Extremely high vacuum gauge calibration device and method

A technology of extremely high vacuum and calibration device, applied in the field of measurement, it can solve the problems of uncertainty and complex measurement links, and achieve the effect of accurate calibration, small measurement uncertainty, and widening the range of flow measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

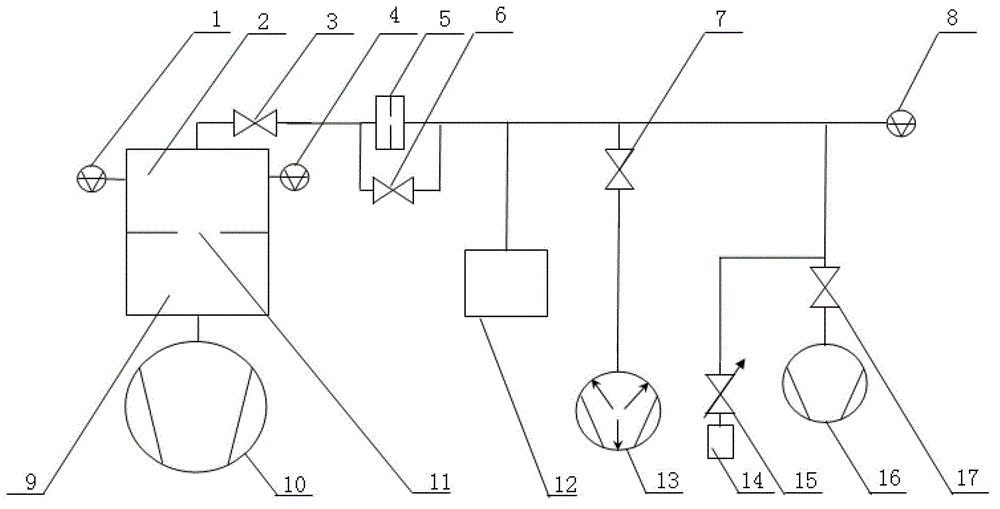

[0033] Such as figure 1 Said, a very high vacuum gauge calibration device, said device comprises: very high vacuum gauge 1, very high vacuum calibration chamber 2, first valve 3, calibrated vacuum gauge 4, small hole 5, second valve 6, The third valve 7, high-precision vacuum gauge 8, extremely high vacuum pumping chamber 9, very high vacuum pumping unit 10, flow limiting hole 11, voltage stabilizing chamber 12, non-evaporable getter pump 13, gas source 14, Fine-tuning valve 15, flow meter air extraction unit 16 and fourth valve 17, peripheral equipment including heating device;

[0034] Wherein, the extremely high vacuum pumping unit 10 is connected with the very high vacuum pumping chamber 9, the very high vacuum pumping chamber 9 is connected with the very high vacuum calibration chamber 2, the very high vacuum pumping chamber 9 is connected with the very high vacuum calibration chamber There is a flow limiting hole 11 in the middle of 2, the extremely high vacuum gauge 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com