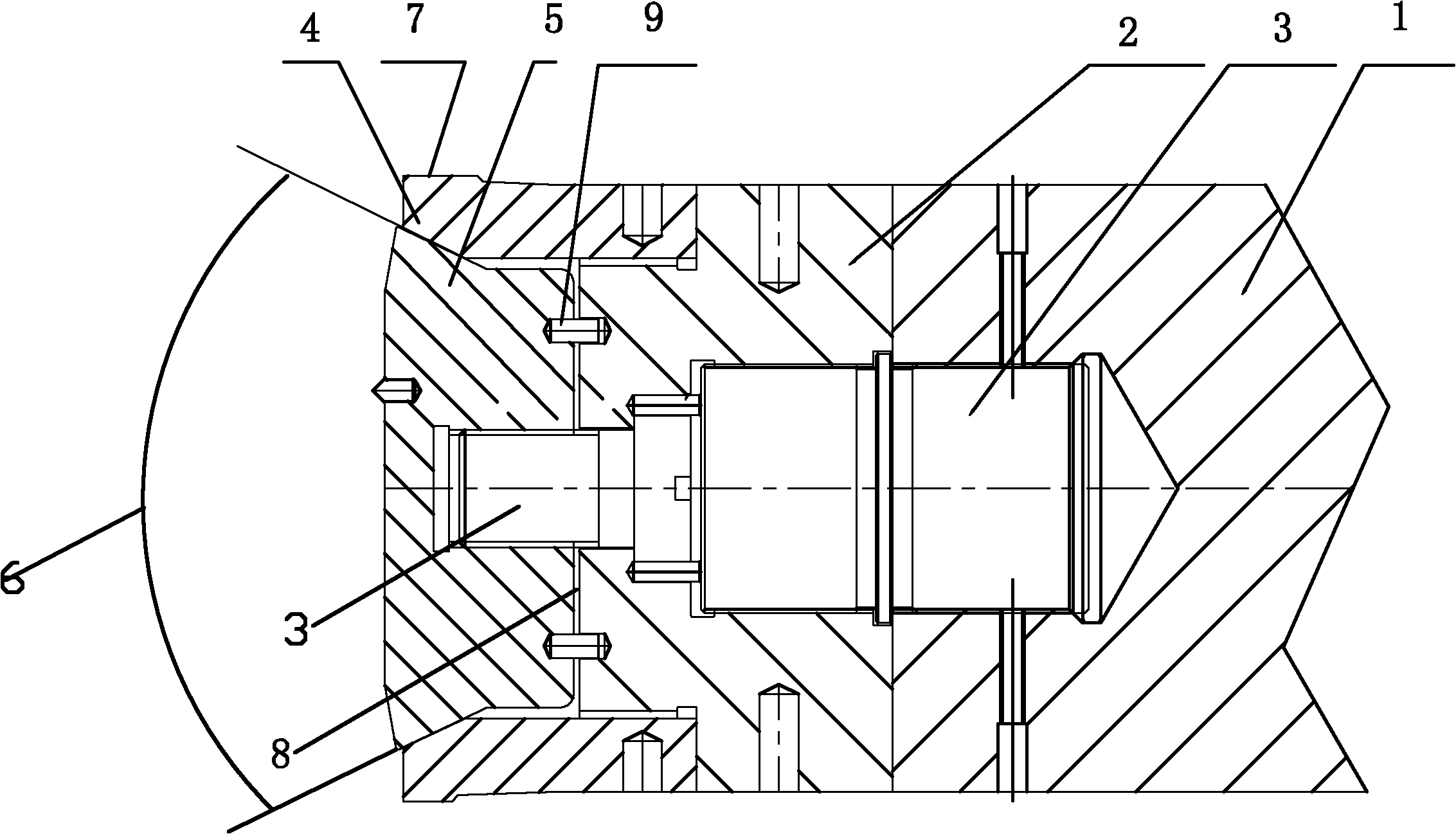

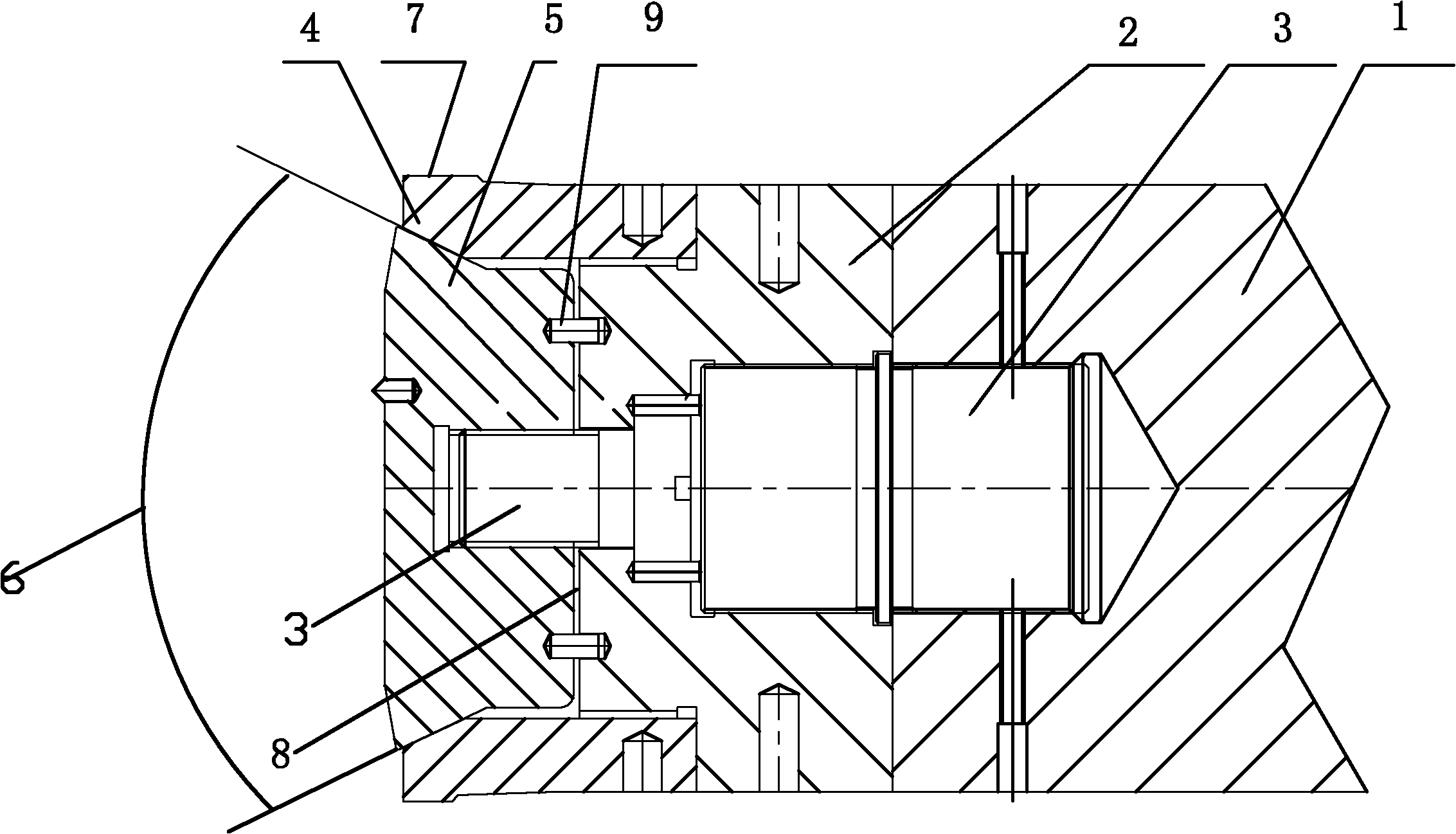

Fixed dummy block for aluminum section extruder

A technology of extrusion machine and aluminum profile, applied in the direction of metal extrusion, pressure head/punch rod, metal processing equipment, etc., to achieve the effects of easy deformation, improved service life, and increased expansion component force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] Embodiment: The cone surface angle of the pad expansion ring and the cone gasket is designed to be 50°, which is equivalent to increasing the thickness of the cone gasket, solving the problem of fracture, and increasing the expansion force generated by the same extrusion force . The thickness of the expansion ring is designed to be 90mm, and the deformation working zone of the expansion ring is extended by 30mm, so that the expansion and deformation part is deepened and thinned, and is easy to deform. In actual production, the adjustment gap can be controlled. The working gap between the cone gasket and the end face of the fixed seat is 2mm, which can ensure that the cone gasket pushes to the end face of the fixed seat, and the expansion ring can stop deformation. The working gap matches the gap between the expander ring and the extrusion barrel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com