Deep hole extrusion forming process of medium-carbon low-alloy structural steel

An extrusion, low-alloy technology, used in metal extrusion, metal extrusion dies, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

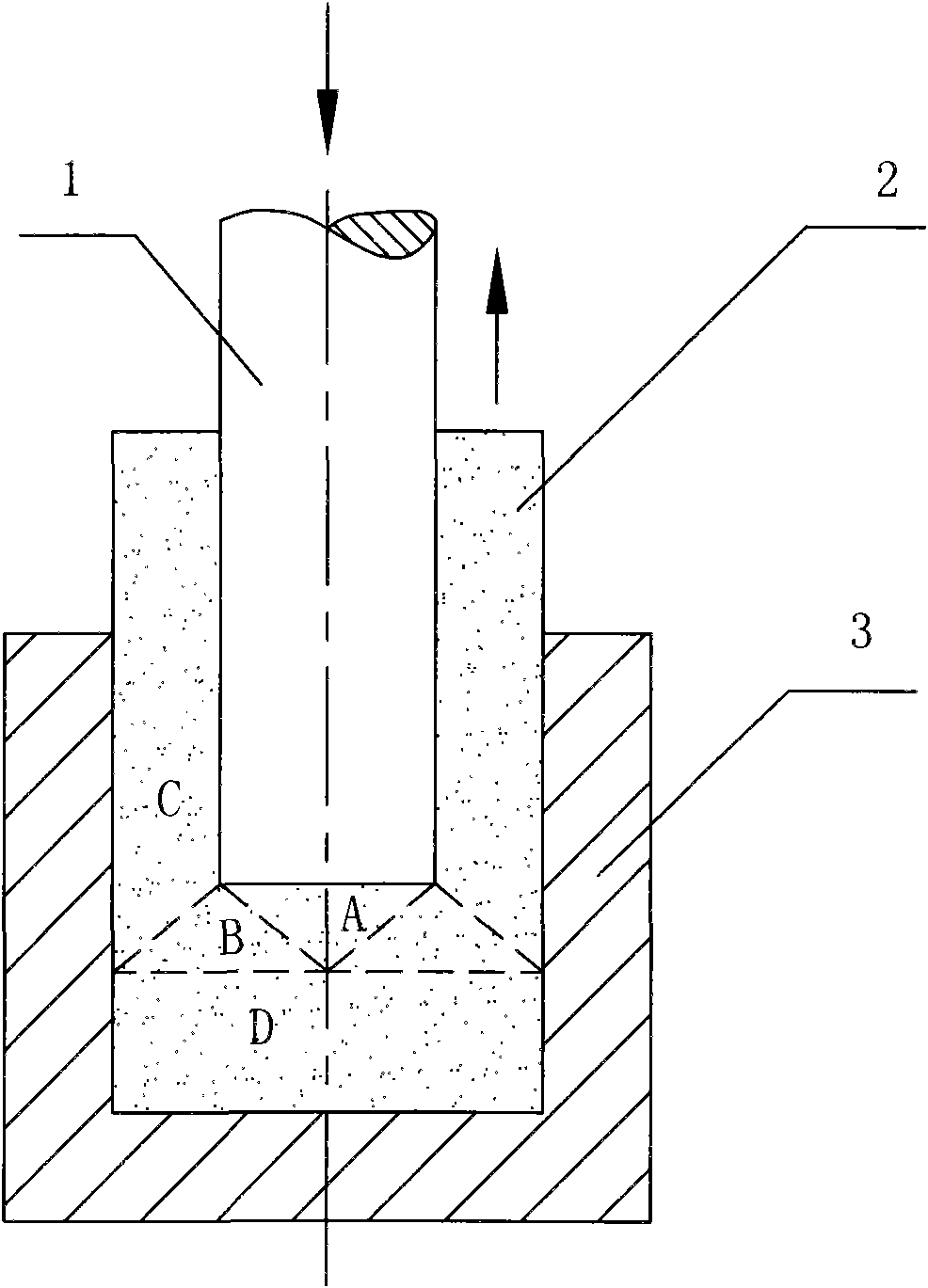

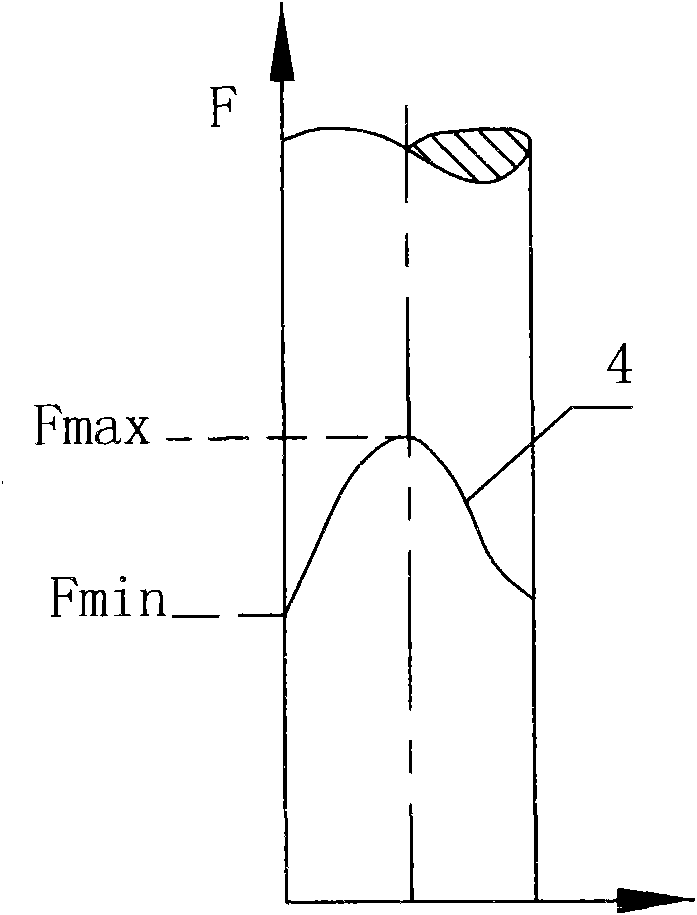

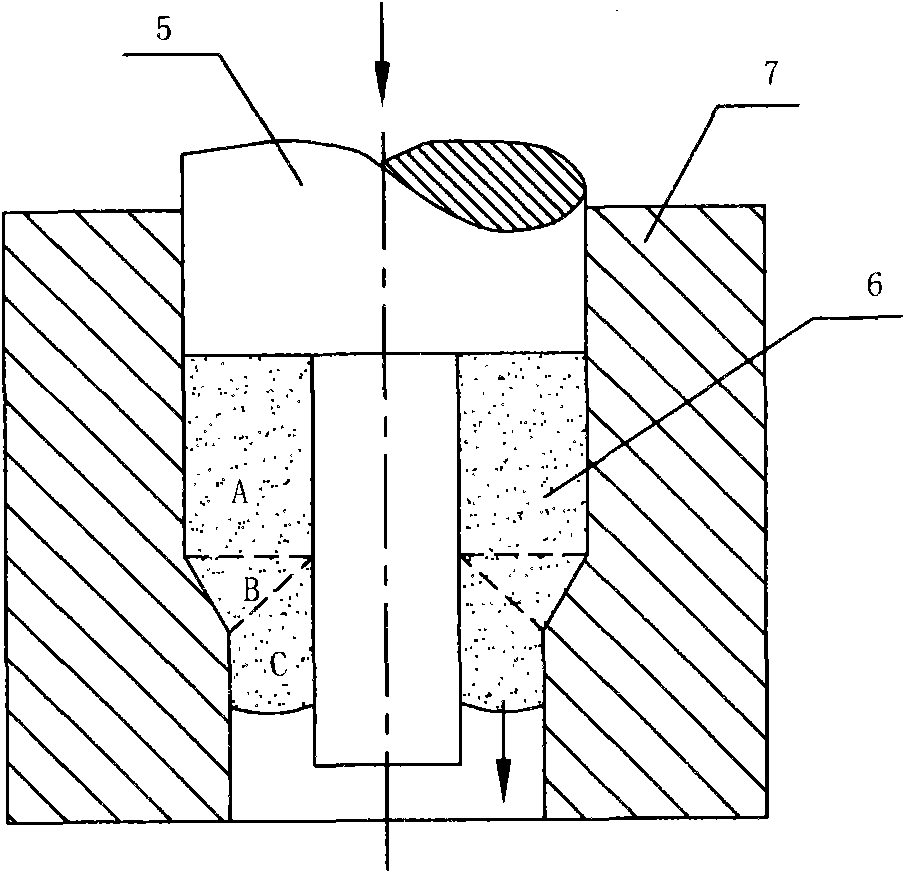

[0057] The deep hole extrusion process diagram of the hollow rod made of 42CrMo:

[0058] Figure 15 Indicates the blank before extrusion, with a bar diameter of 62mm and a length of 160mm; Figure 16 Indicates the first step of deep hole extrusion, the diameter of the punch is 40 mm, the length of the working part of the punch (the length of the part in contact with the blank) is 160 mm, the diameter of the extrusion hole in the first step is 40 mm, and the depth of the extrusion hole is 160 mm; Figure 17 It shows the diagram of the second working step of deep hole extrusion. The extrusion billet is located between the first step and the second step. The length of the contact part) is 241 millimeters, the extrusion hole diameter of the second working step is 40 millimeters, and the extrusion hole depth is 241 millimeters. The metal blanks of the first and second working steps are placed in the same die, the shape and size of the inner wall of the cylindrical die are the sa...

Embodiment 2

[0060] The deep hole extrusion process diagram of the hollow rod made of 40Cr:

[0061] Figure 18 Indicates the rough drawing before extrusion, the bar diameter is 80 mm, and the length is 248 mm; Figure 19 It shows the diagram of the first working step of deep hole extrusion, the diameter of the punch is 62mm, the length of the working part of the punch (the length of the part in contact with the blank) is 248mm, the diameter of the extrusion hole in the first working step is 62mm, and the depth of the extrusion hole is 248mm, The ratio of hole depth to hole diameter is 4; Figure 20 It shows the second working step diagram of deep hole extrusion. The extrusion billet is located between the first step and the second step. The length of the contact part) is 230 mm, the diameter of the extrusion hole in the second working step is 54 mm, the depth of the extrusion hole is 194.6 mm, and the ratio of the hole depth to the hole diameter is 3.6; Figure 21 It shows the diagram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com