Nitrogen and hydrogen mixed gas vacuum leak hole calibration device and method

A nitrogen-hydrogen mixing and vacuum leak technology, which is applied in the field of measurement, can solve the problems of accurate calibration of leak rate of nitrogen-hydrogen mixed gas leaks that have not yet been solved, and achieve the effects of accurate calibration, reducing risk and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0050] This embodiment provides a nitrogen-hydrogen mixed gas vacuum leak calibration device and method, which can calibrate the hydrogen gas leakage rate of the nitrogen-hydrogen mixed gas vacuum leak.

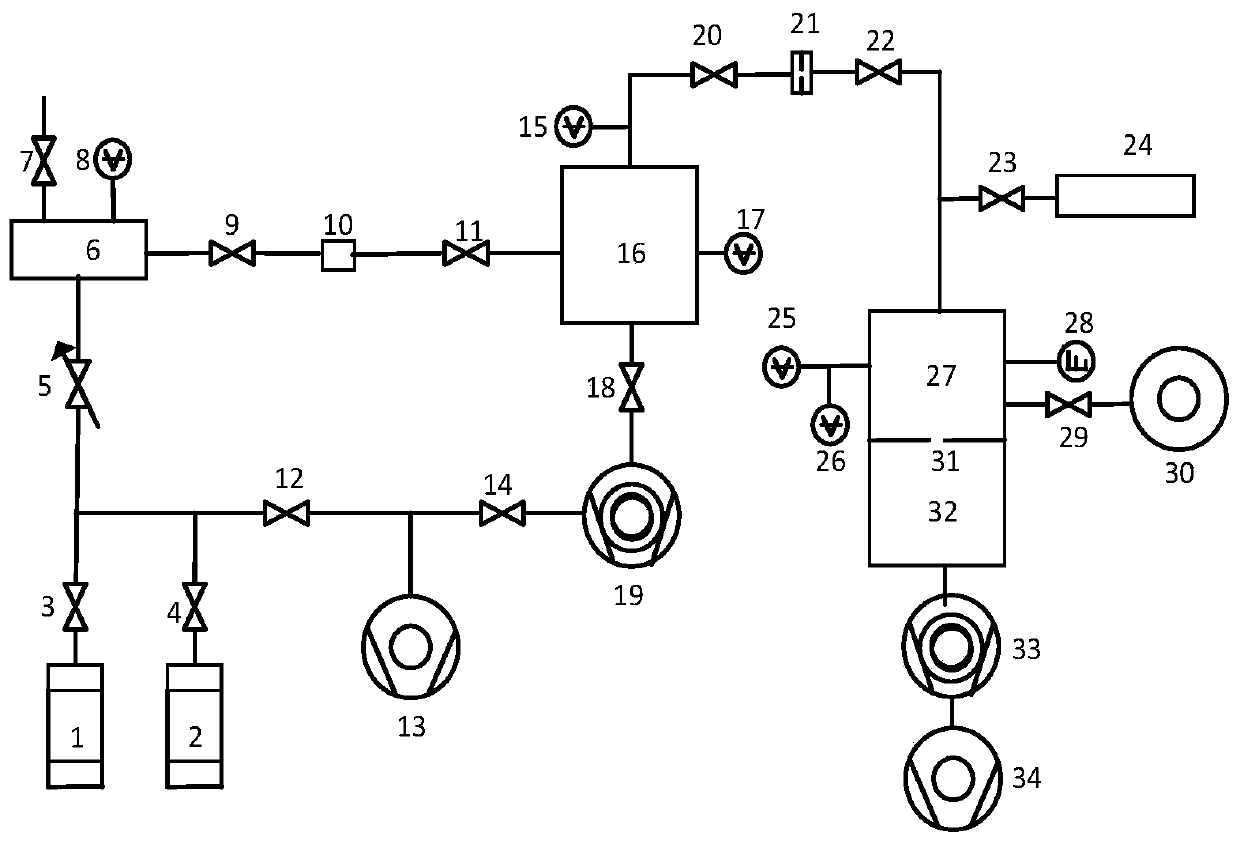

[0051] like figure 1 As shown, the nitrogen-hydrogen mixed gas vacuum leak calibration device includes a hydrogen gas supply system, a nitrogen gas supply system, a gas distribution chamber 6, a pressure gauge A8, a gas sampling chamber 10, a low vacuum pump A13, a pressure gauge B15, and an air intake chamber 16. Vacuum gauge A17, high vacuum pump A19, seepage device 21, pressure gauge C25, vacuum gauge B26, calibration chamber 27, mass spectrometer 28, non-evaporable getter pump 30, restrictor hole 31, pumping chamber 32, high vacuum pump B33 , Rough vacuum pump B34;

[0052] A pressure gauge A8 is arranged on the gas distribution chamber 6 for monito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com