Extrusion equipment with multiple extrusion rods

A technology of extrusion equipment and extrusion rod, which is used in metal extrusion, indenter/punch rod, metal processing equipment, etc. The effect of low production cost and good production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

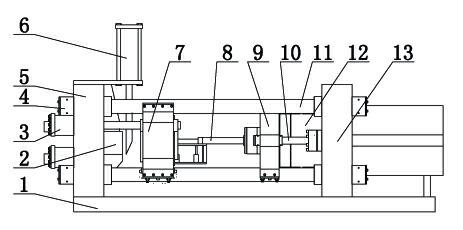

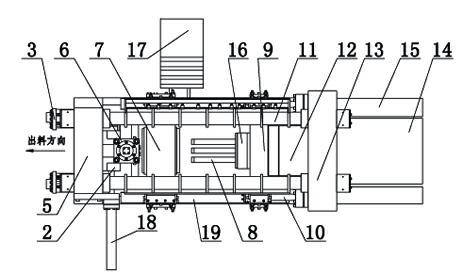

[0034] like figure 1 , 2 , 3, 4, 8, 9, 10, and 11, a multi-extrusion rod 8 extrusion equipment, which includes a main cylinder 14, an auxiliary cylinder 15, a rear beam 13, a main plunger 12, an auxiliary plunger 10, a front Beam 5, column 11, slide rail 19, clamping cylinder 3, base 1 and lock nut 4, main cylinder 14 and auxiliary cylinder 15 are fixed on the back beam 13, the front end of main cylinder 14 is provided with main plunger 12, auxiliary cylinder The front end of 15 is provided with an auxiliary plunger 10, the front beam 5 and the rear beam 13 are connected by a column 11, the column 11 and the front and rear beams 13 are all fixed by lock nuts 4, the front beam 5 and the rear beam 13 are fixed on the machine base 1, and the column 11 is provided with a slide rail 19 and a feeding trolley 17, and the front beam 5 is provided with a clamping cylinder 3, an extrusion mold base 2, a scissors cylinder 6 and a mold changing cylinder 18, and an extrusion mold is arran...

Embodiment 2

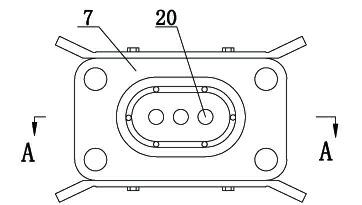

[0039] like Figure 5 As shown, Example 1 is repeated, with the following differences. The extrusion cylinder 7 is a cylindrical extrusion cylinder 7, and three extrusion holes 20 are arranged in the extrusion cylinder 7, and the extrusion holes 20 are arranged in a straight line. In this embodiment, the maximum width of the extruded hollow profile is: B=(3 root square root)*1.3*D=2.25D, where D is the diameter of the extrusion hole when extruding with a single extrusion hole.

Embodiment 3

[0041] like Figure 12 Shown, repeat embodiment one, following difference is arranged, and described extruding die is split flow die, promptly die bridge 26 is set in the middle of upper die 23 and lower die 24, and die bridge 26 connects upper die 23 and lower die 24 The metal runner is divided into two parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com