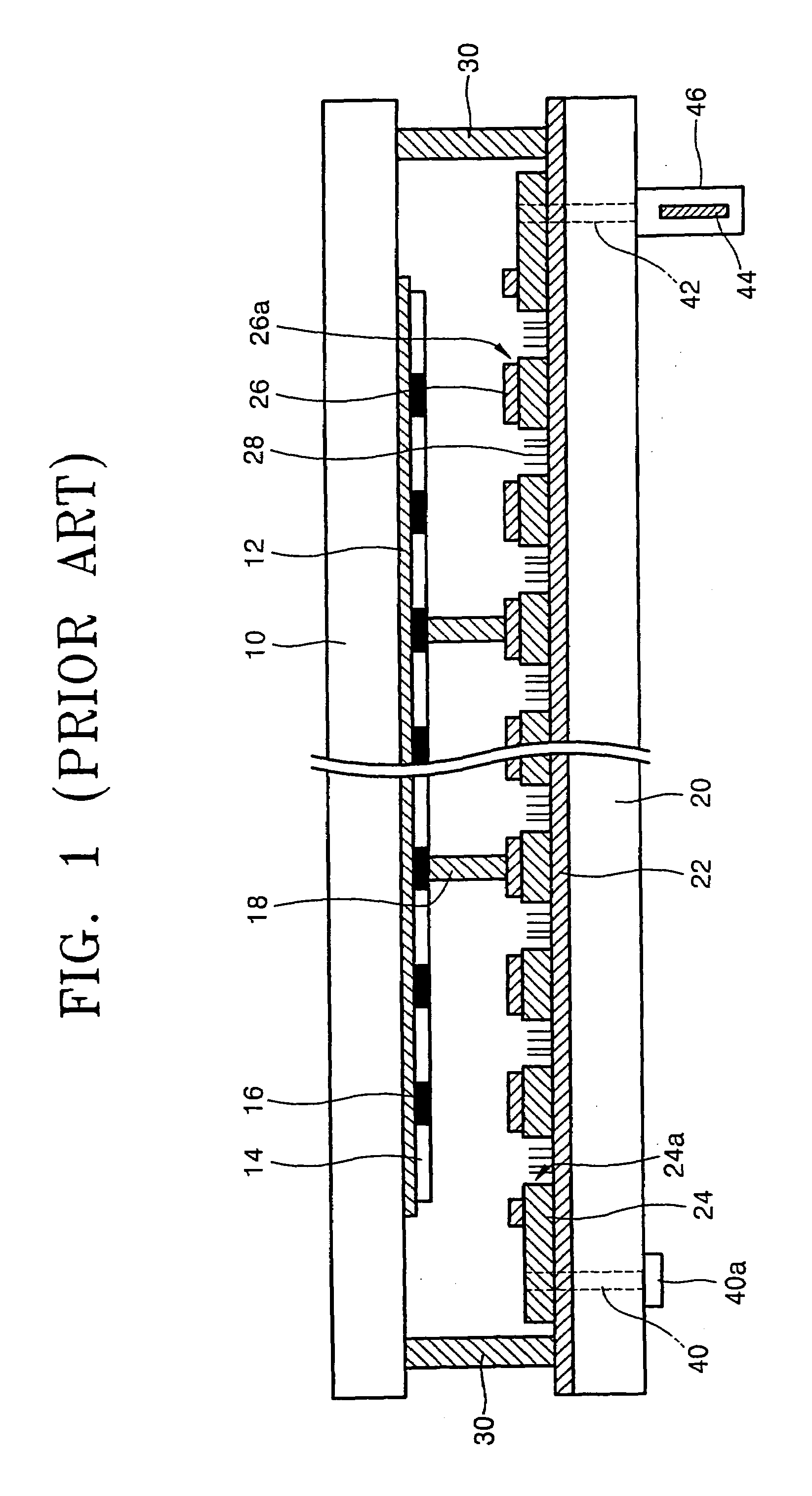

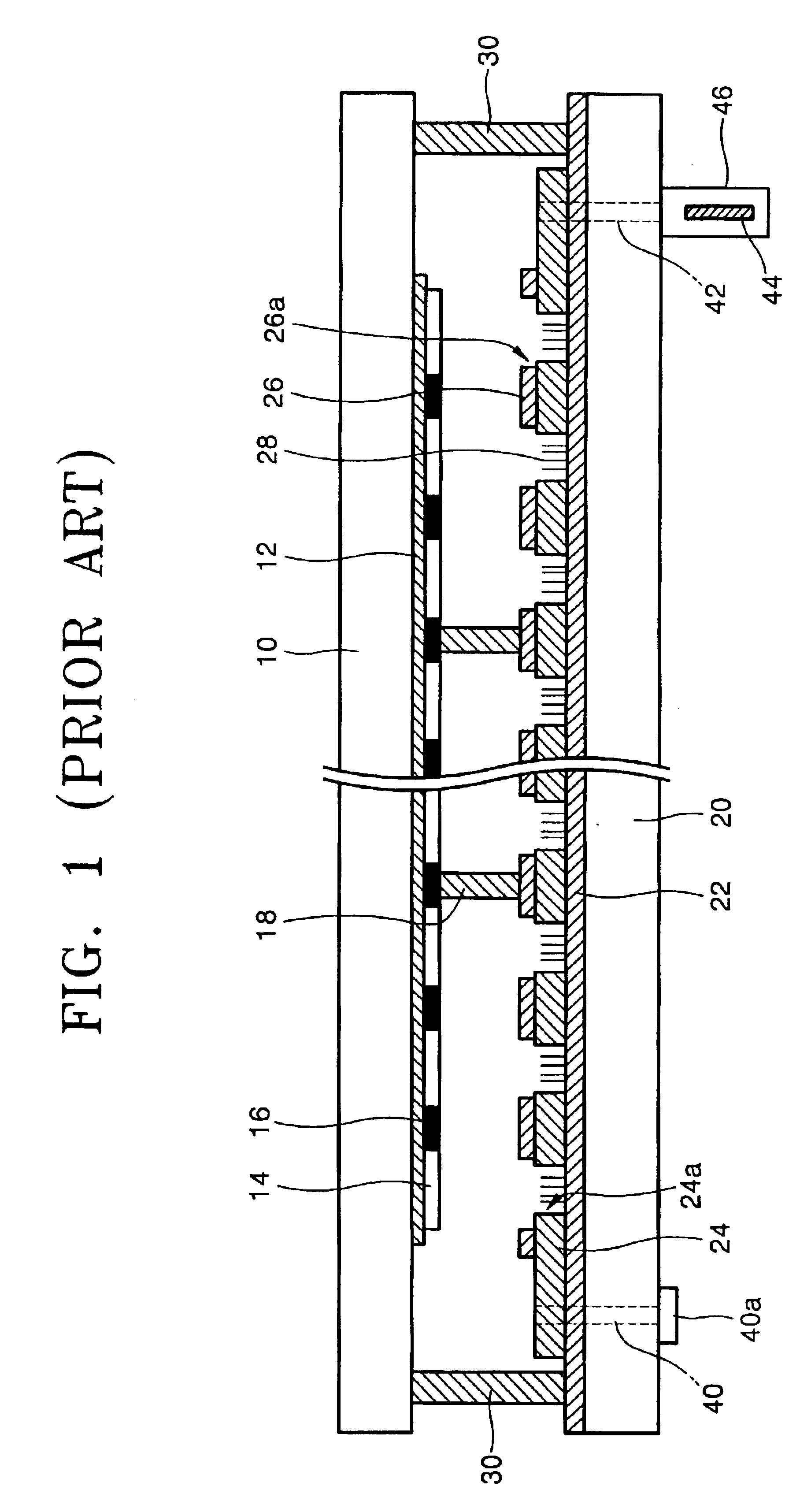

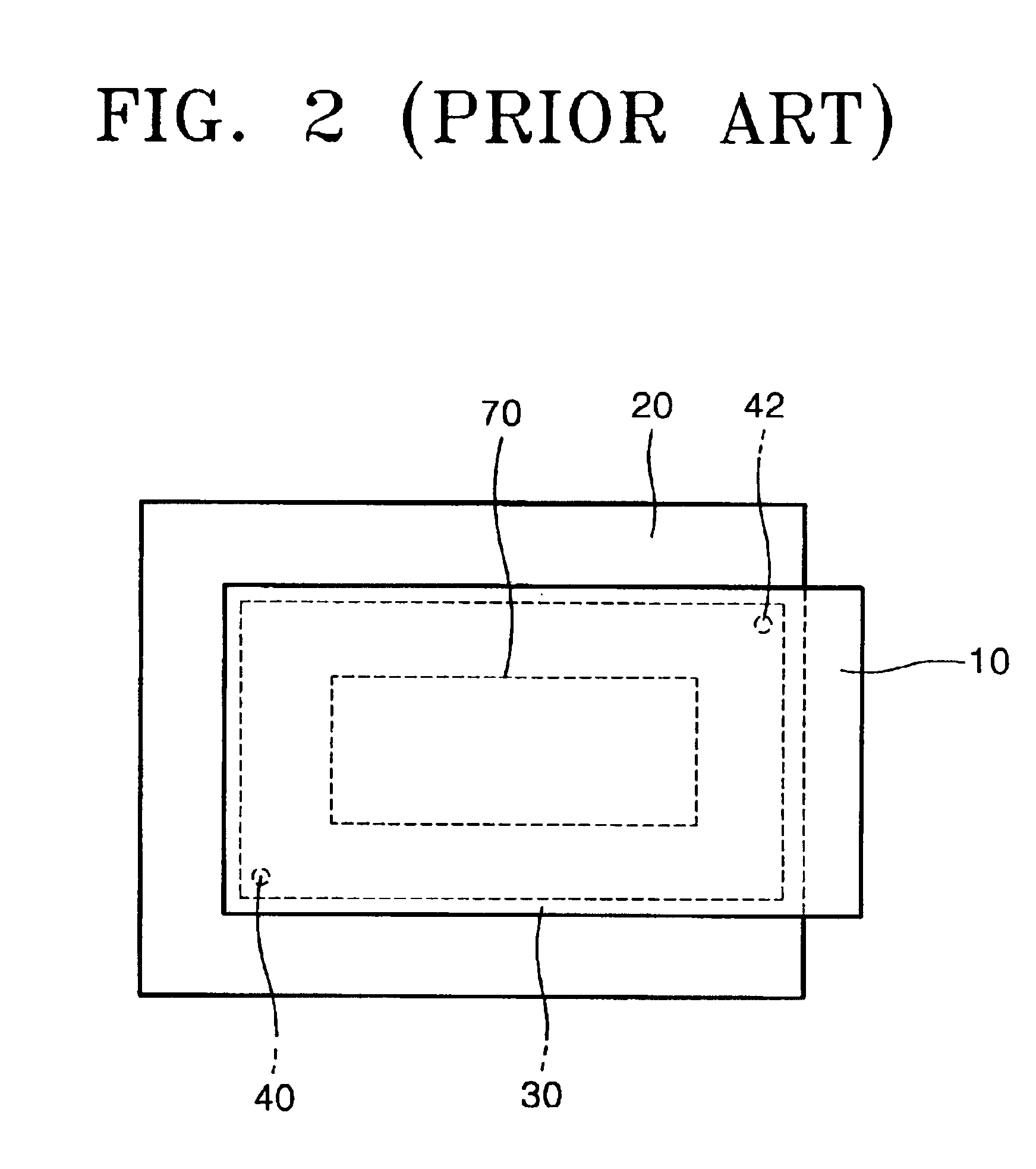

Field emission display having integrated getter arrangement

InactiveUS6963165B2Efficient removalGas filling substance selectionDischarge tube luminescnet screensField emission displayElectron

A field emission display (FED) and a manufacturing method thereof are provided. The FED includes a getter portion isolated outwardly from an active display region. This getter portion includes a non-evaporable getter layer for absorbing gas and an electron emission source for activating the getter layer. Accordingly, by activating the non-evaporable getter, the gas generated in the display is easily absorbed, and the FED is maintained in a high vacuum state.

Owner:SAMSUNG SDI CO LTD

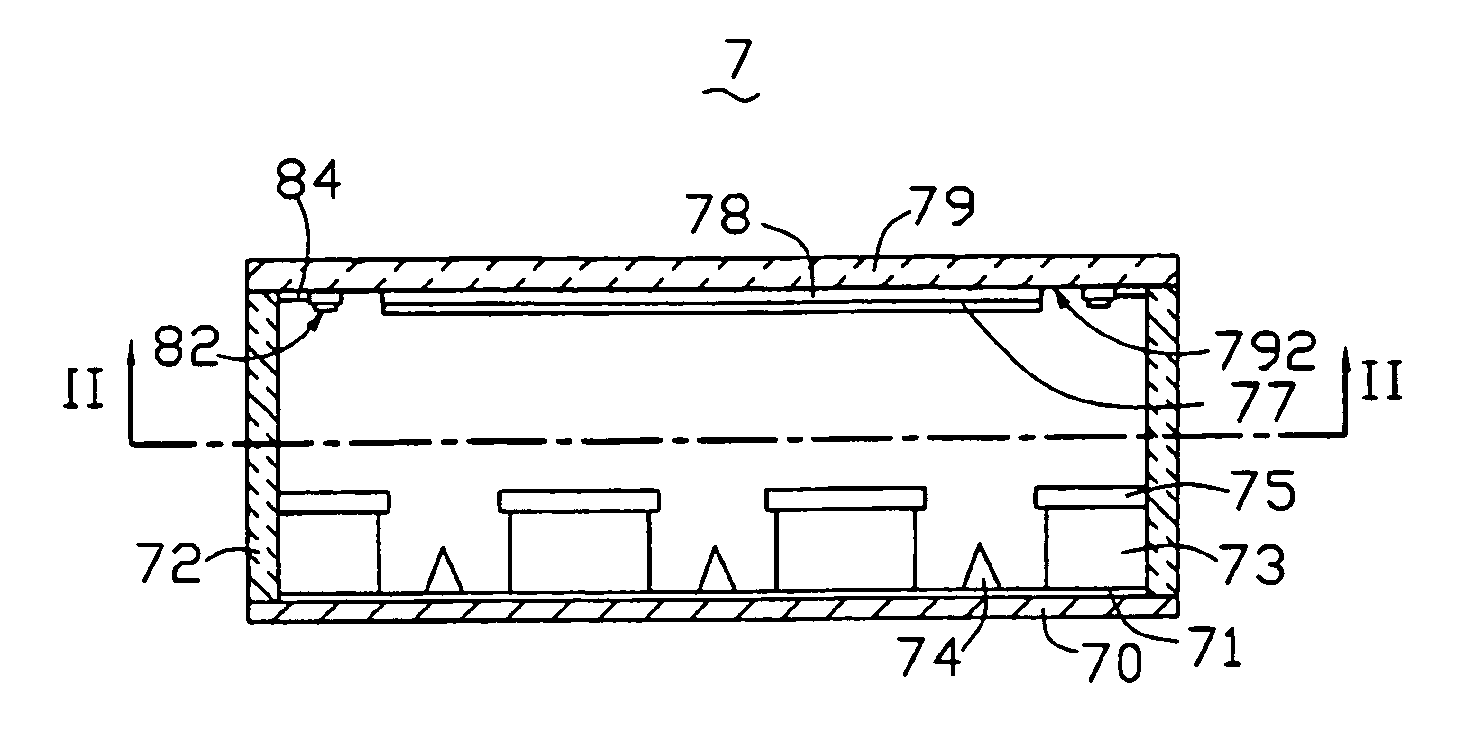

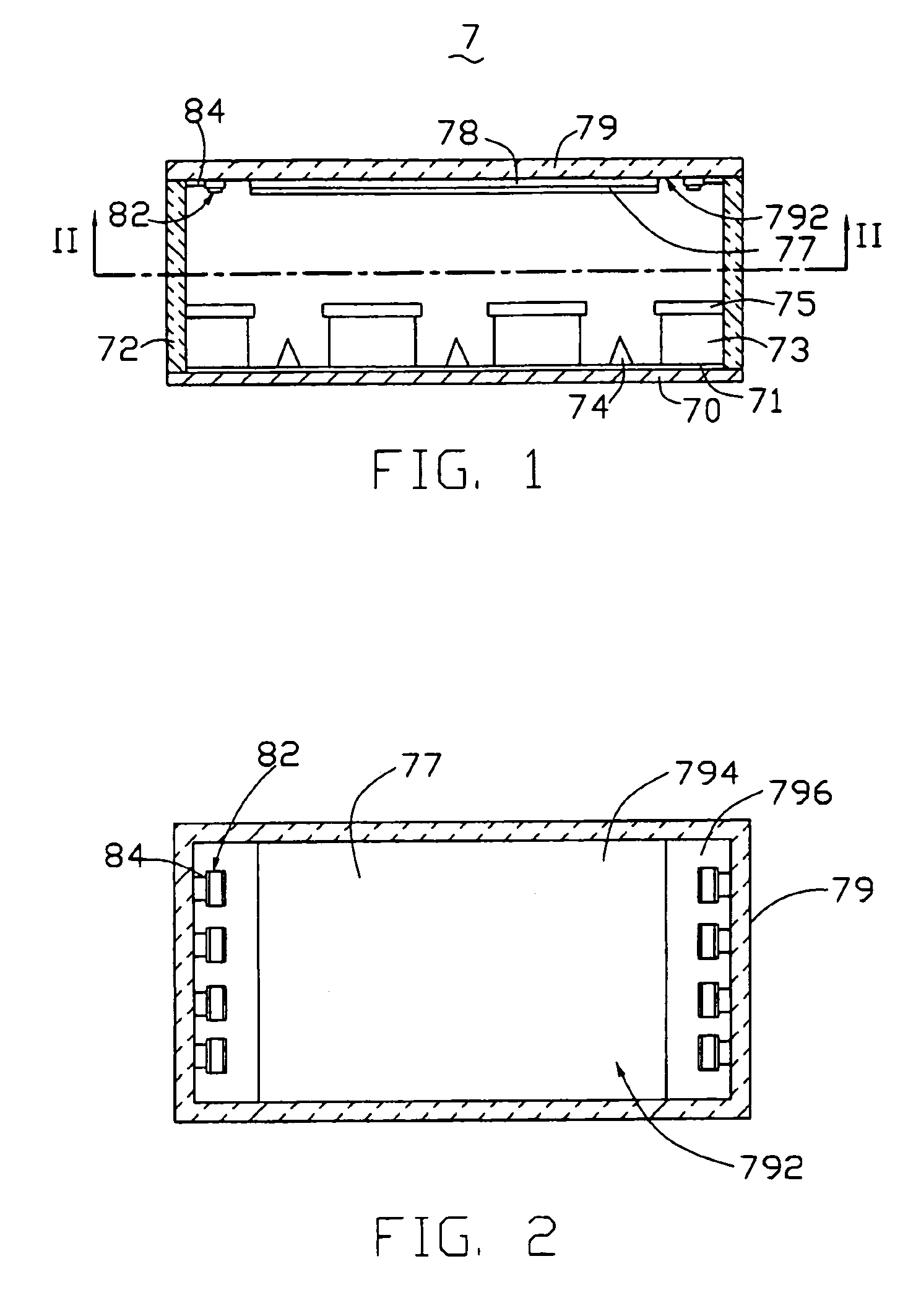

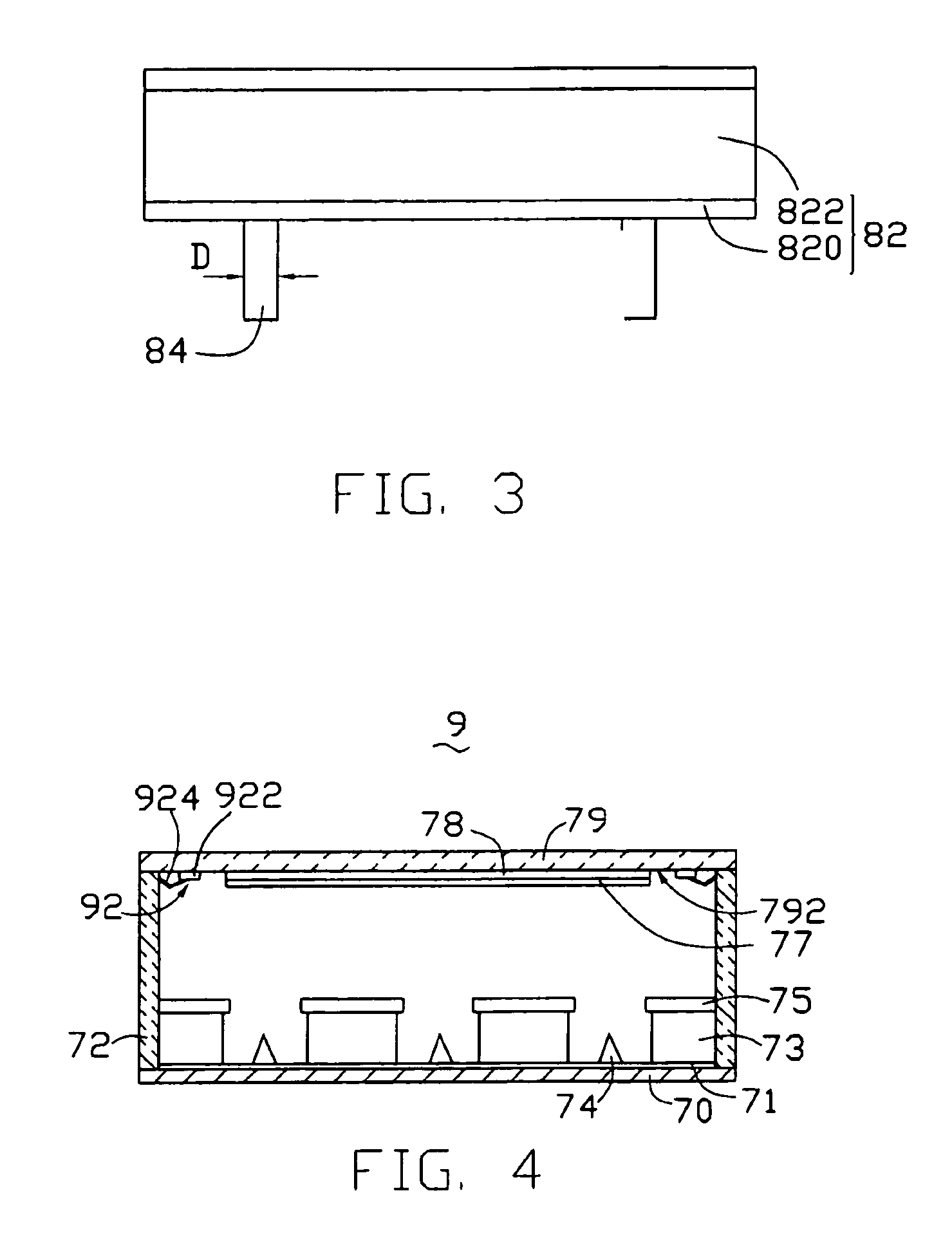

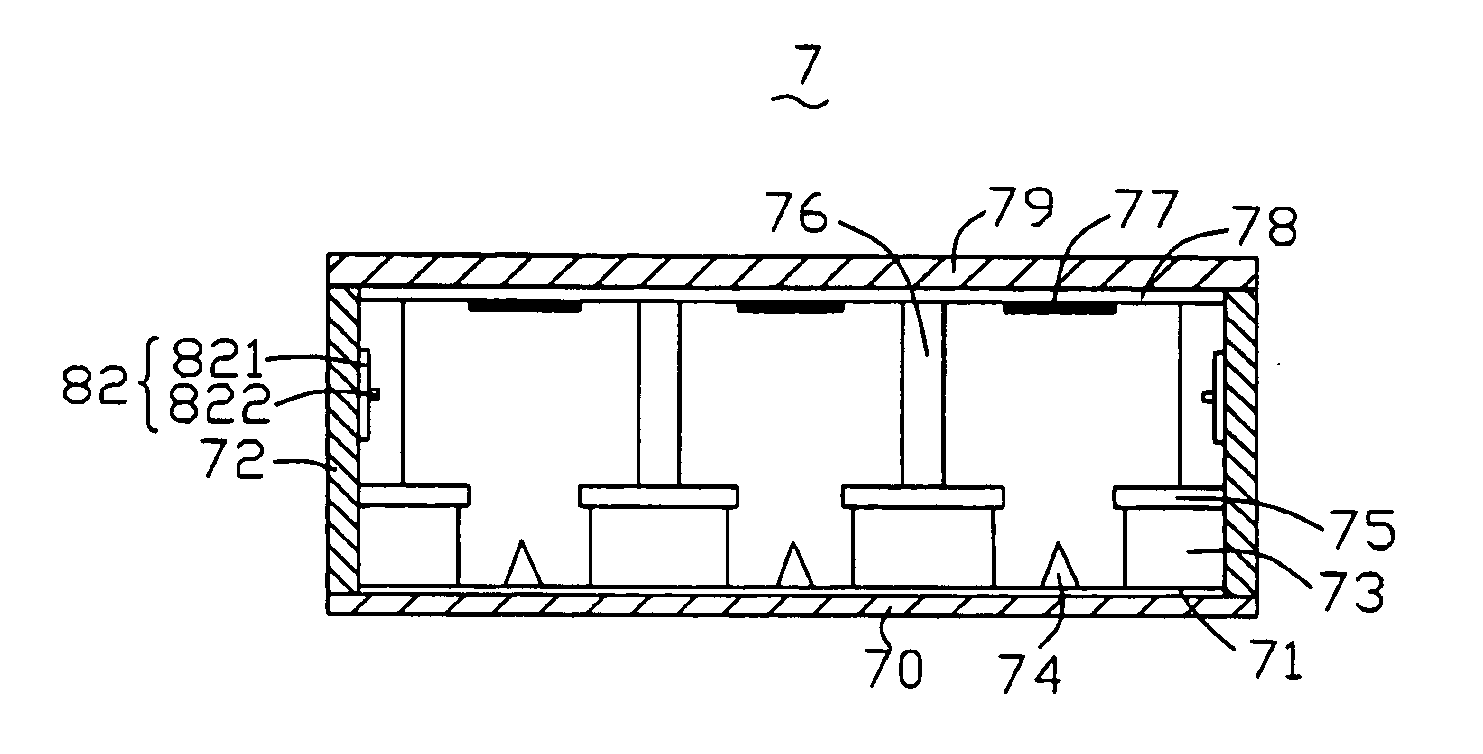

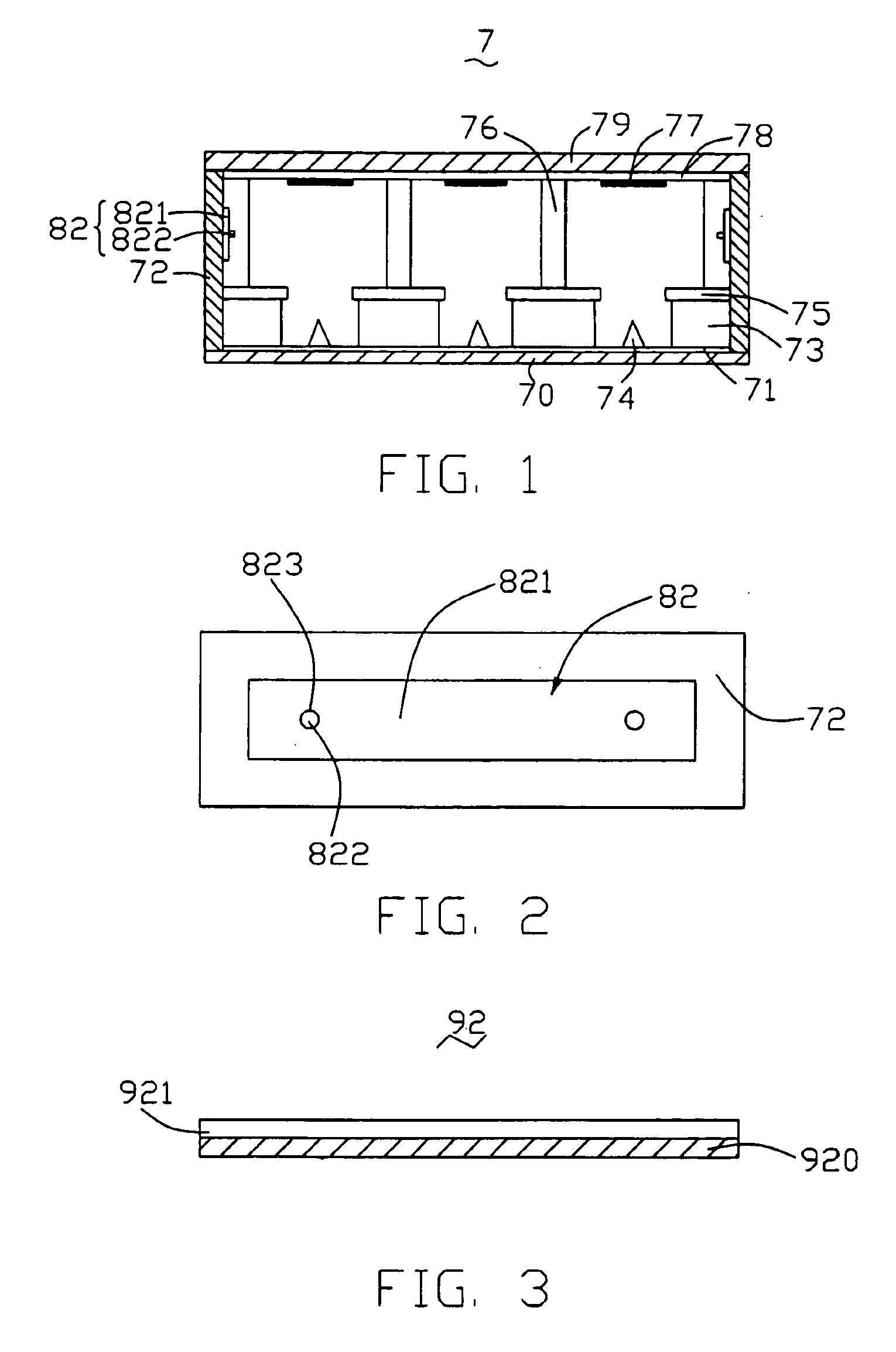

Flat panel display having non-evaporable getter material

ActiveUS7745995B2Gas filling substance selectionDischarge tube luminescnet screensDisplay deviceEngineering

A flat panel display (7) generally includes a front substrate (79) and a rear substrate (70) opposite thereto. The front substrate is formed with an anode (78). The rear substrate is formed with a cathode (71) facing the anode. Several sidewalls (72) are interposed between the front substrate and the rear substrate. A plurality of getter devices (82) are arranged on the front substrate. Thereby, a chamber between the front substrate and the rear substrate is maintained as a low-pressure vacuum. Each of the getter devices includes a base (820), a getter layer (822) comprised of non-evaporable getter material formed thereon, and securing wires (84) arranged on the base.

Owner:TSINGHUA UNIV +1

Electronic device sealed under vacuum containing a getter and method of operation

InactiveUS20060183299A1Gas filling substance selectionSemiconductor/solid-state device detailsEngineeringDielectric layer

An electronic device that is sealed under vacuum includes a substrate, a transistor formed on the substrate, and a dielectric layer covering at least a portion of the transistor. The electronic device further includes a layer of non-evaporable getter material disposed on a portion of the dielectric layer; and a vacuum device disposed on a portion of the substrate. Electrical power pulses activate the non-evaporable getter material.

Owner:LIEBESKIND JOHN

Flat panel display having non-evaporable getter material

A flat panel display (7) generally includes a front substrate (79) and a rear substrate (70) opposite thereto. The front substrate is formed with an anode (78). The rear substrate is formed with a cathode (71) facing the anode. Several sidewalls (72) are interposed between the front substrate and the rear substrate. At least one of the sidewalls has a getter unit (82), and a securing member (822) for fixing the getter unit thereon. The getter unit is comprised of non-evaporable getter material. Thereby maintaining a substantial vacuum in a chamber between the front substrate and the rear substrate.

Owner:TSINGHUA UNIV +1

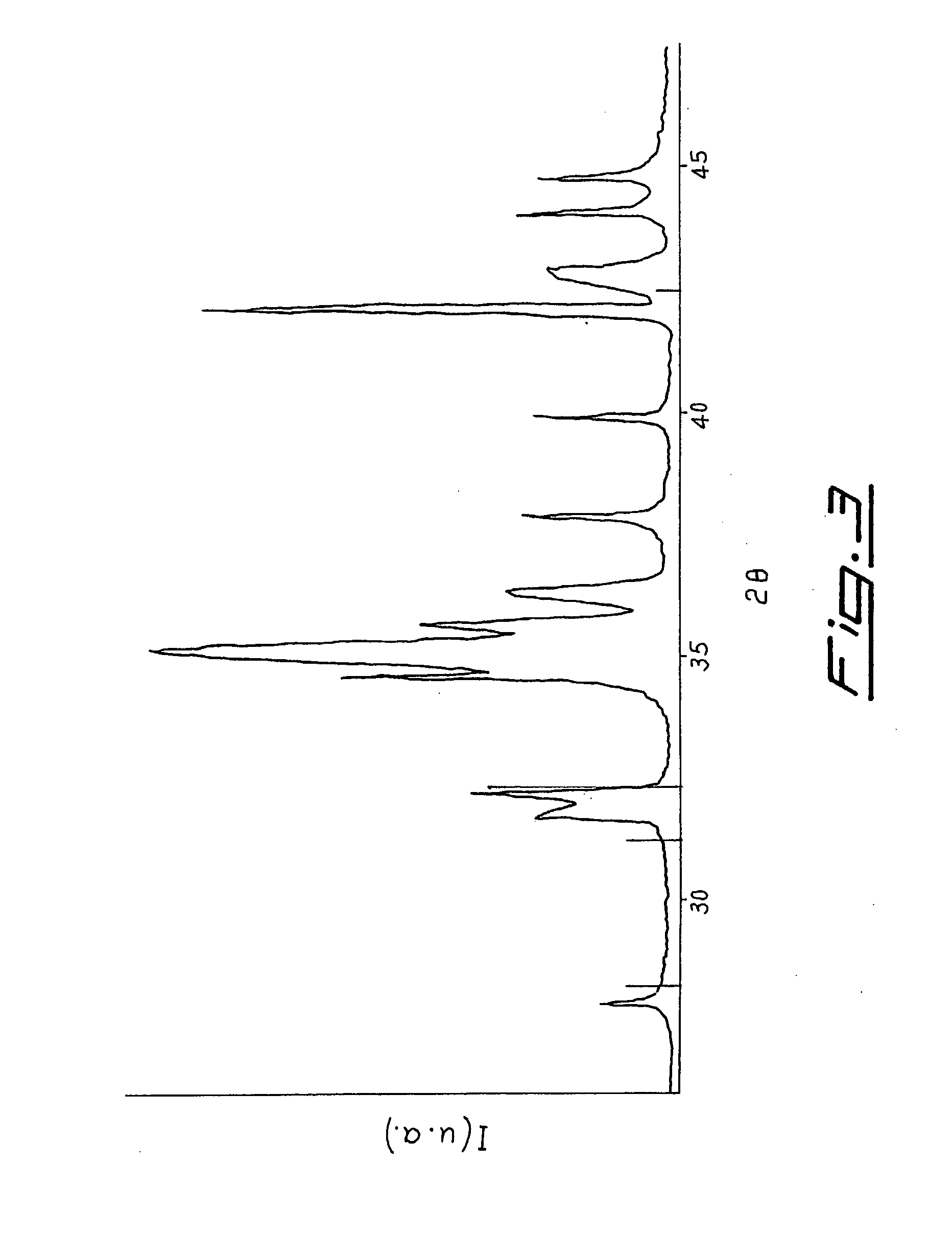

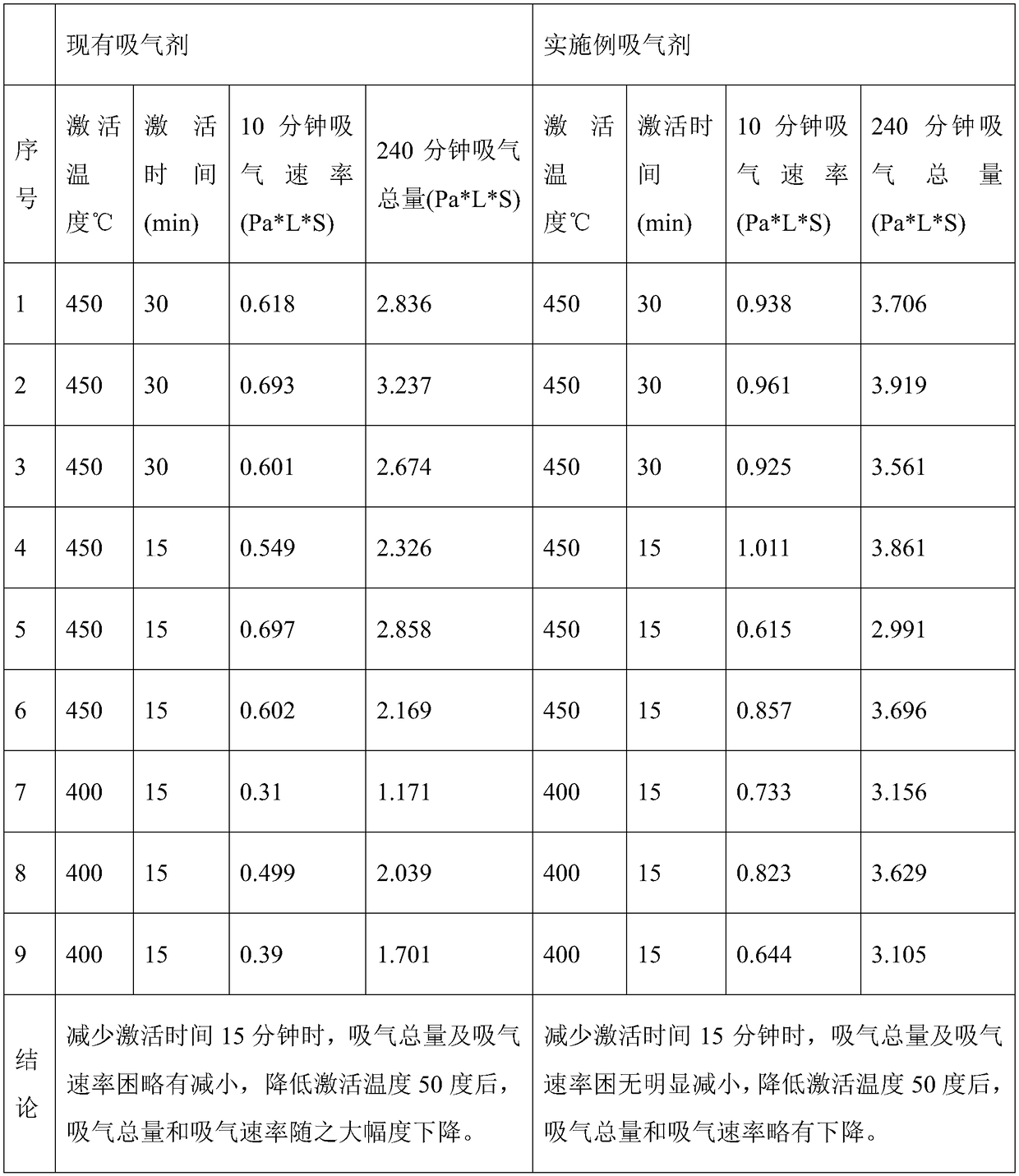

Preparation method of zirconium non- evaporable getter

InactiveCN109225119AReduce use costIncrease speedOther chemical processesDispersed particle separationNiobiumBall mill

The invention discloses a preparation method of a zirconium non- evaporable getter, comprising the following steps: (1) selecting 60-75 parts by weight of zirconium, 0-21 parts by weight of vanadium,4-25 parts by weight of bismuth and 3-11 parts by weight of iron as raw materials; (2) putting the mixed raw materials into a vacuum melting furnace to form a vacuum environment; (3) starting a heating system of the vacuum melting furnace, and melting the mixture in the furnace until the mixture is completed molten into a liquid state; (4) cooling the liquid melt into an alloy ingot, and crushingthe alloy ingot to alloy particles of 1-3 cm; (5) putting the alloy particles into a vacuum ball mill to make powder of 100 microns or less, and pressing the powder into a certain shape or into a carrier to form the getter. A formula and a preparation method of the existing non-evaporable getter are improved, so that the getting rate and the getting performance of a product are greatly improved, and meanwhile the activation temperature is lowered.

Owner:南京恩瑞科技有限公司

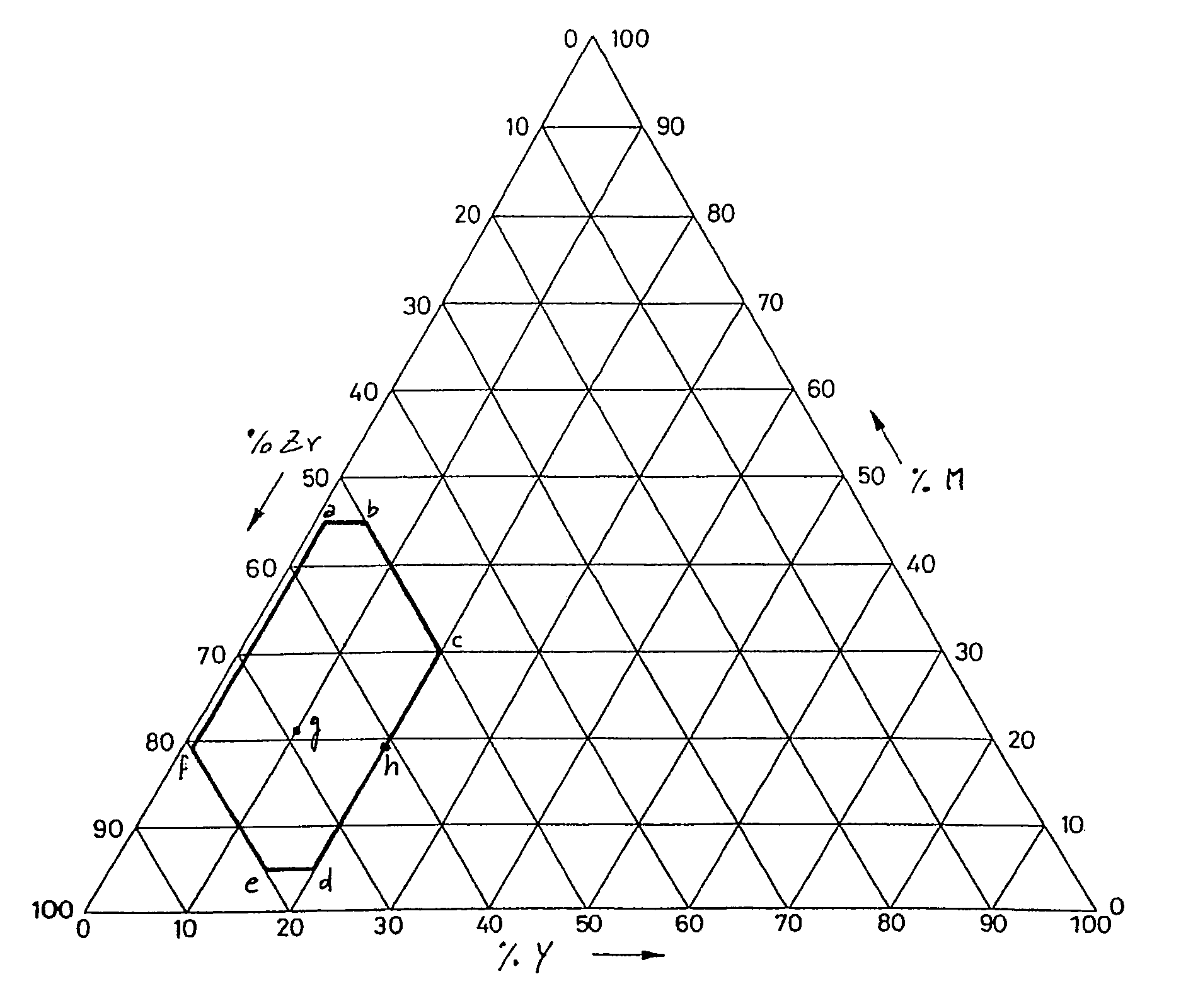

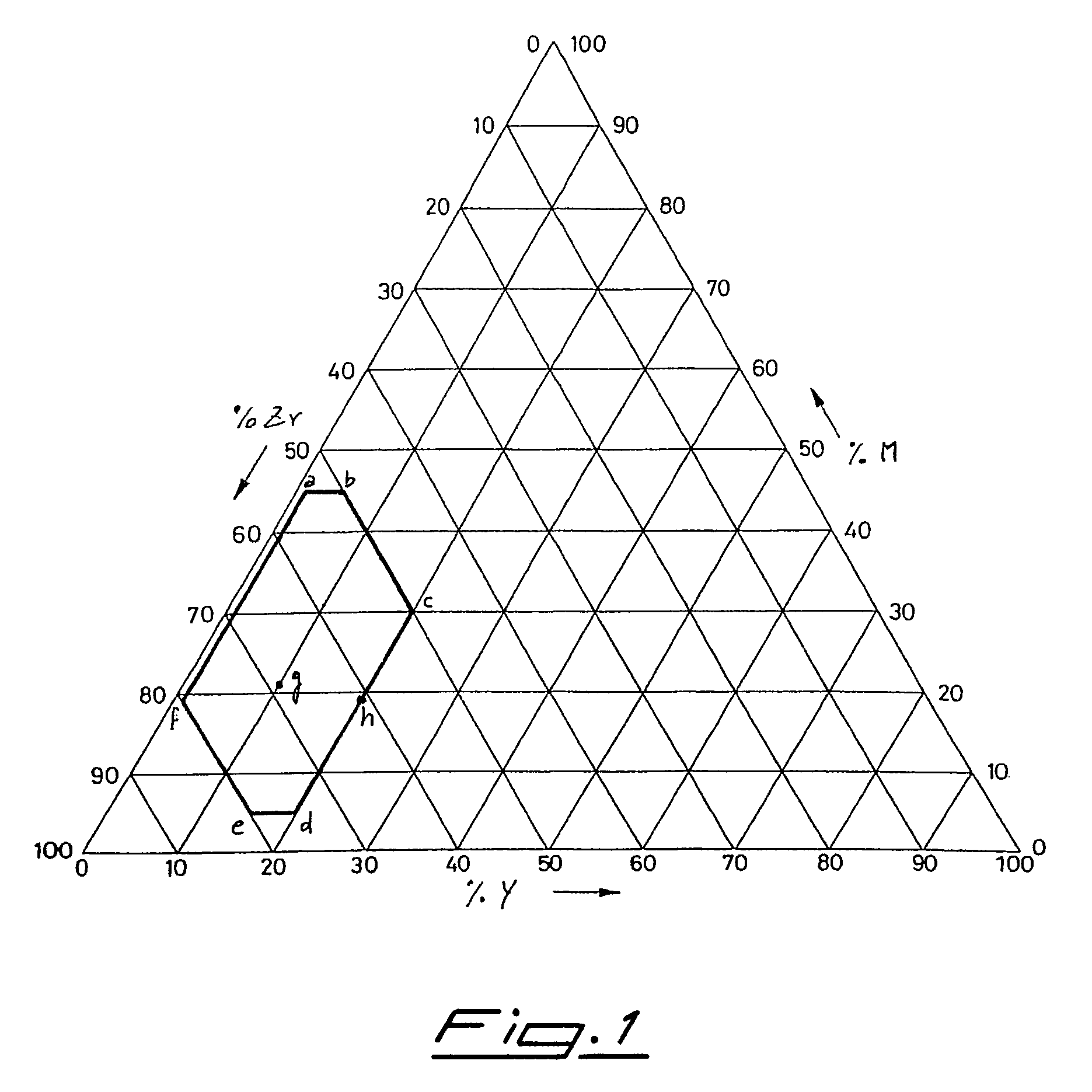

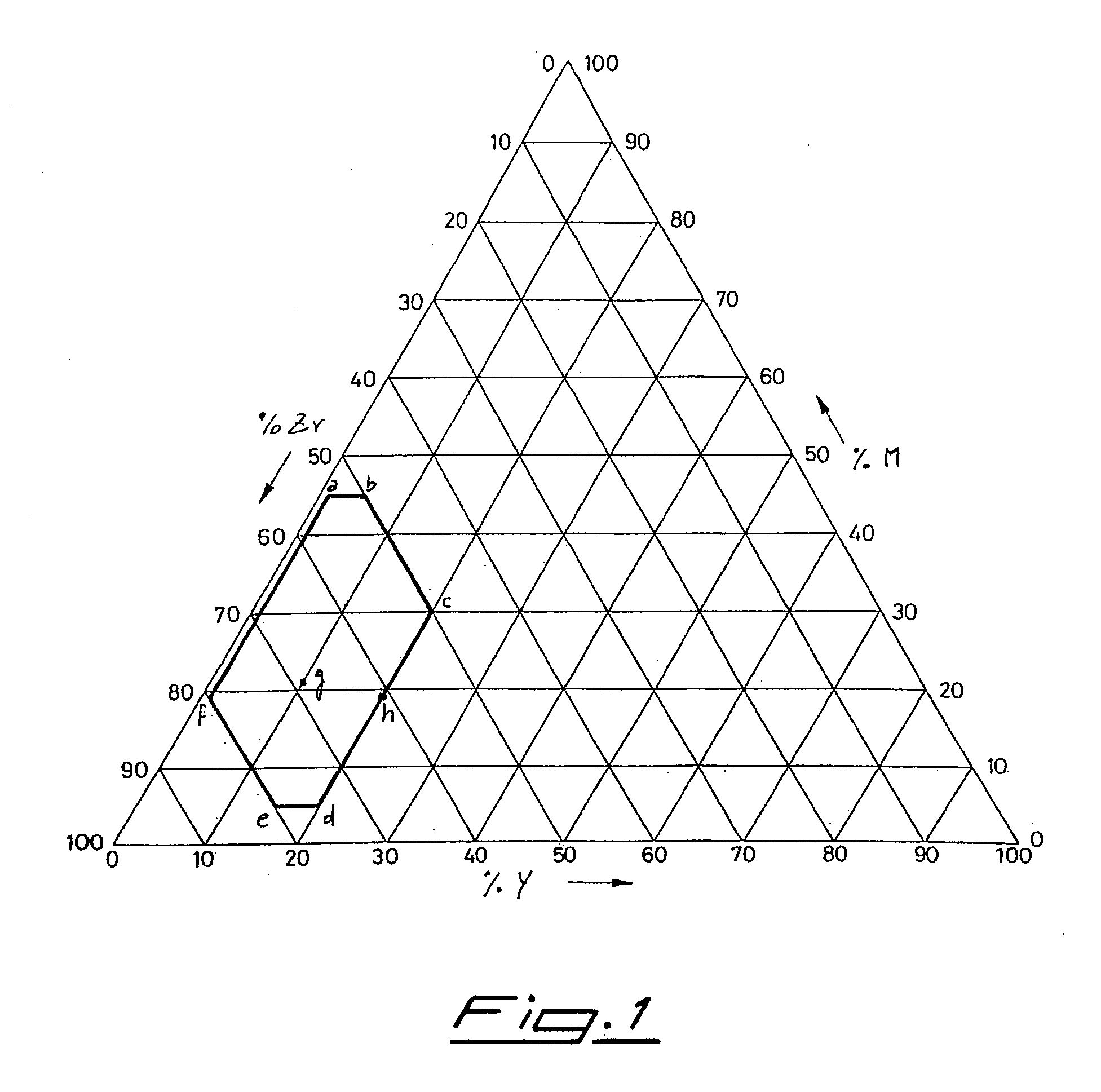

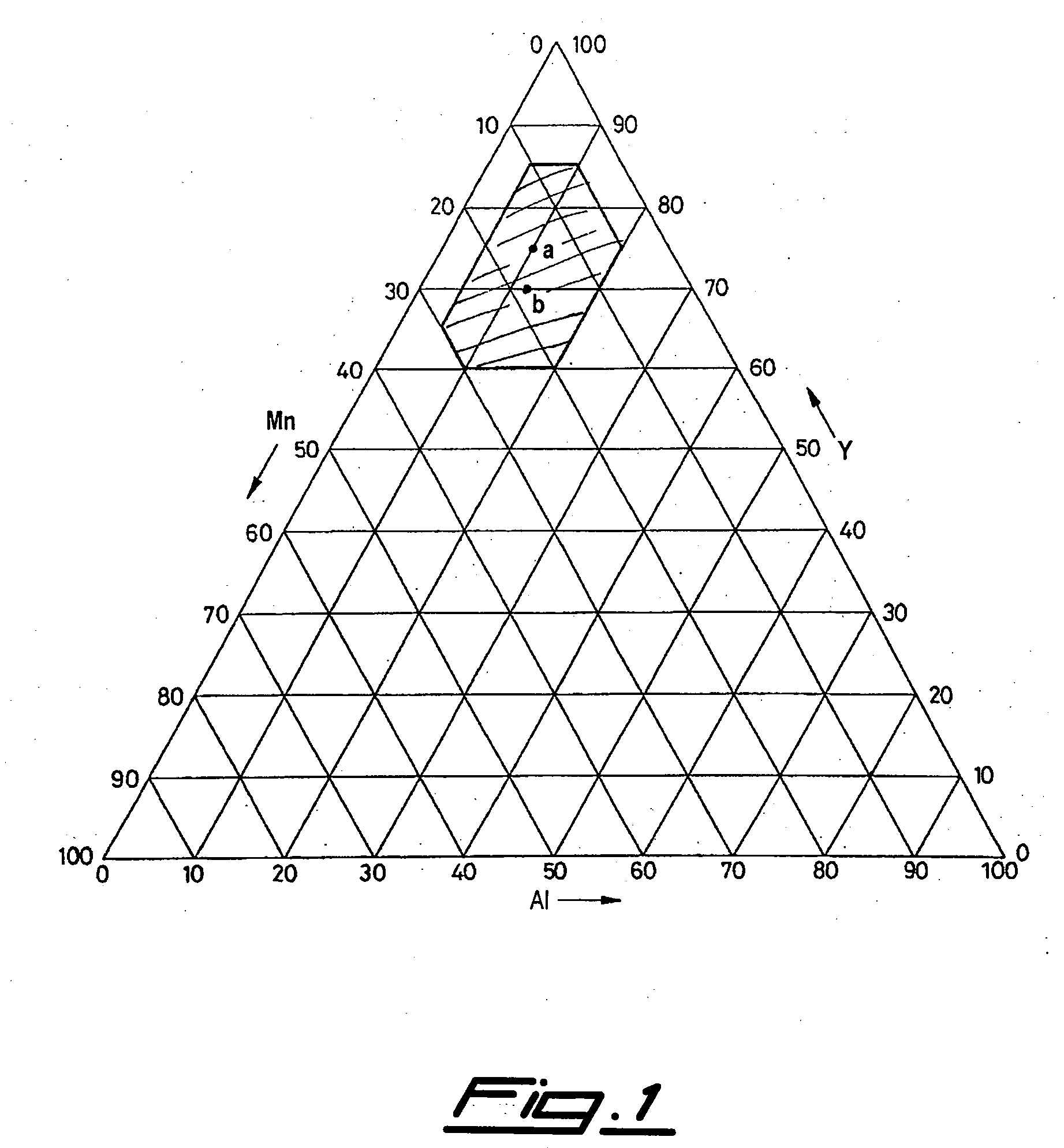

Non-evaporable getter alloys based on yttrium for hydrogen sorption

ActiveUS20090148635A1Improve hydrogen absorption performanceMaintain good propertiesHydrogen separation by selective and reversible uptakeEnvelopes/bags making machineryHydrogenAlloy

Owner:SAES GETTERS SPA

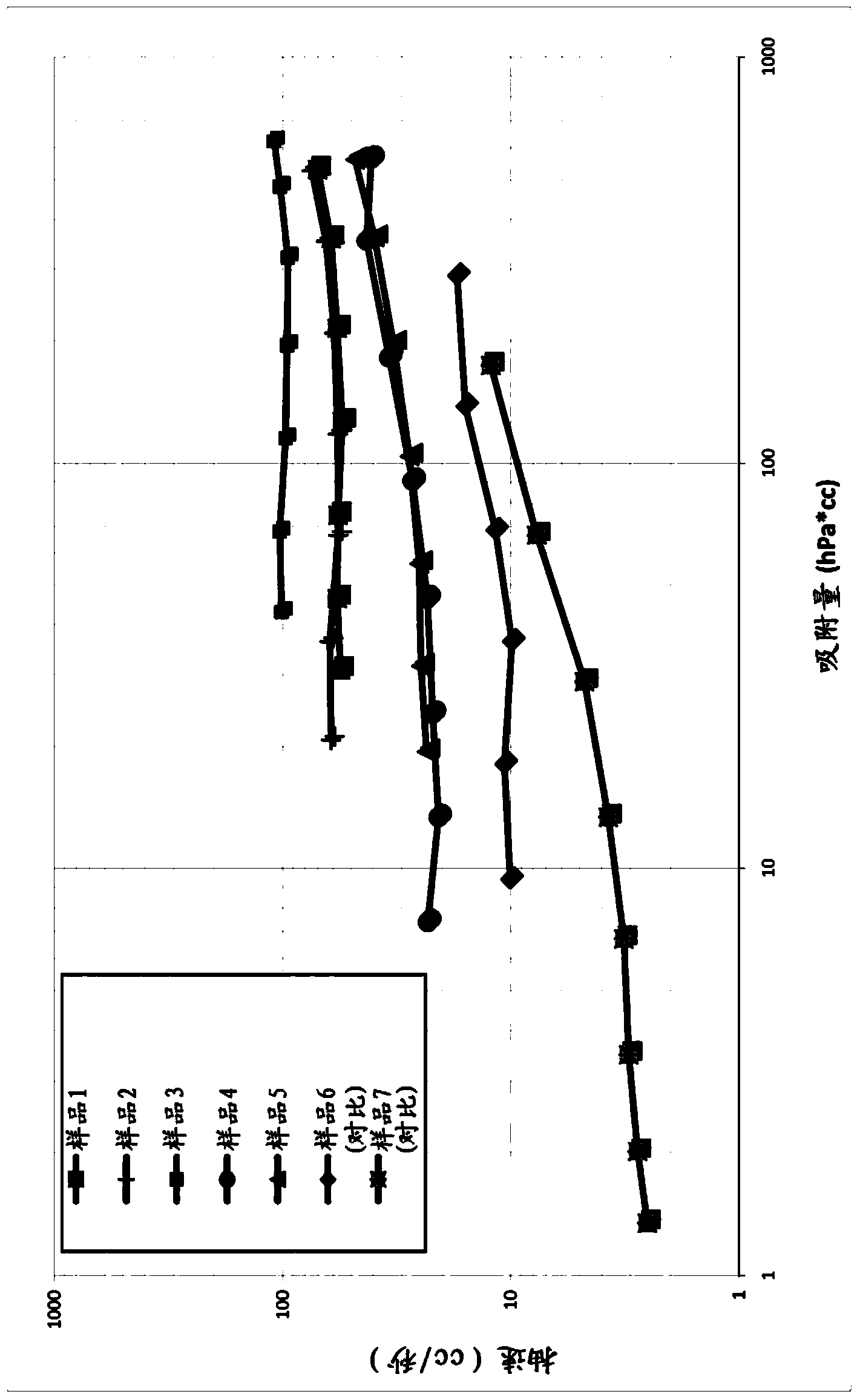

Non-evaporable getter compositions which can be reactivated at low temperature after exposure to reactive gases at a higher temperature

ActiveCN103843103AGood adsorption propertiesElectric discharge tubesThin material handlingReactive gasAlloy

Compositions containing a mixture of non-evaporable getter alloys are described which, after having lost their functionality in consequence of the exposure to reactive gases at a first temperature, can then be reactivated through a thermal treatment at a second temperature that is lower than the first one.

Owner:SAES GETTERS SPA

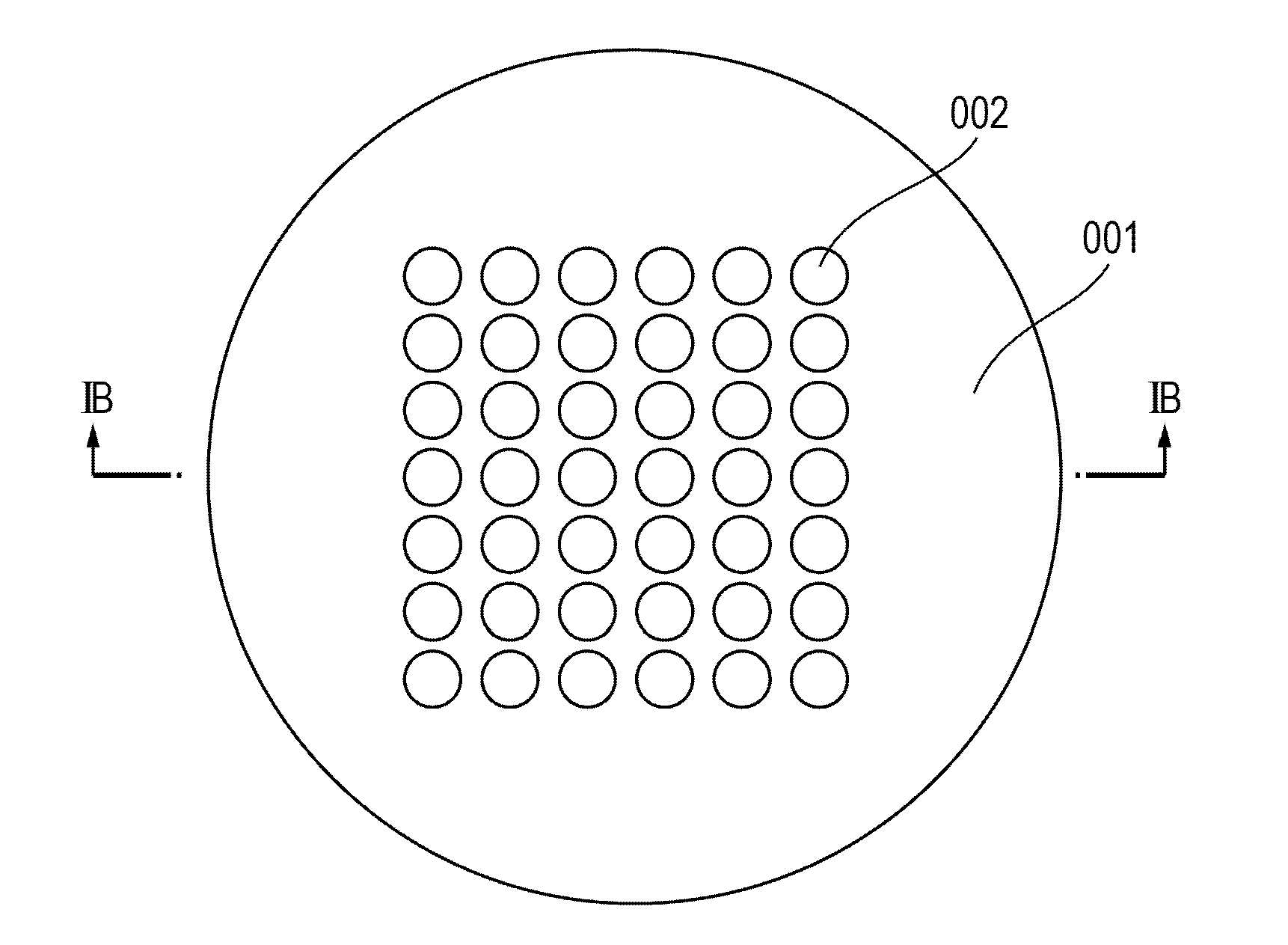

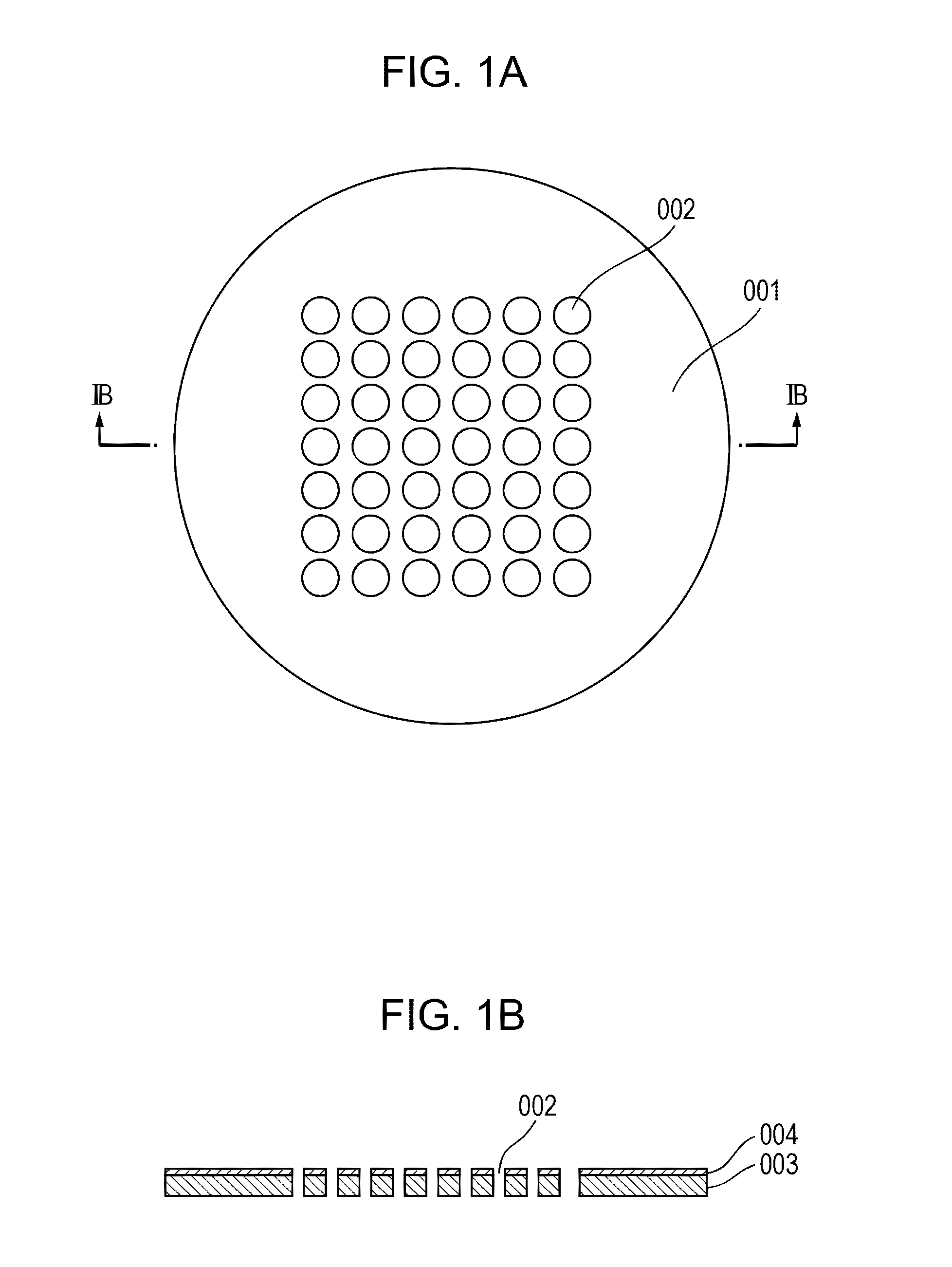

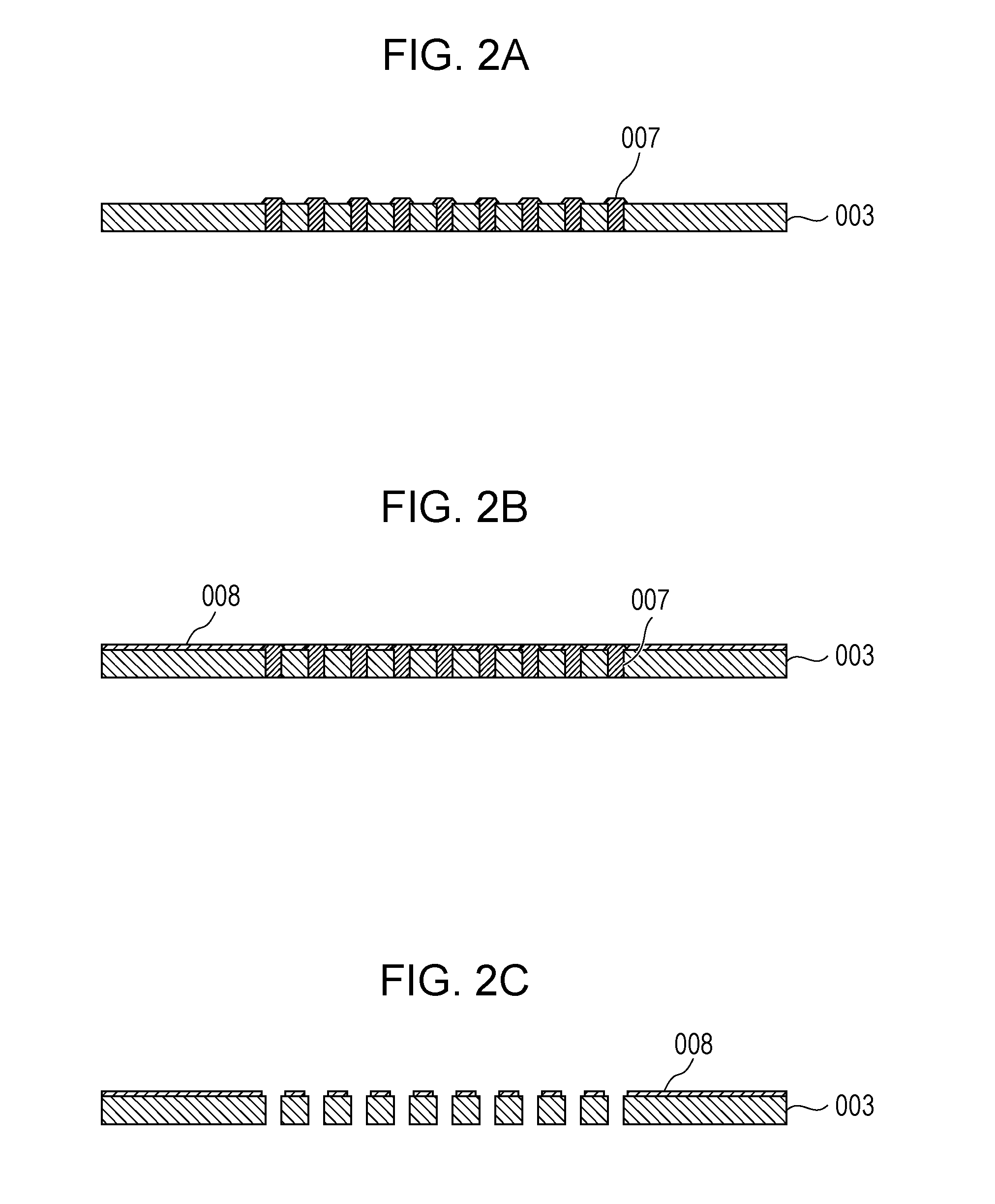

Charged particle beam forming aperture and charged particle beam exposure apparatus

InactiveUS20130048882A1Prevent exhaust capacityImprove the exhaust effectNanoinformaticsElectrode and associated part arrangementsParticle physicsCharged particle beam

An aperture that forms a charged particle beam includes a non-evaporable getter on a surface of the aperture. The non-evaporable getter is disposed in a position to which the charged particle beam is irradiated. The degradation of the exhaust performance around a charged particle source while the charged particle source is driven is suppressed.

Owner:CANON KK

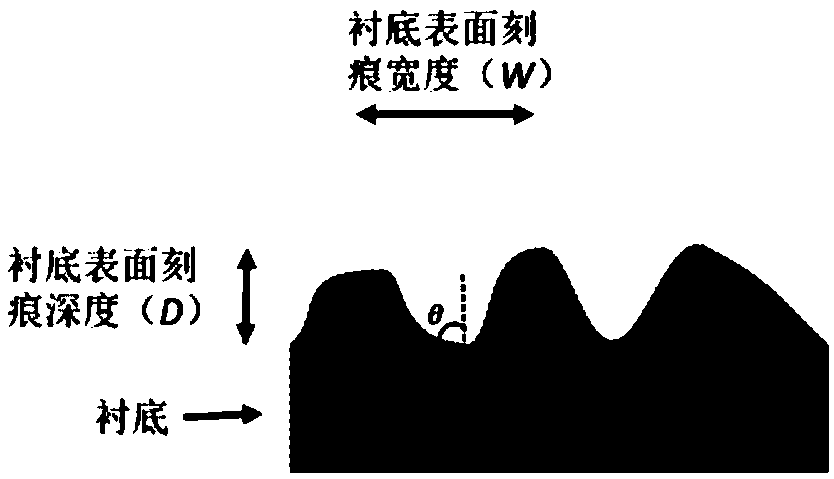

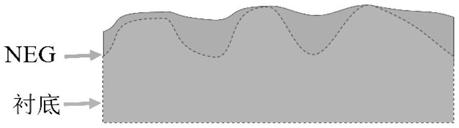

Preparation method of low secondary electron yield non-evaporable getter film

ActiveCN109082636AImprove inhalation effectLower output of secondary electronicsVacuum evaporation coatingSputtering coatingLaser etchingSecondary electrons

The invention discloses a preparation method of a low secondary electron yield non-evaporable getter film. The preparation method comprises the following steps that laser etching is conducted on the surface of a substrate, and the surface of the substrate is made to be of a zigzag groove structure; and then a non-evaporable getter film is arranged on the surface of the substrate in a sputtering deposition mode, and the low secondary electron yield non-evaporable getter film is obtained. The notch width W of the surface of the substrate is 1-200 [mu]m, the notch depth D of the surface of the substrate is 1-190 [mu]m, and the half-angular width of notches in the surface of the substrate is 10-80 degrees. The non-evaporable getter film prepared through the preparation method is low in secondary electron yield and better in absorption performance.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com