Preparation method of zirconium non- evaporable getter

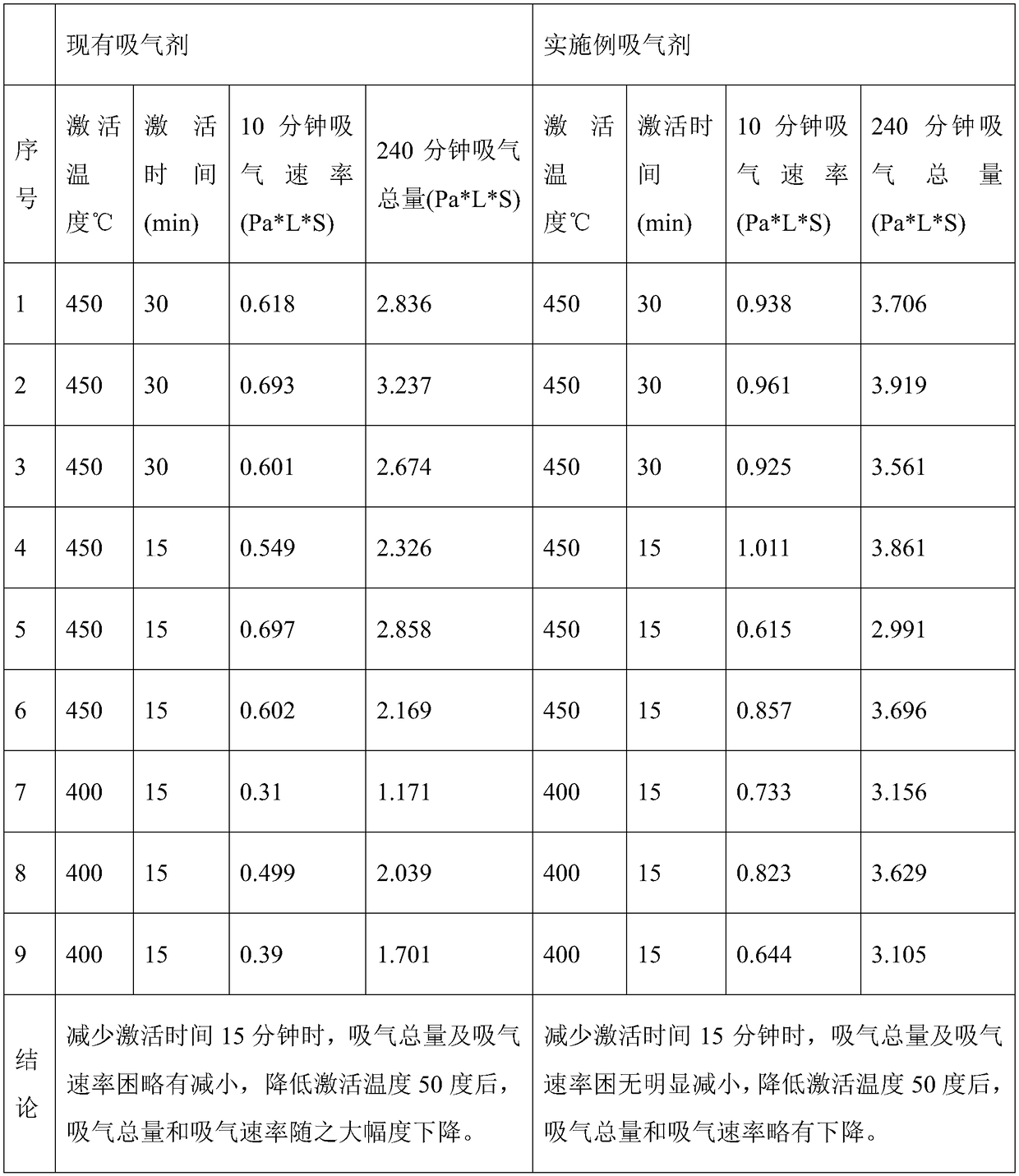

A getter and non-evapotranspiration technology, which is applied in the field of getter preparation, can solve problems such as harsh use conditions, high activation temperature, and waste of energy, and achieve the effects of saving use costs, reducing activation temperature, and increasing the inhalation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: A kind of preparation method of zirconium type non-evaporable getter, comprises the following steps:

[0017] (1) choose the zirconium that is 75 parts by weight, the vanadium of 21 parts, the niobium of 25 parts and the iron of 11 parts as raw material, after mixing, it is standby;

[0018] (2) Put the mixed raw materials into the vacuum intermediate frequency melting furnace, start the vacuum system, and form a vacuum value of less than 3×10 -1 Pa vacuum environment;

[0019] (3) Under the vacuum condition of step (2), start the heating system of the vacuum intermediate frequency smelting furnace, raise the temperature to 1900° C. and melt the mixture in the furnace until the mixture is completely melted into a liquid state;

[0020] (4) cooling the liquid molten material into an alloy ingot, and then crushing the alloy ingot to 2cm alloy particles;

[0021] (5) Put the alloy particles into a vacuum ball mill to make a powder with a size of less than 1...

Embodiment 2

[0022] Embodiment 2: a kind of preparation method of zirconium type non-evaporable getter, comprises the following steps:

[0023] (1) choose the zirconium that is 60 parts by weight, the vanadium of 15 parts, the niobium of 4 parts and the iron of 3 parts as raw material, after mixing, it is standby;

[0024] (2) Put the mixed raw materials into the vacuum intermediate frequency melting furnace, start the vacuum system, and form a vacuum value of less than 3×10 -1 Pa vacuum environment;

[0025] (3) Under the vacuum condition of step (2), start the heating system of the vacuum intermediate frequency melting furnace, raise the temperature to 2100° C., and melt the mixture in the furnace until the mixture is completely melted into a liquid state;

[0026] (4) cooling the liquid molten material into an alloy ingot, and then crushing the alloy ingot to 3cm alloy particles;

[0027] (5) Put the alloy particles into a vacuum ball mill to make a powder with a size of less than 100...

Embodiment 3

[0028] Embodiment 3: a kind of preparation method of zirconium type non-evaporable getter, comprises the following steps:

[0029] (1) choose the zirconium that is 72 parts by weight, the vanadium of 0 part, the niobium of 20 parts and the iron of 8 parts as raw material, after mixing, it is standby;

[0030] (2) Put the mixed raw materials into the vacuum intermediate frequency melting furnace, start the vacuum system, and form a vacuum value of less than 3×10 -1 Pa vacuum environment;

[0031] (3) Under the vacuum condition of step (2), start the heating system of the vacuum intermediate frequency melting furnace, raise the temperature to 2000° C., and melt the mixture in the furnace until the mixture is completely melted into a liquid state;

[0032] (4) cooling the liquid molten material into an alloy ingot, and then crushing the alloy ingot to 2cm alloy particles;

[0033] (5) Put the alloy particles into a vacuum ball mill to make a powder with a size of less than 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com