Novel arrangement of non-evaporable getters for a tube solar collector

a technology of non-evaporable getters and solar collectors, which is applied in the safety of solar heat collectors, solar heat systems, lighting and heating apparatus, etc., can solve the problems of increasing thermal losses, increasing the size or the number of getter pellets, and reducing the efficiency of the system in a significant manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

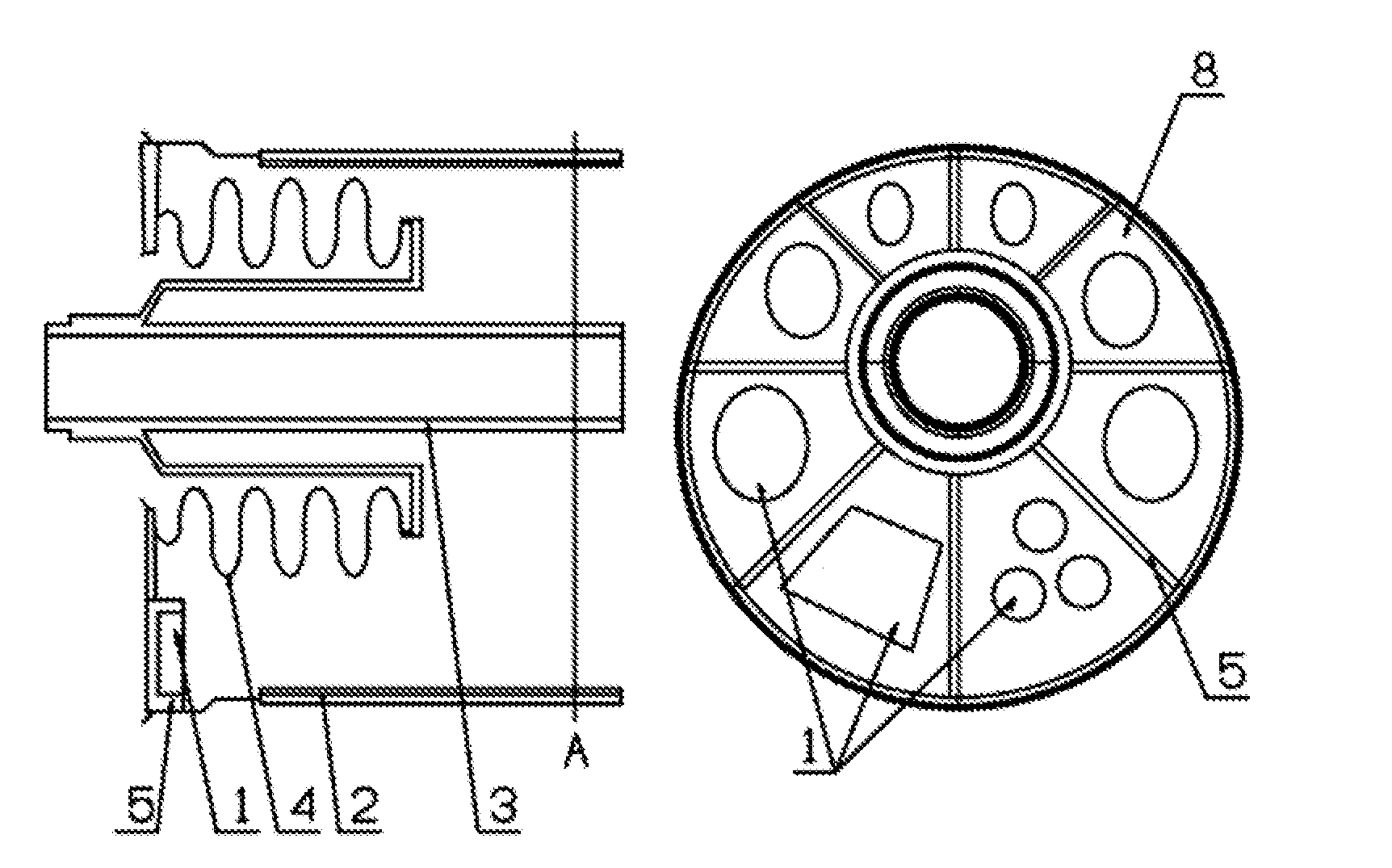

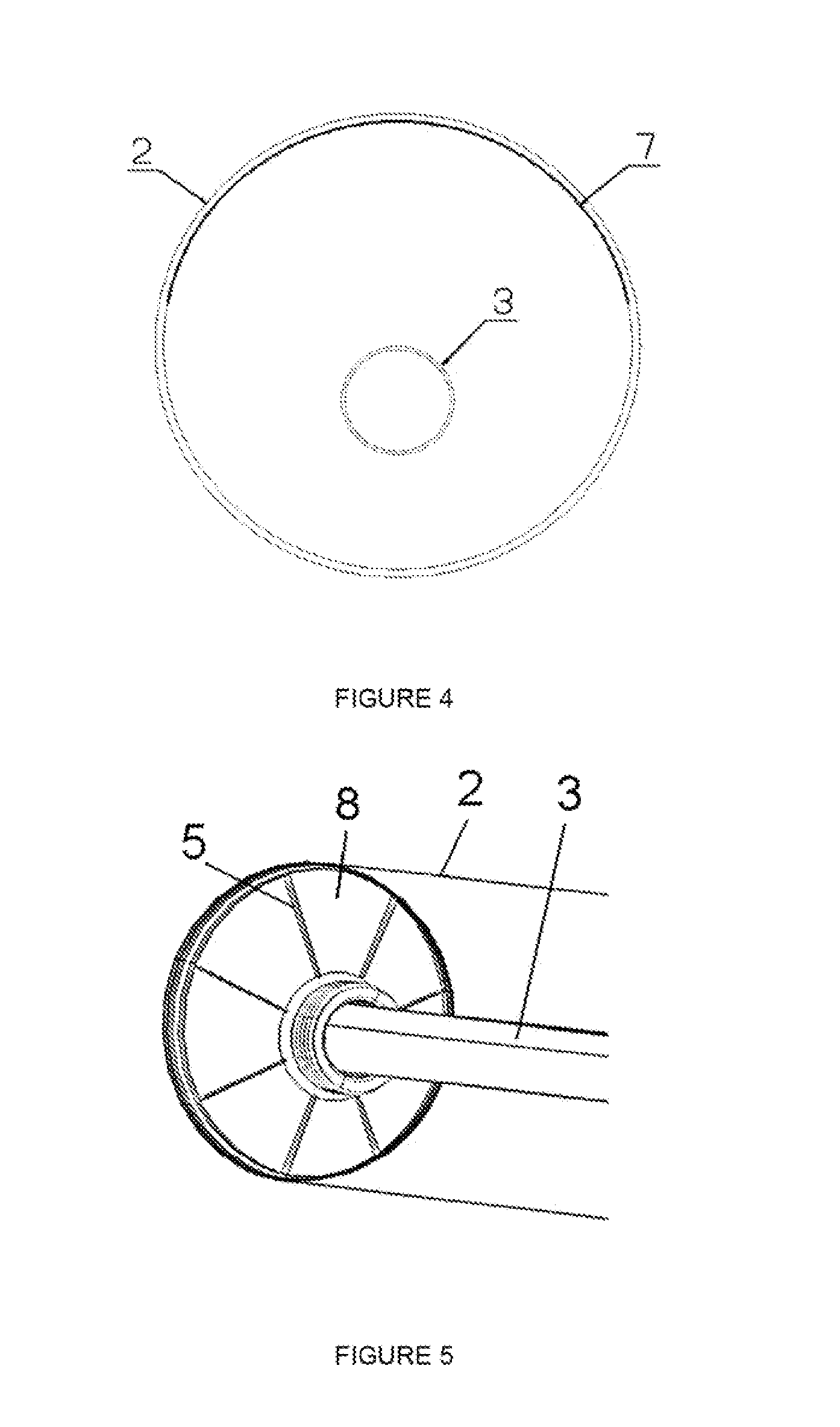

[0011]The invention consists of a new getter arrangement for a tube solar collector, as well as several modifications to the rest of the tube, mainly to its ends, according to this novel arrangement.

[0012]Despite its importance, the function of the non-evaporable getters should not interfere with the main purpose of the receiver tube, which is to maximize its thermal performance. Its arrangement should allow this situation without compromising its function to guarantee the correct aging of the product.

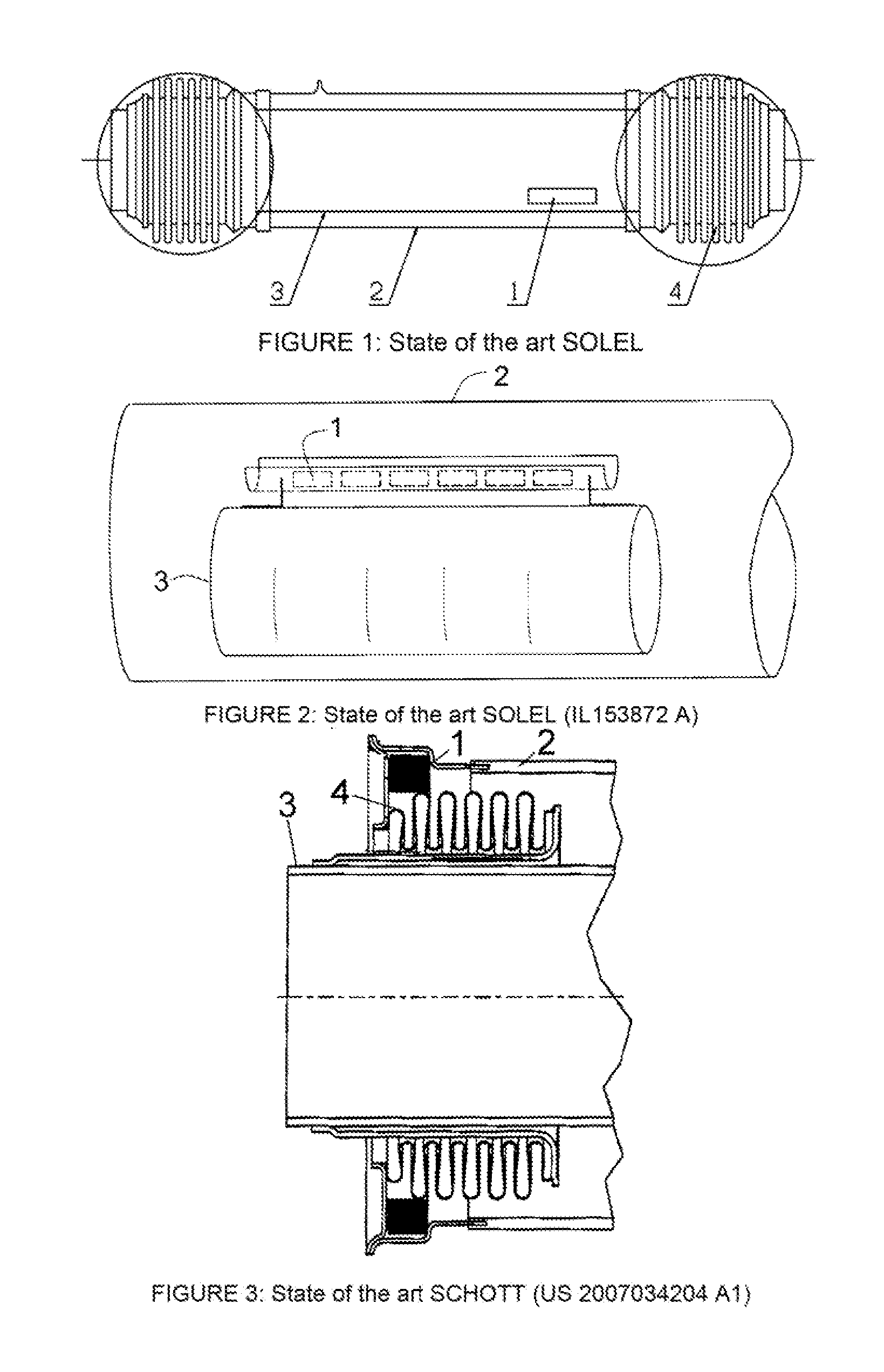

[0013]As commented above, due to its diverse locations in the state of the art, it used to originate a different casing shape in each one of the ends in order to house it, which in turn conditioned the value of the diameter of the glass or boron-silicate cylinder.

[0014]In order to solve the problems found in the known state of the art, new design proposals related to the geometry and arrangement of the tube collector and the set of non-evaporable getters have been developed.

[0015]These...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com