Testing method of external permeability of fiber fabric surface and testing mold

A technology of fiber fabrics and testing methods, applied in the field of testing the permeability of porous materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

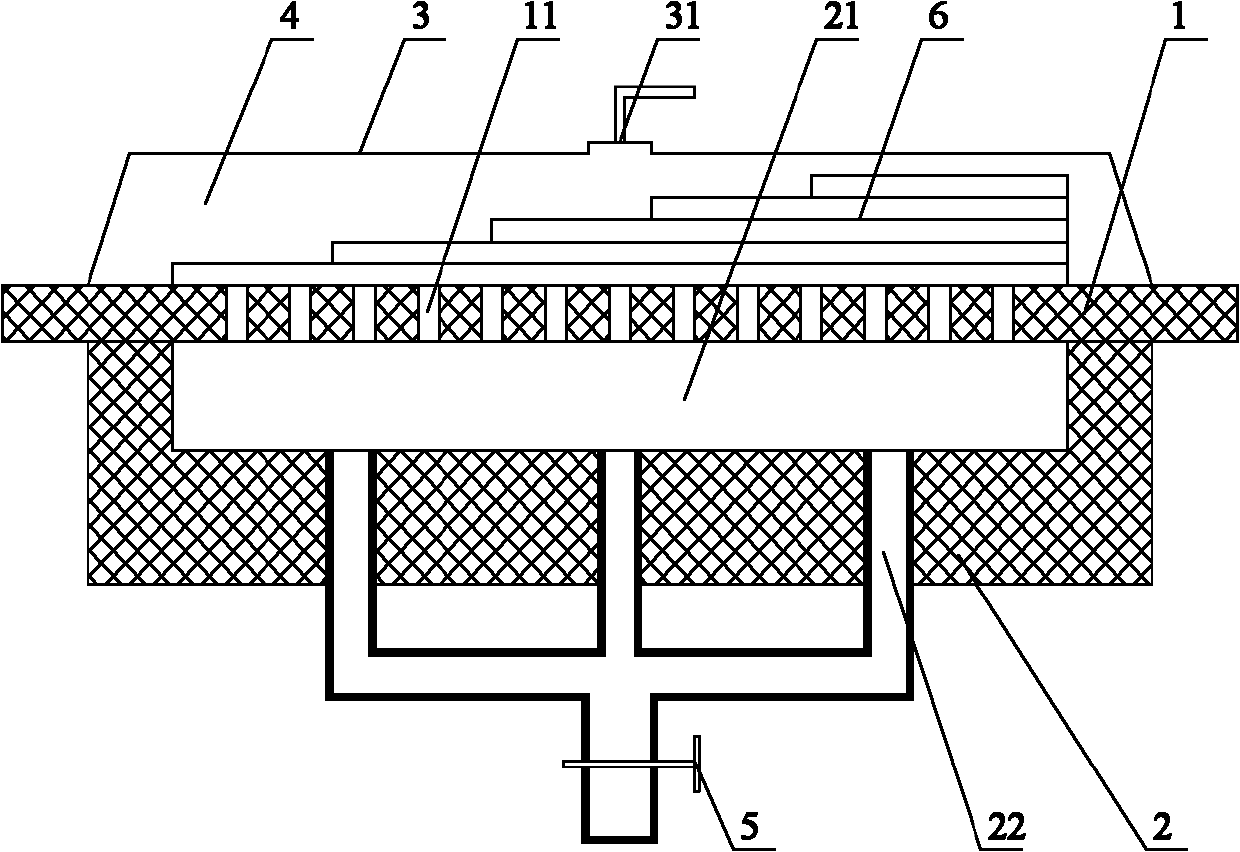

[0043] a kind of like figure 1 The test mold of the out-of-plane permeability of fiber fabric shown in the present invention, this test mold comprises the storage tank 2 of mold panel 1 and testing fluid, and mold panel 1 is smooth and flat, and can bear certain pressure, and storage box 2 is a concave Groove shape, the mold panel 1 is similar to a cover on the storage box 2, and is fixed on the top of the storage box 2 to form a closed cavity 21. A flexible vacuum bag film 3 is covered above the mold panel 1 to form a mold cavity 4. The edge of the flexible vacuum bag film 3 forms a seal with the mold panel 1. A vacuum pump connected to the external vacuum system is provided on the flexible vacuum bag film 3. Air port 31. A plurality of microholes 11 are evenly distributed on the mold panel 1 (through holes communicating with the mold cavity 4 and the airtight cavity 21, see figure 1 ), the pore diameter of the micropore 11 is 50 μm; the bottom of the storage box 2 is eve...

Embodiment 2

[0052] This embodiment adopts the same test mold as that of Embodiment 1.

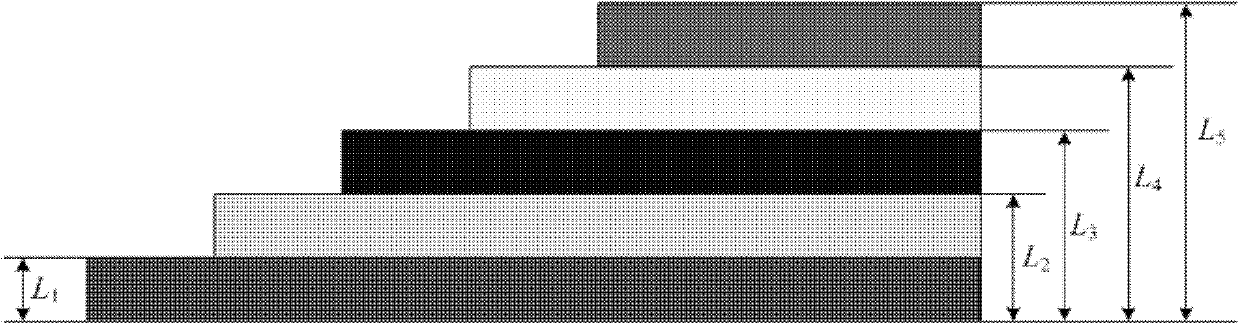

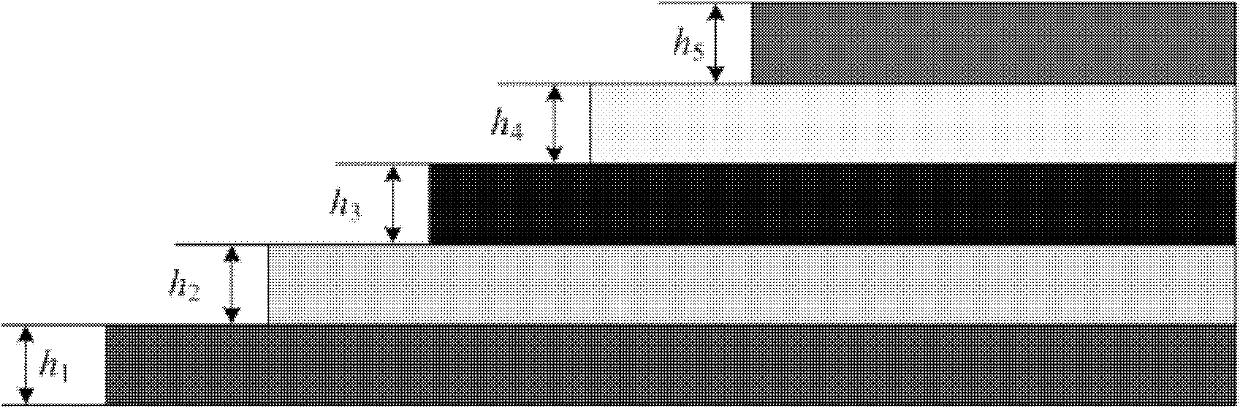

[0053]The objects tested in this embodiment are 72 layers of 02 glass cloth, 36 layers of 04 glass cloth, 18 layers of 4:1 glass fiber woven cloth (weft 4 warp 1) and 18 layers of 1:4 glass fiber woven cloth ( Weft 1 and warp 4), the vacuum negative pressure ΔP in the test is 0.097MPa, the operating steps of the test method of this embodiment and all the other process parameters are the same as in Example 1 (the linear relationship diagram of the fiber fabric preform of four different layers) Respectively as Figure 9 ~ Figure 12 shown).

[0054] The test results of this embodiment are shown in Table 2 below:

[0055] Table 2: The test process parameter list of different ladder ply numbers in embodiment 2

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com