Electronic device sealed under vacuum containing a getter and method of operation

a technology of electronic devices and getters, applied in the field of electronic devices, can solve the problems of increasing the difficulty of assembly, and increasing the volume of the packag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

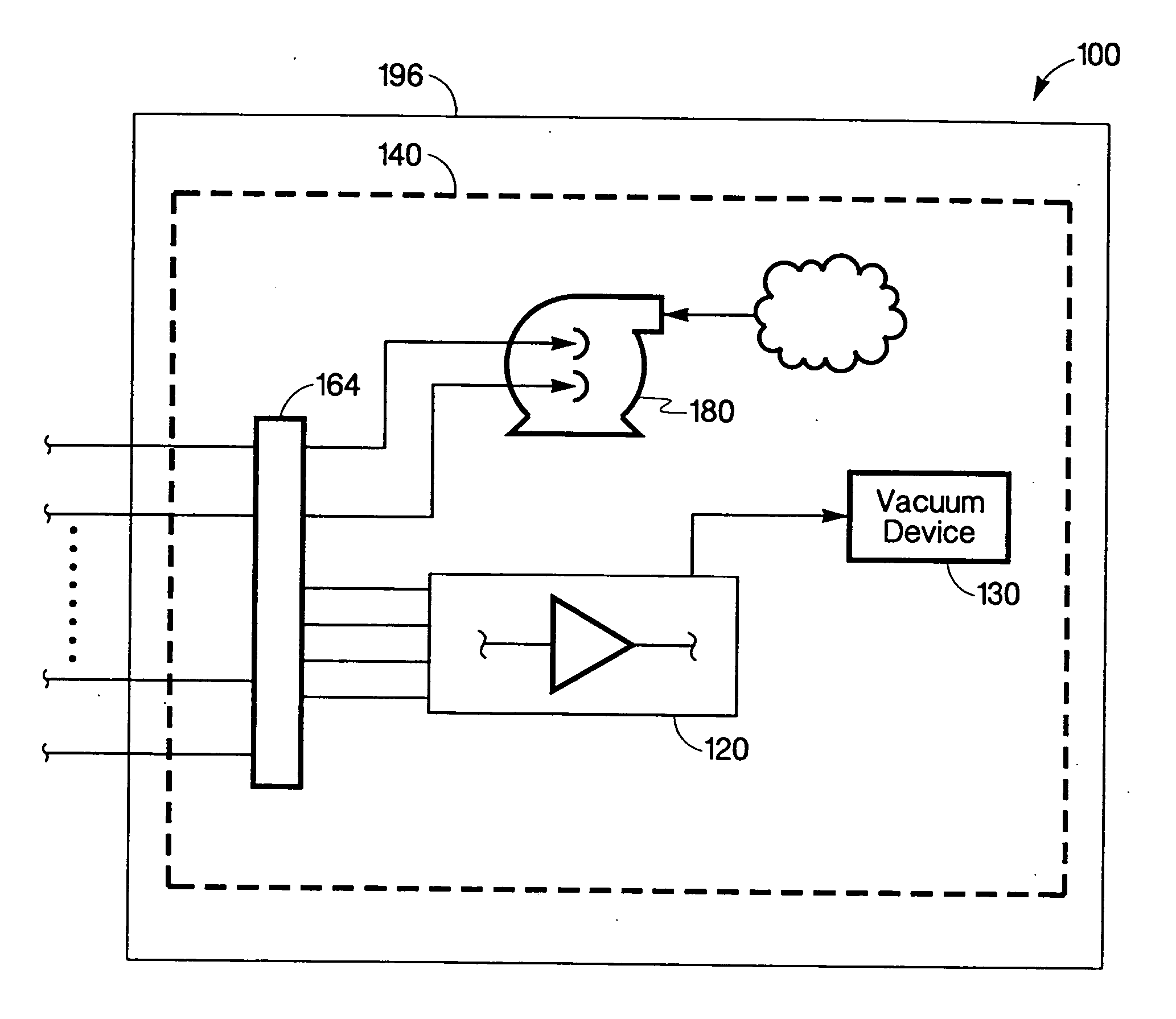

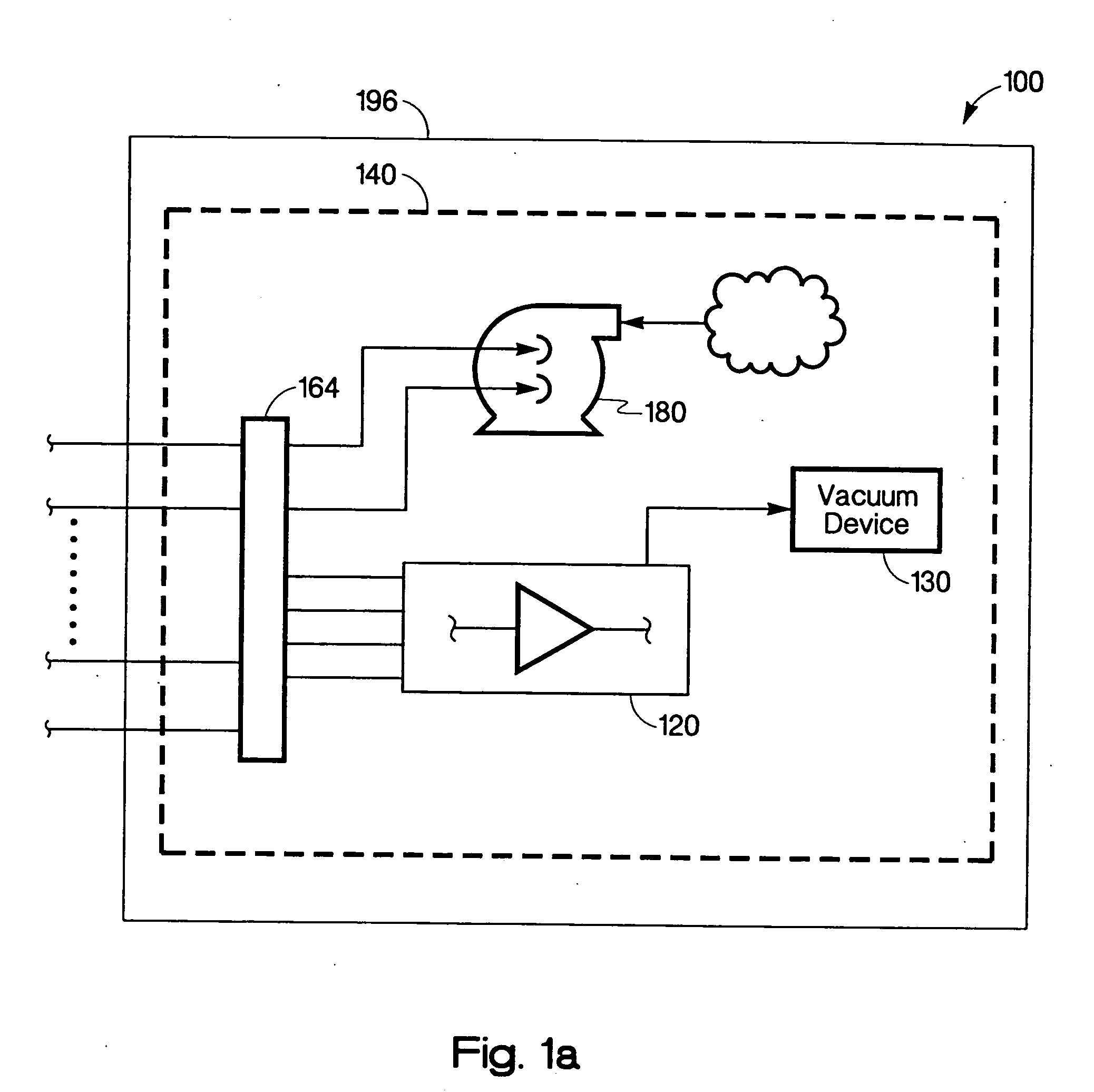

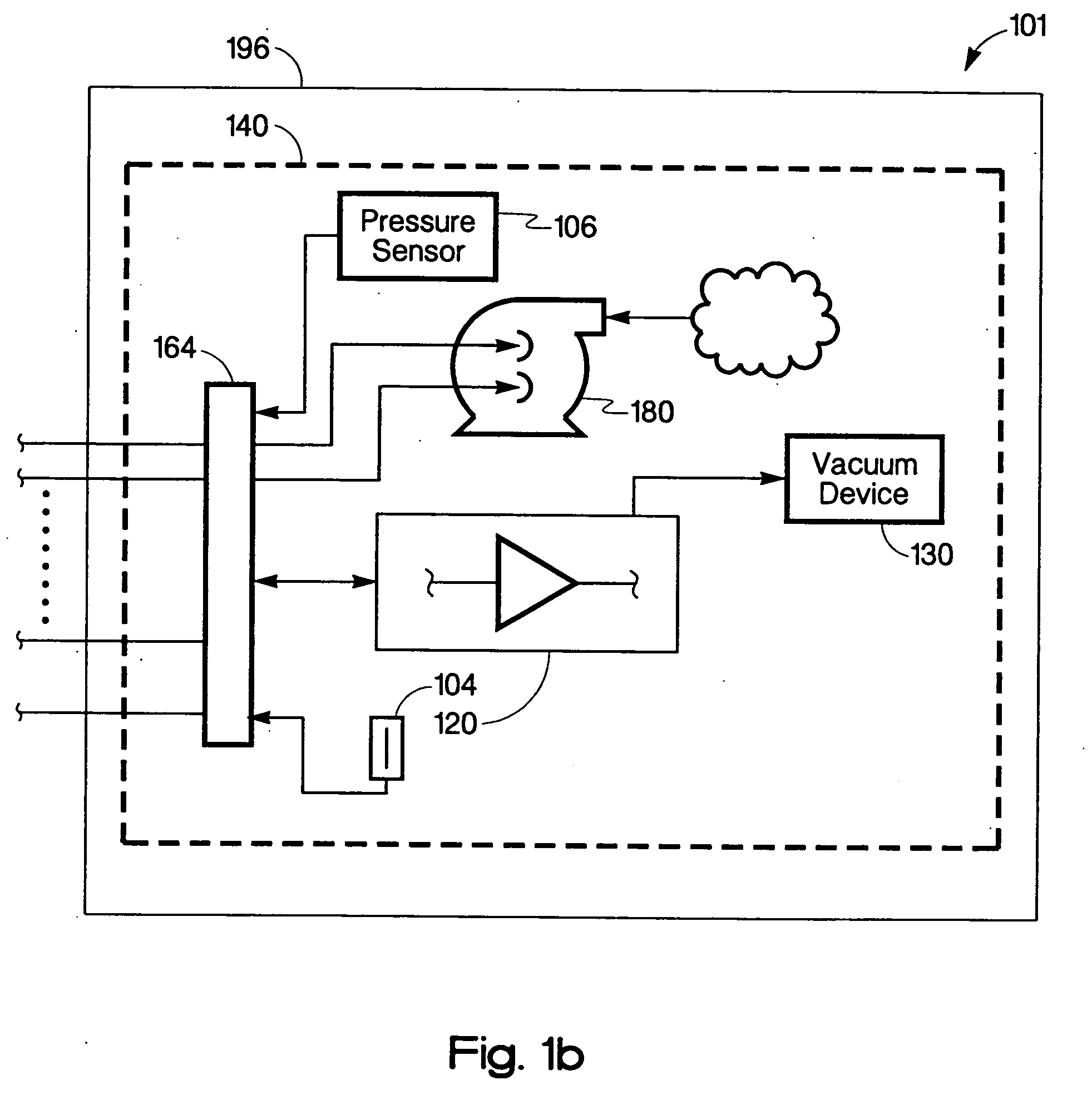

[0019]FIG. 1a is a block diagram of an electronic device sealed and maintained under vacuum, according to an embodiment of this invention. This device is referred to as electronic device 100 utilizing non-evaporable getter pump 180 (hereinafter NEG pump 180) to assist in evacuation, sealing, and maintenance of the vacuum during operation. Electronic device 100 includes the integration of NEG pump 180, vacuum device 130, and transistors 120 onto substrate 140 enclosed in package 196 that is vacuum-sealed. Vacuum device 130 relates to any electronic device that requires a vacuum to operate such as a charged particle emitter (e.g. electron or ion). Bond pads 164 are also affixed to substrate 140 providing electrical input and output. In this embodiment, there is a direct electrical connection between bond pads 164 and NEG pump 180; thus, this embodiment is commonly referred to as direct drive. NEG pump 180 includes non-evaporable getter material 181 (hereinafter NEG material 181) as sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com