Automatized continuous processing equipment for T shaped corner extrusion press and its processing method

A technology of corner extrusion and processing equipment, which is applied in the direction of metal processing equipment, metal extrusion, metal extrusion dies, etc., can solve the problem of high processing cost, and achieve easy operation, simple structure, and strong ability of uniform grain refinement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

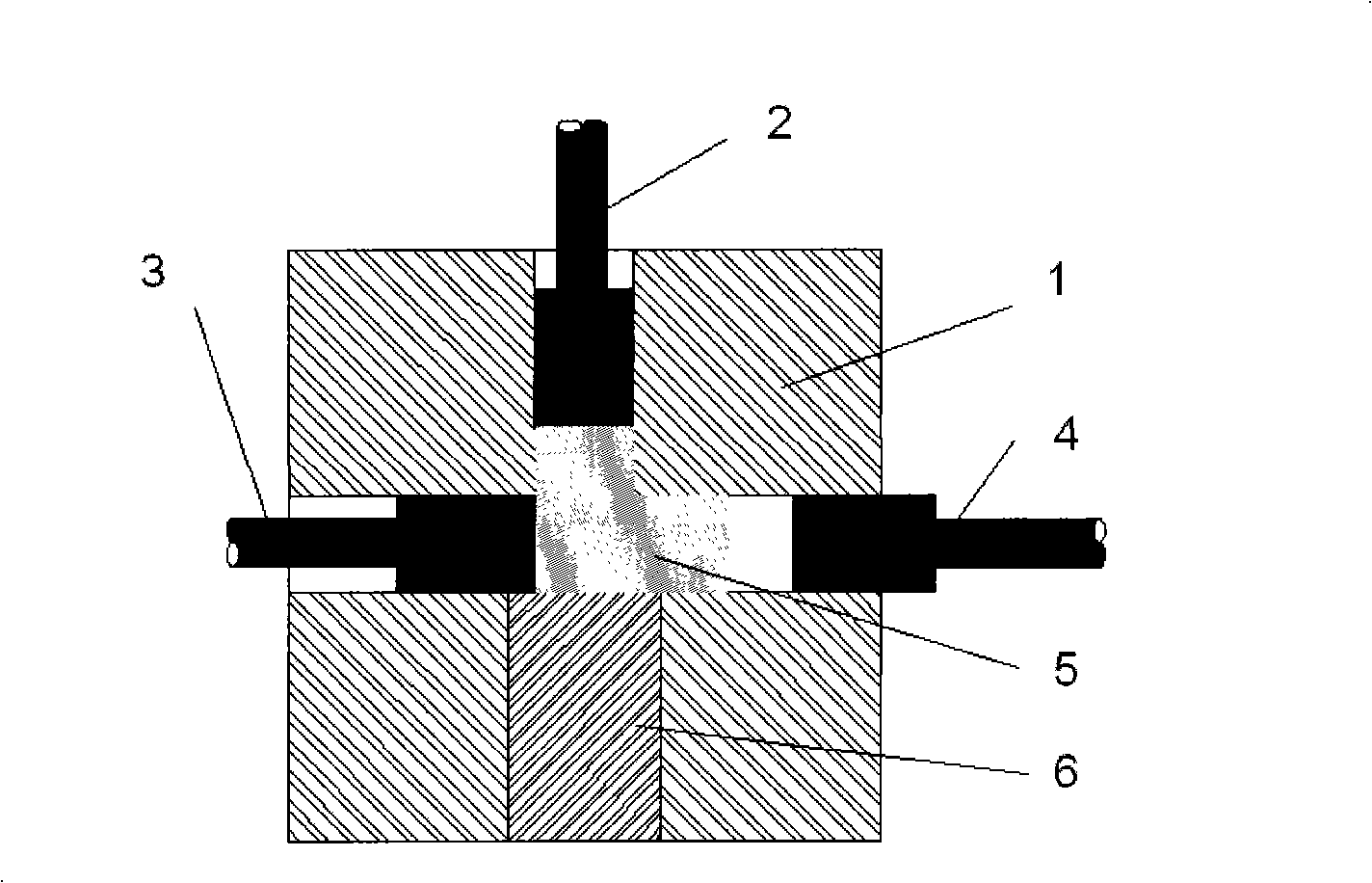

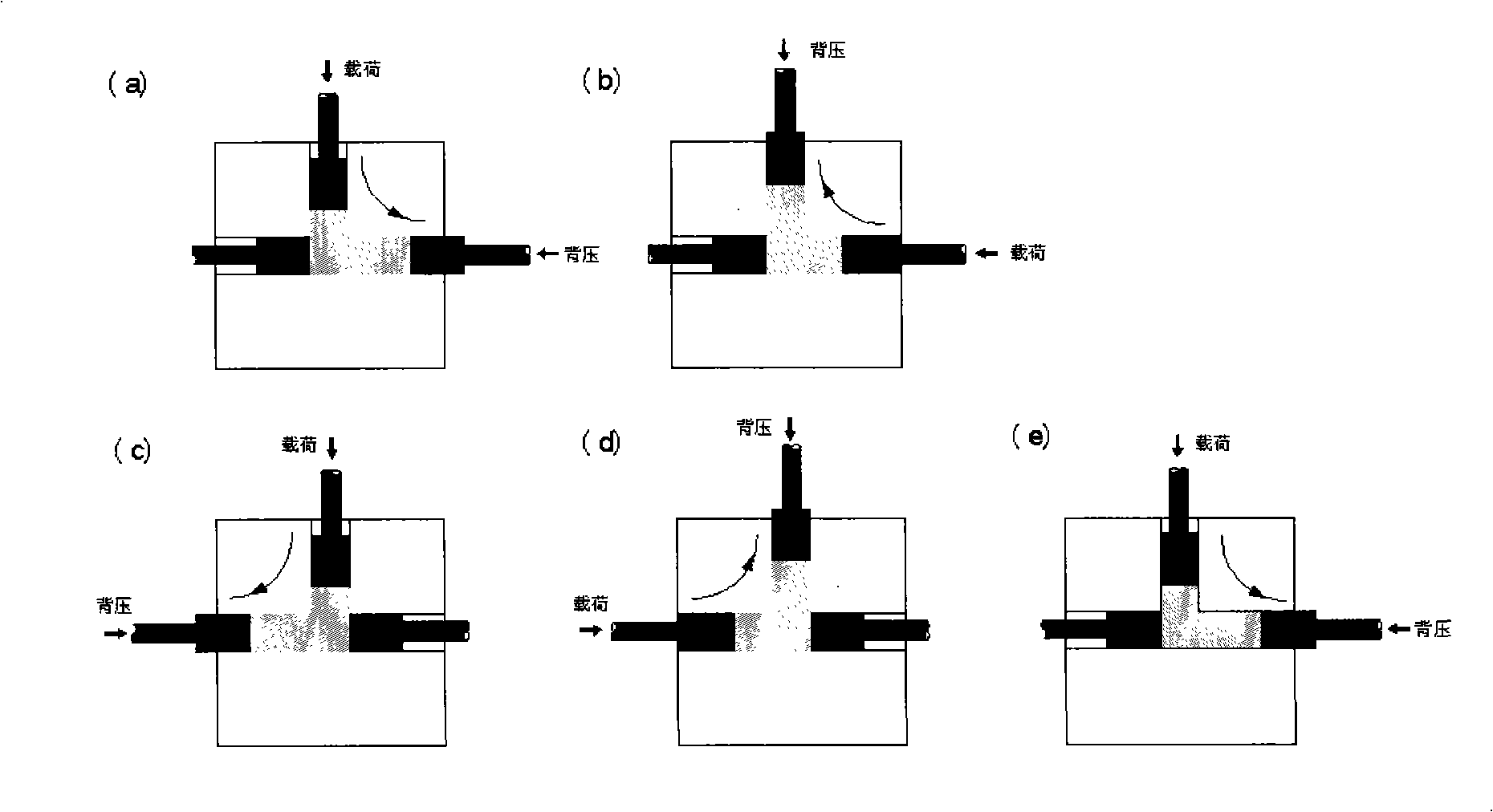

[0031] Such as figure 1 As shown, the present invention includes a mold 1, a first punch 2, a second punch 3, a third punch 4, and an inlet and outlet 6, and three adjacent directions in the mold 1 are provided with T-shaped corner extrusion cavities , the first punch 2, the second punch 3, and the third punch 4 are respectively set in the three cavities, and the inlet and outlet 6 are arranged on the other side, and the cross-sectional size of the inlet and outlet 6 is larger than that of the first punch 2 , the second punch 3, and the third punch 4; the first punch 2, the second punch 3, and the third punch 4 are respectively connected to the hydraulic control system.

[0032] Preferably, the centerlines of the second punch 3) and the third punch 4 of the present invention are coaxial straight lines, and the centerline of the first punch 2 intersects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com