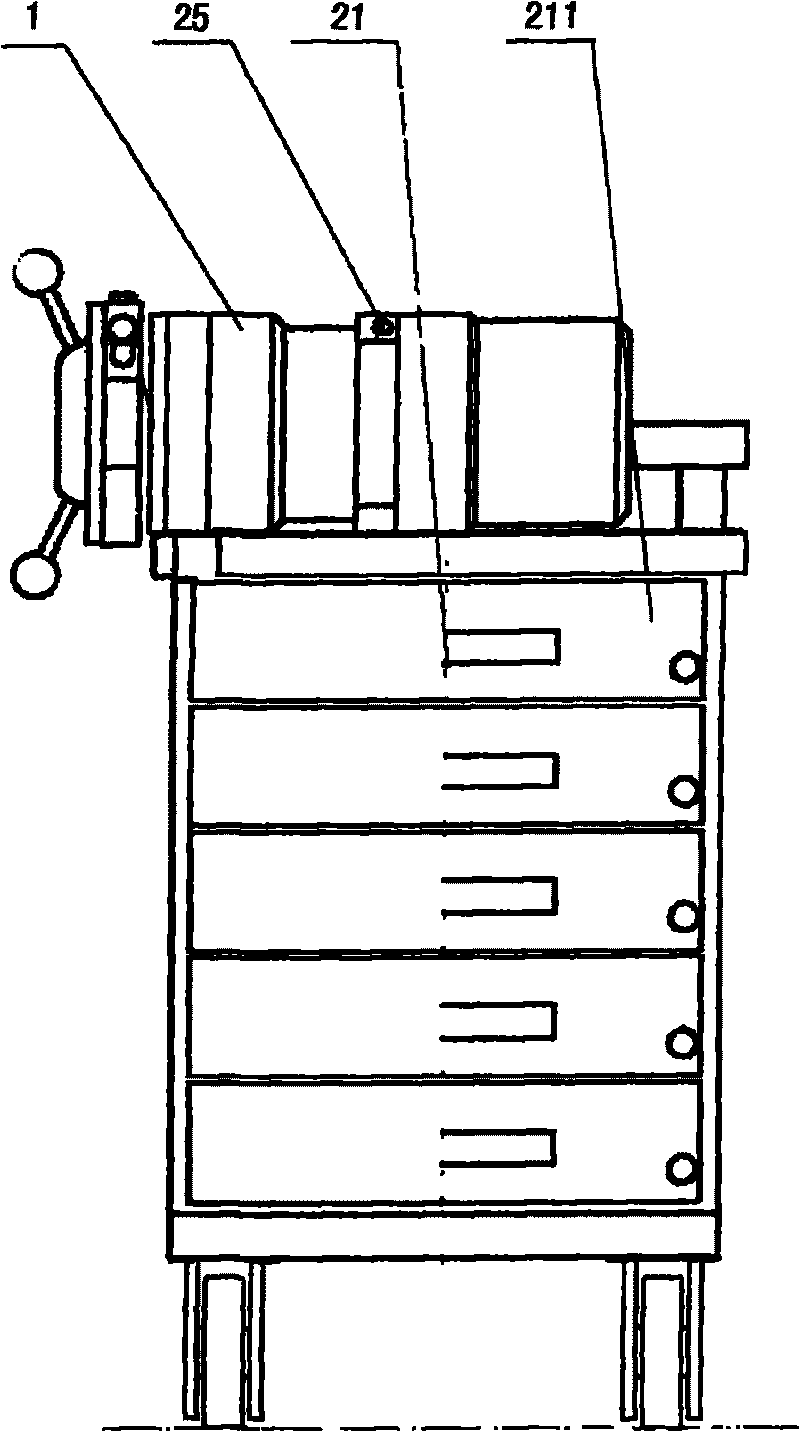

Pipe end extrusion molding machine

A technology of forming machine and pipe end, applied in the direction of metal extrusion, metal extrusion die, metal extrusion control equipment, etc. Ring mismatch and other problems, to achieve the effect of good molding quality, low noise, and overall performance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

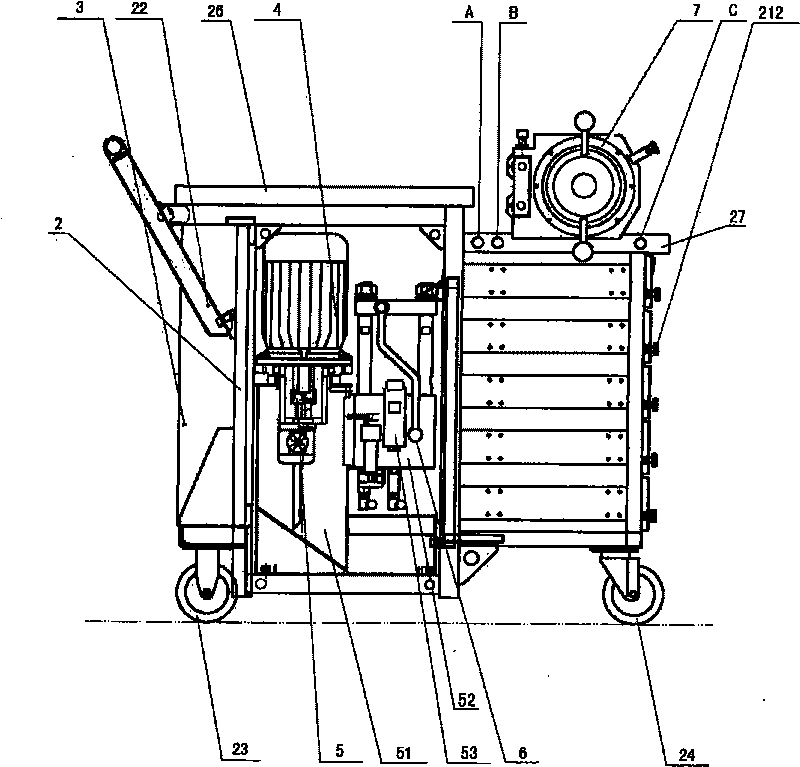

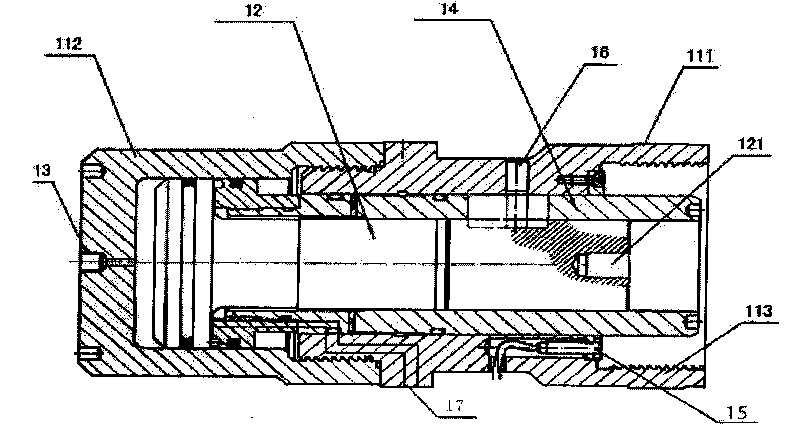

[0051] Extrude a 316 stainless steel tube with a diameter of 12.7 mm and a wall thickness of 1.24 mm. Pull out the positioning pin (71), rotate 90 degrees and put it down; operate the rotating handle (72), turn the machine head (7); put it into the clamping mold (8), and put the extrusion mold (9) into the machine head (7 ) and tighten it clockwise; after the clamping mold (8) is tightened clockwise (about 5 turns), turn the positioning pin (71) 90 degrees and put it down, when the positioning pin (71) automatically falls into the pin hole, that is Stop the rotation; press the preload switch A to preload, so that the clamping mold (8) is automatically adjusted in place, and the nut is inserted into the steel pipe to be processed; the diameter to be extruded is 12.7mm, and the wall thickness is Put the 1.24mm 316 stainless steel pipe into the machine head (7), press the squeeze switch C, press the squeeze switch C, the programmable logic controller (PLC) (3) receives the signal...

Embodiment 2

[0053] Extrude a carbon steel pipe with a diameter of 33.4mm and a wall thickness of 4.55mm. Pull out the positioning pin (71), rotate 90° and put it down; operate the rotating handle (72), turn the machine head (7), put it into the clamping mold (8), and put the extrusion mold (9) into the machine head (7 ) and screw it clockwise; after the clamping mold (8) is screwed clockwise (about 5 turns), turn the positioning pin (71) down by 90°, when the positioning pin (71) automatically falls into the pin hole, that is Stop the rotation; press the pre-press switch A to pre-press, so that the clamping mold is automatically adjusted in place, and the nut is inserted into the steel pipe to be processed; the diameter to be extruded is 33.4mm, the wall thickness is 4.55mm Put the carbon steel pipe into the machine head (7), press the squeeze switch C, press the squeeze switch C, the programmable logic controller (PLC) (3) receives the signal, and the hydraulic mechanism oil pump (5) sup...

Embodiment 3

[0055] Select the extruded steel pipes of the above-mentioned embodiment 1 and embodiment 2. After placing a special sealing ring at the extruded pipe port, use a pipe joint to connect the two pipe ends of the extruded steel pipe of the same size. After the oil pressure test, the pressure rating of the pipe fittings is above 40Mpa.

[0056] The production plant of the pressure sensor involved in the embodiment of the present invention is: Swiss Xiuba Huba, the model is 0511.943253542; the production plant of the displacement sensor is: Japan Omron, the model is E2E-X2-3DIS; Products for sale; the content not described in the embodiments is prior art, so no more details are given.

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage rating | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com