Vacuum glass with getter film

A technology of vacuum glass and getter film, applied in the field of vacuum glass, can solve the problems of reducing the strength of glass plates, threatening the safety of vacuum glass use, increasing the processing cost of vacuum glass, etc., and achieving the effect of easy adjustment and easy setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Further illustrate the present invention below in conjunction with accompanying drawing.

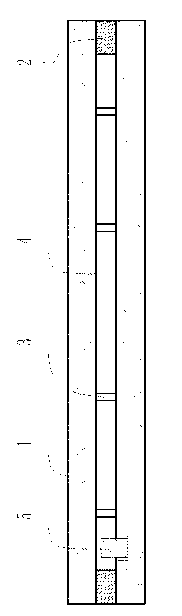

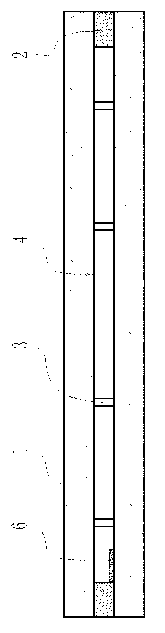

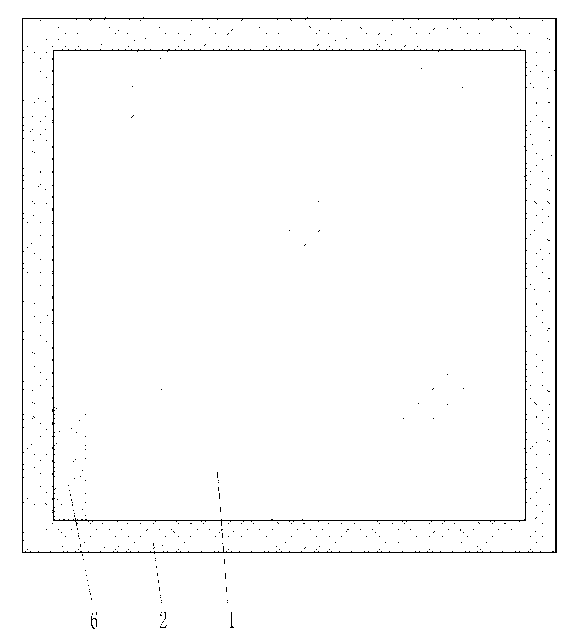

[0032] Taking the two-layer structure vacuum glass made of two glass plates as an example, the structure of the vacuum glass of the present invention is as follows figure 2 , image 3 As shown, it includes upper and lower glass plates 1, the periphery of the two glass plates is hermetically sealed by the sealing edge, and an array of intermediate supports 3 is arranged between the two glass plates on the inner side of the sealing edge, and the vacuum space in the vacuum glass One corner of 4 is provided with getter film 6, and this getter film 6 is made of non-evaporable getter, such as, can adopt Zr-V-Fe alloy or Ti-Zr-V alloy or Getters for Zr-Al alloys.

[0033] The preparation steps of the getter film 6 on the surface of the glass plate in the vacuum glass of the present invention are:

[0034] 1) Preparation of slurry with low glass powder, getter powder and organic binde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com