Array substrate as well as maintenance method and display device thereof

An array substrate and the same technology are applied in the fields of display devices, array substrates and maintenance methods thereof, which can solve the problems of prolonged production cycle, poor data line disconnection, poor gate line disconnection, etc., so as to ensure the success rate of maintenance and reduce production. The effect of cycle and operation method is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

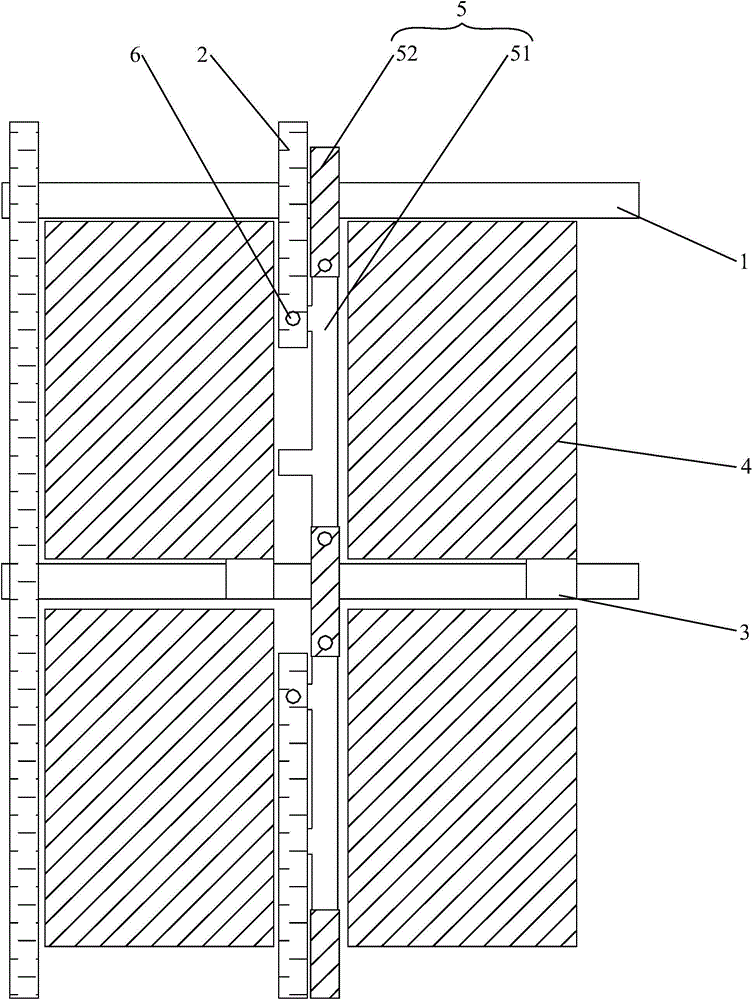

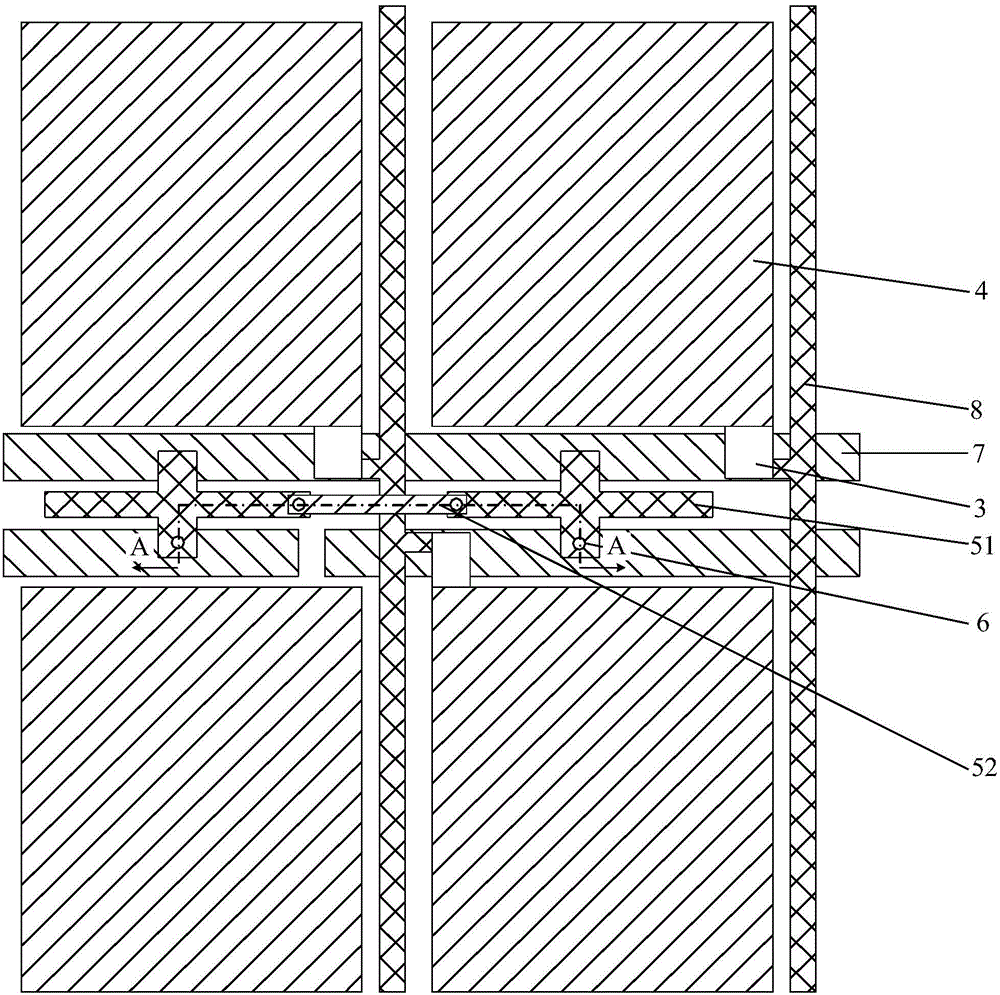

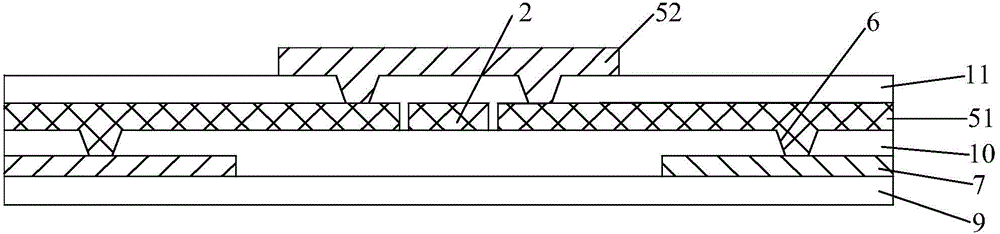

[0034] An embodiment of the present invention provides an array substrate, such as figure 1 As shown, the array substrate includes:

[0035] The first signal line 1 and the second signal line 2 formed on the array substrate, the first signal line 1 and the second signal line 2 intersect to define a plurality of pixel units, and each pixel unit includes a thin film transistor 3 and pixel electrode 4, further comprising:

[0036] The connection structure 5 arranged side by side with the first signal line 1, wherein the connection structure 5 includes a first part 51 arranged on the same layer as the second signal line 2 and a first part 51 arranged on the same layer as the pixel electrode 4 Two parts 52, the first signal line 1, the second signal line 2 and the pixel electrode 4 are respectively in different layers, the first part 51 partially overlaps the first signal line 1, and the second part 52 Partially overlapping with the first portion 51 , the first portion 51 and the...

Embodiment 2

[0056] An embodiment of the present invention provides a method for maintaining the array substrate described in Embodiment 1, including:

[0057] If the first signal line is disconnected, the first part of the connection structure overlaps with the first signal line, and at the same time connects the first part and the second part of the connection structure overlaps.

[0058] Specifically, the overlap between the first part of the connection structure and the first signal line may be connected by welding, and the overlap between the first part and the second part of the connection structure may be connected by welding.

[0059] Among them, during welding, the laser can not only form a via hole connecting the first part and the first signal line at the intersection of the first part and the first signal line, but also use the instantaneous high temperature to melt the first part to fill it into the via hole , realizing the electrical connection between the first part and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com