Non-evaporable getter compositions which can be reactivated at low temperature after exposure to reactive gases at a higher temperature

A technology of getter and composition, applied in electrical components, thin material processing, discharge tubes, etc., can solve the problem of limited ability to reactivate other gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

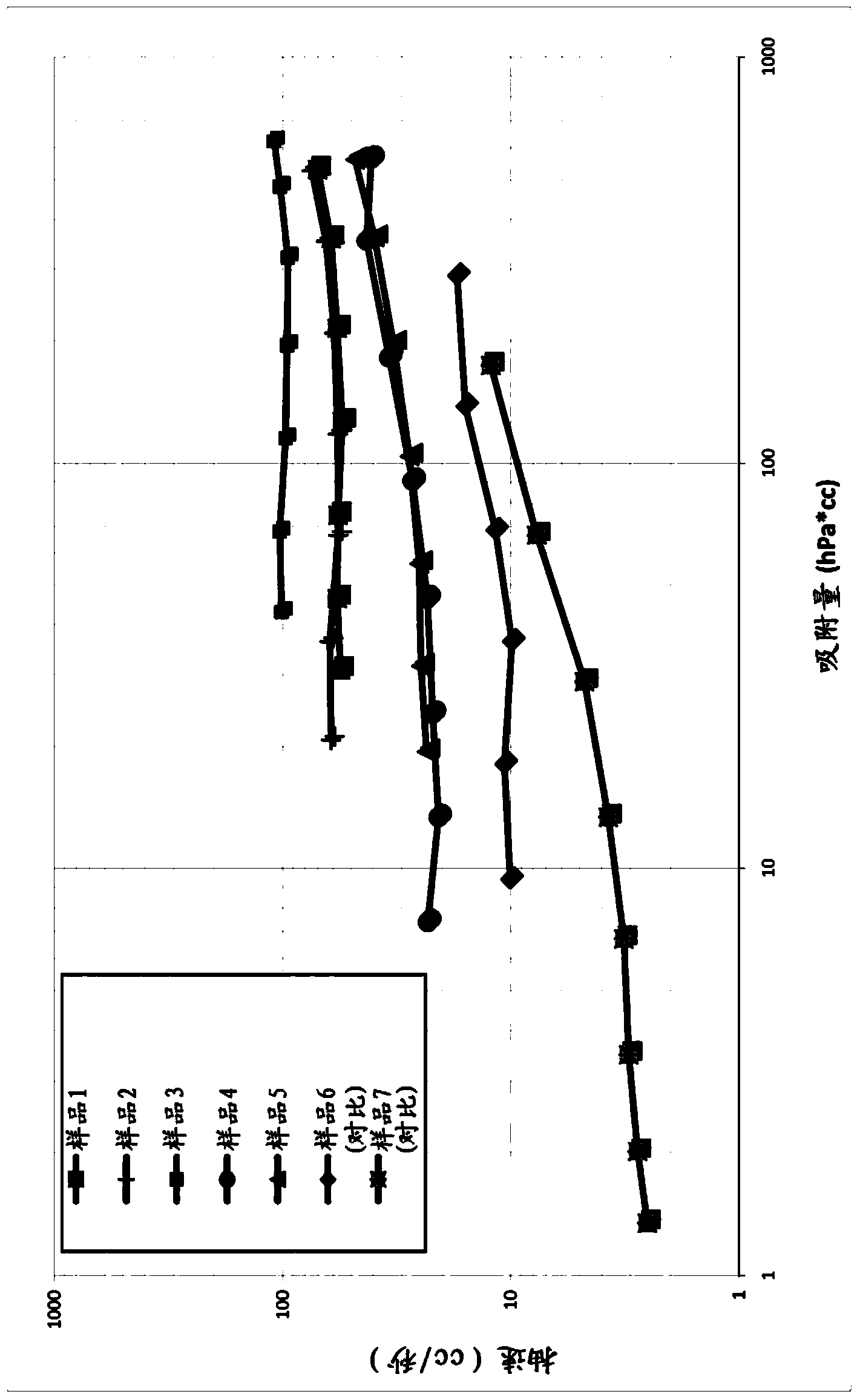

example 1

[0030] A sample of the composition according to the invention was prepared by mixing the powder of the high activation temperature alloy Zr86%-Al14%wt with the powder of the low activation temperature alloy Zr70%-Fe15%-Y15%wt in a ratio of 2:3; alloy, the particle size of the powder is included between 0 μm and 125 μm. Then use about 4000Kg / cm in a suitable ring container 2 120 mg of the mixture was squeezed, and the sample was heated at 420° C. in air for about 1 minute.

[0031] After activating at 400°C for 1 minute, the final product was used under static conditions at a volume of about 5000 cm 3 (also referred to as "cubic centimeters", or "cc") in the aspirating chamber with a dose of hydrogen at an initial pressure of 0.133 hPa to perform on samples at 400 °C for H 2 adsorption test.

example 2

[0033] A sample of the composition according to the invention was prepared by mixing the powder of the high activation temperature alloy Zr76%-Ni24%wt with the powder of the low activation temperature alloy Zr70%-Fe15%-Y15%wt in a ratio of 2:3; alloy, the particle size of the powder is included between 0 μm and 125 μm. Samples were then prepared and tested according to Example 1.

example 3

[0035] The composition according to the invention is prepared by mixing powder of high activation temperature alloy Zr79.2%-Ni21.8%wt with powder of low activation temperature alloy Zr70%-Fe15%-Y15%wt in a ratio of 2:3 Samples; powders with particle sizes comprised between 0 μm and 125 μm for both alloys. Samples were then prepared and tested according to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com