Method for preparing equal-channel reciprocating extrusion magnesium alloy with back pressure and extrusion die thereof

A technology of reciprocating extrusion and extrusion dies, applied in metal extrusion dies, metal extrusion control equipment, metal extrusion, etc., can solve problems such as crushing, cracking, and inability to carry out extrusion deformation, and achieve increased density , avoid cracking, improve the effect of internal tissue morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The technical scheme of the present invention will be described in detail below by taking the back-pressure equal-channel reciprocating extrusion of No. 2 deformed magnesium alloy (MB2) as an example.

[0028] ① First, the MB2 alloy sample is processed into an extrusion sample with a size of 19.5mm×19.5mm×100mm.

[0029] ② Debug the three-way extrusion hydraulic press to ensure that each cylinder works normally.

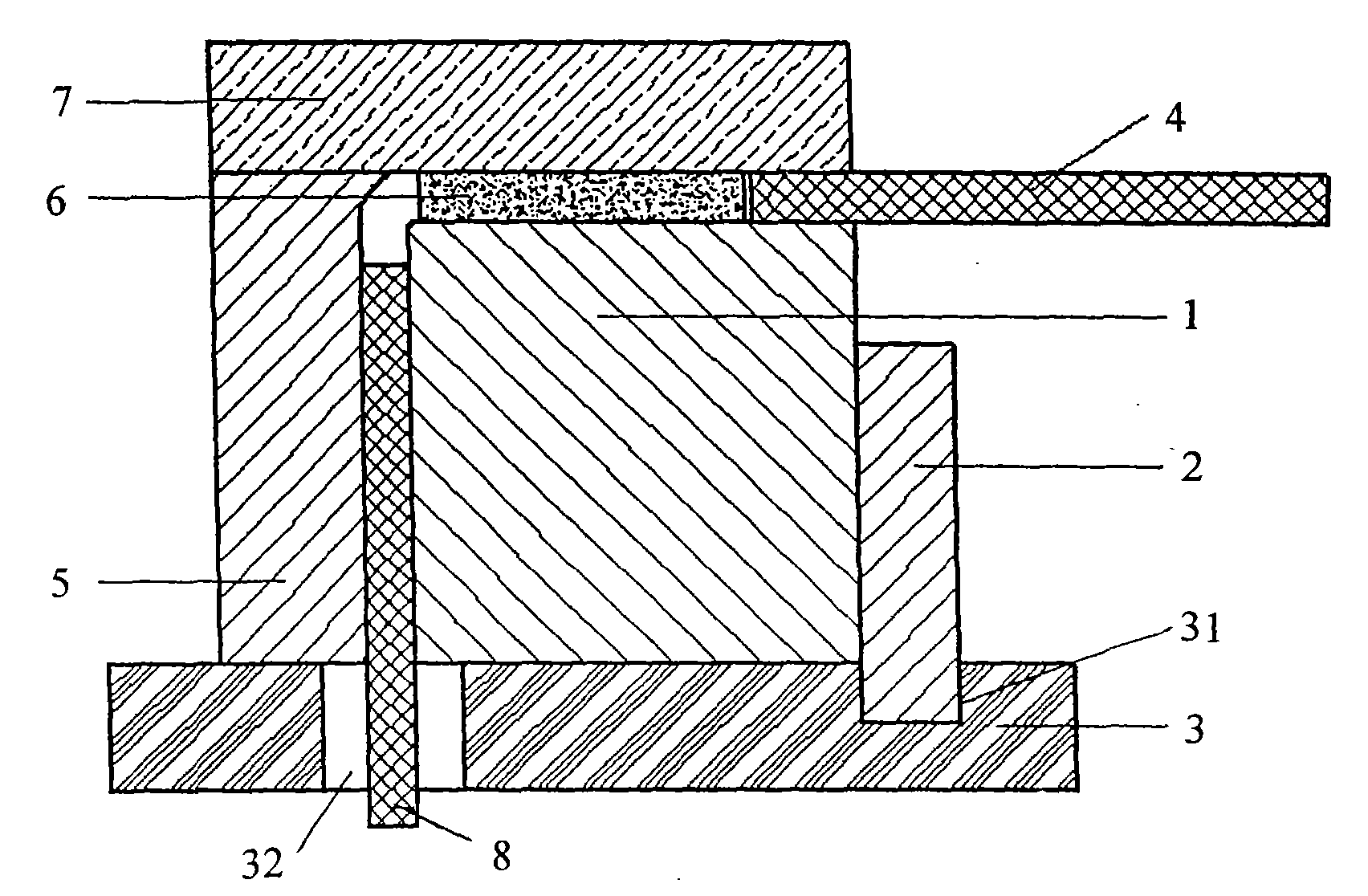

[0030] ③ press figure 1 As shown, the mold base plate 3 is fixed on the workbench of the three-way extrusion hydraulic press, and the circular through hole 32 on the base plate 3 is aligned with the working hole on the press workbench.

[0031] ④ Put the right baffle 2 into the baffle groove 31 of the bottom plate 3, the mold main body 1 is placed on the bottom plate 3 close to the right baffle 2, and the lower extrusion rod 8 is placed on the bottom along the vertical extrusion groove of the mold main body 1. On the cylinder column, adjust the height of th...

Embodiment 2

[0039] Low-temperature synthesis preparation process of Mg-6Al-5Zn material.

[0040] ① First, according to the composition requirements, 150 purpose pure magnesium powder, 200 purpose pure aluminum powder and 150 purpose pure zinc powder are proportioned by weight percentage: 6% aluminum, 5% zinc, and the balance is magnesium.

[0041] ② Process the prepared material into an extrusion sample with a size of 19.5mm×19.5mm×100mm by means of cold isostatic pressing and cutting.

[0042] ③ Debug the three-way extrusion hydraulic press to ensure that each cylinder works normally.

[0043] ④ Press figure 1 As shown, the mold base plate 3 is fixed on the workbench of the three-way extrusion hydraulic press, and the circular through hole 32 on the base plate 3 is aligned with the working hole on the press workbench.

[0044] ⑤ Put the right baffle 2 into the baffle groove 31 of the bottom plate 3, the mold main body 1 is placed on the bottom plate 3 close to the right baffle 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com