Rubber forming method and rubber forming mould of high-curvature high-flanging sheet metal part

A technology of sheet metal parts and forming dies, which is applied in the field of aircraft manufacturing, can solve problems such as the inability to freely undulate in the thickness direction of materials, the structural limitations of large curvature flanged parts, and the wrinkling of convex flanged parts, etc., to achieve simple and convenient installation and operation methods , Reduce the workload of knocking and edge finishing, and the effect of low level dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

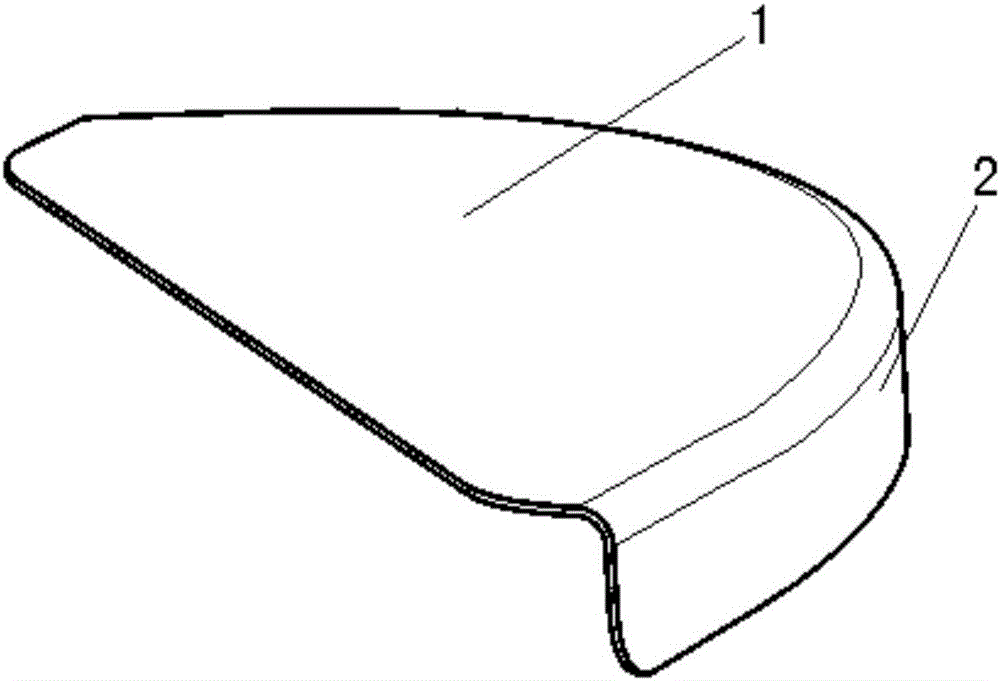

[0015] Referring to the accompanying drawings, the aircraft parts provided by the embodiment are as figure 1 As shown, the part 1 is a sheet metal part with a convex curve and high flanging, and the part is in the shape of a "fish head". The biggest problem with the forming of the existing technology is that the flanging surface 2 is prone to wrinkles or even dead wrinkles during the forming of the part. , the amount of manual correction is large, and the surface quality is poor.

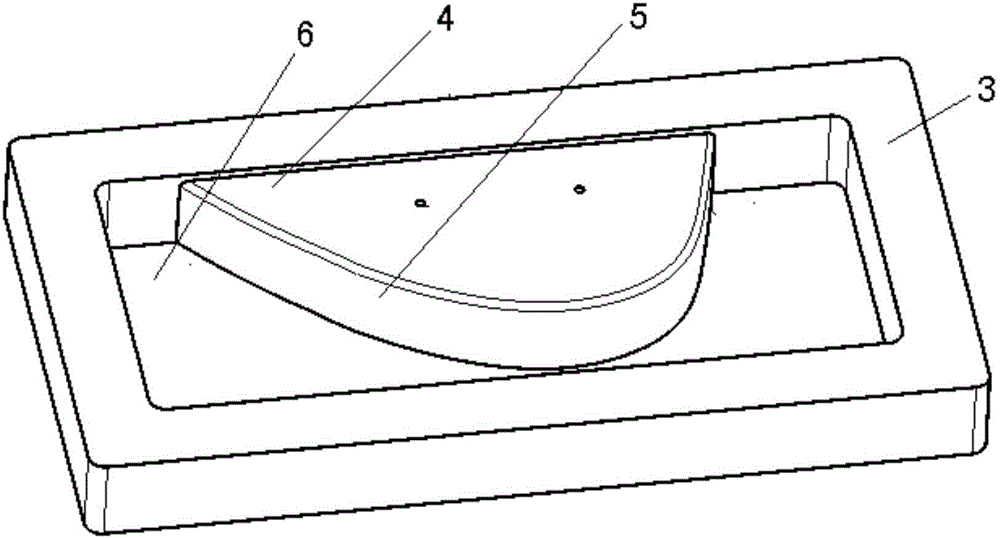

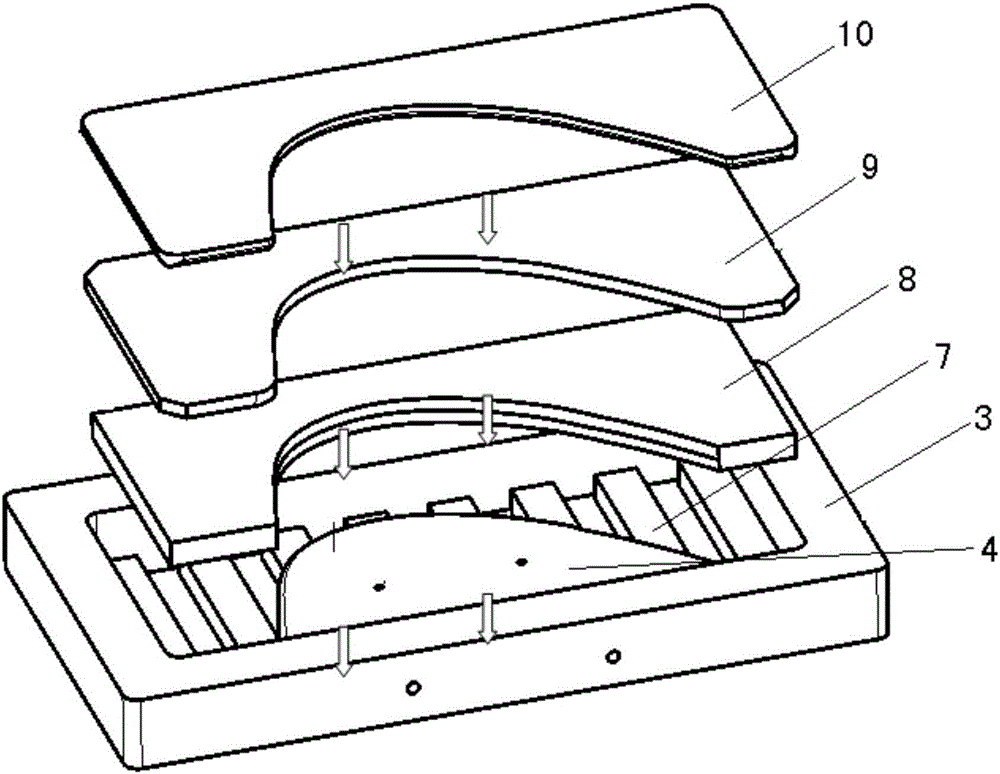

[0016] The molding die that the present application proposes is as shown in the figure, and the molding die contains a container frame 3, a molding die 4, a pressing plate 10, a support plate 9 and a rubber cushion block 7, and the described container frame 3 is a cuboid frame, and the described molding die 4 is a module that matches the sheet metal part 1, the working surface 5 on the outer side of the forming die 4 matches the inner side of the flanging surface 2 of the sheet metal part 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com