Patents

Literature

37results about How to "Improve forming accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

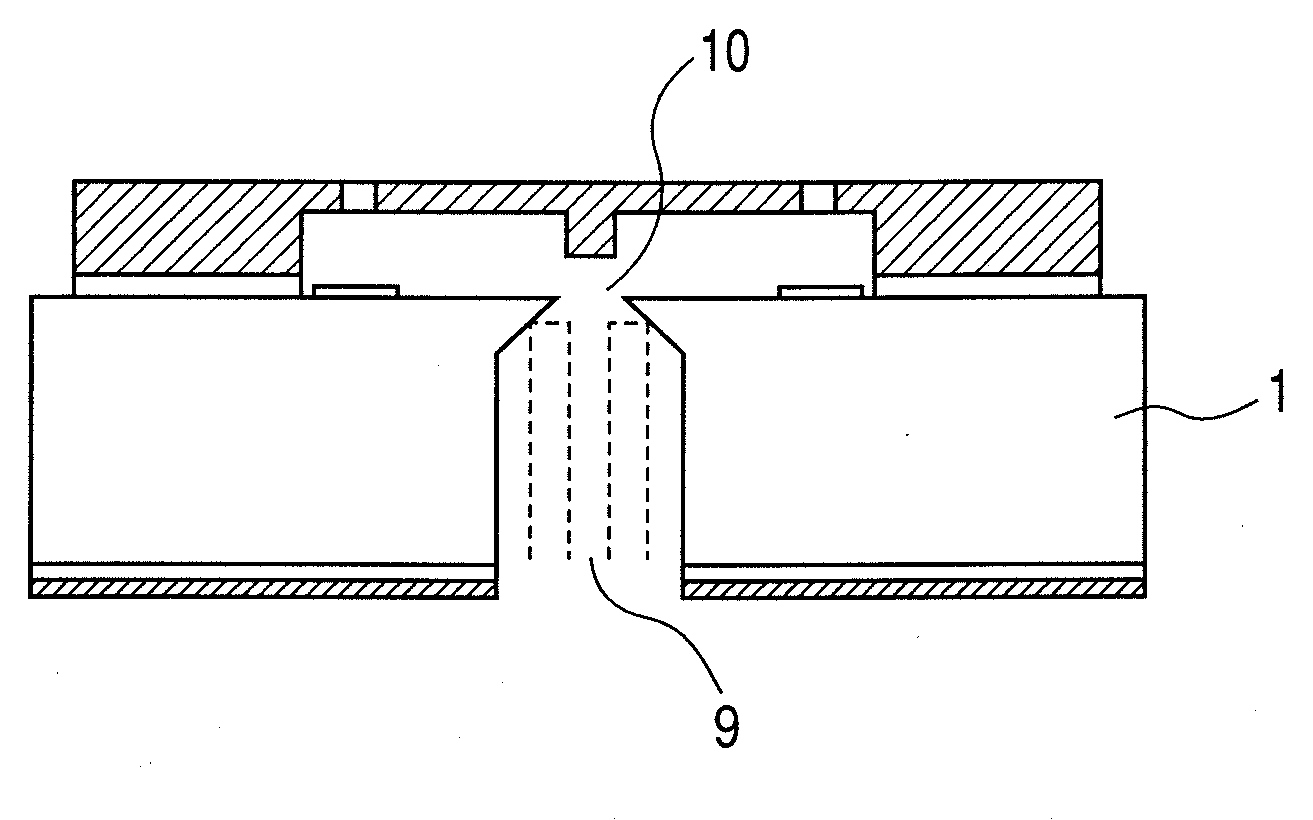

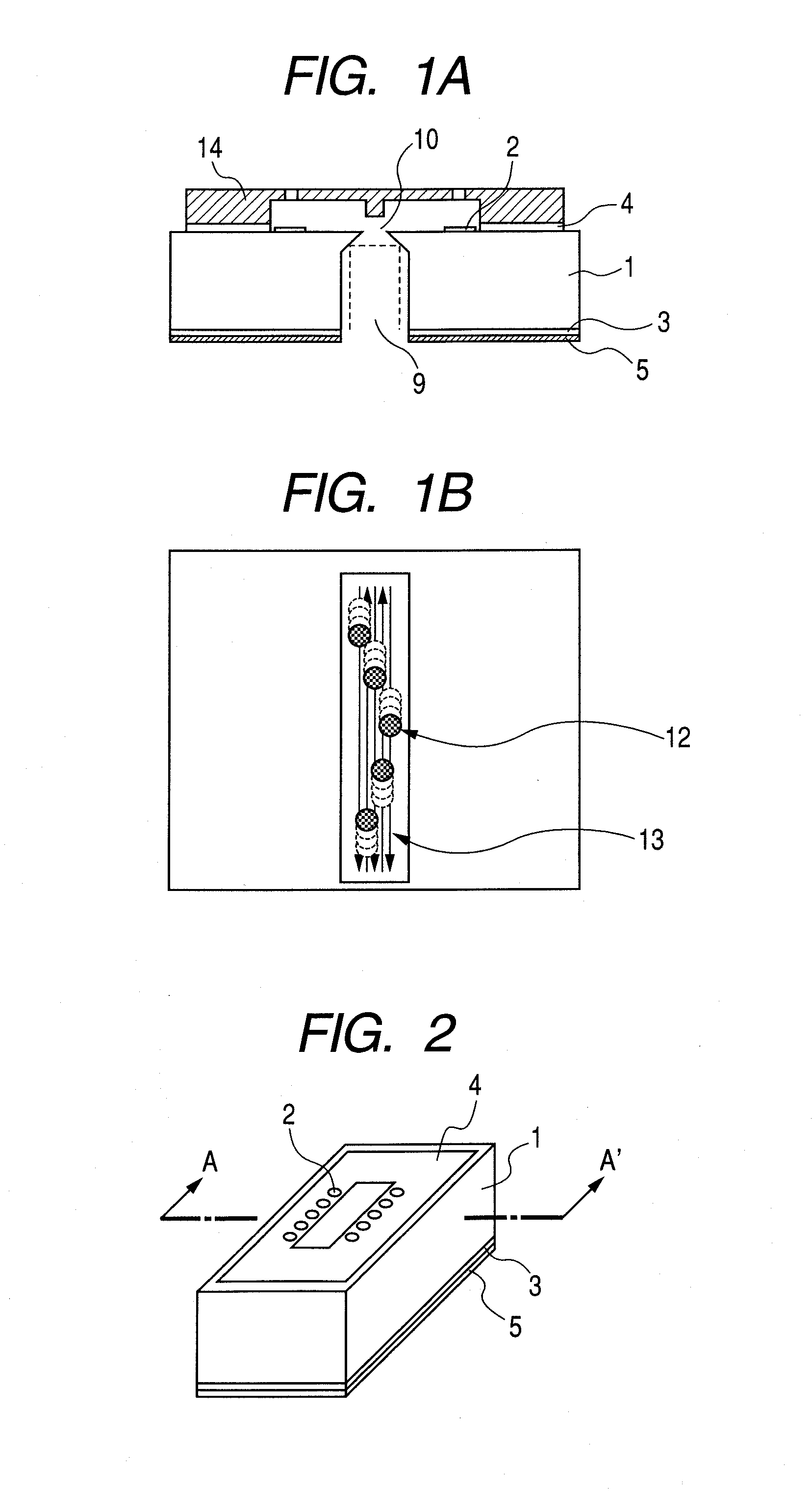

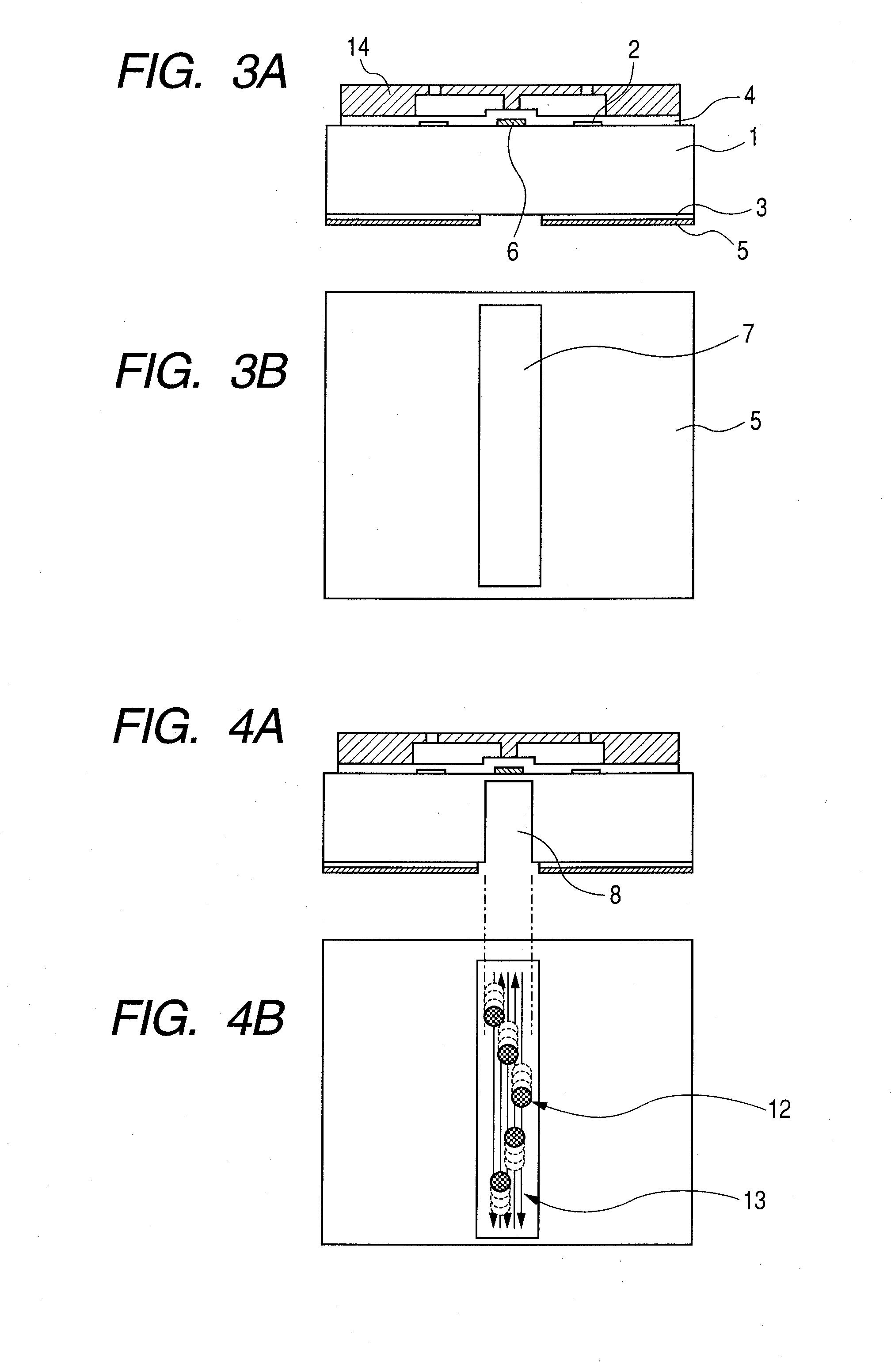

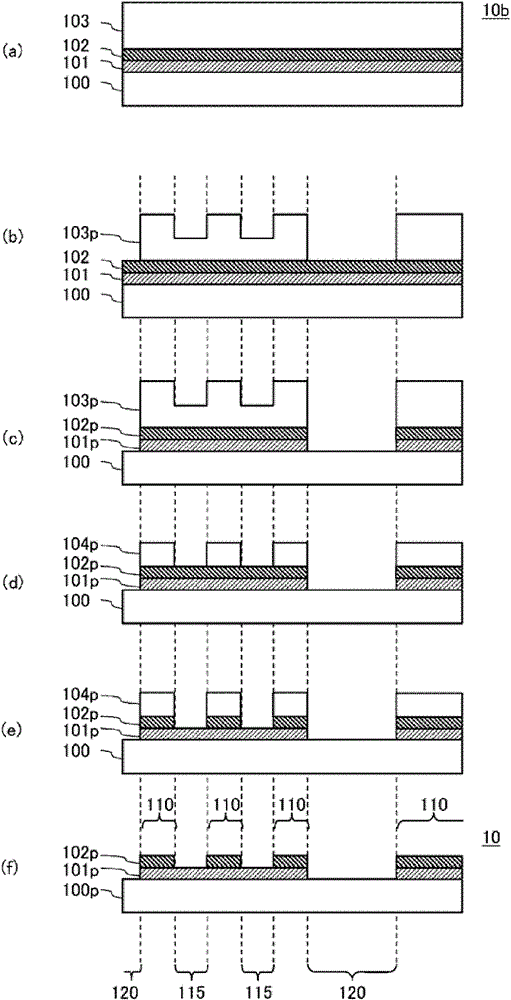

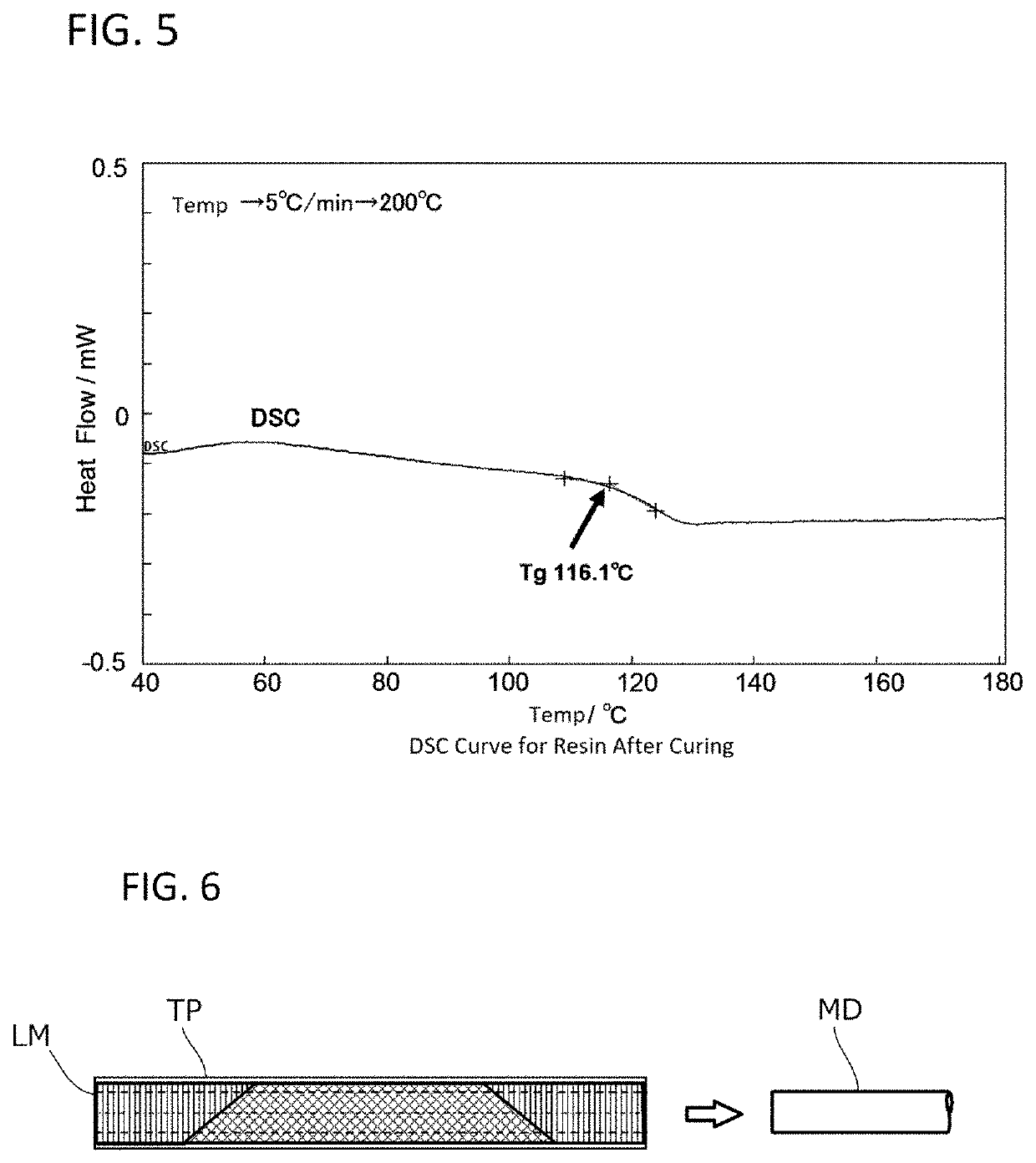

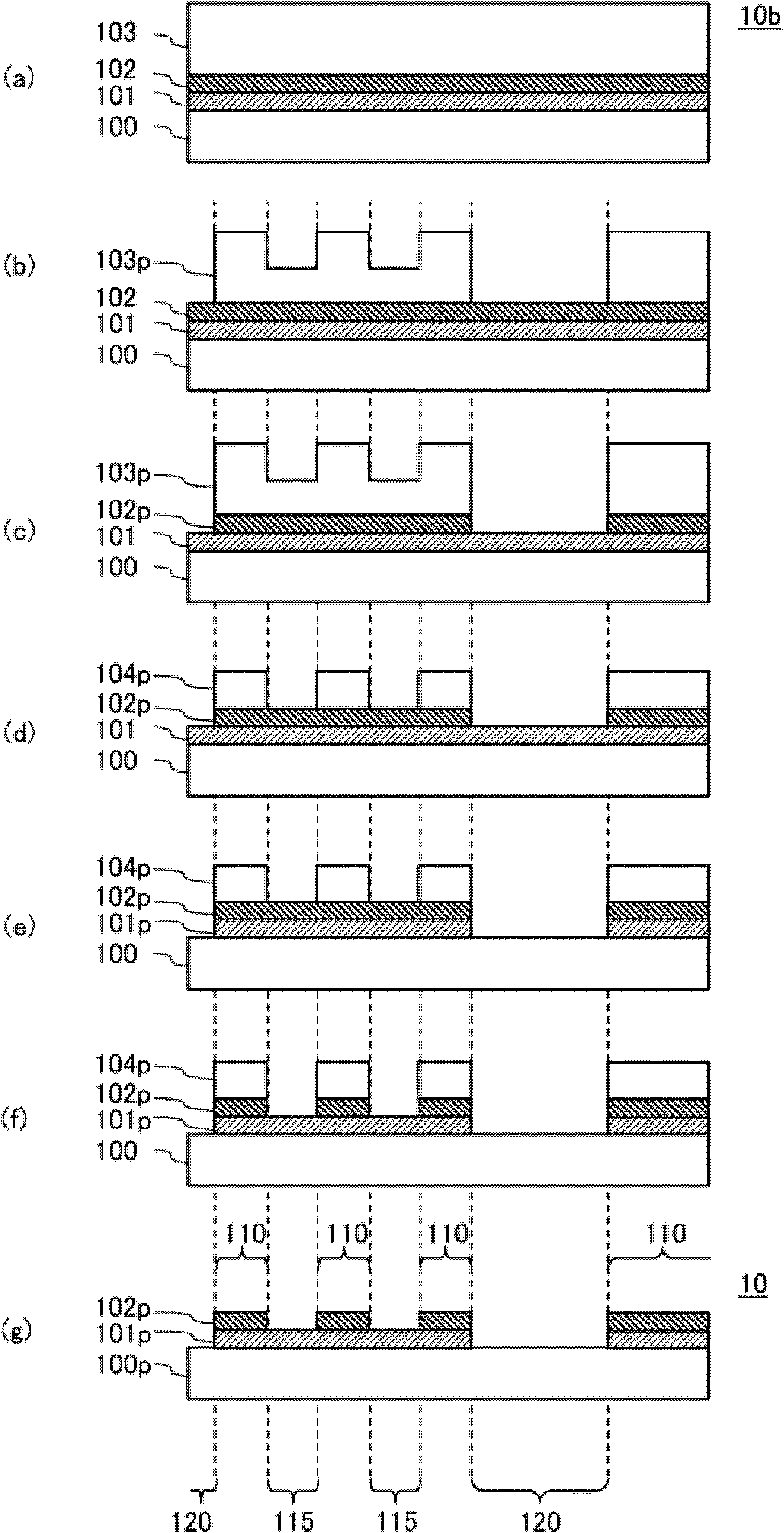

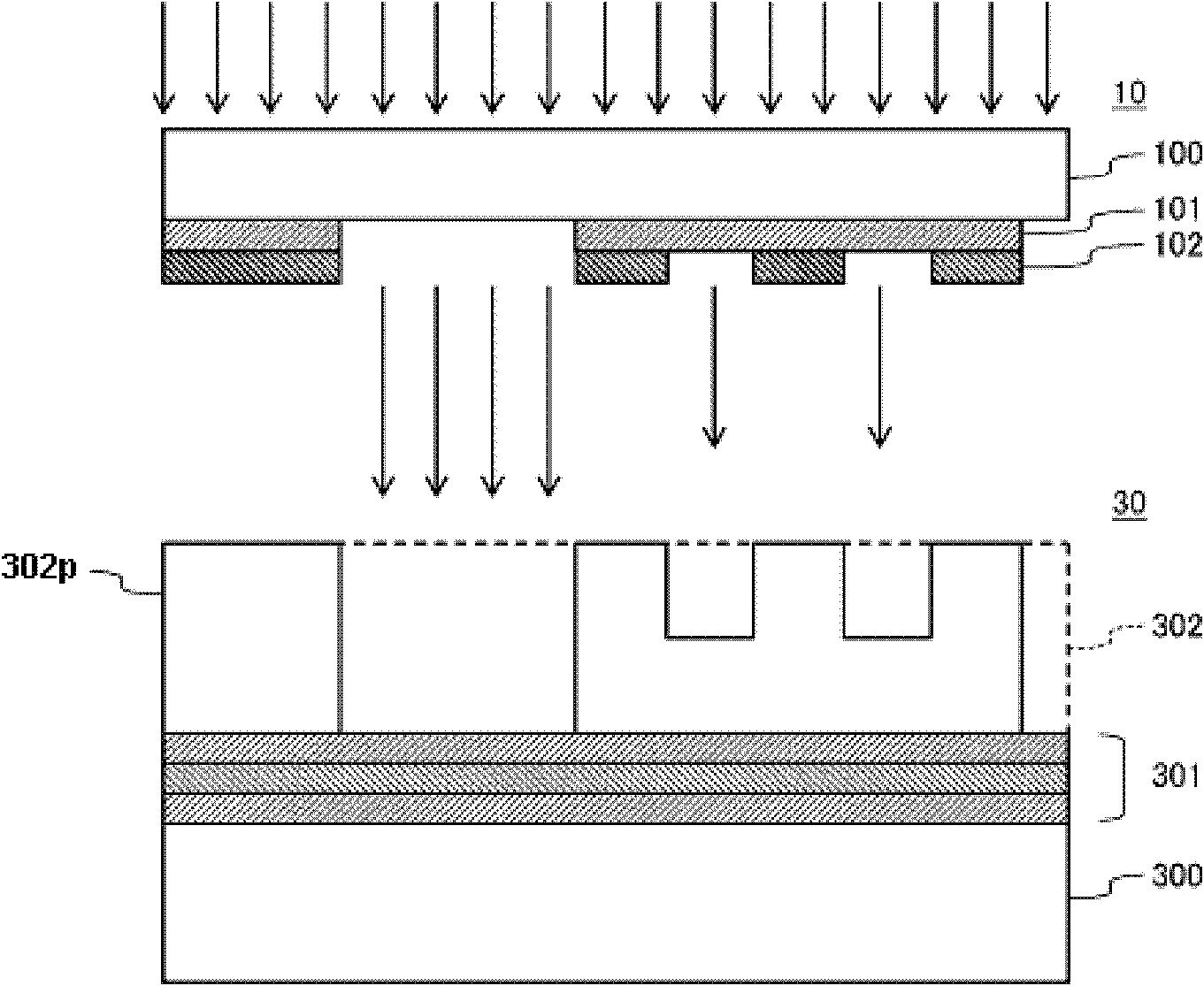

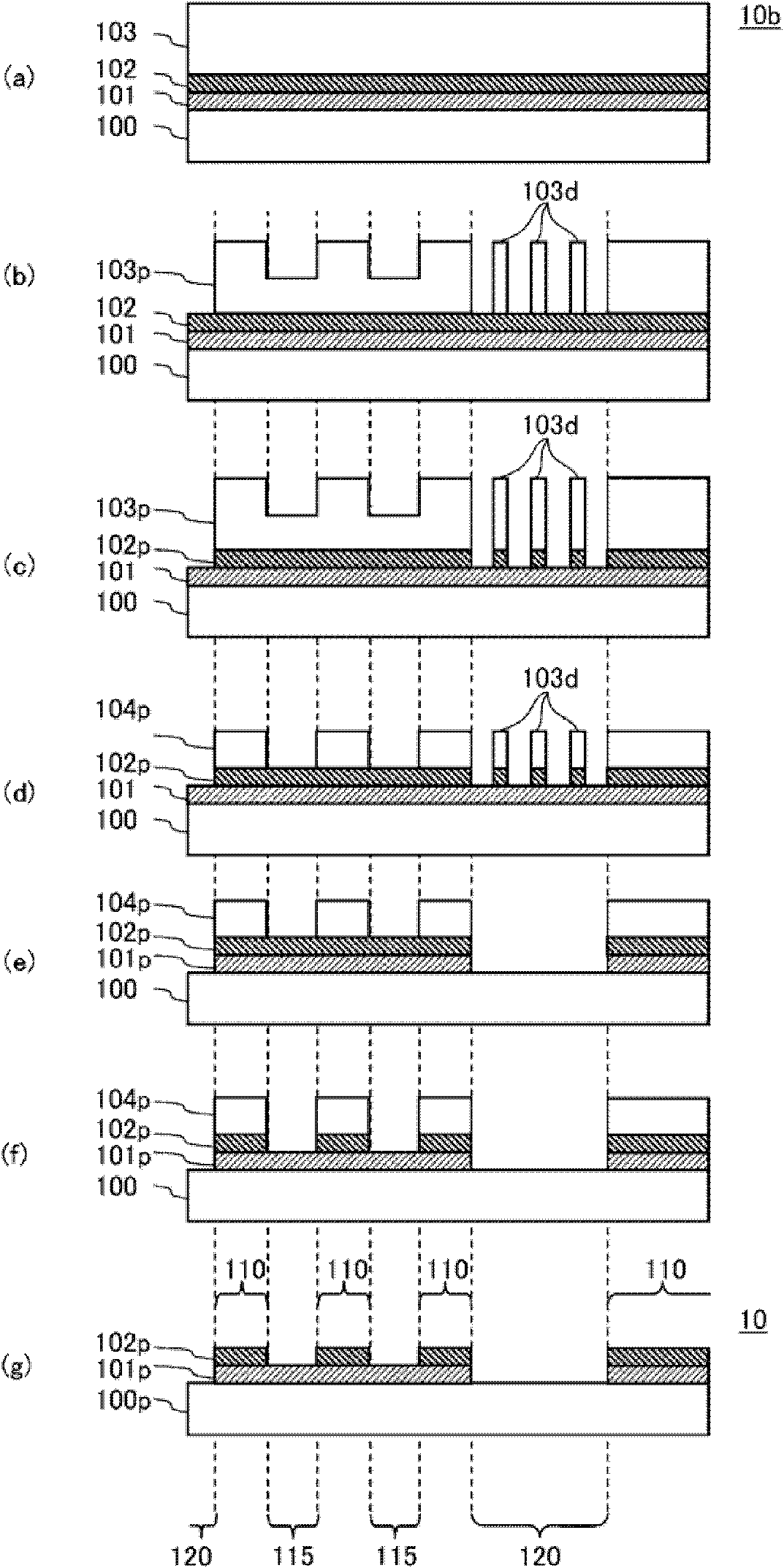

Method of manufacturing substrate for liquid discharge head

InactiveUS20090065482A1Improve forming accuracyMiniaturizationRecording apparatusDecorative surface effectsLaser processingEngineering

Provided is a method of manufacturing a substrate for a liquid discharge head, the substrate including a silicon substrate with a liquid supply opening formed therein, the method including: forming one processed portion by laser processing on the substrate from one surface of the substrate; expanding the one processed portion to form a recess portion by performing laser processing at a position which overlaps a part of the one processed portion and does not overlap another part of the one processed portion; and etching from the one surface the substrate with the recess portion formed therein to form the liquid supply opening.

Owner:CANON KK

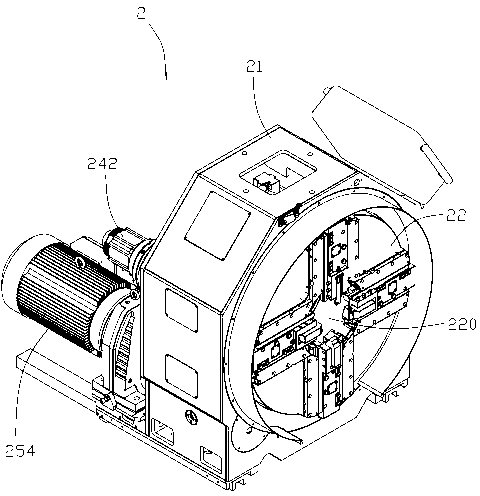

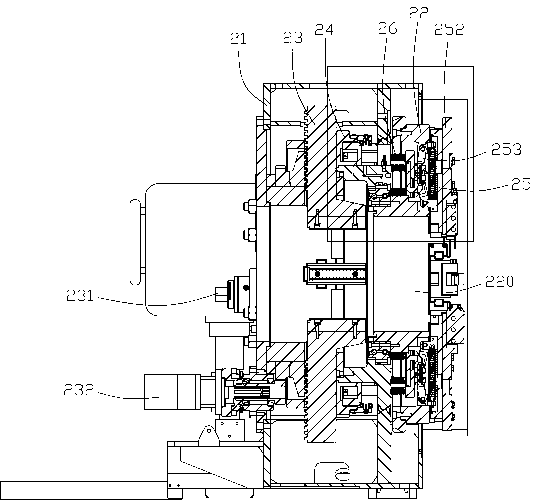

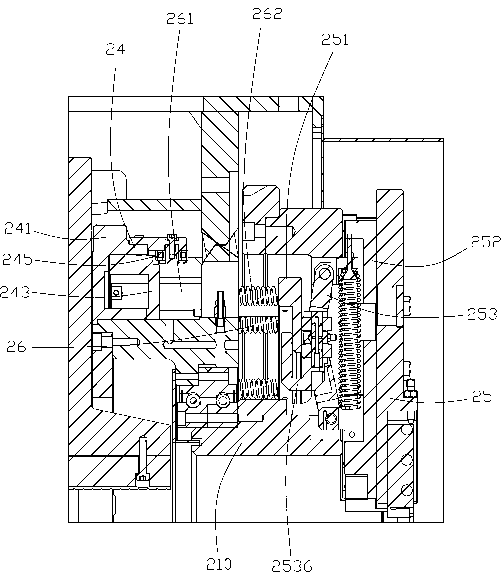

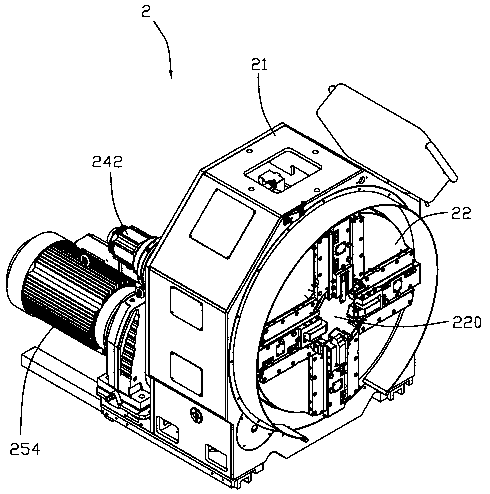

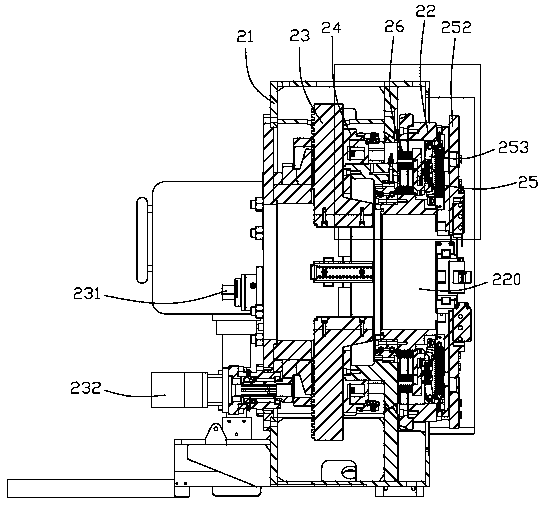

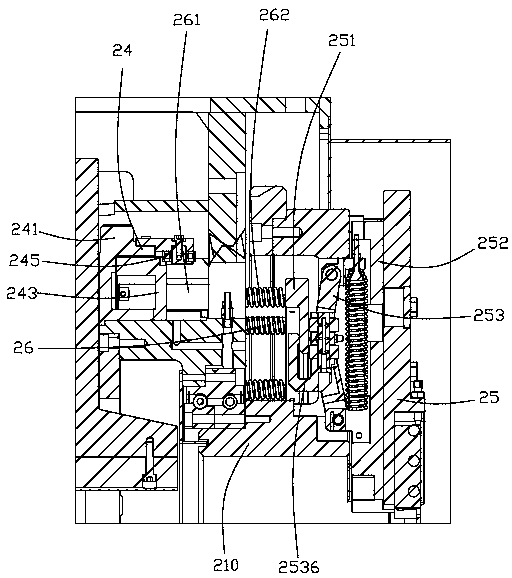

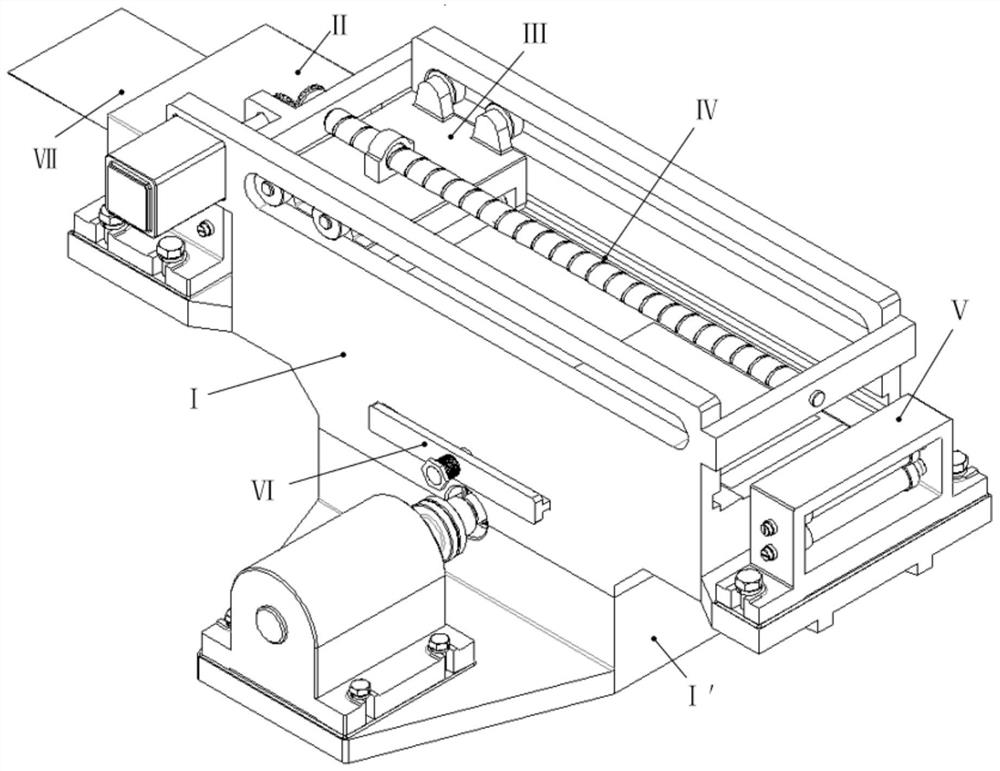

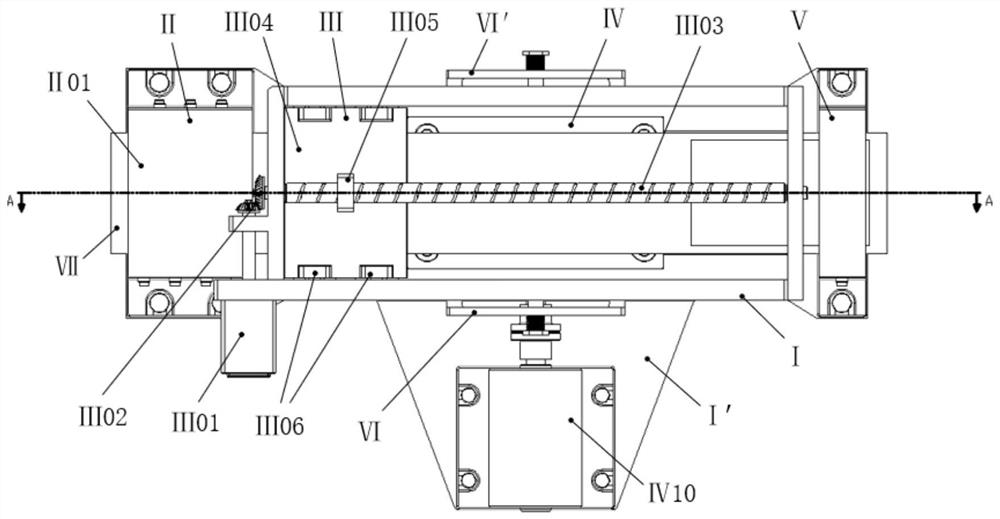

Cutter feeding and retracting mechanism used for pipe facing machine

The invention provides a cutter feeding and retracting mechanism used for a pipe facing machine. The cutter feeding and retracting mechanism comprises a gear disc, a servo drive motor, a cam disc and a bevel cutter mechanism, wherein the servo drive motor drives the gear disc to rotate, the cam disc is arranged to be matched with the gear disc, and the bevel cutter mechanism is arranged on one side, deviating from the gear disc, of the cam disc. The gear disc is provided with a plurality of first cam faces arranged facing toward the direction of the cam disc, and the first cam faces are evenly arranged in the peripheral direction of the gear disc. The cam disc is provided with a plurality of second cam faces which are matched with the first cam faces and evenly arranged in the periphery direction, when the servo drive motor rotates, the first cam faces move on the second cam faces and push the cam disc to perform axial movement along a pipe to be beveled.

Owner:HUAHENG WELDING

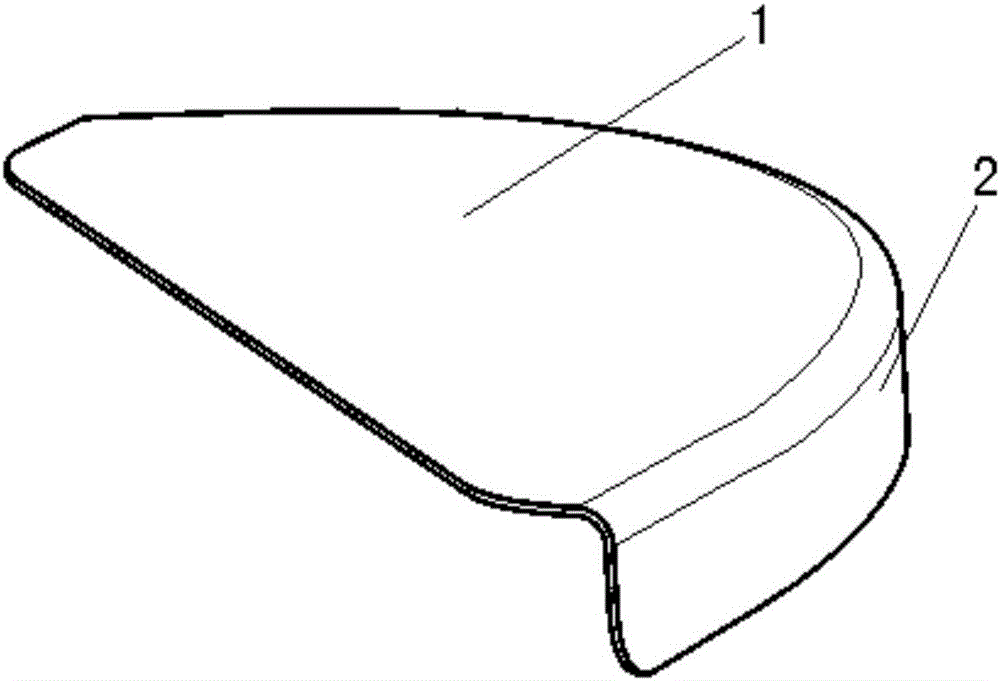

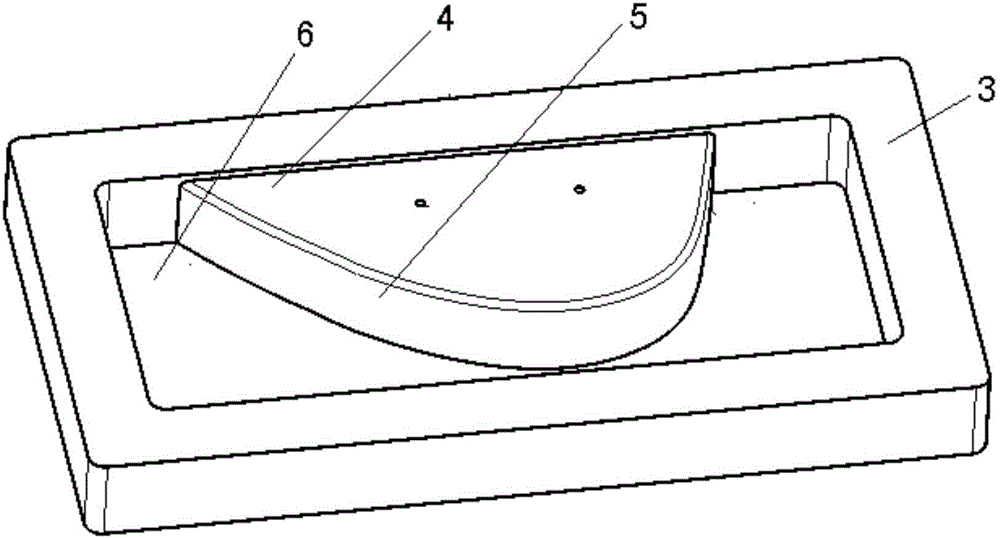

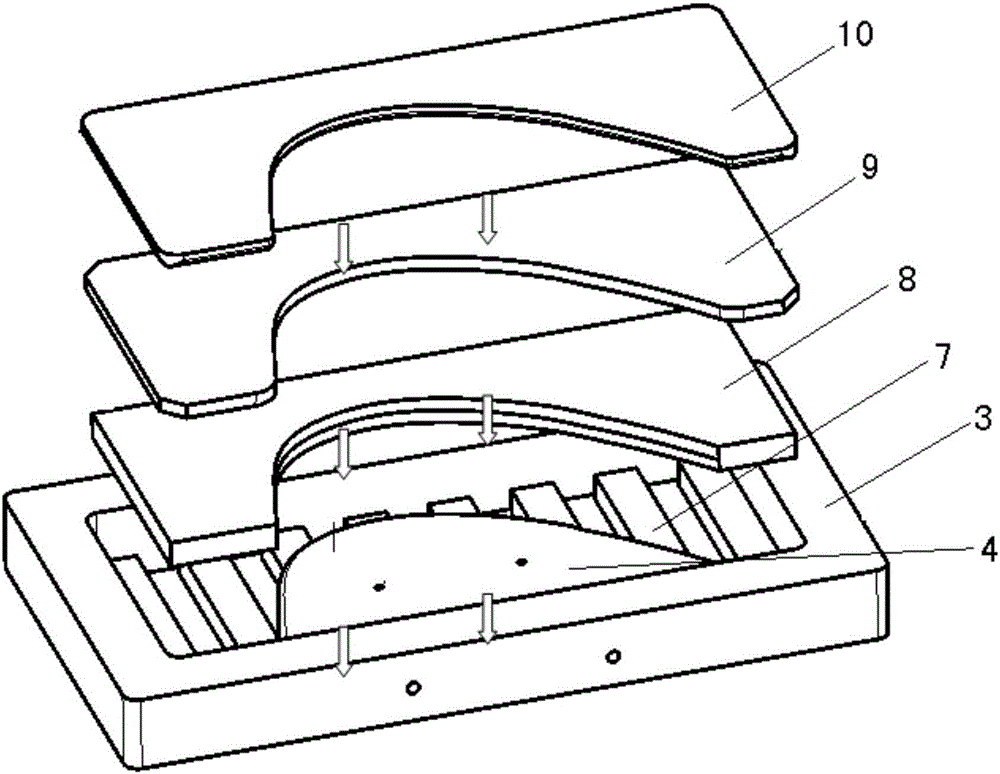

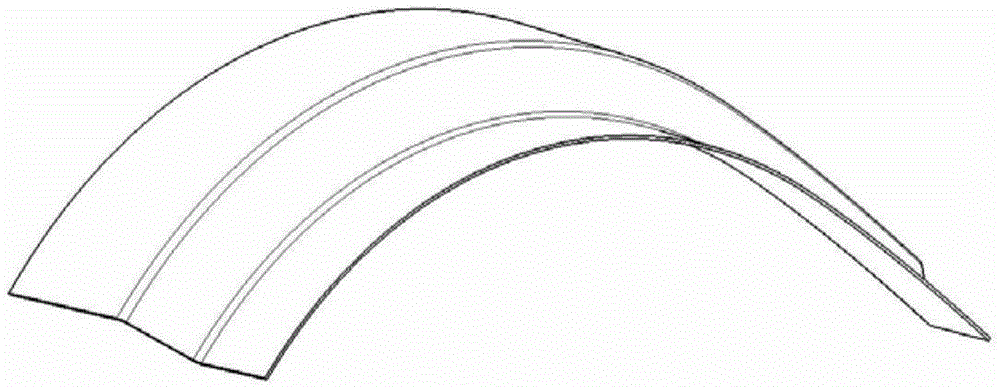

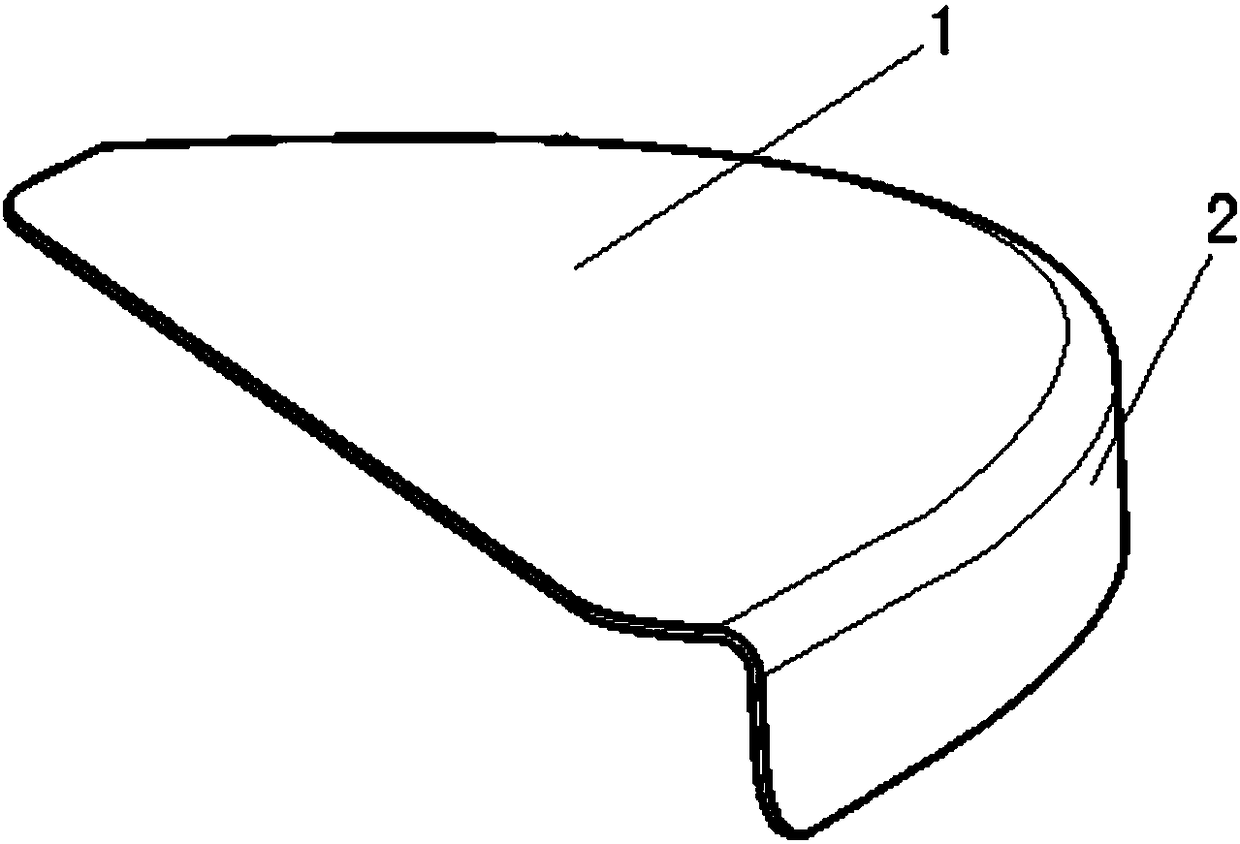

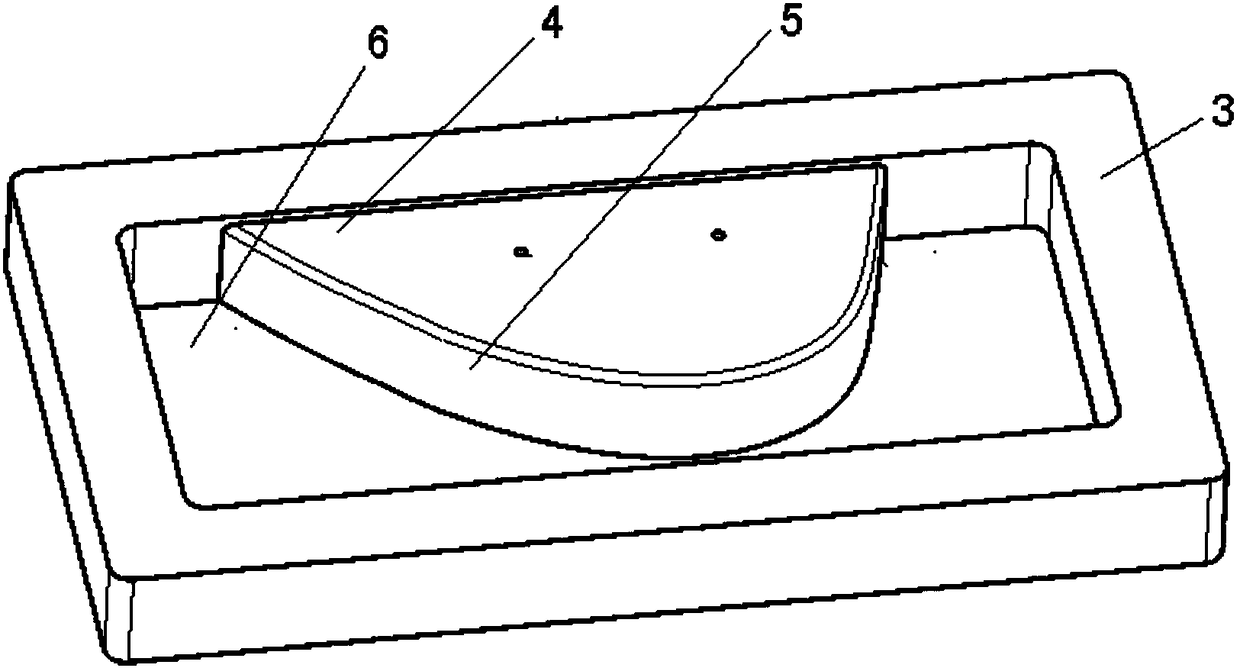

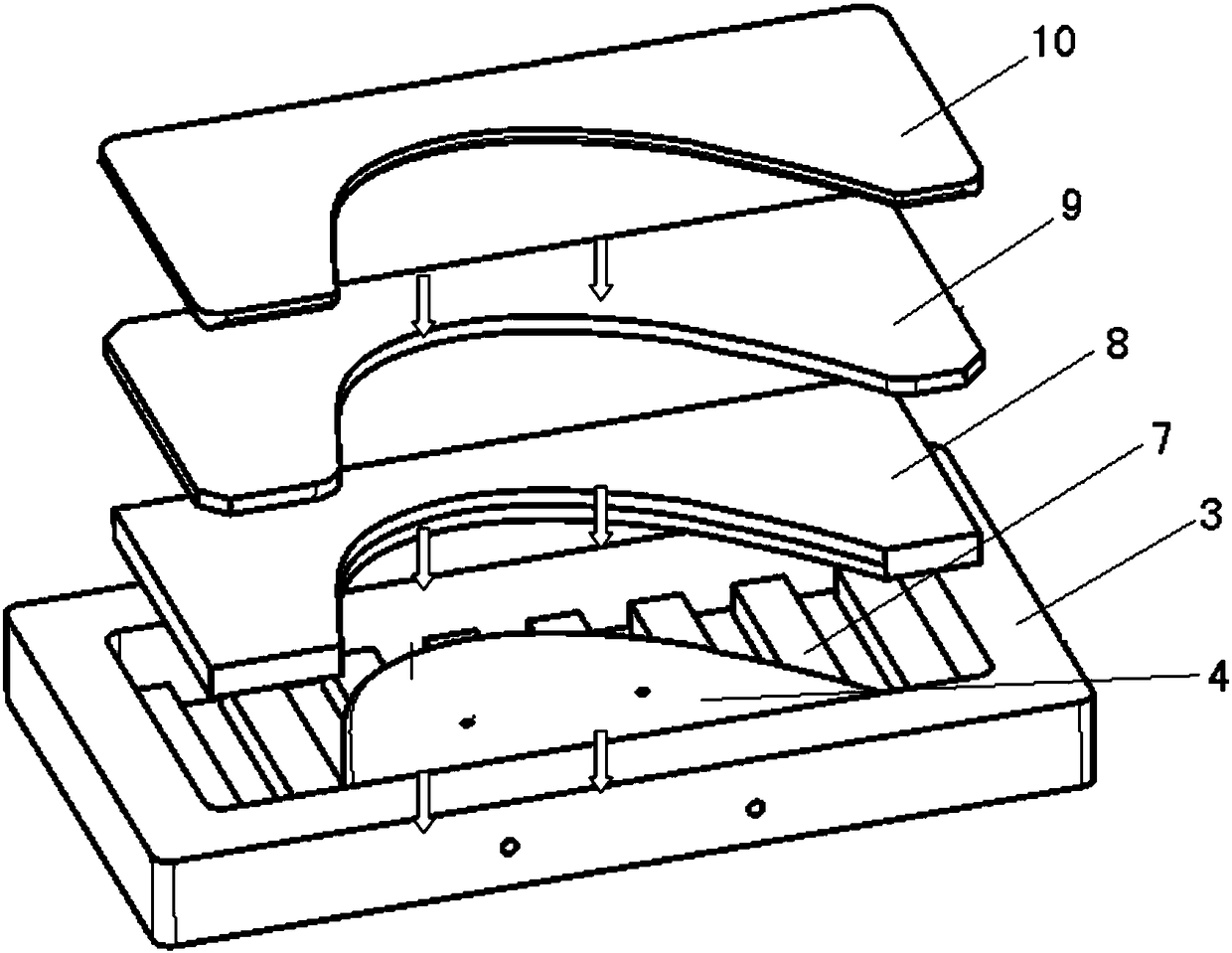

Rubber forming method and rubber forming mould of high-curvature high-flanging sheet metal part

ActiveCN106825096AThe operation method is simple and convenientStrong structural versatilityExtrusion diesRams/plungersEngineeringHydroforming

The invention discloses a rubber forming method and a rubber forming mould of a high-curvature high-flanging sheet metal part. The rubber forming mould comprises an accommodating box, a forming die, a pressing plate, a supporting plate and rubber pads, wherein the non-working surface on the inner side of the forming die is connected to the inner wall of one side of the accommodating box; a moulding cavity is formed between the working surface on the outer side of the forming die and the inner wall of the accommodating box; the outlines of the pressing plate and the supporting plate are smaller than the outline of the moulding cavity; the inner sides of the pressing plate and the supporting plate are matched with the working surface on the outer side of the forming die. The rubber forming method comprises the following steps: placing the accommodating box on a workbench of a hydraulic machine, placing a plurality of rubber pads with equal height inside the moulding cavity, and placing the supporting plate on the upper surfaces of the rubber pads so as to make the surface height of the supporting plate consistent with the height of the forming die; overlapping the pressing plate and the supporting plate, and clamping a flanging area of an unfolded blank; downwardly pressing the pressing plate by using hydraulic forming equipment, fitting the flanging area of the unfolded blank with the working mould surface of the forming die, and forming.

Owner:XIAN AIRCRAFT IND GROUP

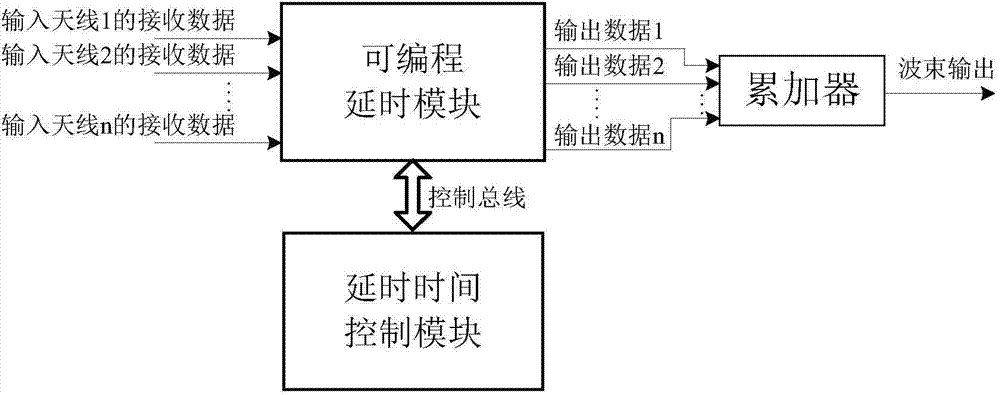

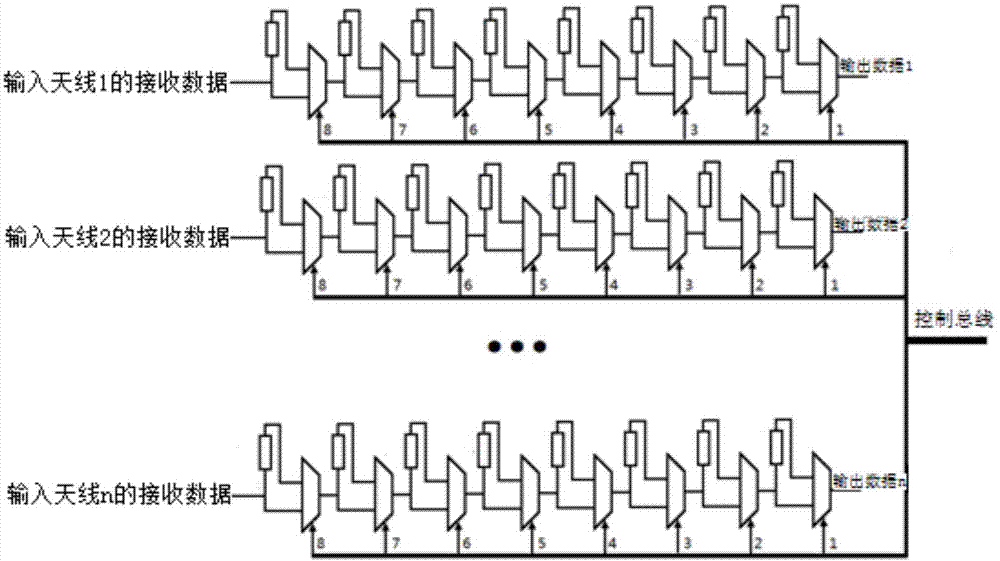

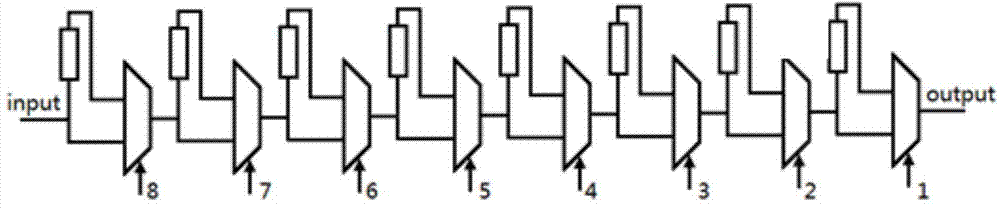

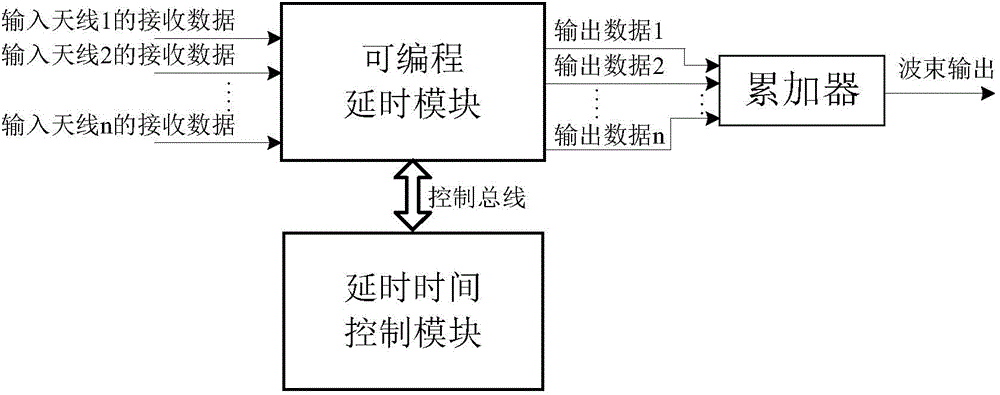

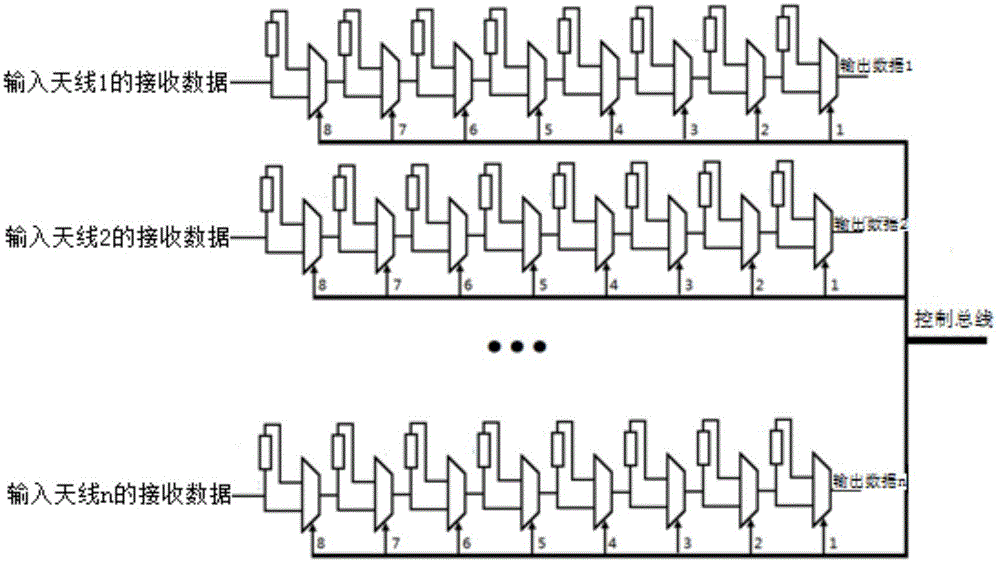

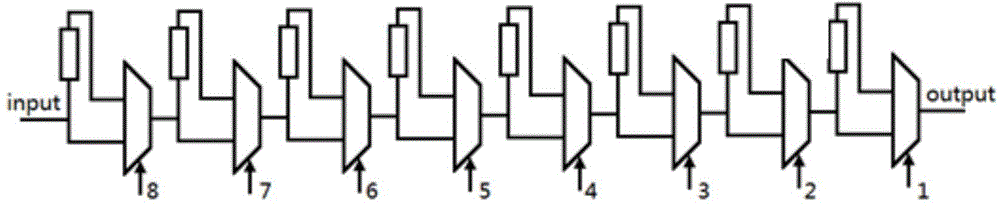

Digital beam forming device and method of programmable time delay circuit on basis of FPGA

ActiveCN103543440AAchieving Waveform Phase ShiftDelay time error is smallWave based measurement systemsWavefrontPhase shifted

The invention discloses a digital beam forming device and method of a programmable time delay circuit on the basis of an FPGA. The device comprises a programmable time delay module, a delay time control module and an accumulator. The delay time control module and the programmable time delay module are connected through a control bus, beams are output after an array antenna signal undergoes time delay through the programmable time delay module and is accumulated through the accumulator, the programmable time delay module is formed through parallel connection of programmable time delay units, each programmable time delay unit is formed through sequential serial connection of an either-or selector and a longitudinal time delay unit, each longitudinal time delay unit is formed through cascade connection of a plurality of basic time delay units, and the programmable time delay module is obtained by programmable constraint in a lookup table in the FPGA. According to the device and method, precise time delay can be carried out on the array antenna signal, waveform phase shift is achieved, signals of paths are compensated to wavefront alignment, and then the accumulator is used for accumulating signals after phase shift so as to achieve the aim that digital beams are formed without the need of a multiplier, and time delay can be accurate to a nanosecond level.

Owner:NANJING UNIV OF SCI & TECH

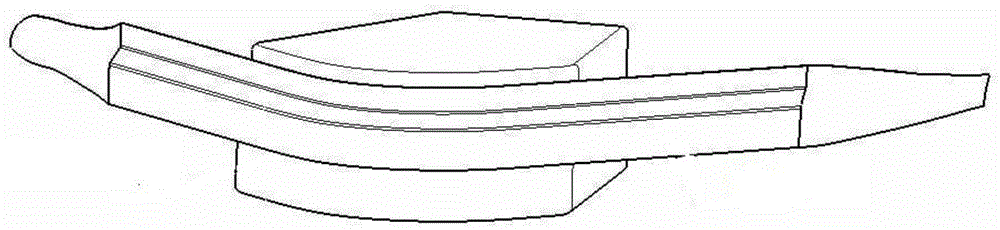

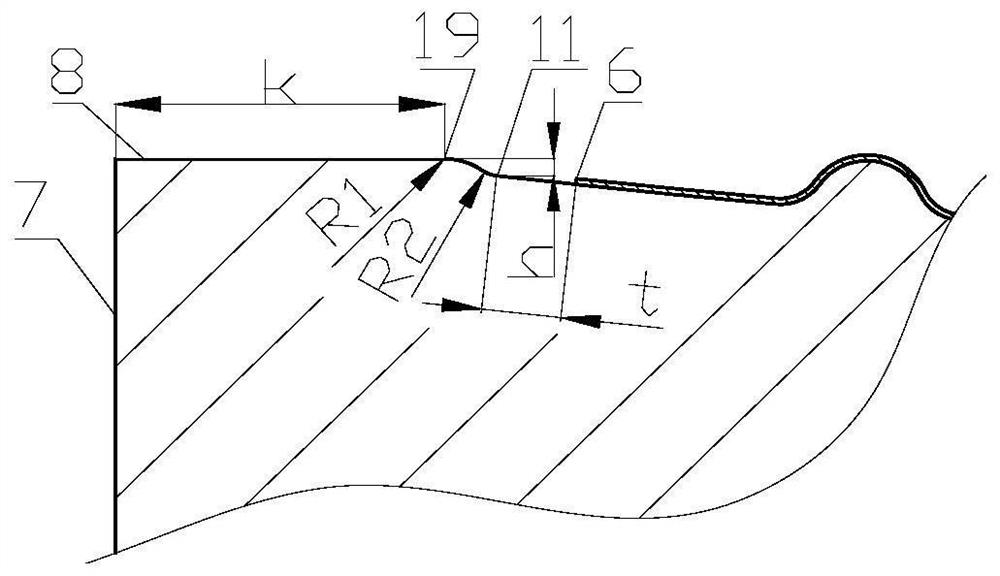

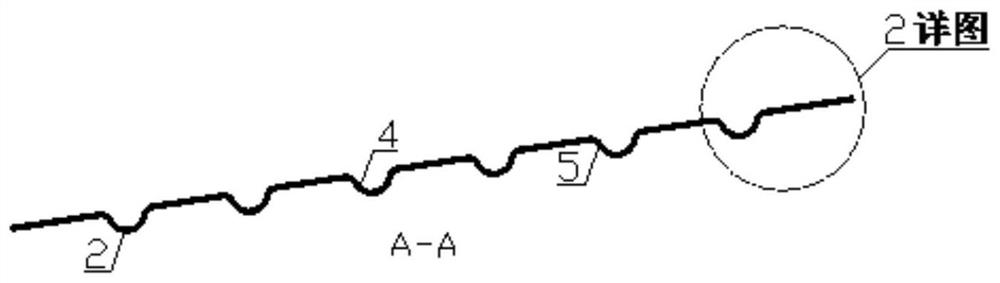

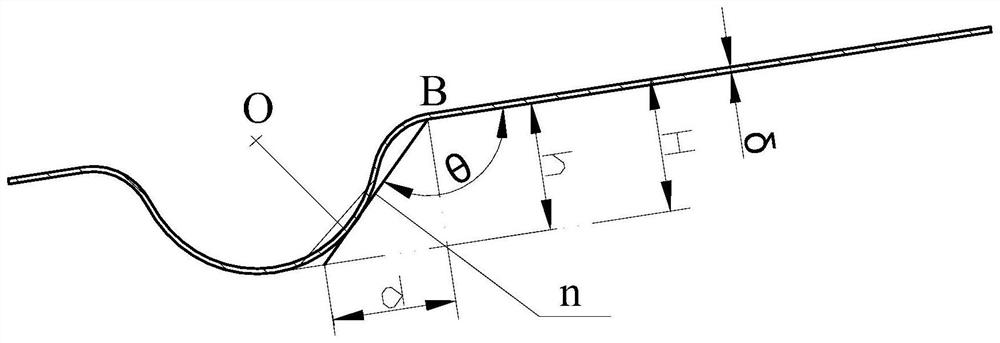

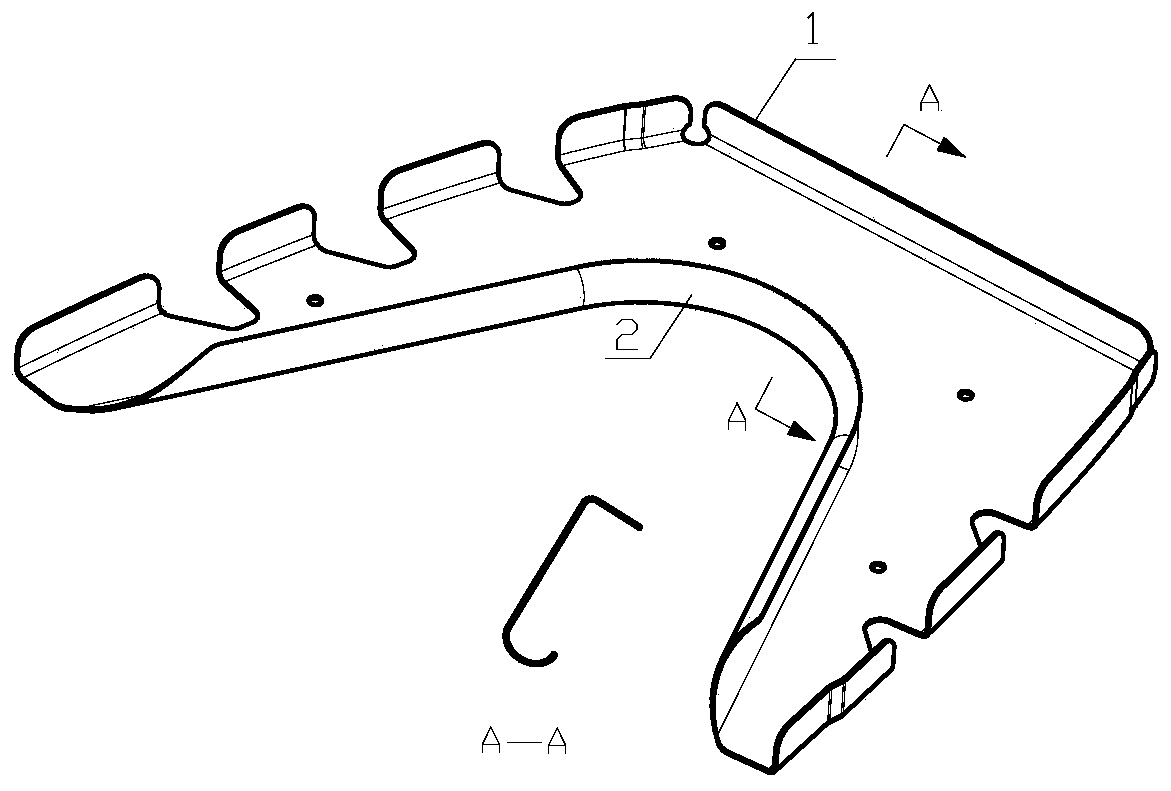

Accurate forming method for large-curvature and high-order-difference edge sealing frame

ActiveCN106825307AAchieve precise formingHigh profile precisionMetal-working apparatusEngineeringBend radius

The invention provides an accurate forming method for a large-curvature and high-order-difference edge sealing frame. The accurate forming method is characterized by comprising the following steps that a rectangular blank is blanked, the margin of 15 mm is added to each of the two edges, in the width direction, of the blank on the basis that the part is expanded in the width direction, the length between a die to a transition section of a stretch bending equipment jaw and the length between the die and a clamping section of the stretch bending equipment jaw are added to the blank length during stretch bending forming on the basis of the length of the stretch bending forming die; trichloro ethylene vapor degreasing is conducted on the blank, the surface of a part is cleaned, burrs on the edge of the blank are removed, and an end face is sanded through abrasive paper; and a bending forming machine is used for conducting pre-forming on the blank, the order difference, the bending radius and the angle of the blank are completely the same with those of the part, the blank is pre-bent to form a ruled-surface transition part with a 45-degree Z-shaped section, the two ends of the blank are flattened to have the clamping width of the stretch bending forming machine jaw, and therefore clamping is facilitated.

Owner:HARBIN

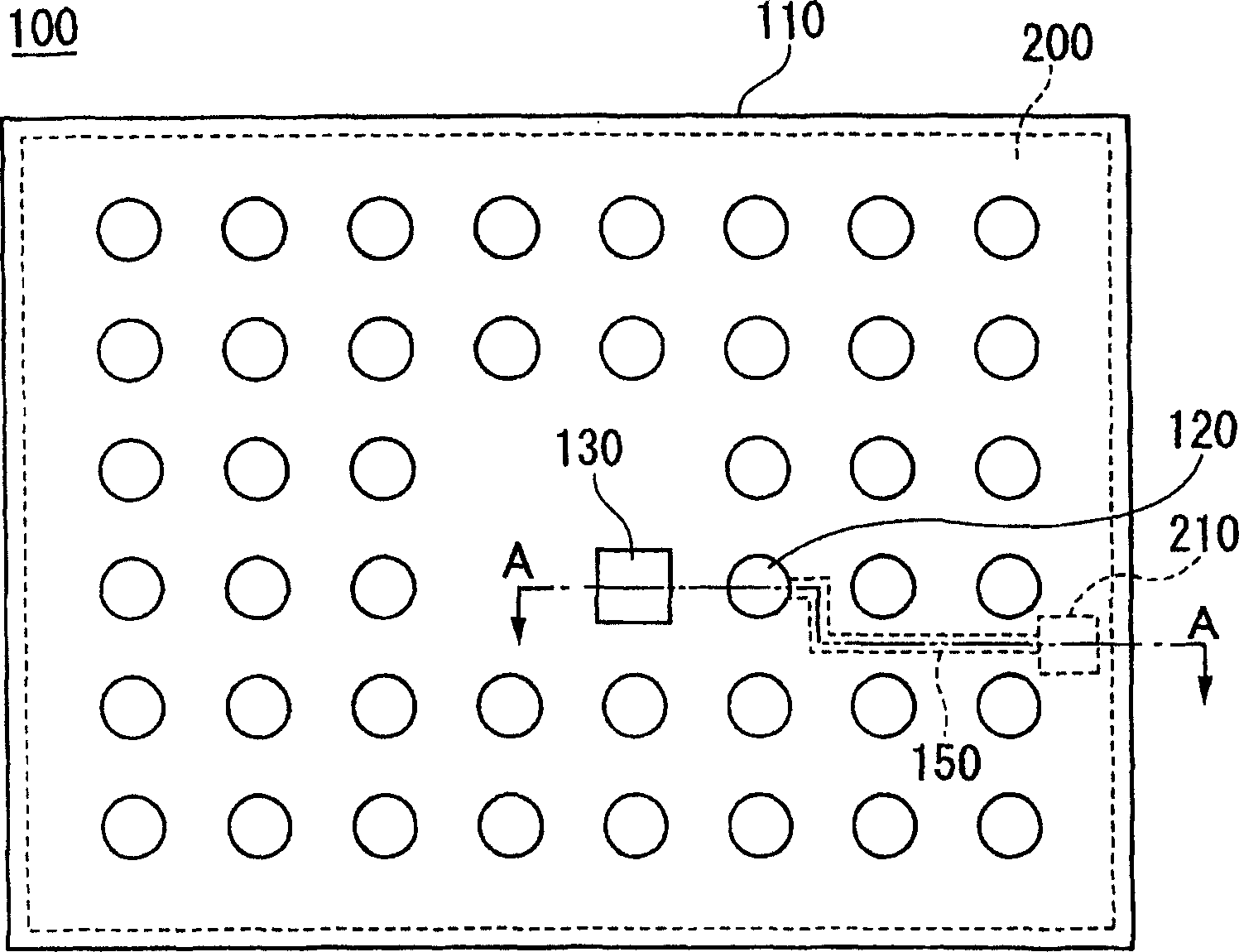

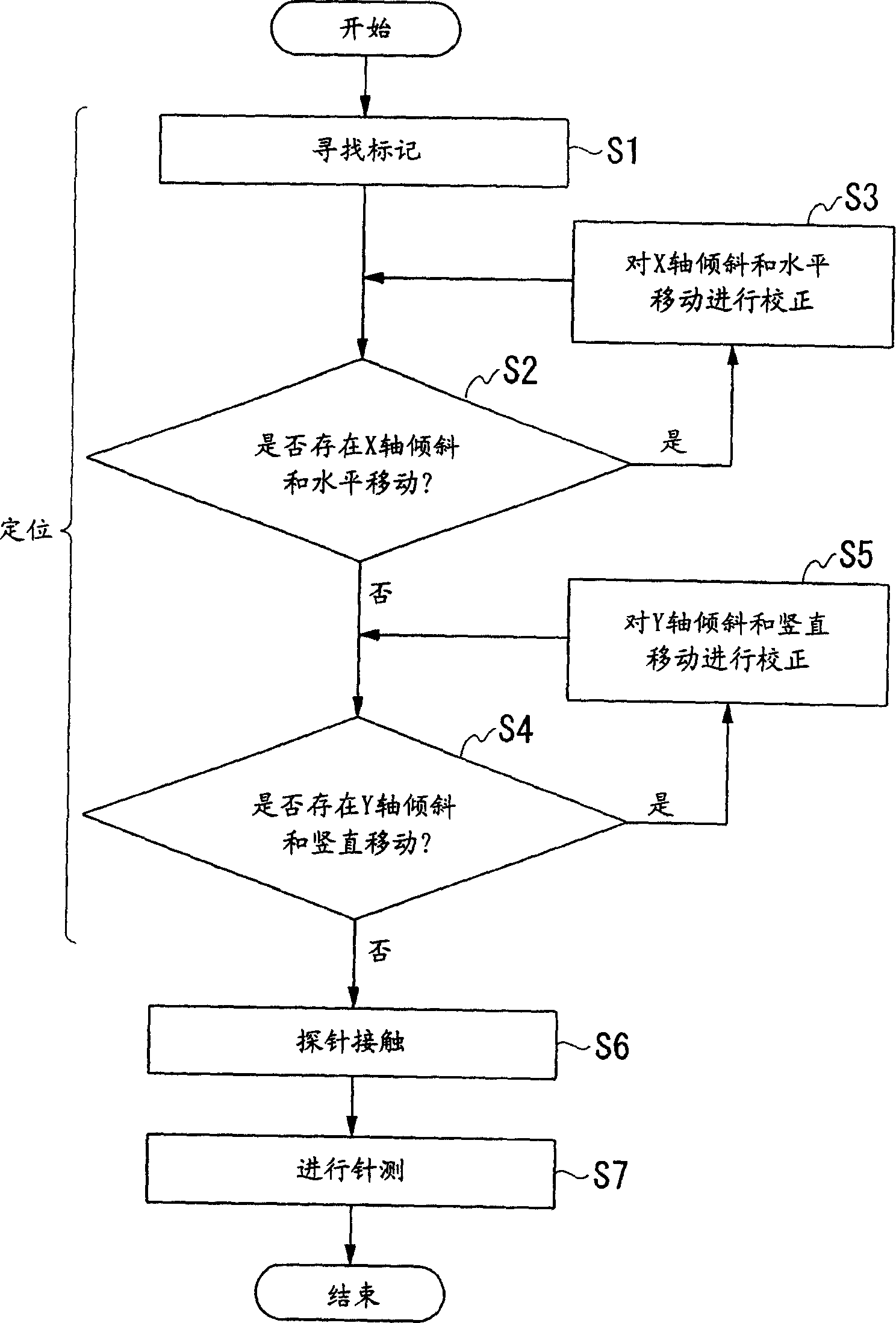

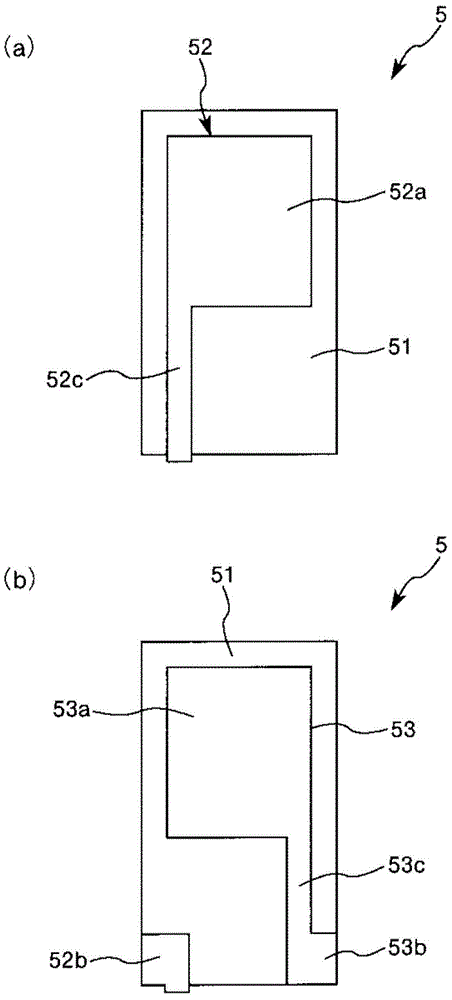

Surface installation chip package

InactiveCN1510388AImprove forming accuracyPrevent oxidationSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectrical conductorSurface mounting

A surface mount chip package comprises a package housing made of a prescribed resin, which is formed to cover a semiconductor chip while avoiding a plurality of conductors extending from the semiconductor chip. A plurality of solder balls are arranged in the package housing in correspondence with a main surface of the semiconductor chip having an integrated circuit and are interconnected with the conductors respectively. An index serving as a marking member is arranged together with the solder balls so as to bring a directivity realized by the shape thereof when viewed in the thickness direction of the semiconductor chip. This allows a user to easily recognize the inclination and position of the package housing without using the solder balls in view of the index, thus establishing a prescribed positioning for an electrical test such as a probing test.

Owner:YAMAHA CORP

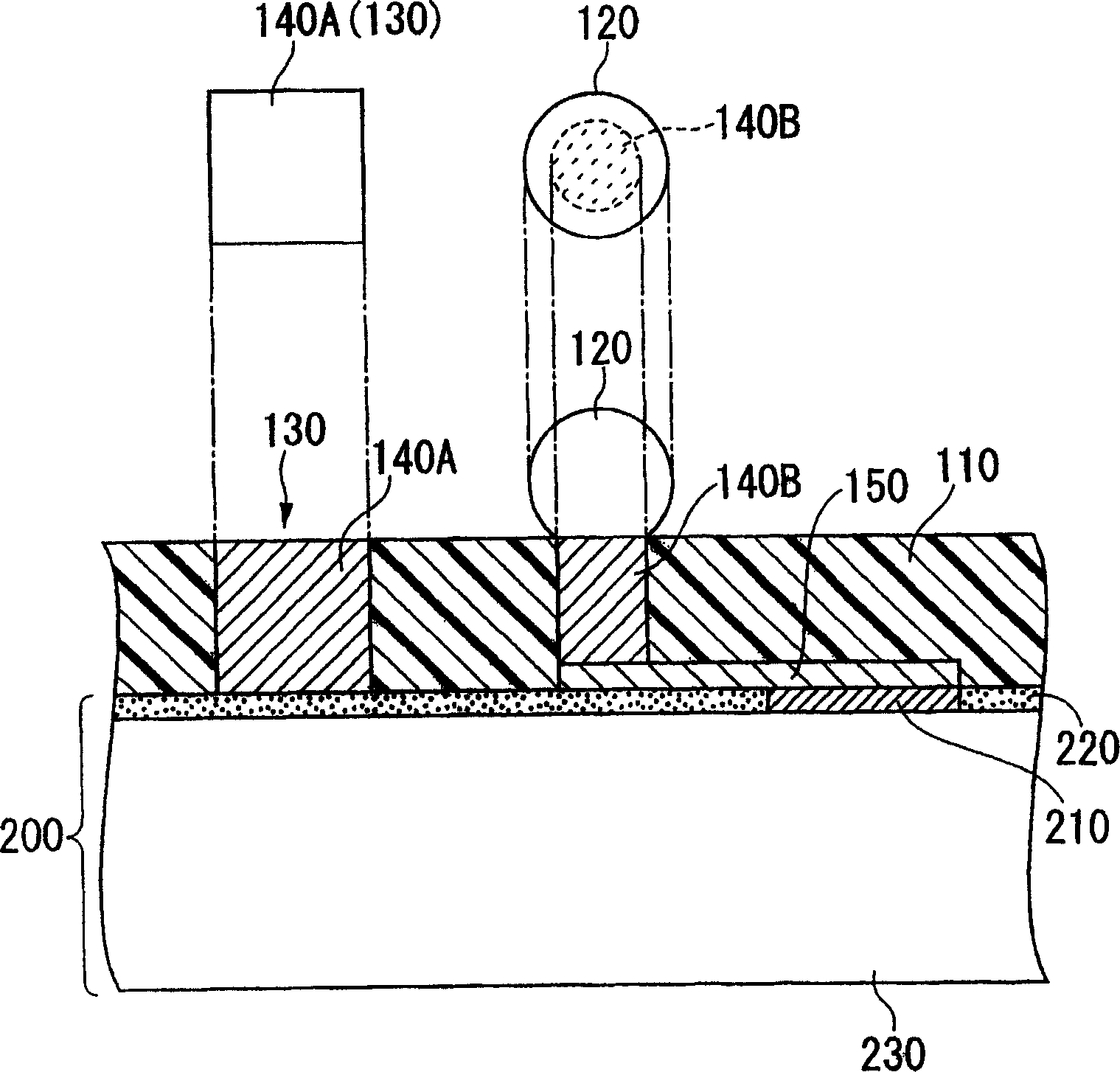

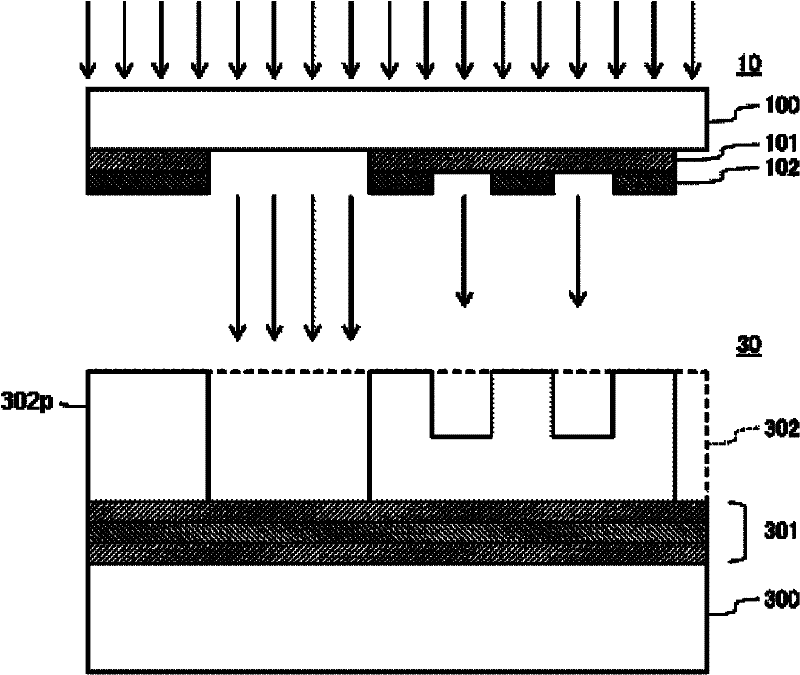

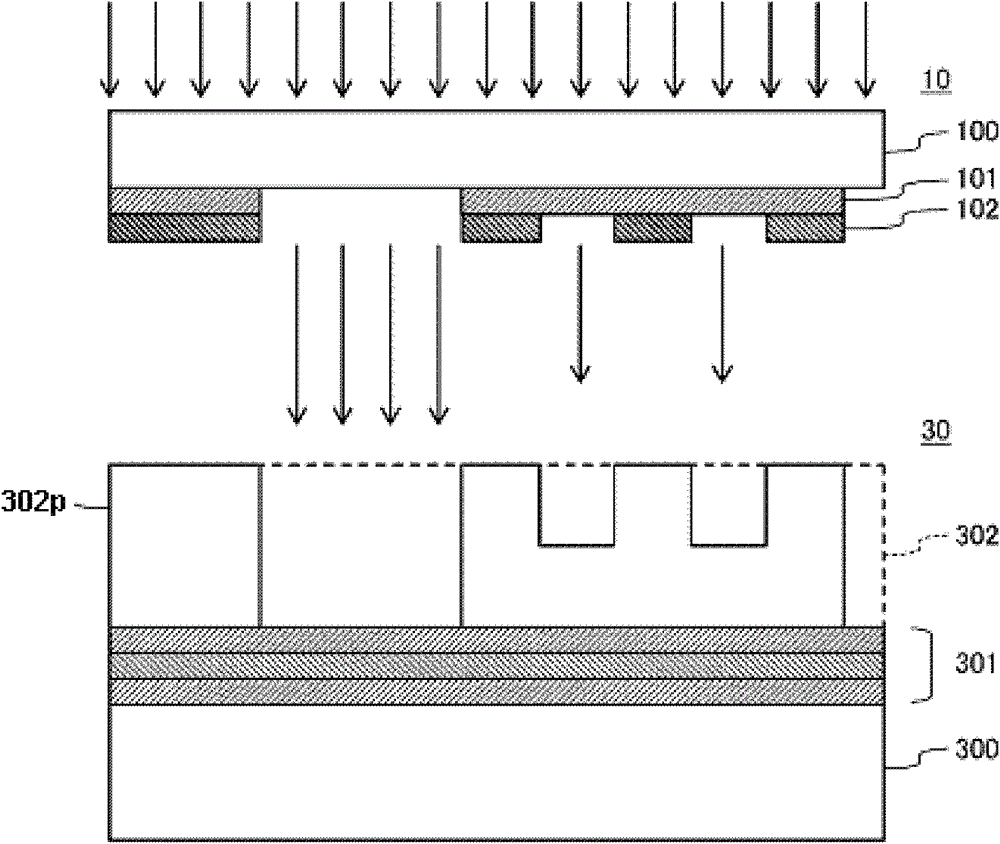

Substrate for electronic device package, electronic device package, electronic device, and method of manufacturing electronic device

InactiveCN105322909AImprove forming accuracyImpedence networksSemiconductor/solid-state device detailsPhysicsElectrical and Electronics engineering

Owner:SEIKO EPSON CORP

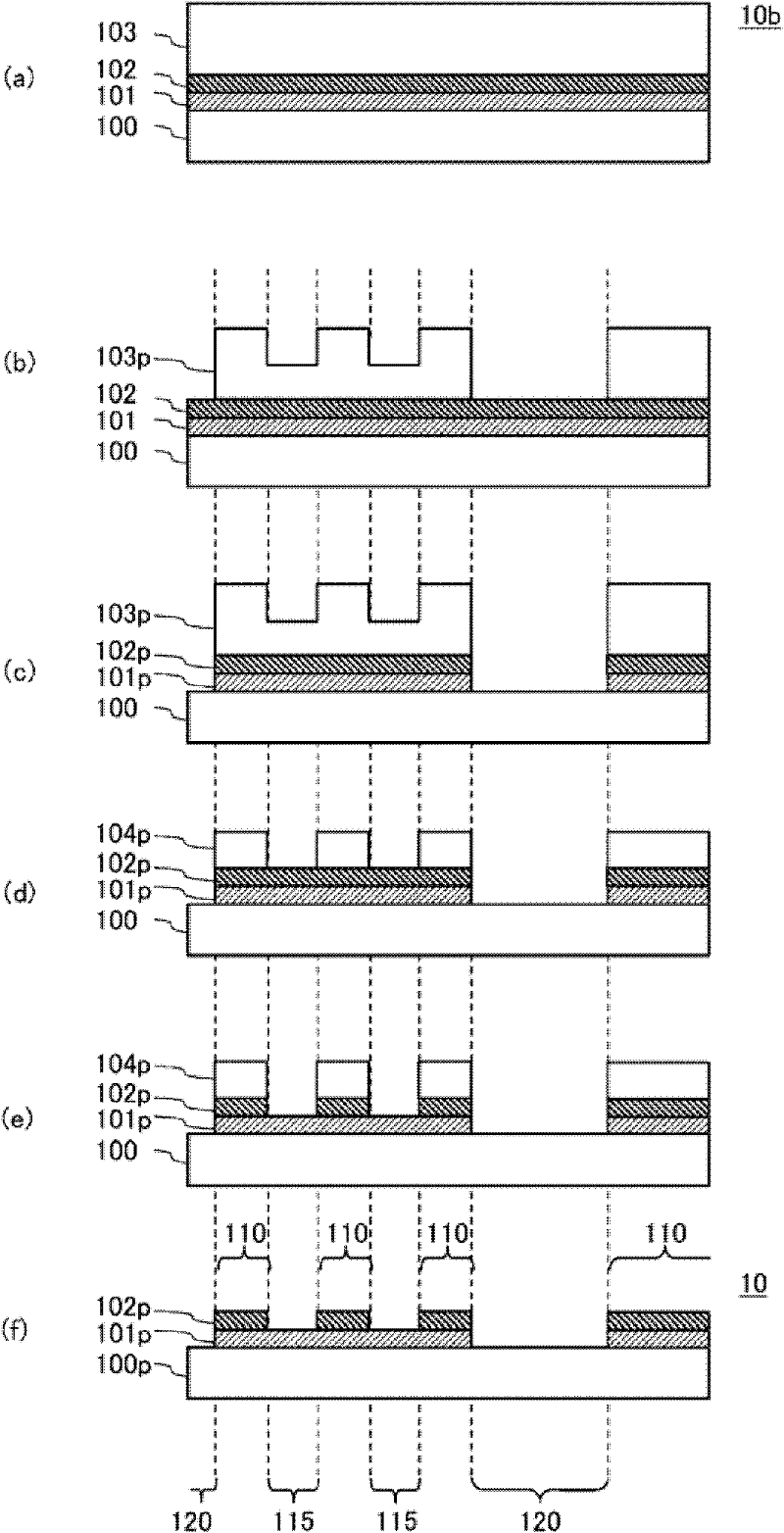

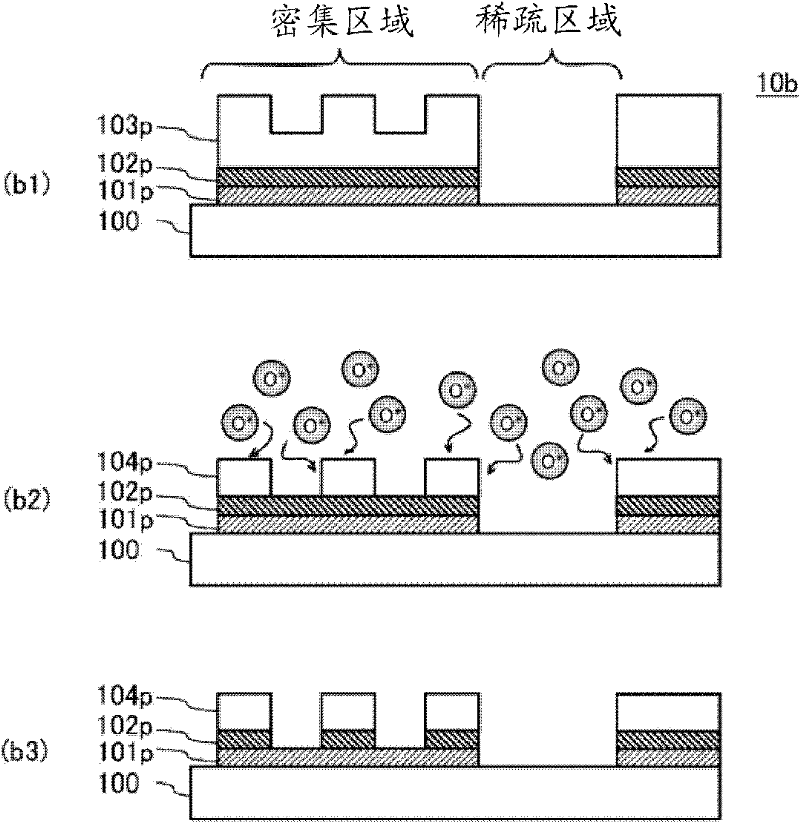

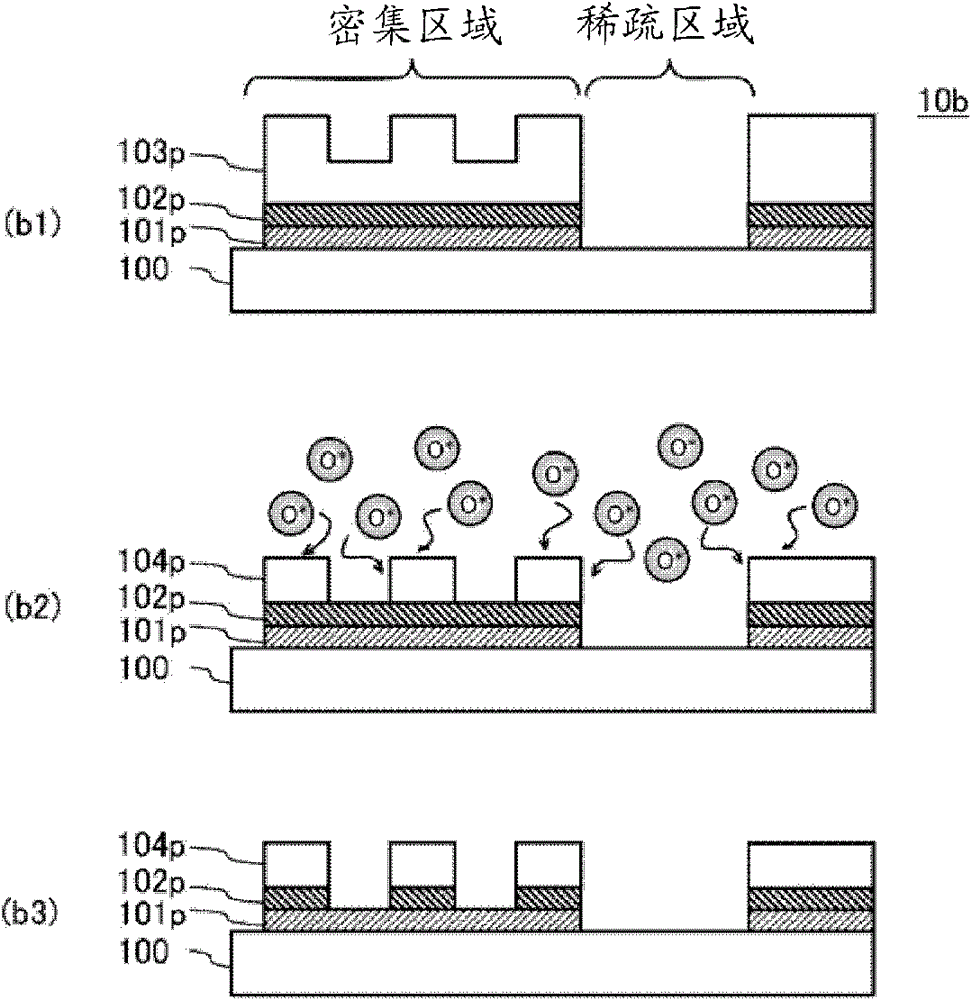

Method for producing multi-color photomask and method for pattern transfer

ActiveCN102262353AImprove in-plane uniformityImprove forming accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistEngineering

A manufacturing method of multicolour dimming mask and a pattern transfer method provided by the invention can reduce drawing and developing times by using membrane reduction of anti-corrosion patterns, and can improve inplane uniformity of membrane reduction speed of the anti-corrosion patterns between a dense part and a sparse part. The manufacturing method comprises steps of: forming a first anti-corrosion pattern, wherein the first anti-corrosion pattern covers a formation region of a shading portion and a formation region of a half-transmitting portion, and thickness of a resist film of the formation region of the half-transmitting portion is smaller than that of a resist film of the formation region of the shading portion, and feeding ozone to the first anti-corrosion pattern, wherein the feeding method is as follows: active oxygen per unit area provided to the first anti-corrosion pattern is larger than active oxygen per unit area consumed by membrane reduction conducted on thefirst anti-corrosion pattern.

Owner:HOYA CORP

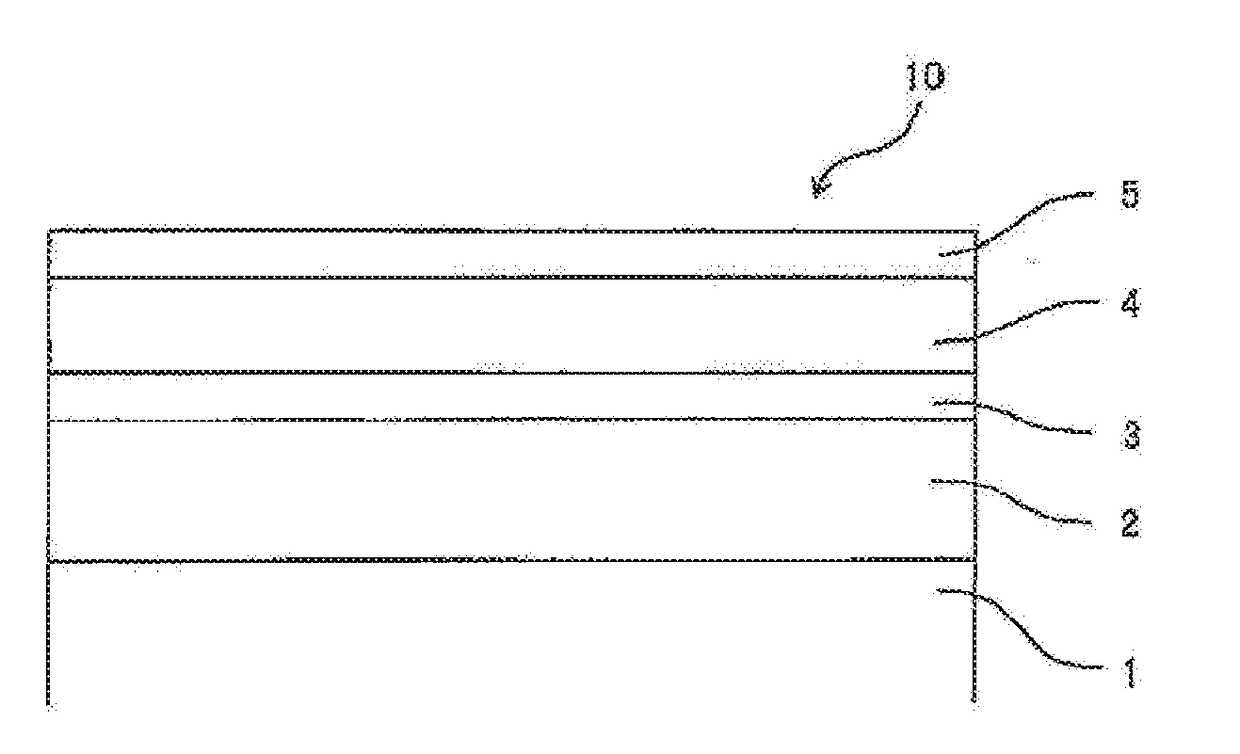

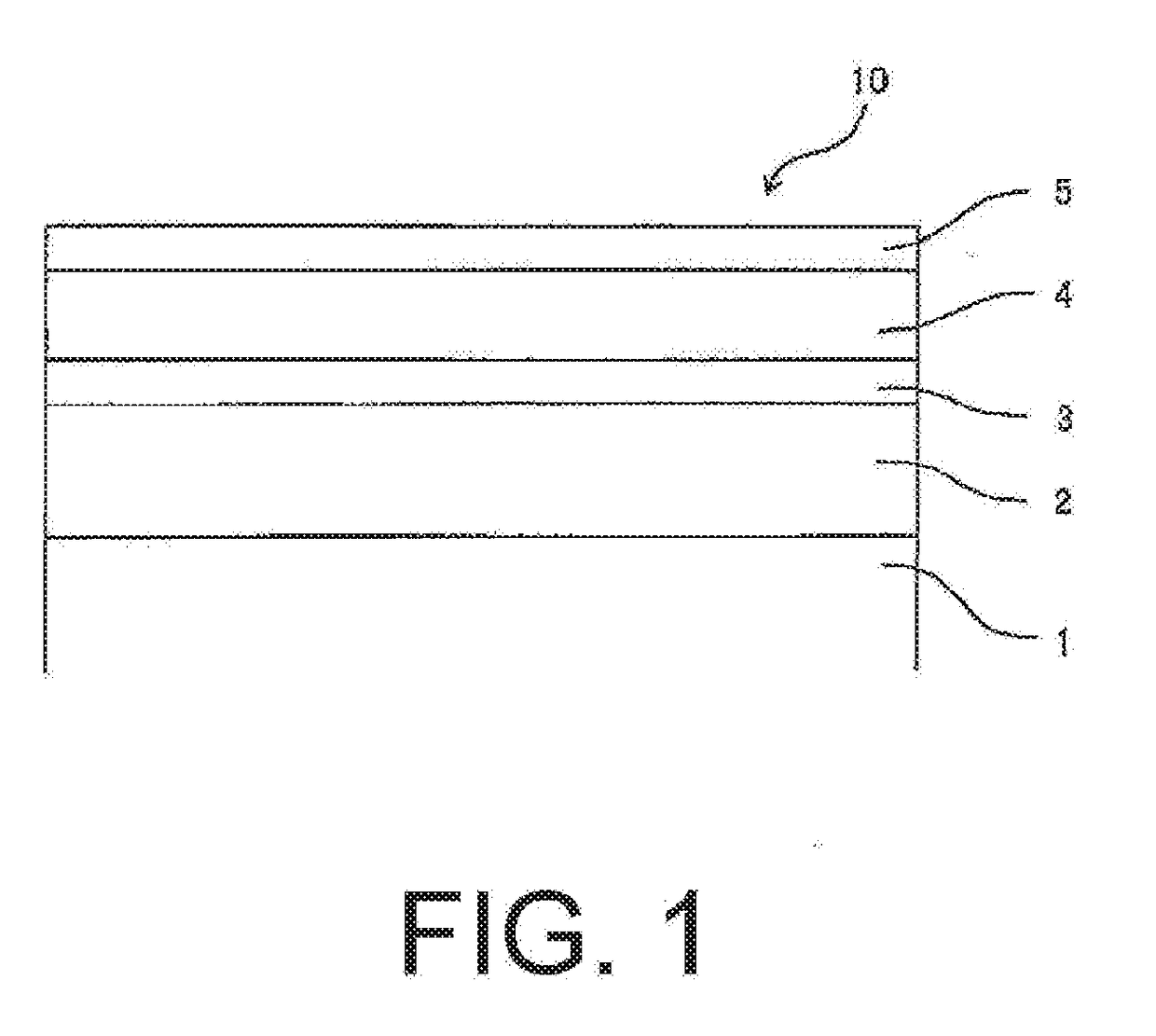

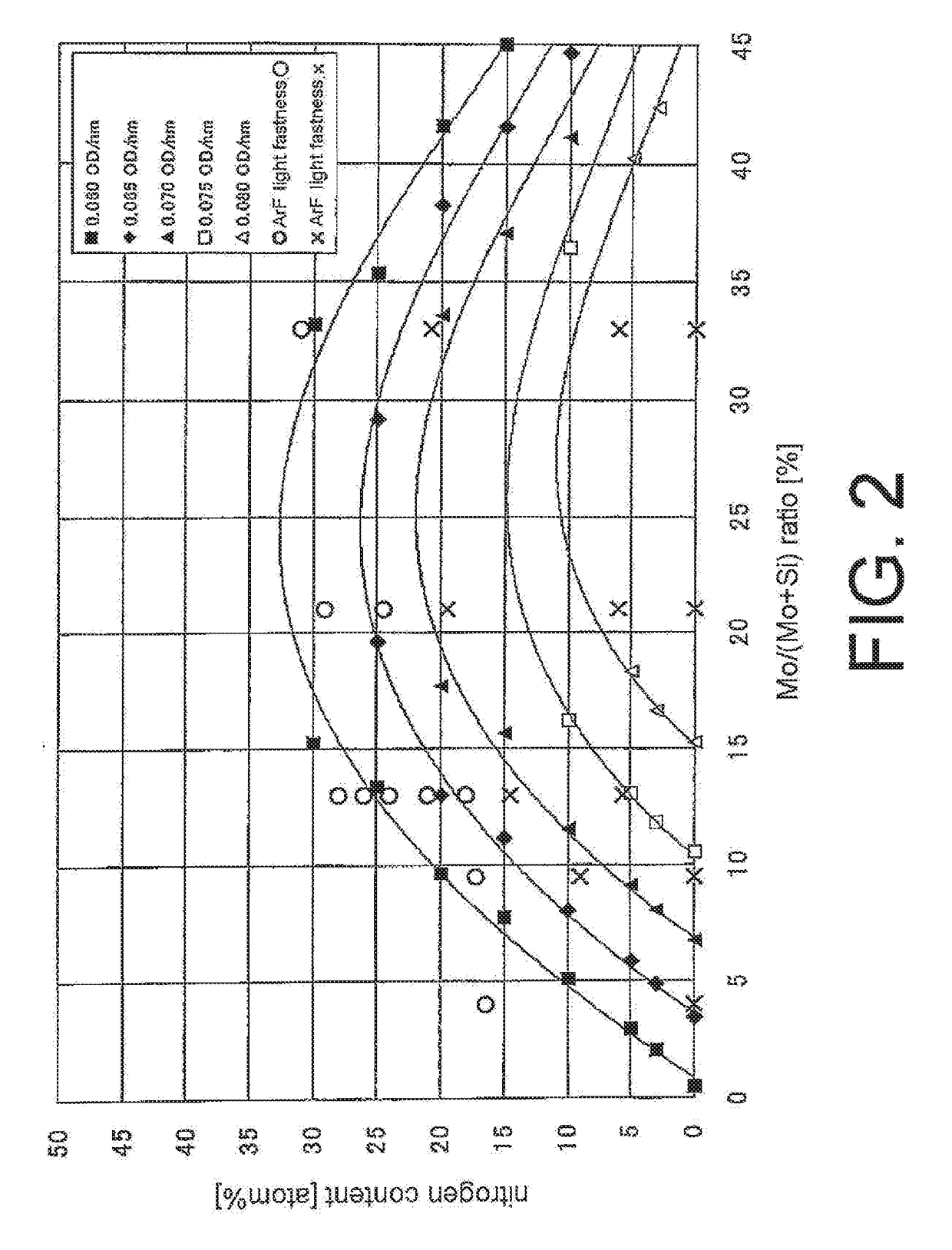

Mask blank, phase shift mask and method for manufacturing semiconductor device

ActiveUS20180252995A1Reduce thicknessImprove accuracyPhotomechanical apparatusSemiconductor/solid-state device manufacturingPhase shiftedSurface layer

According to the present invention, provided is a mask blank (10), in which; a light shielding film (4) has a single layer structure or a laminate structure of a plurality of layers; at least one layer of the light shielding film (4) is formed of a material which contains a transition metal and silicon and is free from nitrogen and oxygen, or a material which contains a transition metal, silicon, and nitrogen and satisfies a condition of the following expression (1); a phase shift film (2) has a surface layer and a layer other than the surface layer; and the layer other than the surface layer is formed of a material which contains a transition metal, silicon, nitrogen, and oxygen, has a content of oxygen of 3 atom % or more, and satisfies a condition of the following expression (A).CN≤9.0×10−6×RM4−1.65×10−4×RM3−7.718×10−2×RM2+3.611×RM−21.084 Expression (1)0.04×AS−0.06×AM>1 Expression (A)

Owner:HOYA CORP

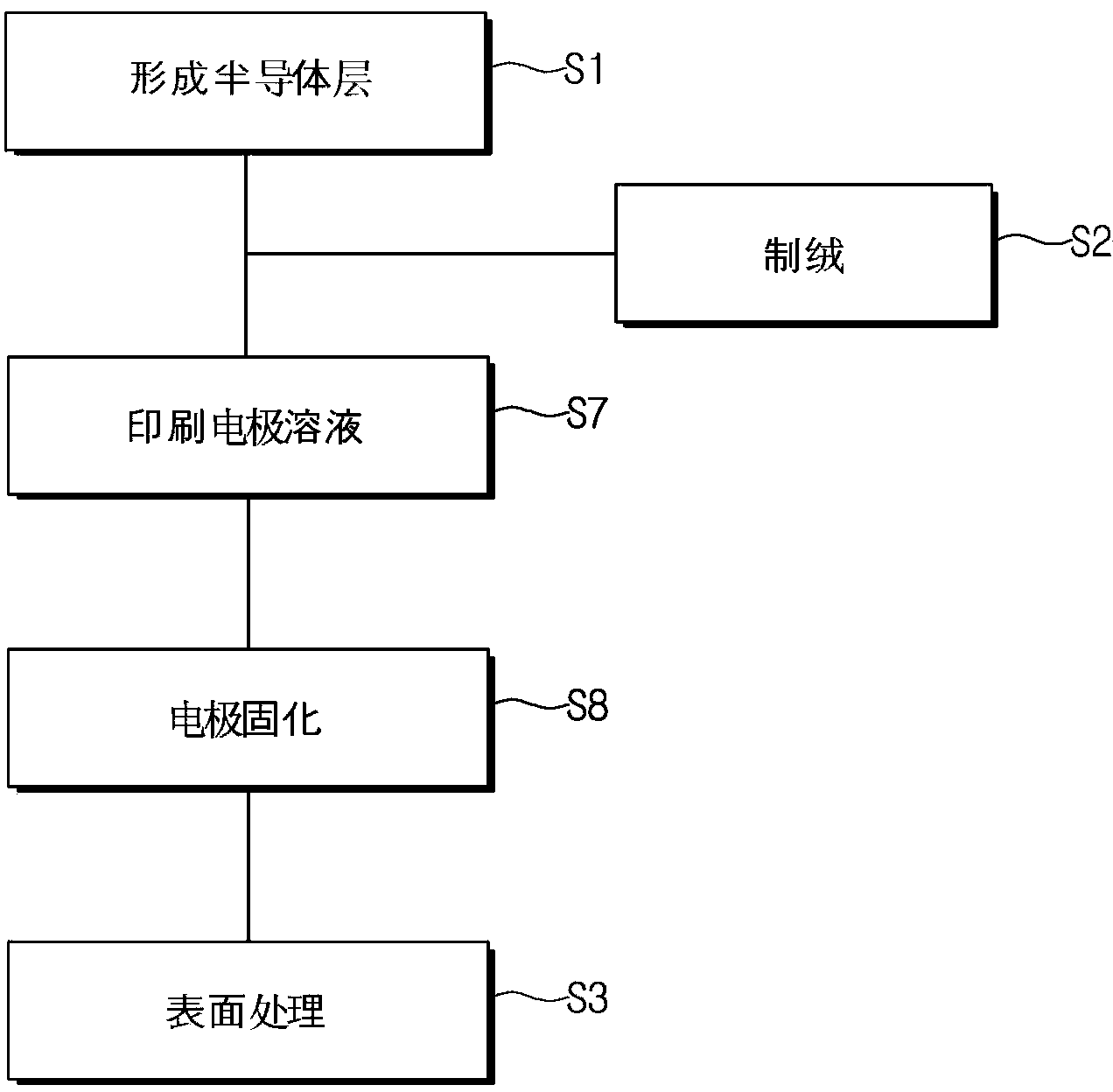

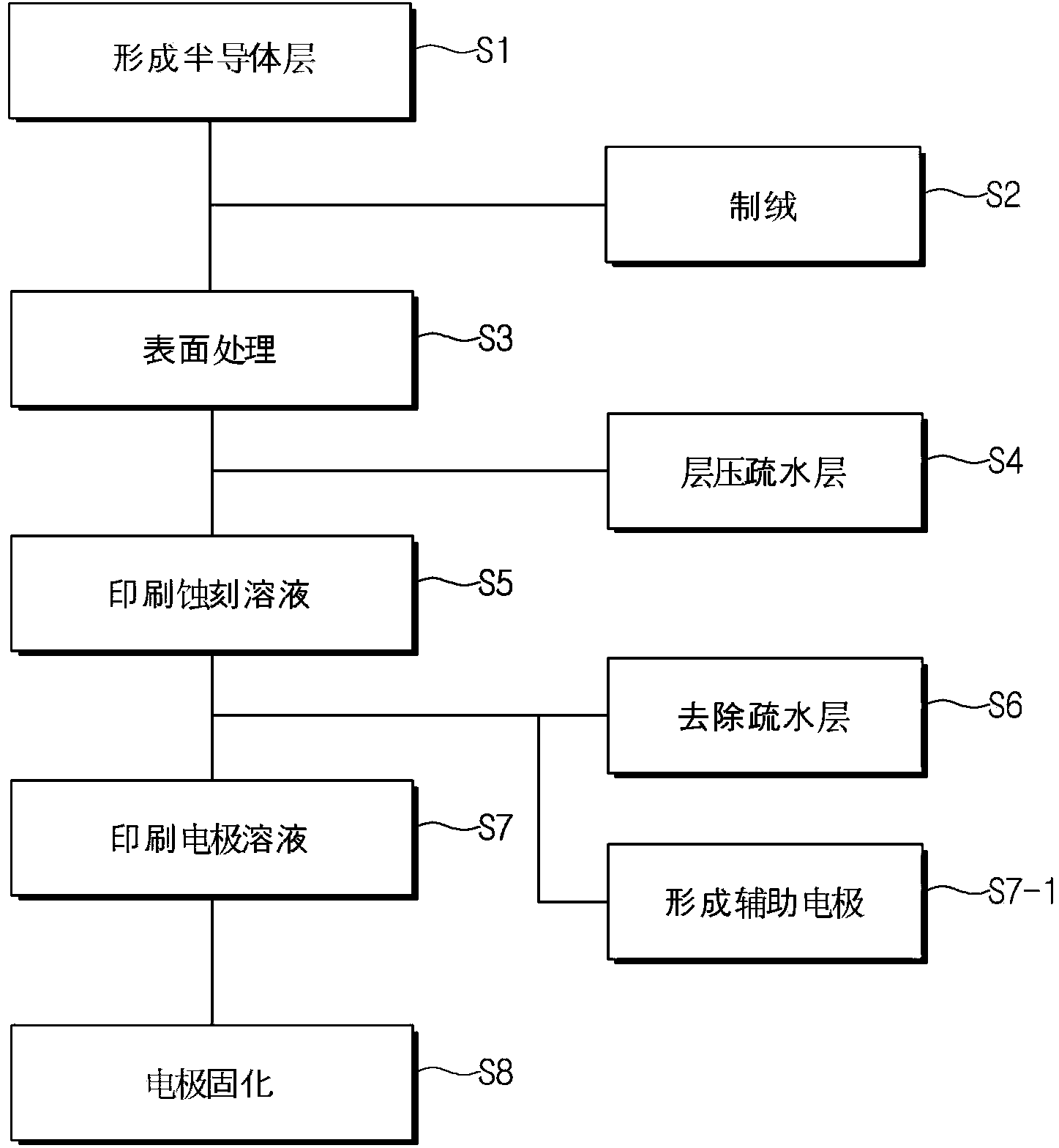

Method for forming front electrode of solar cell

InactiveCN103493221AReduce electrode widthIncrease the amount of lightDuplicating/marking methodsOther printing apparatusElectrical batterySolar cell

The method for forming a front electrode of a solar cell according to the present invention relates to a process whereby a front electrode is formed on the surface of a semiconductor layer of a solar cell. The method for forming a front electrode on the front surface of the semiconductor layer of a solar cell, comprises the steps of: printing an electrode solution on the front surface of the semiconductor layer for forming the electrode; and hardening said electrode solution such that said electrode solution printed on said semiconductor layer by said electrode-forming step configures said front electrode. Said electrode solution is formed by mixing a bonding agent for bonding said semiconductor layer and said metal, and the metal for forming said front electrode. Said electrode-forming step provides an electric charge to said electrode solution by means of the electric energy applied by one or more electrohydrodynamic (EHD) inkjet printing operations, and discharges said electrically-charged electrode solution from a nozzle by means of an electrostatic force.

Owner:NJETTE

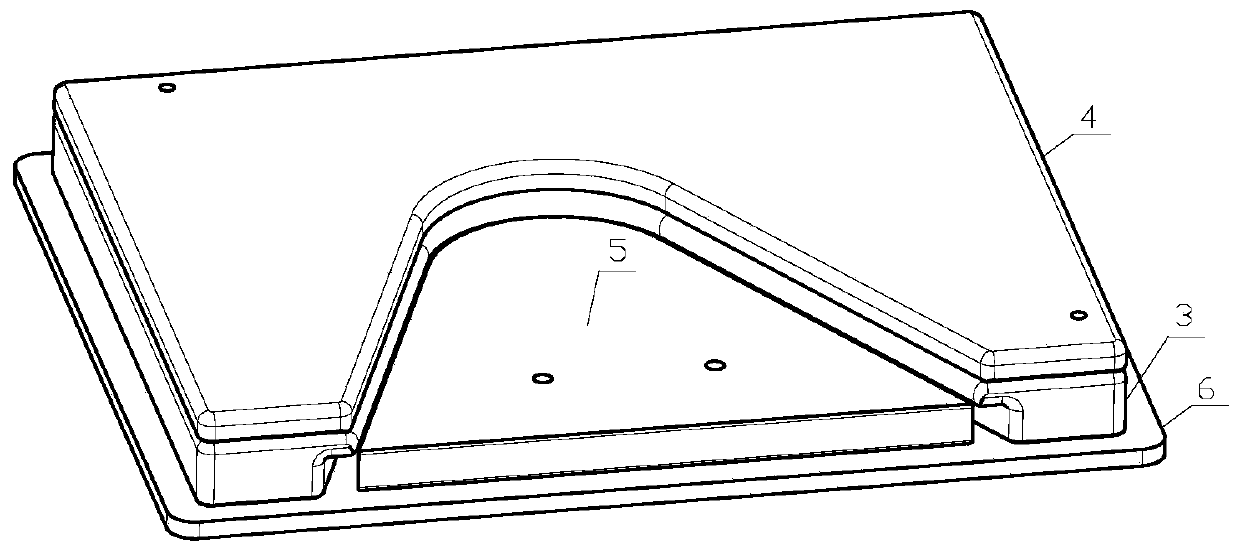

Liquid filling forming method for large-arch-height multi-cavity thin-wall opening inner skin

ActiveCN113385605AImprove unidirectional tensile deformation defectsSolve the problem of forming crackingAircraft componentsMechanical engineeringMaterial Deformation

The invention provides a liquid filling forming method for a large-arch-height multi-cavity thin-wall opening inner skin. The liquid filling forming method comprises the following steps that a liquid filling forming mold of an inner skin part is manufactured; an unfolded blank manufactured; liquid filling bulging for the first time is performed; secondary liquid filling bulging is performed; and the appearance is trimmed. A transition forming part is constructed, barbell type internal holes are designed, dangerous deformation areas prone to tearing are avoided, and the hole forming quality in the bulging pressure applying process is guaranteed. A sealing liquid chamber is created by additionally arranging the high-elastic-grade thin rubber pad, and the problem that the inner skin of the deep rib is cracked during forming is solved. The two-pass liquid-filling bulging process is designed, the material deformation limit of a conventional aluminum alloy sheet is improved, the monopoly situation that the large-arch height strengthened inner skin is pressed and formed for a long time is broken, dependence on manual operation skills is reduced, and the production efficiency and the product quality are improved.

Owner:XI'AN AIRCRAFT INTERNATIONAL

Production process of automobile thermal-formed structural component

ActiveCN108889819AGood forming accuracyGuaranteed mechanical strengthVehicle componentsRoom temperatureEngineering

The invention provides a production process of an automobile thermal-formed structural component. The production process comprises the following steps of 1) stamping coiled raw materials for thermal forming into a desired outer contour blank; 2) conducting heating and heat preservation operation on the blank, then reducing the temperature at the cooling speed of 15-25 DEG C / s, drawing a partitionline in the middle of the bland after temperature reduction, immersing the portion, at one side of the partition line, of the blank into an ethanol solution of magnesium silicate for standing, and then putting the blank into a heating furnace for complete austenitizing; 3) taking the blank treated in step 2 out of the heating furnace, quickly putting the blank into a thermal forming die, conducting high-temperature stamping formation on a steel blank, and then conducting pressure preservation for 5-10 s; 4) cooling the blank in the die to the room temperature at the cooling speed of 32-35 DEGC / s; 5) taking out a formed piece, and then conducting subsequent processing to obtain the automobile thermal-formed structural component. By means of the process, the yield of finished products whencomponents in complex shapes are manufactured by ultra-high-strength steel plates can be increased. Meanwhile, the invention further provides a production method of thermal-formed automobile components with different strengths.

Owner:成都华翔汽车金属部件有限公司

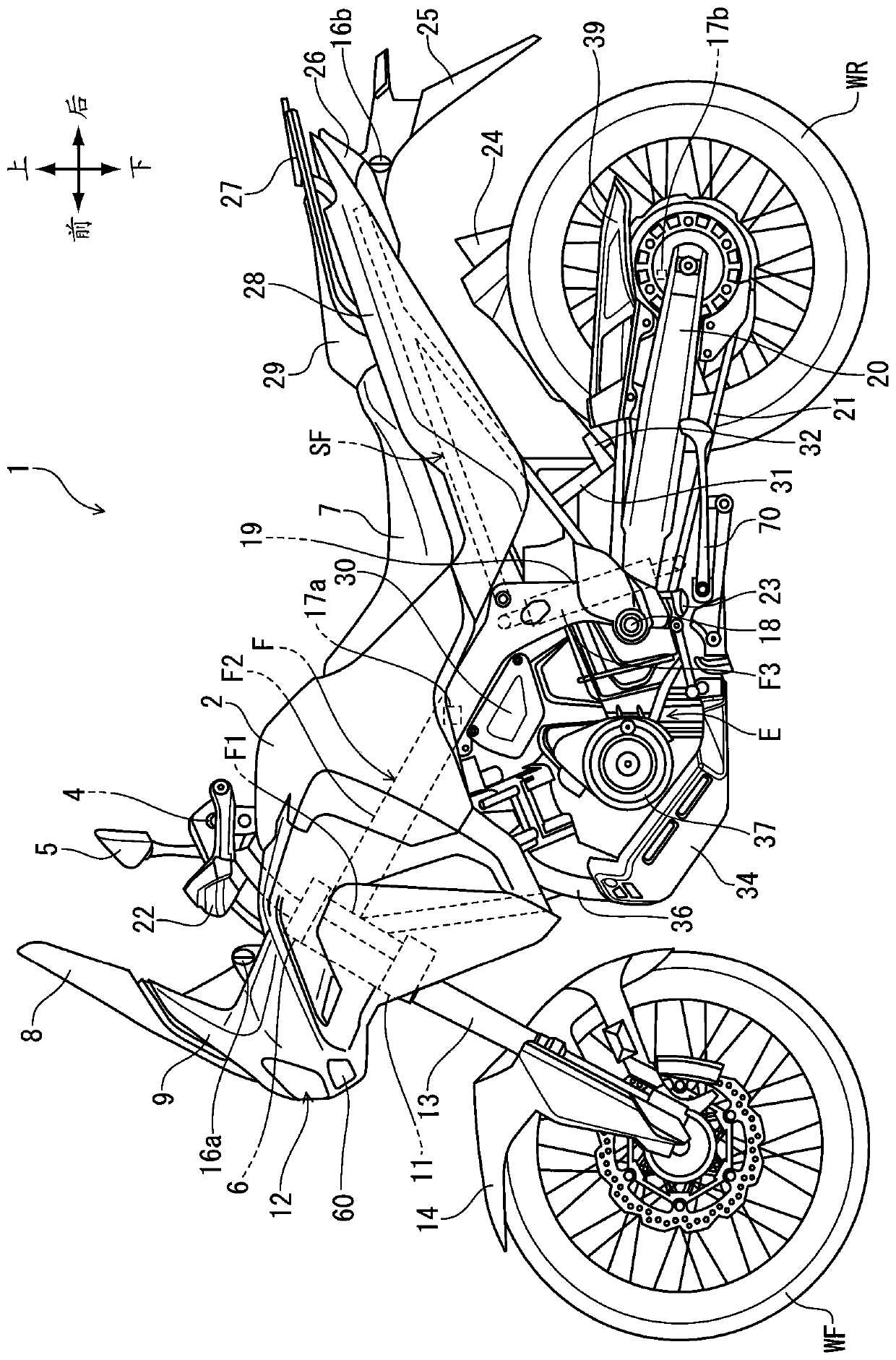

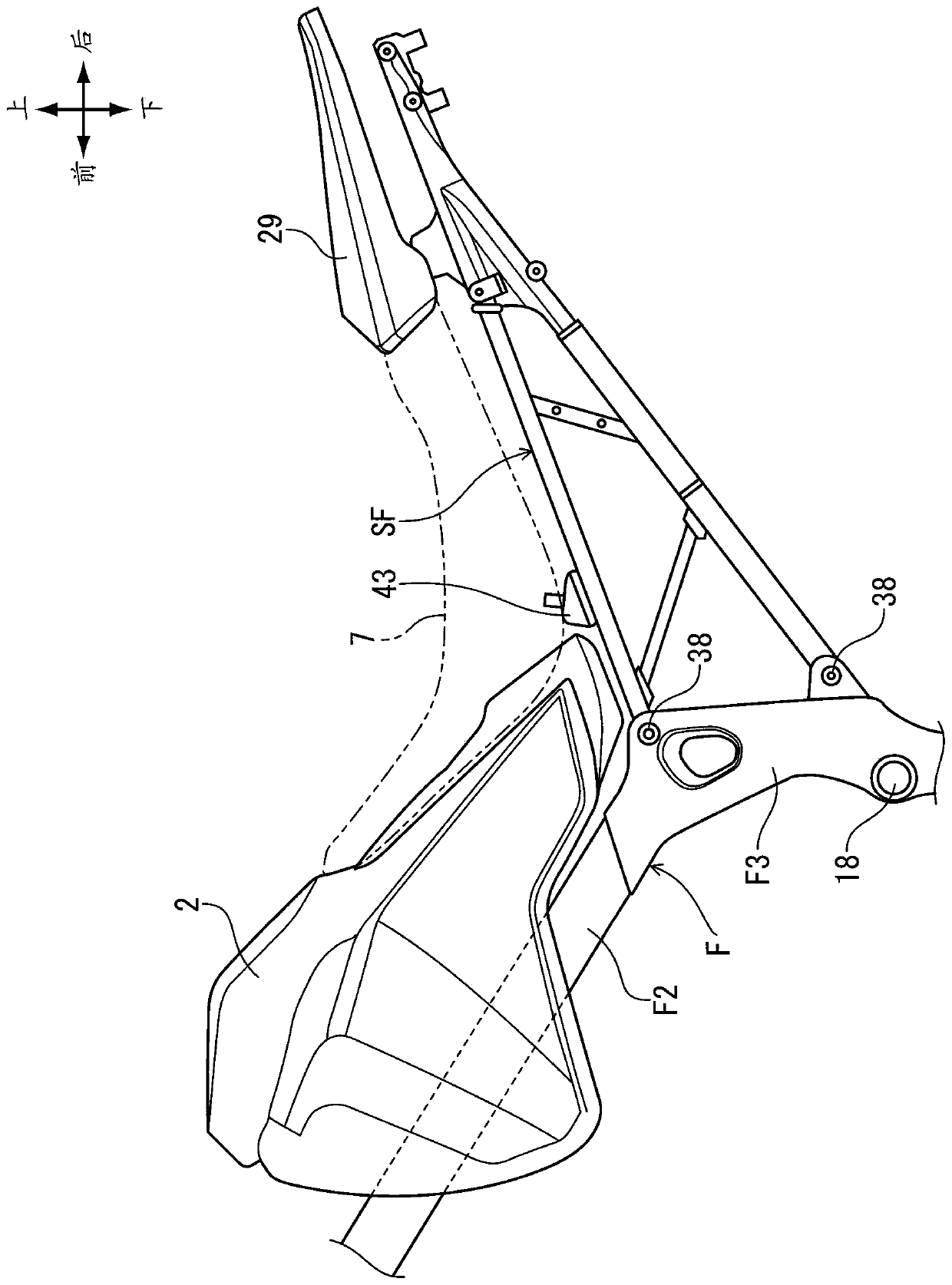

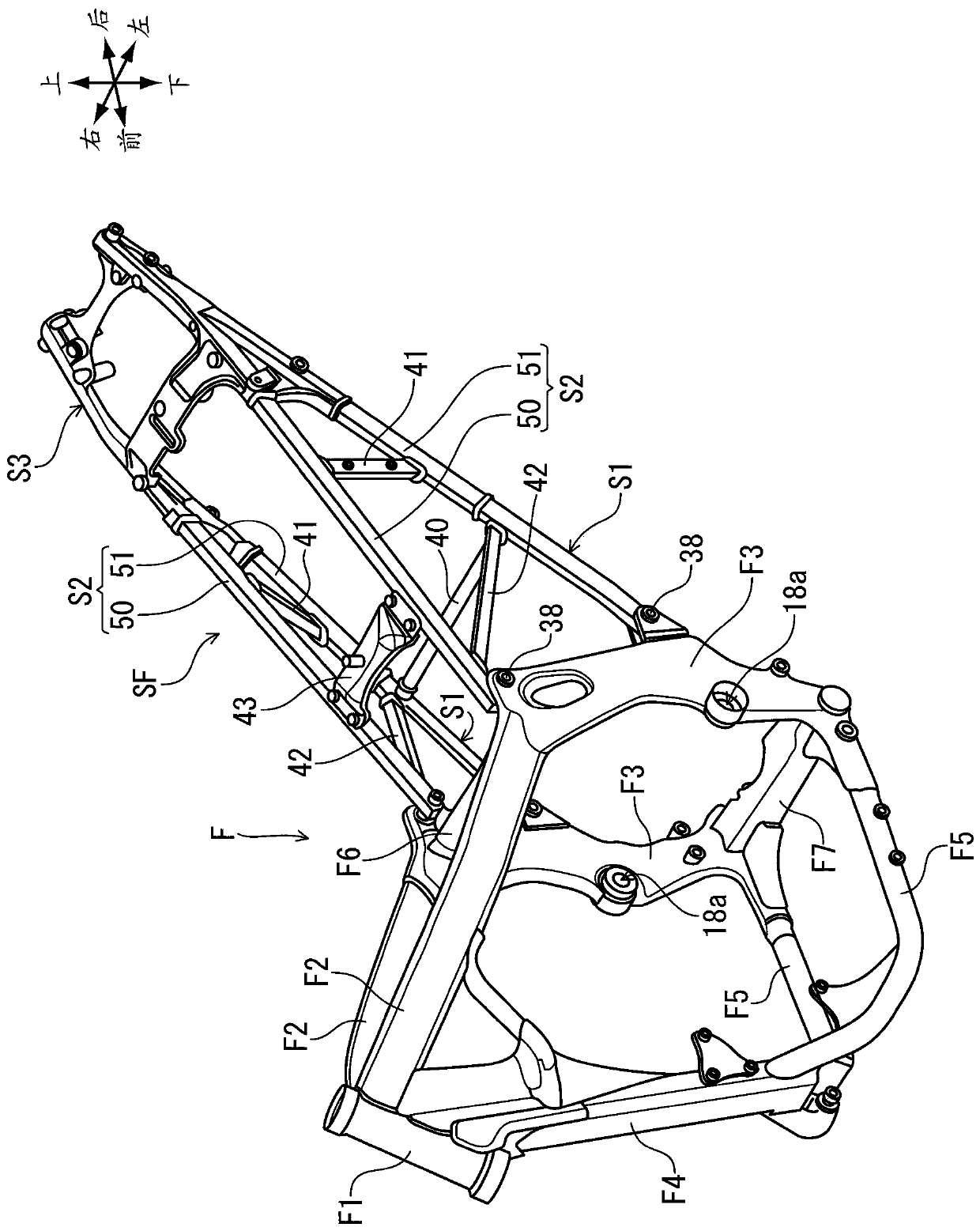

Seat frame for motorcycle

ActiveCN110316296AMeet the intensityMeet the weightMotorcyclesCycle saddlesEngineeringMechanical engineering

The invention provides a seat frame for a motorcycle that includes a plurality of aluminum parts manufactured with different manufacturing methods. A seat frame (SF) includes front members (S1) disposed on a front side of a vehicle body, middle members (S2) connected to rear portions of the front members (S1), and a rear member (S3) connected to rear portions of the middle members (S2), wherein the front members (S1), the middle members (S2), and the rear member (S3) are formed of aluminum members manufactured in different manufacturing methods. The rear member (S3) is formed by integral molding based on a gravity casting method. The rear member (S3) includes a pair of left and right rail portions (71), a front crossbeam portion (72) extending in a vehicle widthwise direction on the frontside of the vehicle body and connecting the left and right rail portions (71), a rear crossbeam portion (73) extending in the vehicle widthwise direction on a rear side of the vehicle body and connecting the left and right rail portions (71), and a plurality of attachment bosses (80-87) for attaching other parts. The left and right rail portions (71) each have an attachment portion (90, 91) to beconnected to a rear end portion of corresponding one of the middle members (S2) provided on an end portion thereof on the front side of the vehicle body.

Owner:HONDA MOTOR CO LTD

Sheet metal plate based on punch forming and processing technology thereof

The invention discloses a sheet metal plate based on punch forming and a processing technology thereof. The sheet metal plate based on stamping forming is prepared by carrying out hot stamping formingon a raw material titanium ingot. The processing technology of the sheet metal plate based on stamping forming comprises the following steps of 1, carrying out homogenization treatment on the raw material titanium ingot; 2, preparing an extruding plate; 3, preparing a rolled plate; 4, carrying out ultrasonic detection on the rolled plate; 5, preprocessing the rolled plate; and 6, carrying out hotstamping forming on the rolled plate so as to obtain the sheet metal plate based on stamping forming. An experiment result shows that the prepared sheet metal plate based on punching forming has hightensile strength and plasticity, the tensile strength of the sheet metal sheet material can reach 2100 MPa or above, the elongation rate can reach 15% or above, the sheet metal plate can be adapted to the production of structural parts with complex shapes, the yield is improved, the problem that the hot stamping titanium alloy plate easily forms cracks can be well solved, and the crack rate is low.

Owner:盐城华旭机械制造有限公司

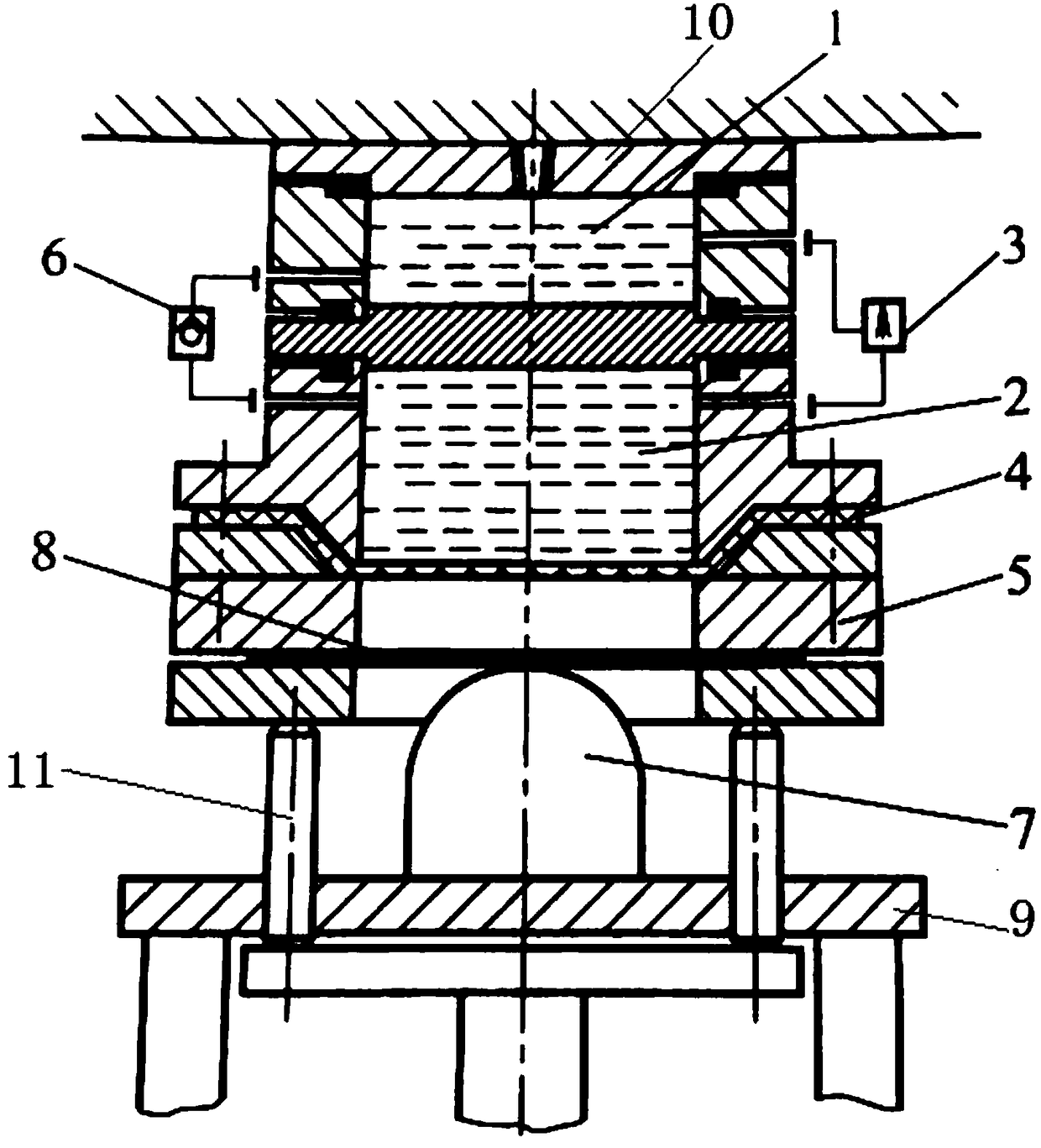

Cutter advancing and retreating mechanism for pipe beveling machine

ActiveCN103358161AImprove forming accuracyAchieve consistencyFeeding apparatusEngineeringMechanical engineering

The invention provides a cutter advancing and retreating mechanism for a pipe beveling machine. The cutter advancing and retreating mechanism comprises a transmission mechanism, a push disc connected with the transmission mechanism, a cutter head component arranged on one side of the push disc and a plurality of steering mechanisms connected between the push disc and the cutter head component, wherein the cutter head component comprises a cutter head provided with an accommodating chamber for accommodating pipes to be beveled and a plurality of cutter boxes movably fixed on the cutter head, and beveling cutters are fixed on the cutter boxes; the steering mechanisms are triaxial link mechanisms and comprise first rotating shafts fixed on the cutter head, second rotating shafts fixed on the cutter boxes, third rotating shafts connected with the push disc, and connecting rods respectively used for connecting the first rotating shafts and the third rotating shafts, as well as the second rotating shafts and the third rotating shafts.

Owner:HUAHENG WELDING

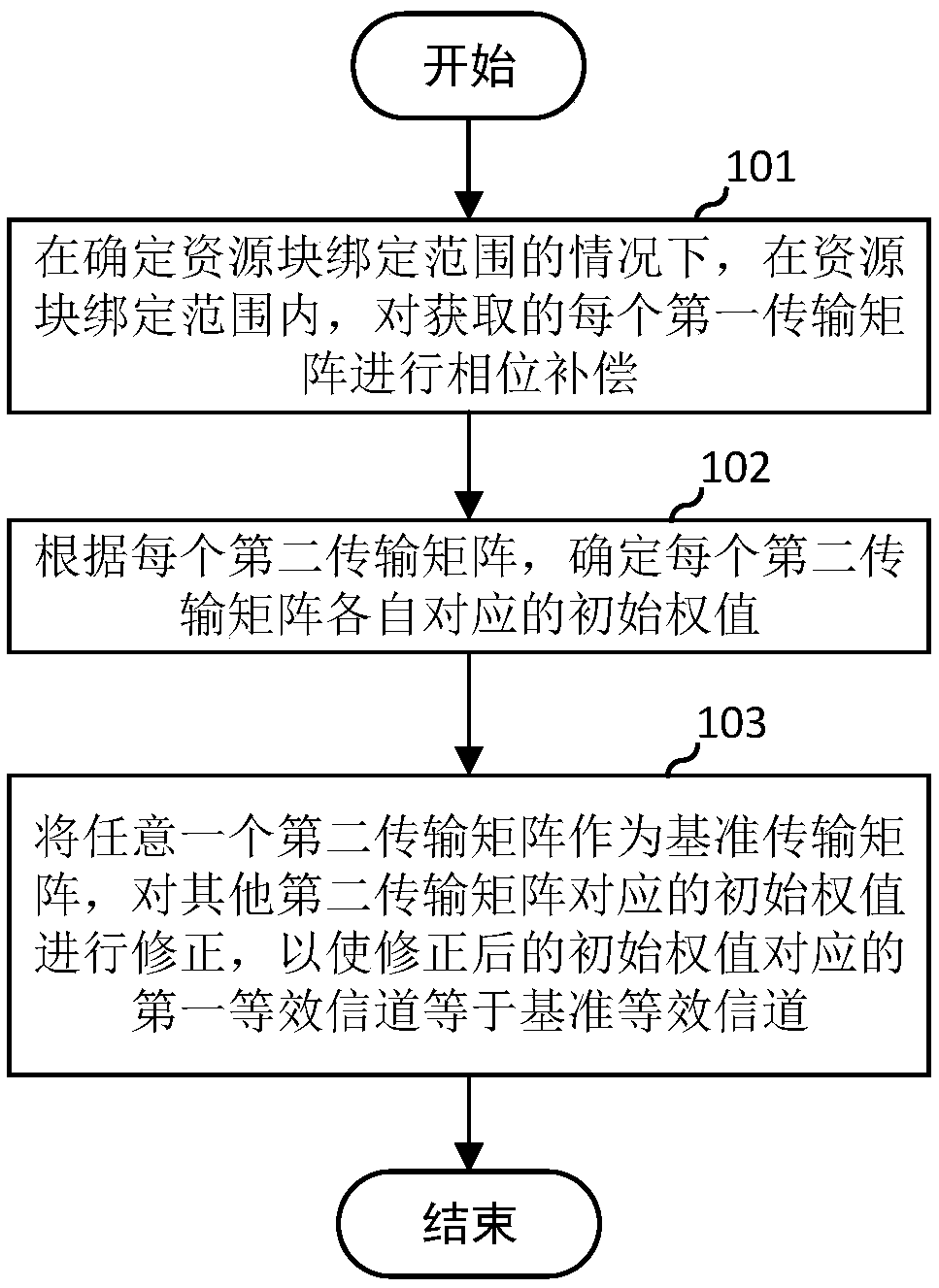

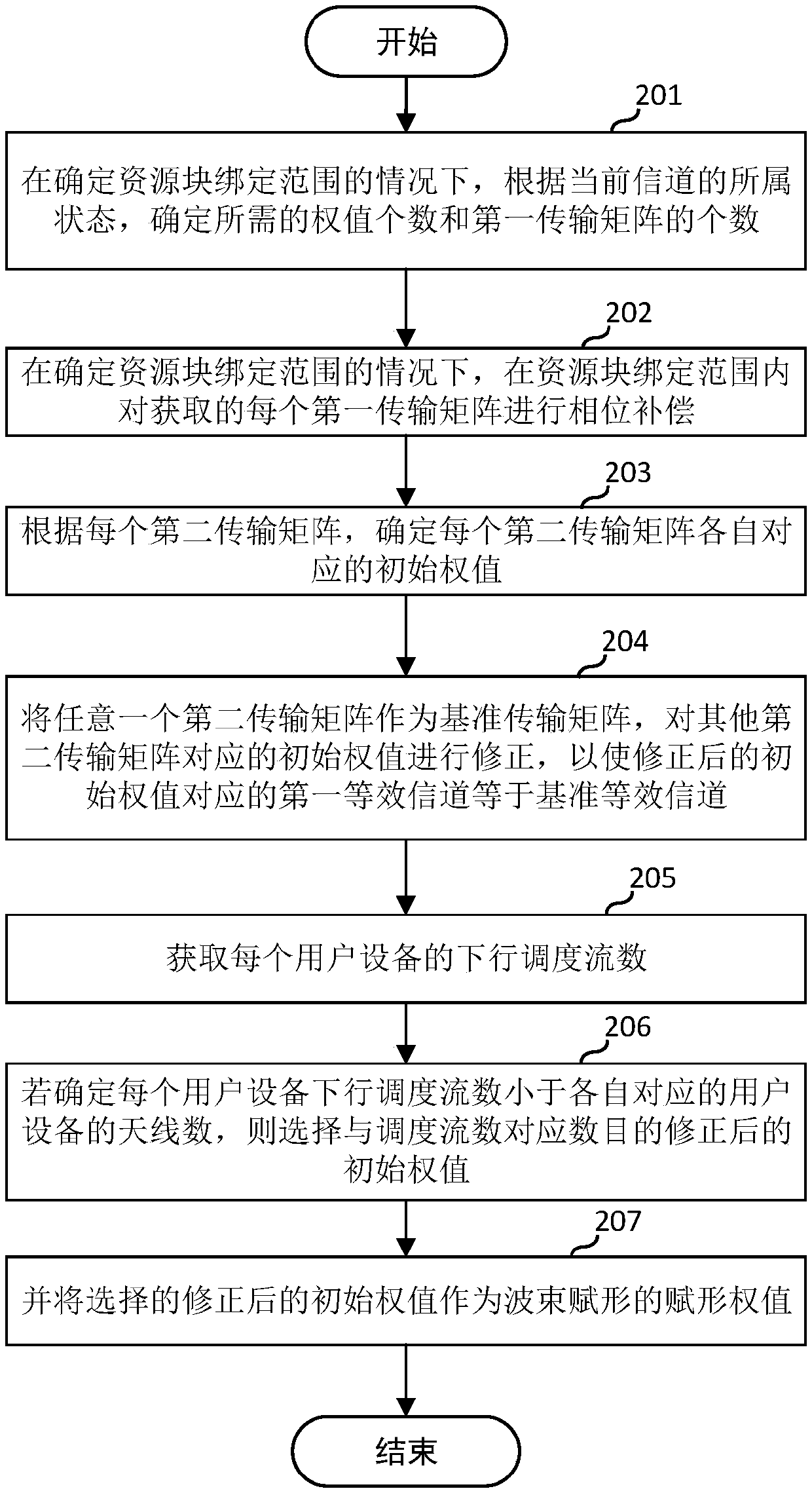

Beam forming method, base station and computer readable storage medium

ActiveCN111385008AGuaranteed continuityImprove accuracySpatial transmit diversityTransmission matrixAlgorithm

The embodiment of the invention relates to the field of communication, and discloses a beamforming method, a base station and a computer readable storage medium. The beamforming method is applied to abase station, and comprises the following steps: under the condition of determining a resource block binding range, performing phase compensation on each acquired first transmission matrix within theresource block binding range; according to each second transmission matrix, and determining an initial weight corresponding to each second transmission matrix, wherein the second transmission matrixis a compensated first transmission matrix; taking any one second transmission matrix as a reference transmission matrix, and correcting the initial weights corresponding to the other second transmission matrixes, so that the first equivalent channel corresponding to the corrected initial weight is equal to the reference equivalent channel. According to the embodiment of the invention, when a plurality of weights are adopted for forming in the resource block binding range, the forming precision can be improved, the continuity of the equivalent channel of UE in the frequency domain can be ensured, the accuracy of channel estimation is improved, and the throughput rate of a cell is improved.

Owner:ZTE CORP

Manufacturing method of multicolour dimming mask and pattern transfer method

ActiveCN102262353BImprove in-plane uniformityImprove forming accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusReduction rateResist

PROBLEM TO BE SOLVED: To reduce the number of drawing and developing processes by using film reduction of a resist pattern, as well as to improve uniformity within a film plane in a film reduction rate of a resist pattern between sparse and dense pattern regions.SOLUTION: A method for manufacturing a photomask is provided, including steps of: forming a first resist pattern covering a region for forming a light-shielding portion and a region for forming a translucent portion, in which the thickness of the resist film in the region for forming a translucent portion is smaller than the thickness of the resist film in the region for forming a light-shielding portion; and reducing the film in the first resist pattern by excessively supplying ozone to the first resist pattern. Ozone is supplied in such a manner that the supply amount of active oxygen per unit area supplied to the first resist pattern is greater than the consumed amount of active oxygen per unit area consumed by the film reduction in the first resist pattern.

Owner:HOYA CORP

Rubber forming method and forming die for sheet metal parts with large curvature and high flanging

ActiveCN106825096BThe operation method is simple and convenientStrong structural versatilityExtrusion diesRams/plungersSurface levelEngineering

The invention discloses a rubber forming method and a rubber forming mould of a high-curvature high-flanging sheet metal part. The rubber forming mould comprises an accommodating box, a forming die, a pressing plate, a supporting plate and rubber pads, wherein the non-working surface on the inner side of the forming die is connected to the inner wall of one side of the accommodating box; a moulding cavity is formed between the working surface on the outer side of the forming die and the inner wall of the accommodating box; the outlines of the pressing plate and the supporting plate are smaller than the outline of the moulding cavity; the inner sides of the pressing plate and the supporting plate are matched with the working surface on the outer side of the forming die. The rubber forming method comprises the following steps: placing the accommodating box on a workbench of a hydraulic machine, placing a plurality of rubber pads with equal height inside the moulding cavity, and placing the supporting plate on the upper surfaces of the rubber pads so as to make the surface height of the supporting plate consistent with the height of the forming die; overlapping the pressing plate and the supporting plate, and clamping a flanging area of an unfolded blank; downwardly pressing the pressing plate by using hydraulic forming equipment, fitting the flanging area of the unfolded blank with the working mould surface of the forming die, and forming.

Owner:XIAN AIRCRAFT IND GROUP

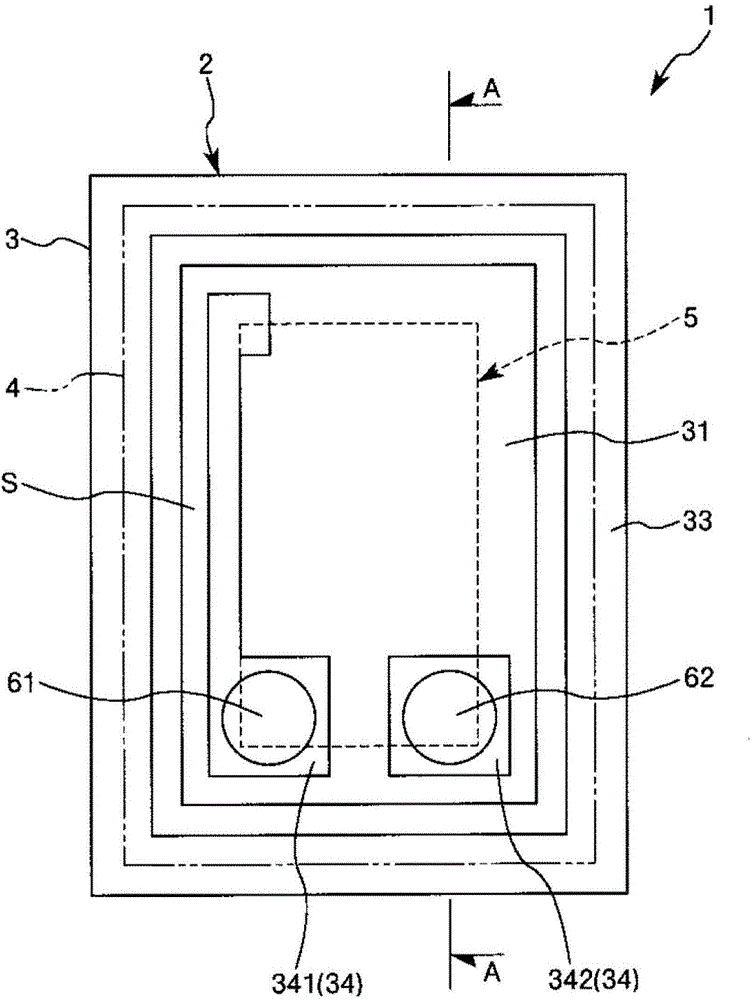

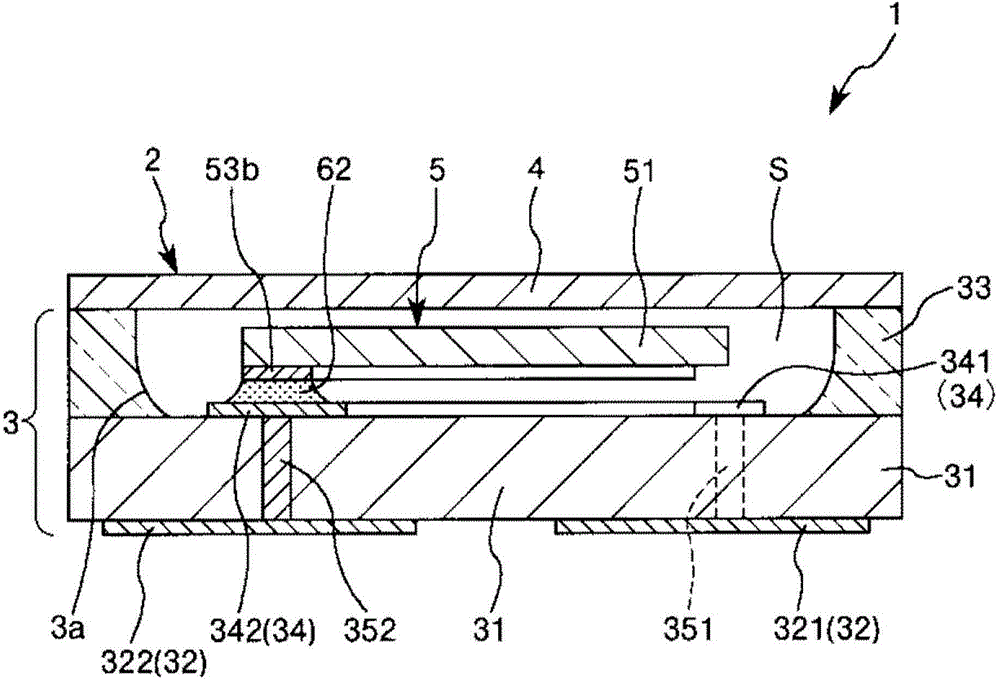

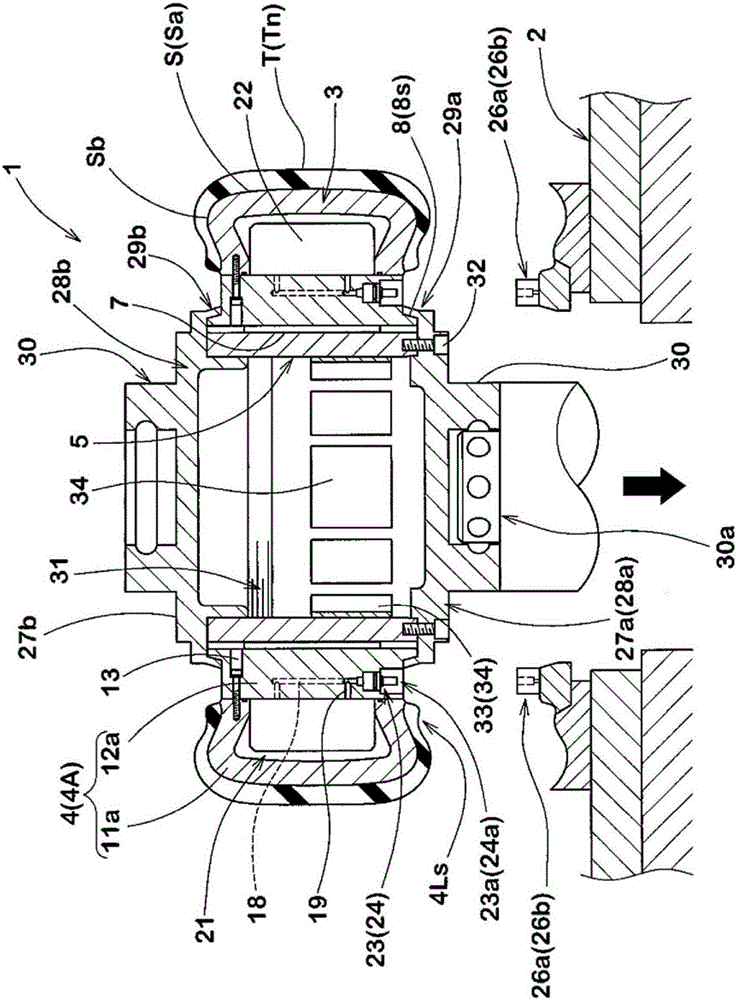

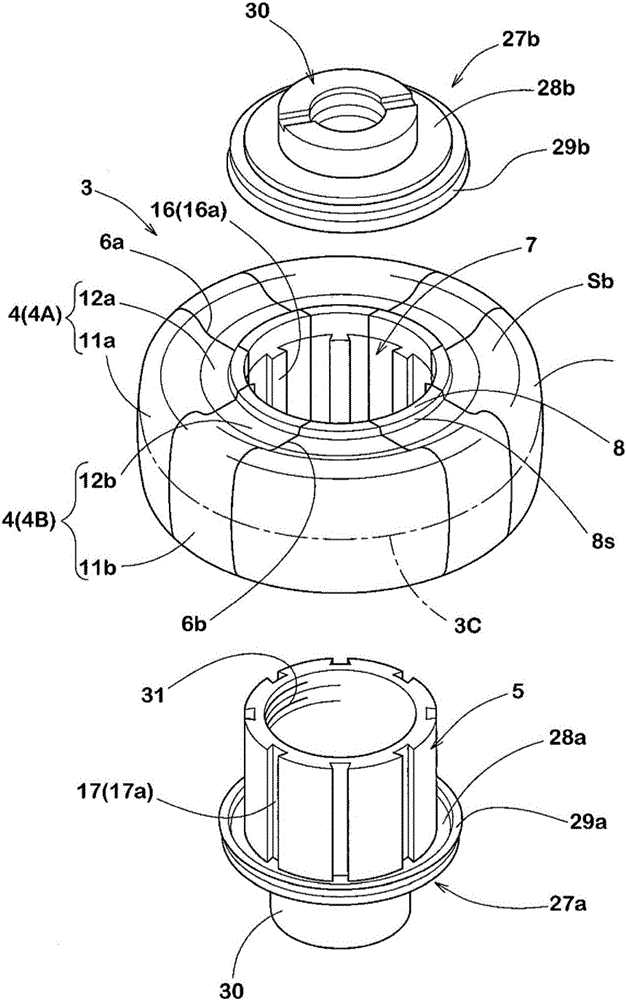

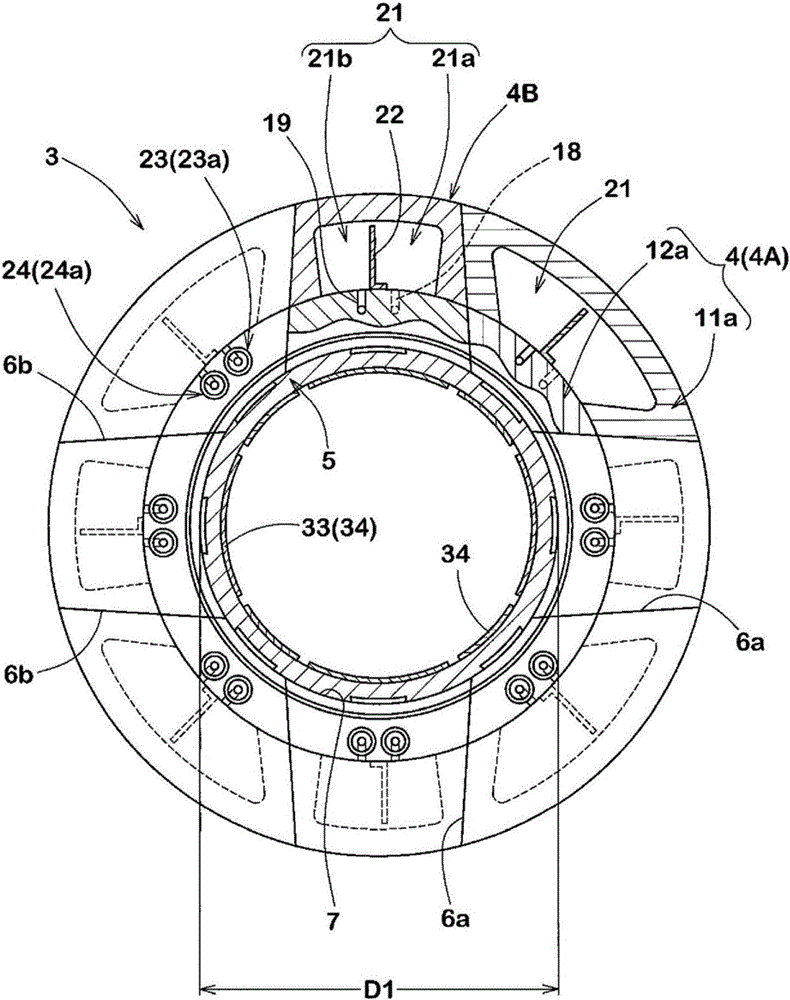

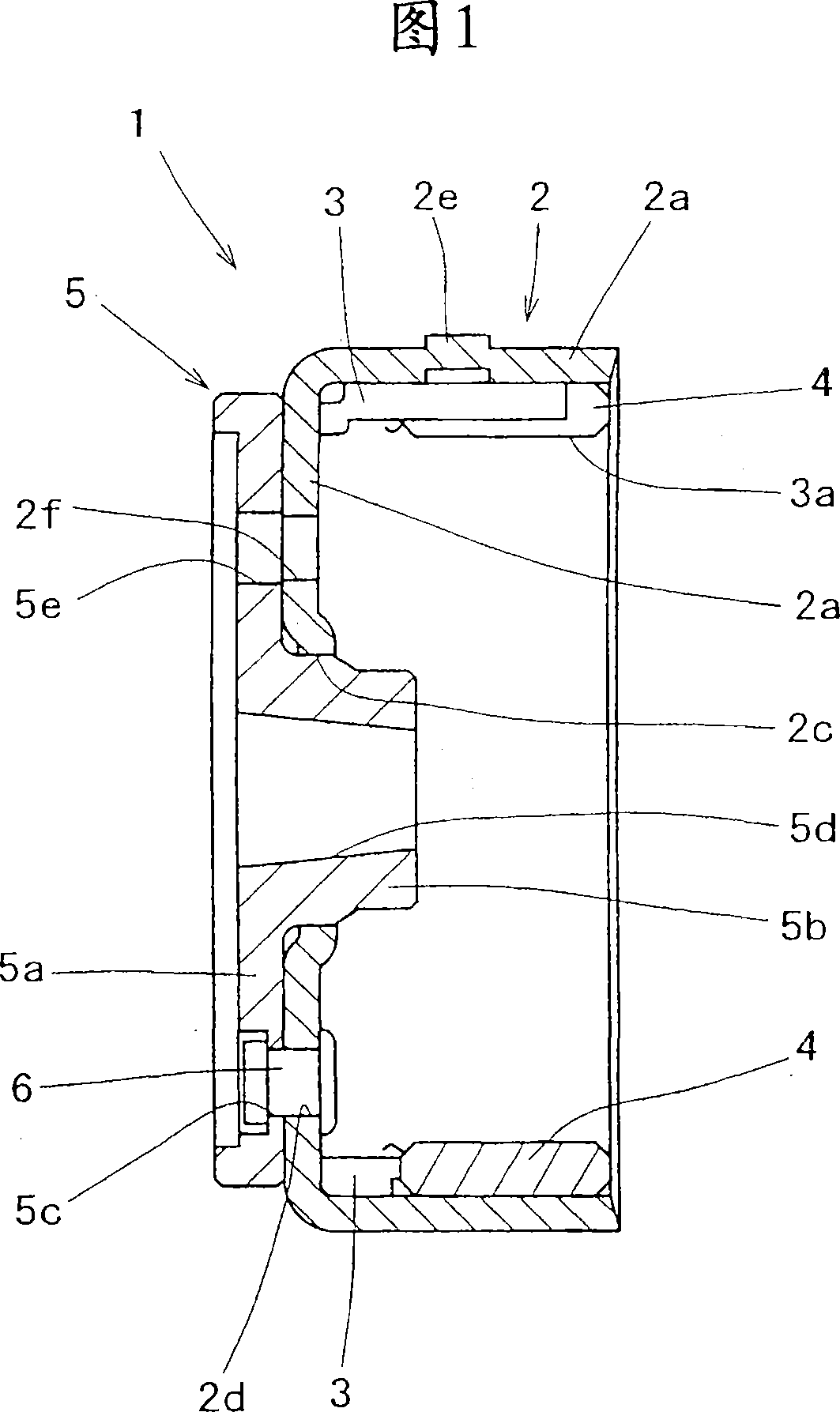

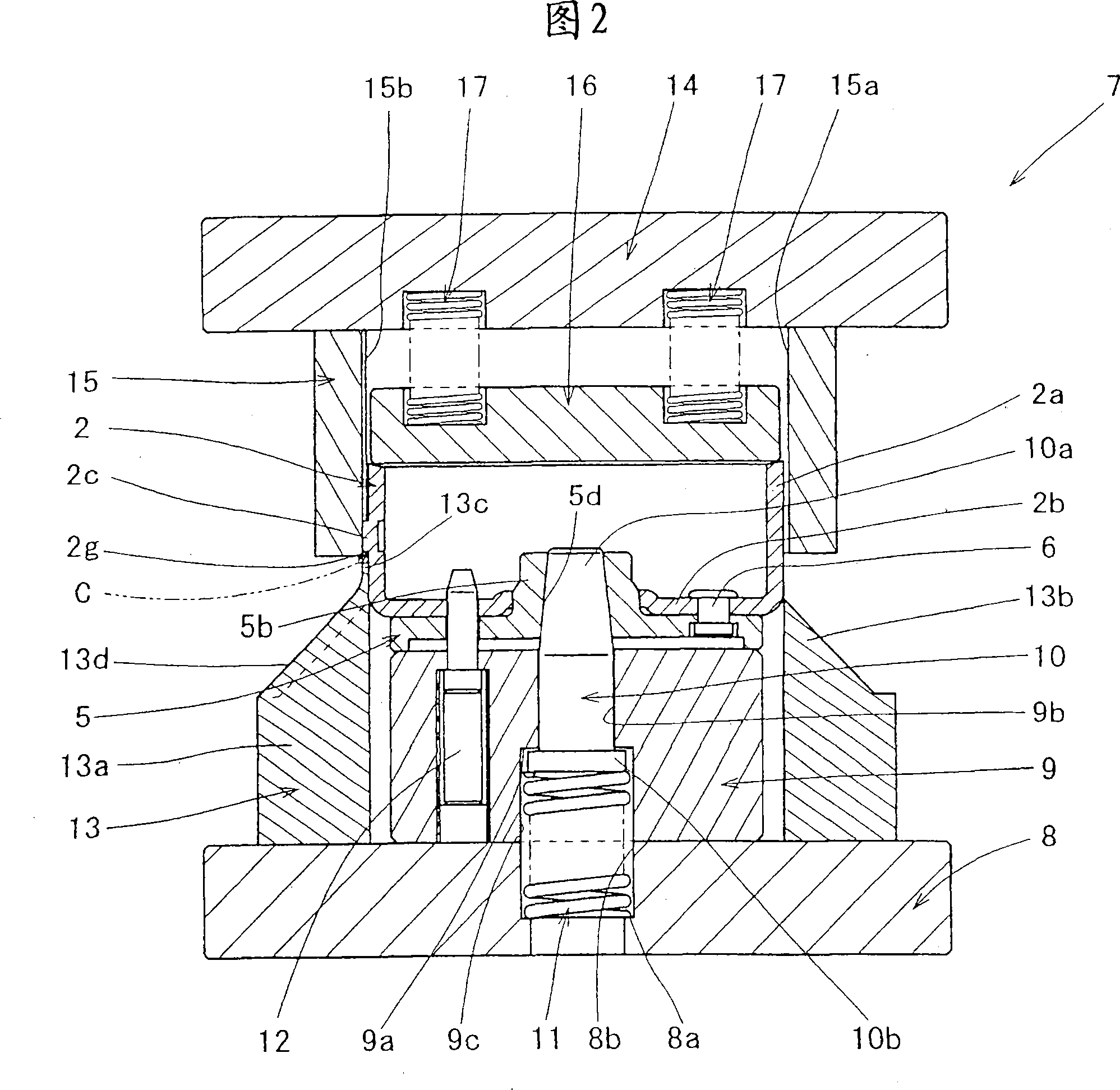

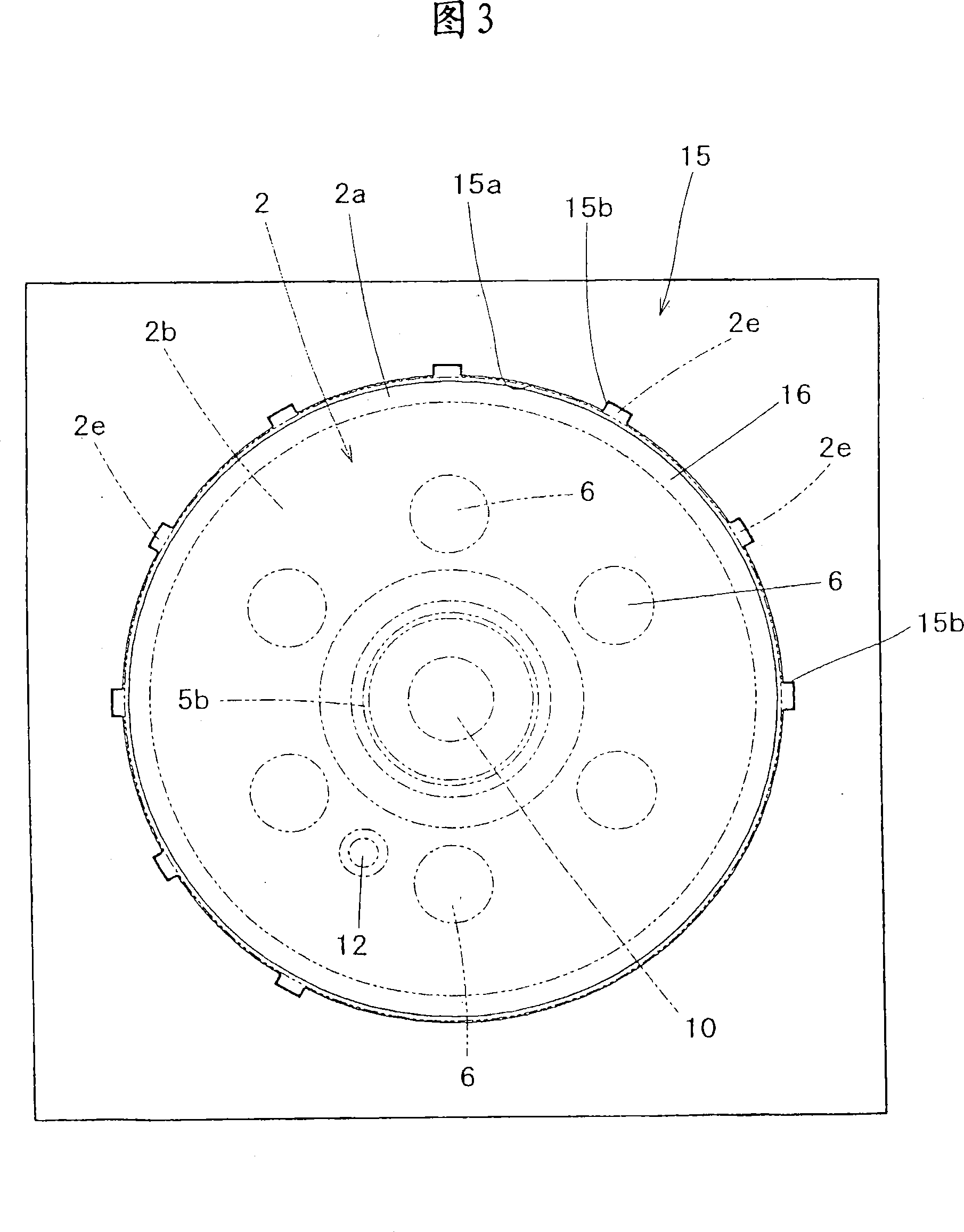

Tire manufacturing method

InactiveCN105764662AIncrease the gapSuppression gapTyresThermometer applicationsVulcanizationEngineering

The present invention increases tire formation precision and is a tire manufacturing method, which comprises a step (S1) for forming a green tire (Tn) on the outer surface (S) of a rigid inner ring (1) and a vulcanization step (S2) for vulcanizing the green tire (Tn). The rigid inner ring (1) comprises: an inner ring body (3), which is obtained from multiple segments (4); a core (5), which substantially binds the various segments (4); and an outer diameter-adjustment means (33) for changing the outer diameter (D1) of the core (5) by changing the temperature of the core (5). Moreover, the rigid inner ring (1) performs changes such that by expansion of the outer diameter (D1) of the core (5), the various segments (4) move outward in the radial direction of the tire and gaps (G) between the segments (4) are enlarged, while by reducing the outer diameter (D1) of the core (5), the various segments (4) move inward in the radial direction of the tire and the level differences (R) on the outer surface (S) between adjacent segments (4) increase. The vulcanization step (S2) comprises an adjustment step (S21) for adjusting the outer diameter (D1) of the core (5) using the outer diameter adjustment means (33) so that the gaps (G) and the level differences (R) are within a previously established range.

Owner:SUMITOMO RUBBER IND LTD

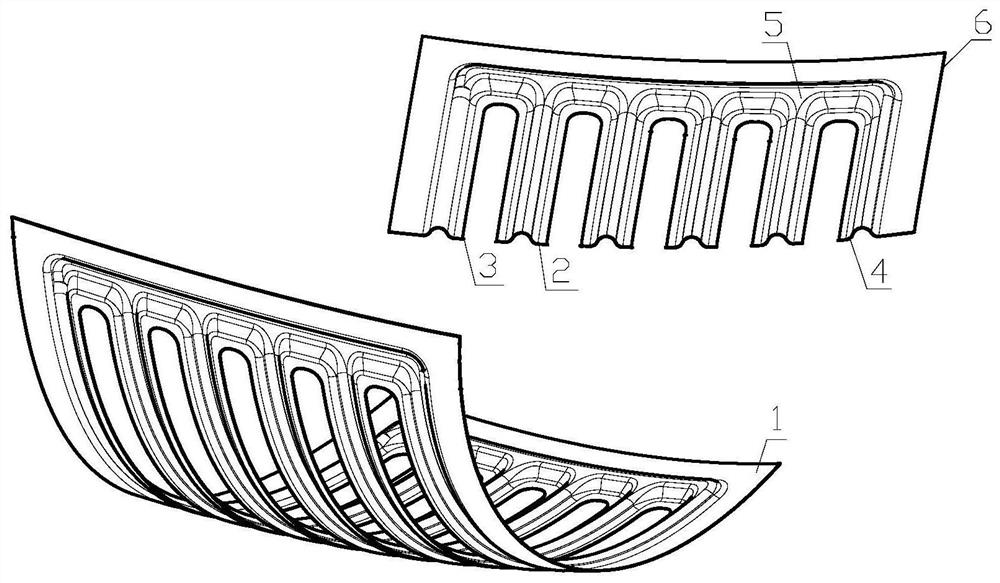

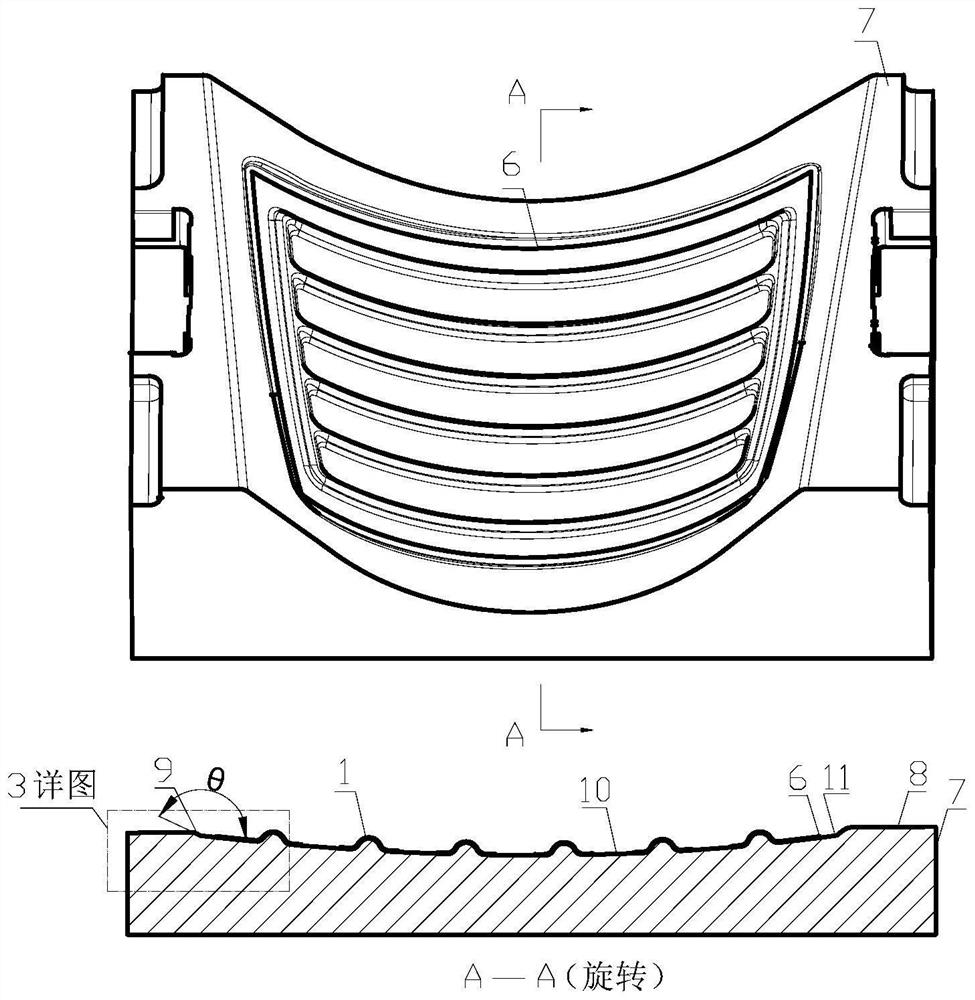

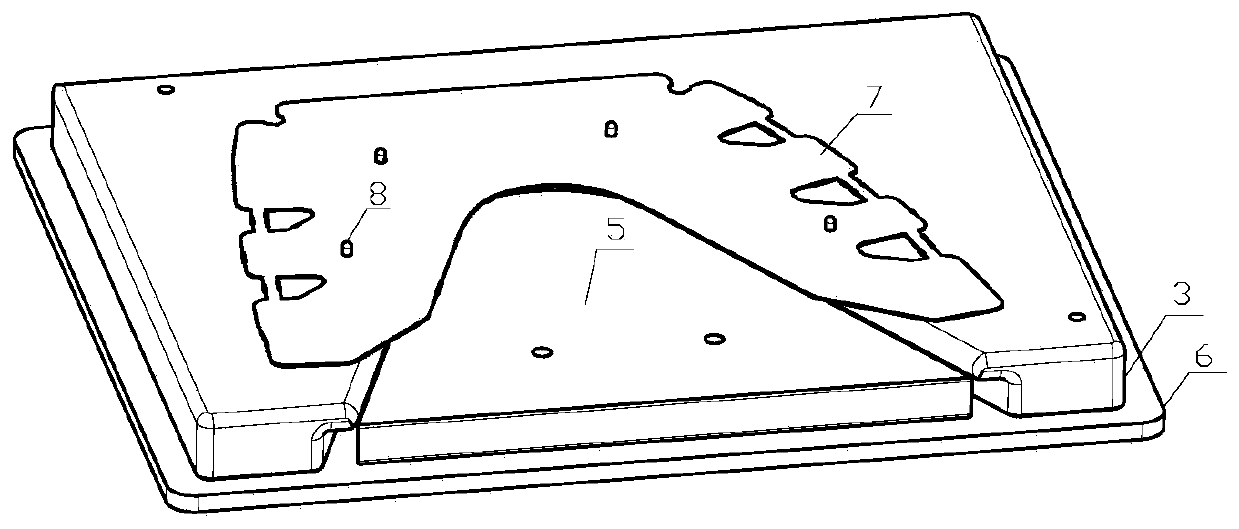

A Rubber Forming Method for Thin-walled Reinforced Panel Parts with Multiple Surrounding Deep Rib Structures

ActiveCN111085595BEasy forming limitImprove forming accuracyAircraft componentsShaping toolsBoard structureCompressive deformation

The invention discloses a rubber forming method for a thin-wall reinforced panel part with a multi-encircling deep rib structure, which comprises the following steps: making a rubber forming mold for the reinforced panel part; making an unfolded blank; the first rubber hydroforming; the second rubber hydroforming; Hydraulic correction; trimming and cutting the shape. The molding die in the present invention adopts a supporting platen structure, which promotes beneficial replenishment of surrounding materials inwards, so that the original unidirectional stretching deformation of the peripheral ring material is optimized into a bidirectional compression deformation method, which solves the problem of forming and cracking of the deep rib reinforced panel. The installation and operation methods of the forming mold are simple and convenient, and the material of the support plate is not limited, and light materials such as machinable plastics are preferred, which are easy to process, low in manufacturing cost, and easy to promote and realize.

Owner:XIAN AIRCRAFT IND GROUP

Advance and retreat knife mechanism for pipe beveling machine

Owner:HUAHENG WELDING

Device for shaving projection formed on flywheel and method of shaving projection

InactiveCN1993873AHigh roundnessImprove forming accuracyShearing machinesFlywheelsEngineeringFlywheel

Triggering projections for obtaining a trigger signal can be shaved with high circularity, and the projections have an excellent sensing function as a trigger, where the projections are punched out in a projecting manner from the outer periphery of a yoke of a flywheel. A boss plate (5) is previously fixed by staking to a yoke (2) that forms a flywheel (1). A shaving device (7) is constructed such that a support shaft section (10), on which a boss tube section of the boss plate (5) is fitted, is provided on the fixed base (8) side and that a shaving die (15) is provided on a movable based (14) side, the shaving die (15) being co-axial with the support shaft section (10) and shaving a projection (2e) in the axial direction of the support shaft section (10).

Owner:MITSUBA CORP

Female die hydro-drawing device

The invention discloses a female die hydro-drawing device comprising a female die, a convex die and an edge pressing ring, and the edge pressing ring is located between the female die and the convex die. By means of the device, the forming accuracy of parts is improved, the wall thickness of the drawn parts is uniform, the thinning rate is lowered, and harmful friction force is lowered.

Owner:JIANGSU GAIZHIBAO PACKAGING TECH CO LTD

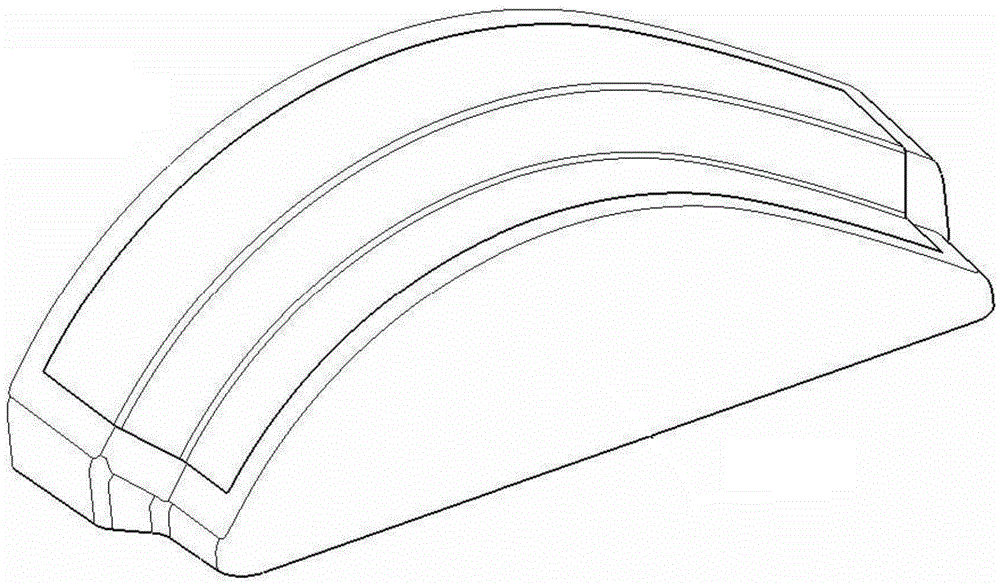

A Rubber Forming Method for Concave Curved Surface and Semi-arc-shaped Reinforced Bend Sheet Metal Parts

ActiveCN110293165BSimple structureThe operation method is simple and convenientShaping toolsEngineeringMetal sheet

The invention discloses a rubber pad forming method of a concave surface semi-arc reinforced flange sheet metal part. A mold is included, the mold comprises a bottom plate, a mold body, a cover plateand an auxiliary cushioning block, the shape of the working face of the mold body is in accord with the concave surface shape of a to-be-molded metal sheet part, the shapes of the auxiliary cushioningblock and the working face of the mold body are matched, the height of the shape of the auxiliary cushioning block is lower than the mold body, the mold body and the auxiliary cushioning block are connected with the bottom plate, wools are fixed to the bottom plate, the cover plate is pressed downwards by using hydraulic molding equipment, suspended sheet materials are pressed by rubber pads to adhere to the working surface of the mold and the upper surface of the auxiliary cushioning block to form a transition work piece with an L-shaped inner flange, the transition work piece is placed on another flanging mold, and therefore the outer side flange of the transition work piece is molded.

Owner:XIAN AIRCRAFT IND GROUP

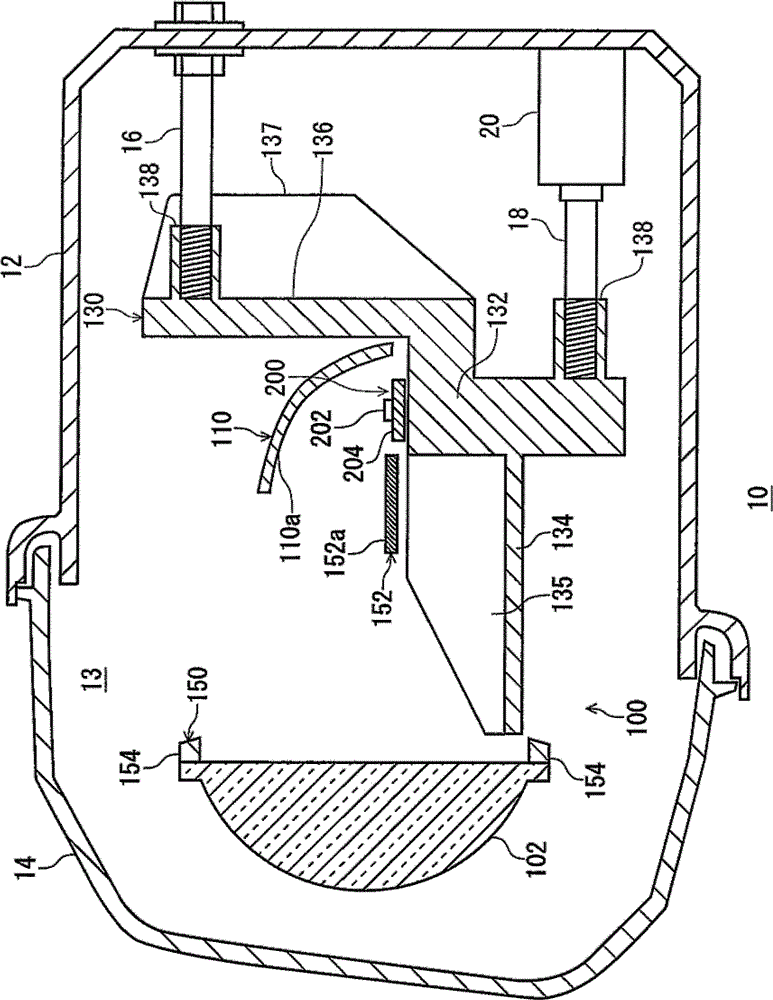

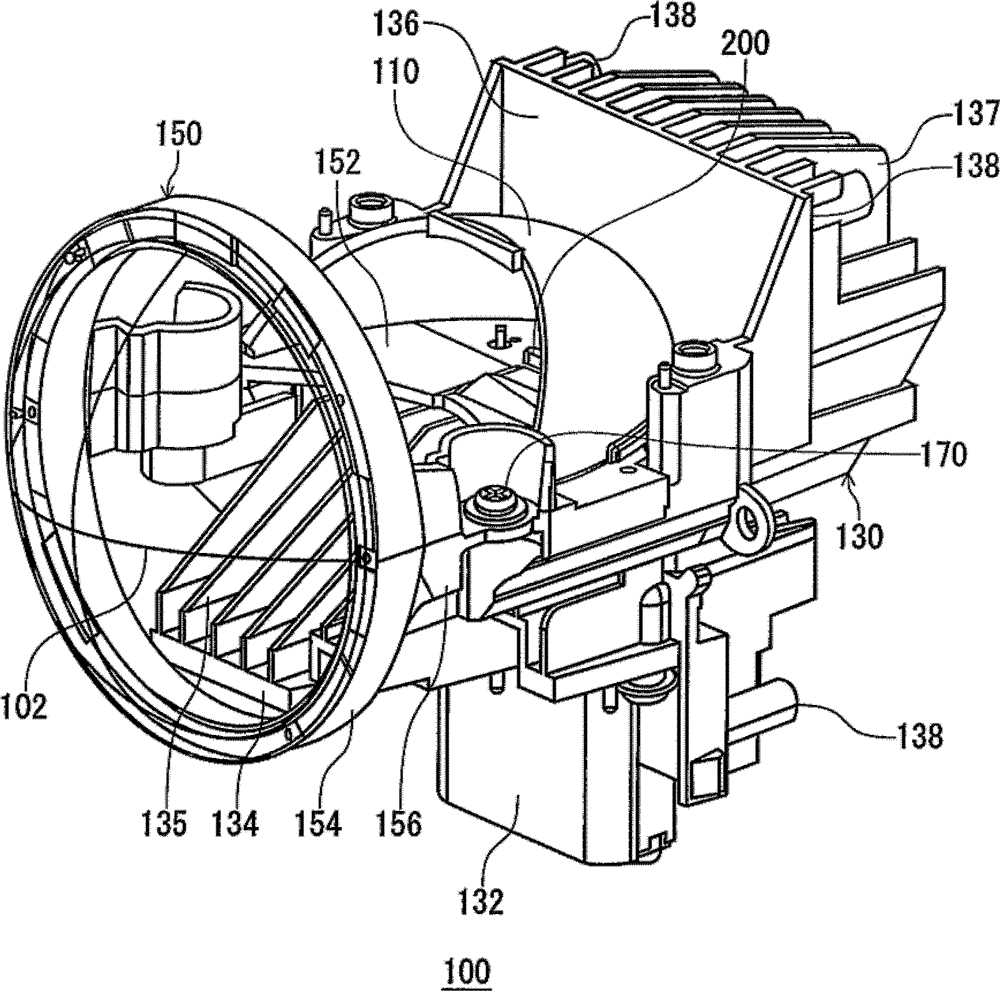

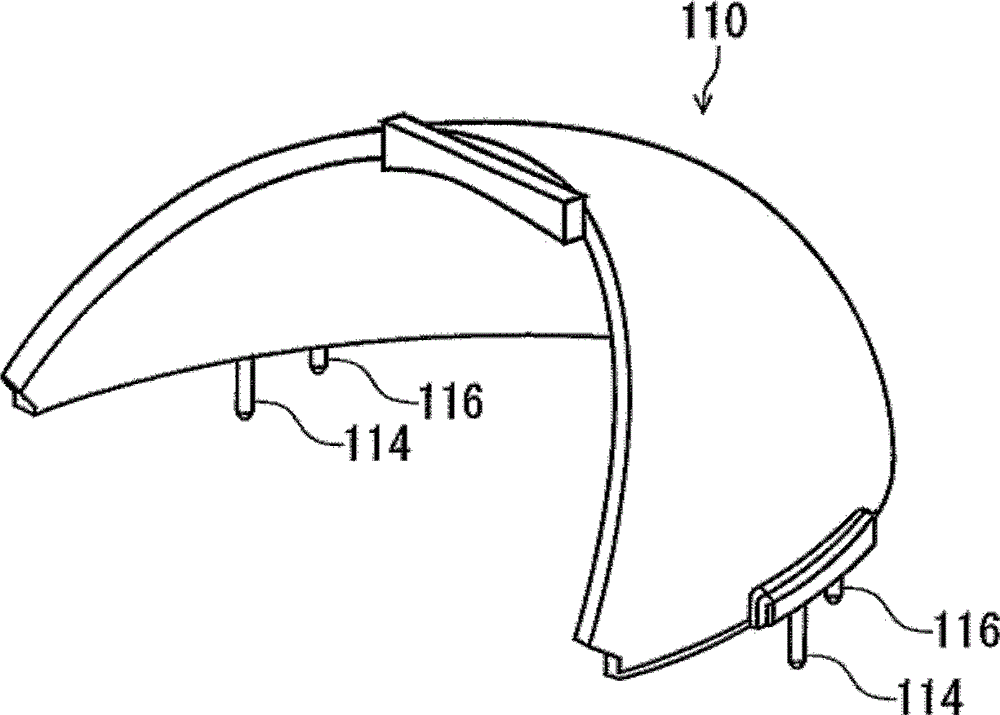

optical components

ActiveCN102418906BAvoid passingAvoid deformationVehicle headlampsOptical signallingOptoelectronicsHeat sink

An optical assembly, comprising: a heat sink for heat dissipation of a light source; a reflector mounting portion, a lens mounting portion, and a joint portion between the reflector mounting portion and the lens mounting portion, and the light of the light source A base part configured such that the reflector attached to the reflector attachment part reflects and enters the projection lens attached to the lens attachment part. The heat sink is exposed in a space surrounded by the lens mounting part, the coupling part, and the reflector mounting part.

Owner:KOITO MFG CO LTD

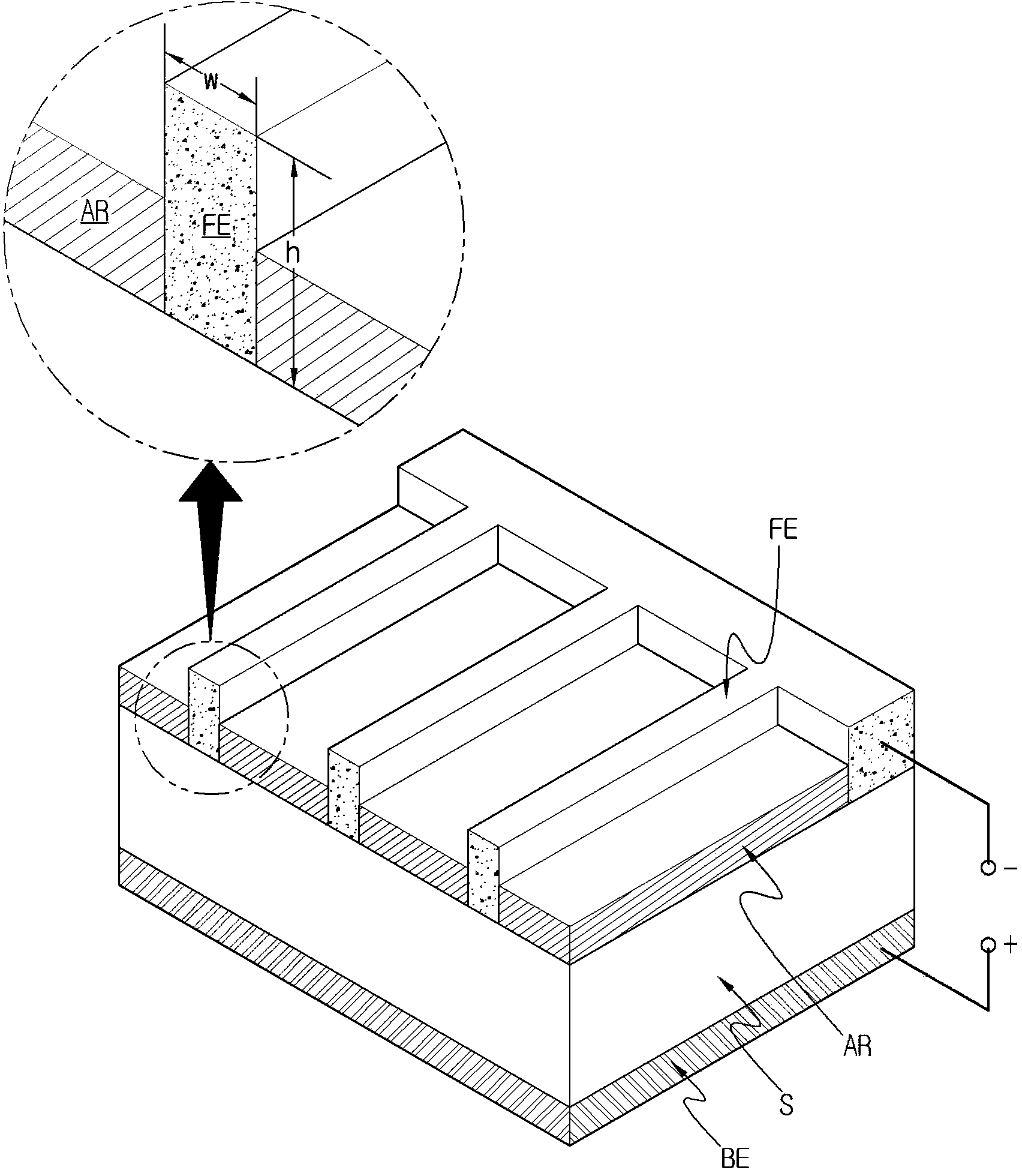

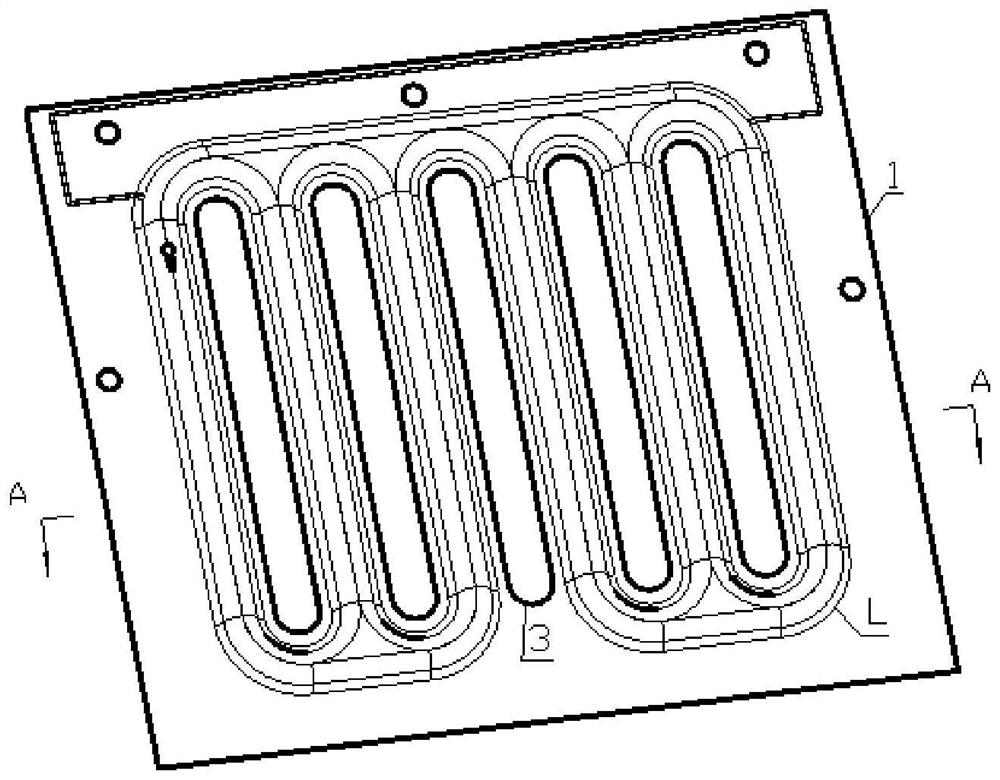

Reciprocating forming equipment for fuel cell metal polar plate

ActiveCN112570452AImprove forming accuracyAvoid damageMetal rolling stand detailsGuiding/positioning/aligning arrangementsFuel cellsElectric machine

The invention discloses reciprocating forming equipment for a fuel cell metal polar plate, and belongs to the technical field of cell metal polar plate forming equipment. The equipment is characterized by comprising a straightening device, a movable forming mechanism, a plane hard die transmission mechanism, a tensioning device and a limiting mechanism. A blank enters a rack, firstly enters the polar plate straightening device and then enters a forming station to be stopped, a plane hard die moving motor drives a plane hard die to move upwards to the forming station through eccentric shaft transmission, the limiting mechanism works simultaneously, a compression spring pushes a U-shaped limiting pin to move inwards to clamp a supporting platform, a moving platform rolls and forms the polarplate from an initial position along an advancing direction of the polar plate, after rolling, an electromagnet nut of the limiting mechanism is electrified to attract the U-shaped limiting pin to return to the initial position, and the plane hard die moving motor drives the eccentricity on the eccentric shaft to rotate downwards, so that the plane hard die is separated from the forming station. The equipment has the advantages that the shape filling performance of soft die forming and the forming accuracy of the polar plate are improved, resilience after forming is reduced, and the requirement for continuous production is met.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

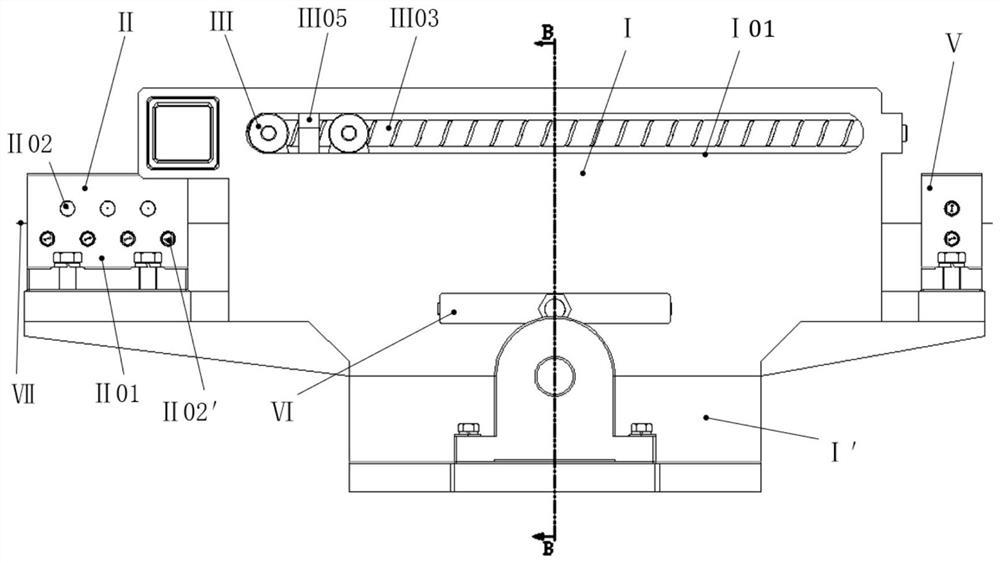

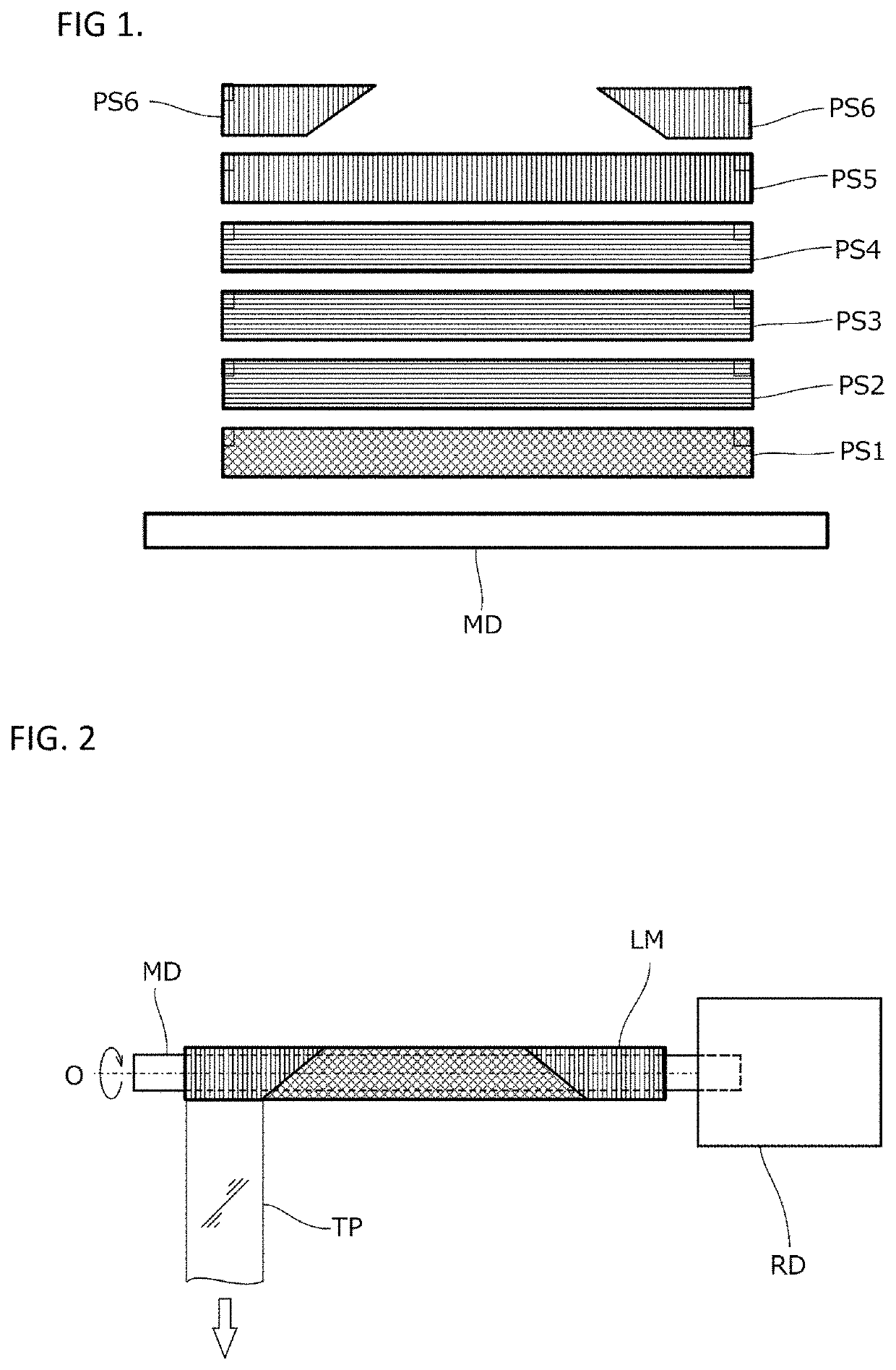

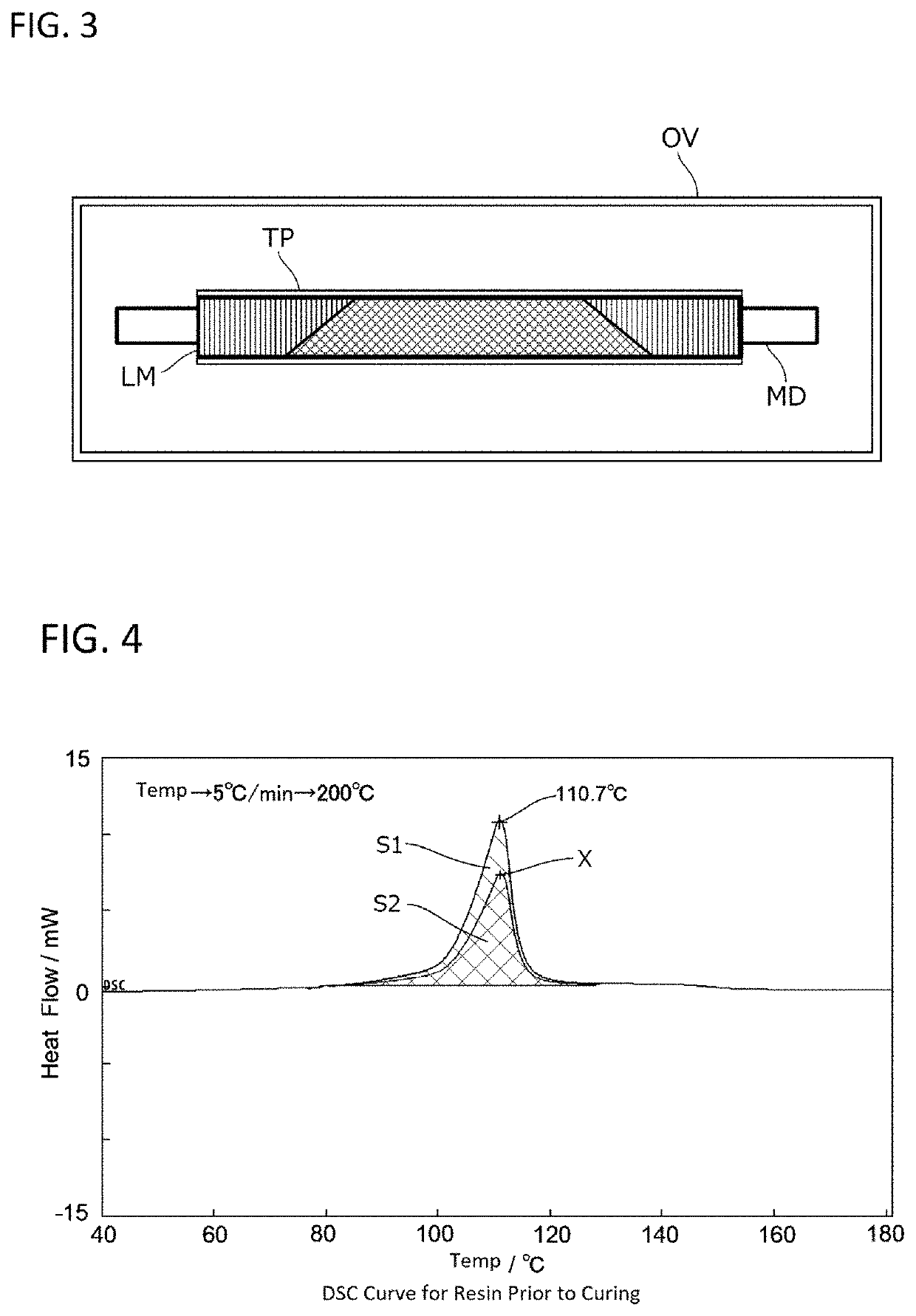

Structural body manufacturing method and structural body

Owner:GRAPHITE DESIGN

Manufacturing Method Of Multicolor Dimming Masking And Pattern Transfer Printing Method

InactiveCN102262354BImprove in-plane uniformityImprove forming accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistEngineering

The invention provides a manufacturing method of a multicolor dimming masking and a patter transfer printing method. By the invention, not only the patterning times and developing times can be reduced by utilizing the film depression of slushing compound pattern, but also the uniformity of the film depression of the slushing compound pattern between dense areas. The manufacturing method includes the steps of forming a first slushing compound pattern covering a forming area of a shading part and a forming area of a semi-transmission part, wherein the thickness of the slushing compound film in the forming area of the semi-transmission part is smaller than the thickness of slushing compound film in the forming area of the shading part; and supplying active oxygen to the first slushing compound pattern to conduct film depression to the first slushing compound pattern. And part of the active oxygen supplied to the first slushing compound pattern is consumed by an exposed semi-transmission film.

Owner:HOYA CORP

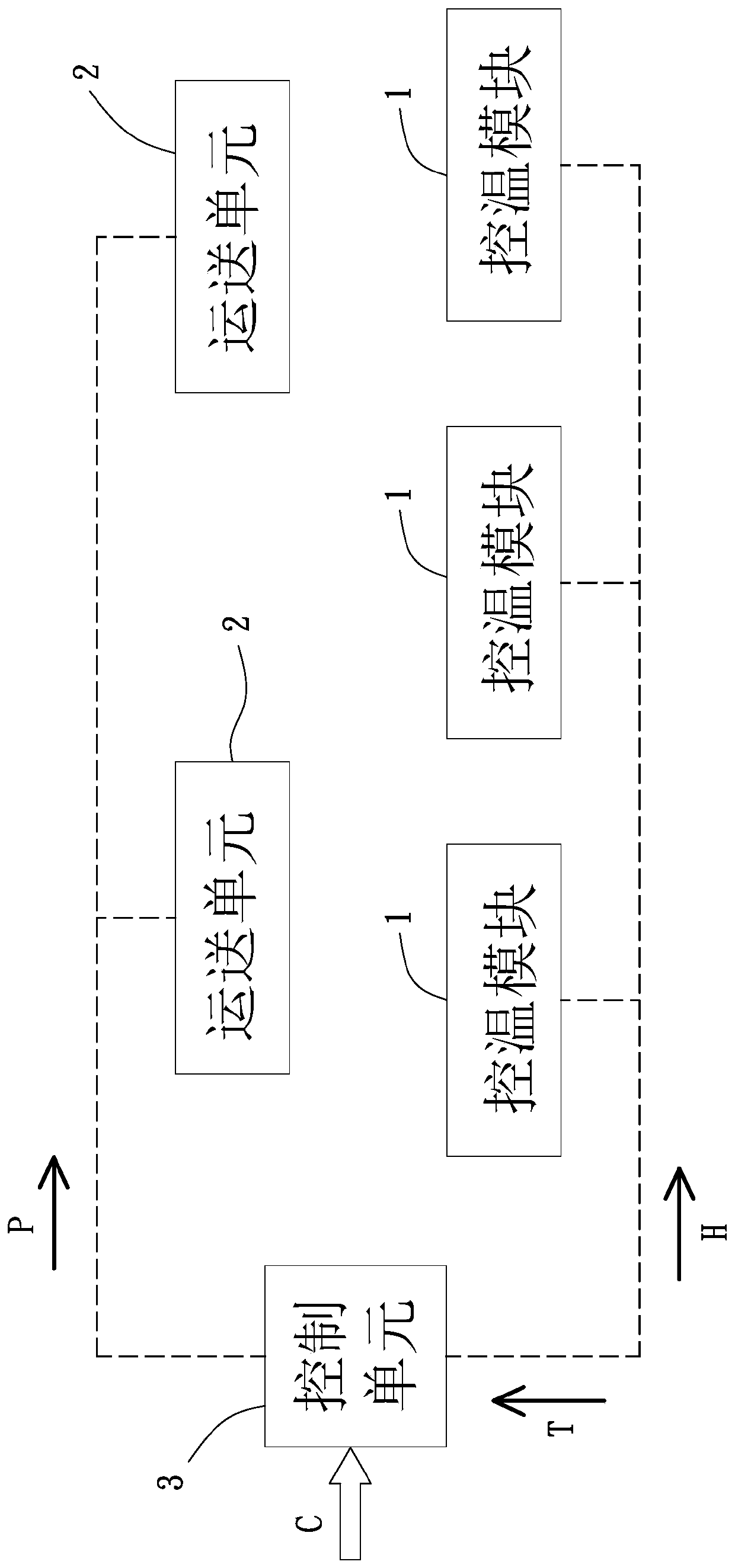

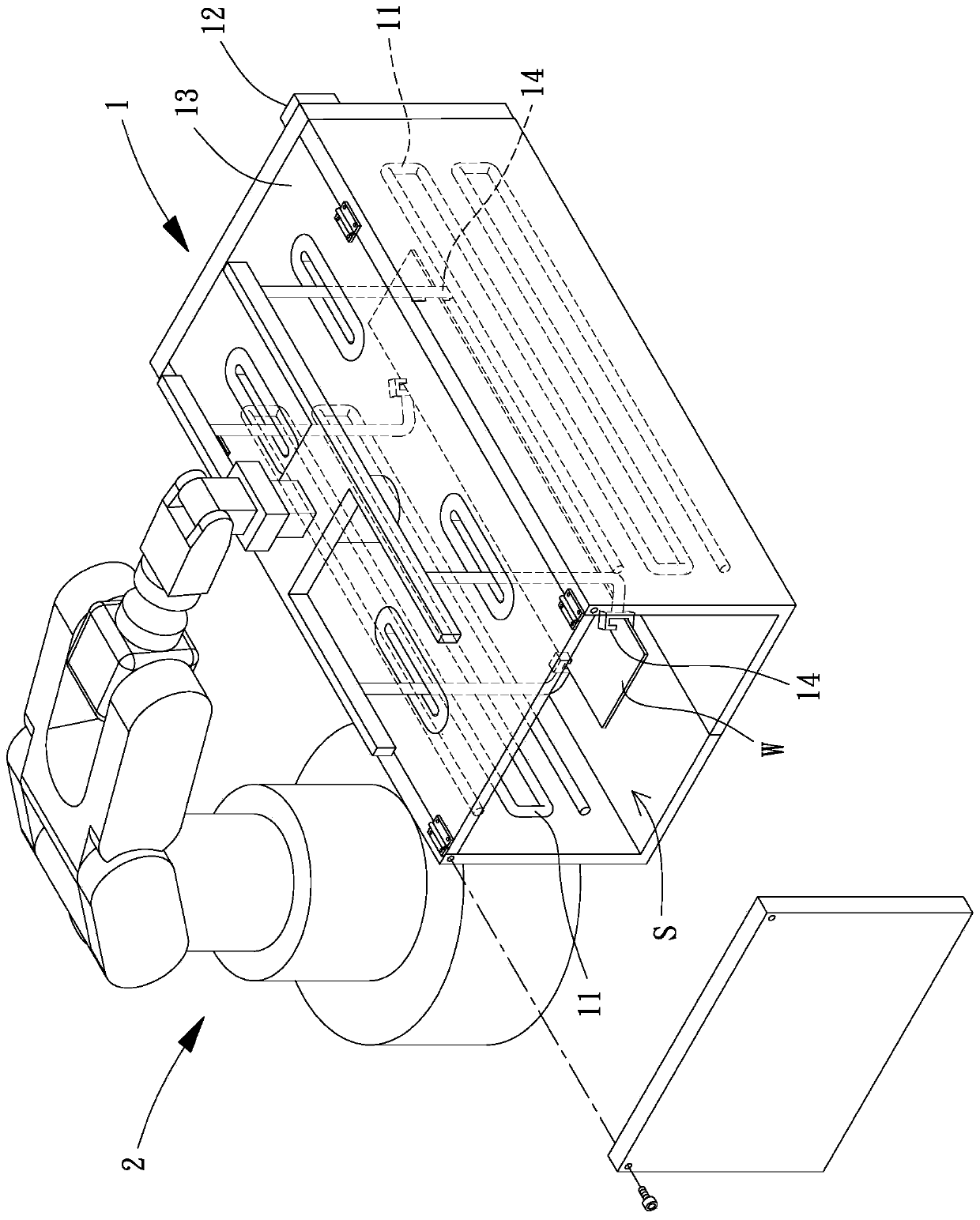

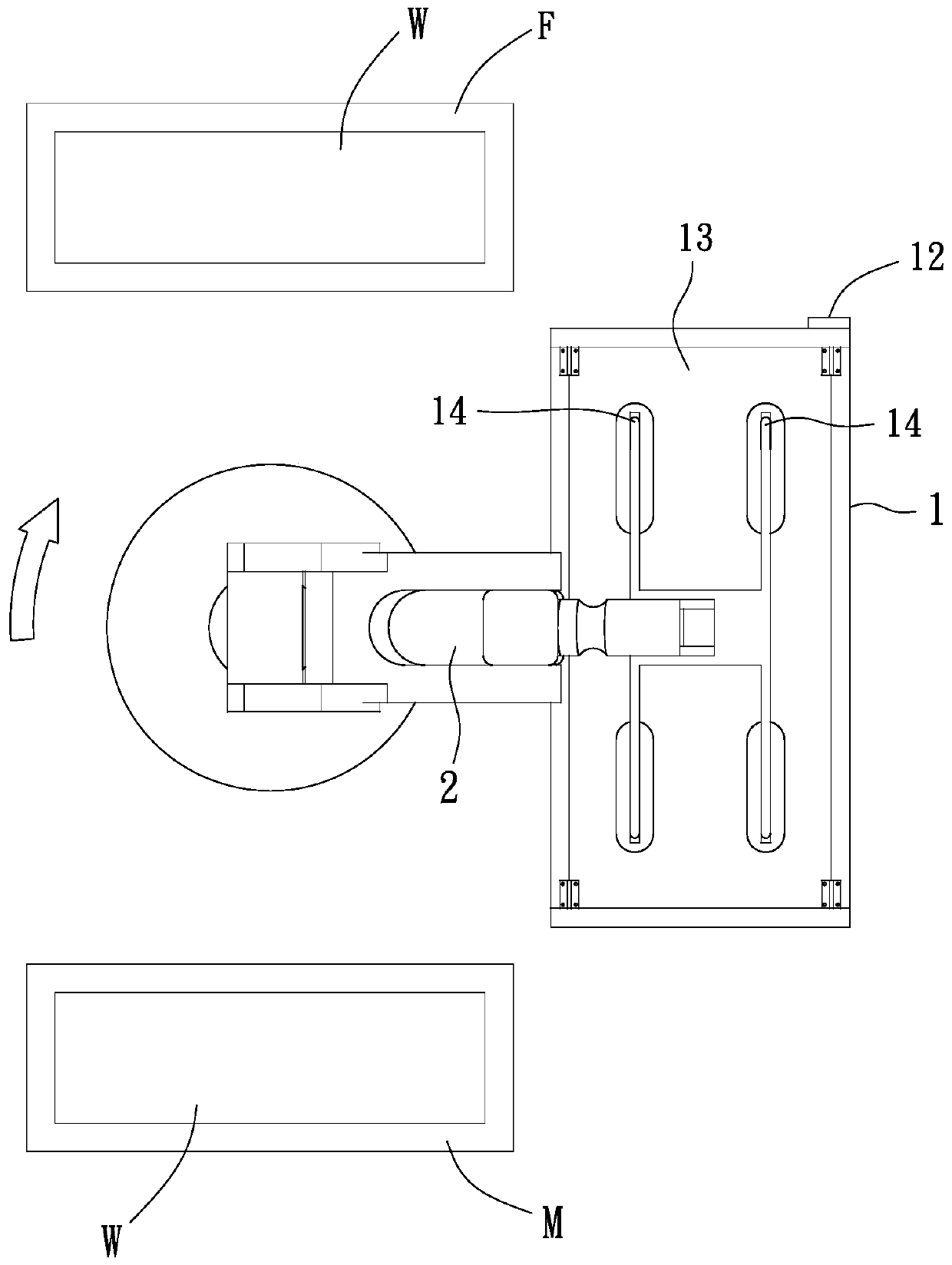

Pre-processing system and pre-processing method for heat formation operation

InactiveCN110883159AImprove forming accuracyIncrease productivityTemperature control modeProcess engineering

A pre-processing system and a pre-processing method for heat formation operation are provided to overcome the issue of temperature reduction of the workpiece during the movement of the workpiece in the conventional heat formation operation. The system includes at least one temperature control module having a heater, at least one conveying unit coupled to the temperature control module, and a control unit coupled with the temperature control module and the conveying unit, wherein the heater heats the workpiece on the temperature control module according to a temperature control mode. The conveying unit conveys the temperature control module and the workpiece to a convey position. The control unit adjusts the temperature control mode and sets the convey position according to a production condition.

Owner:METAL INDS RES & DEV CENT

Digital beamforming device and method based on fpga programmable delay circuit

ActiveCN103543440BAchieving Waveform Phase ShiftDelay time error is smallWave based measurement systemsPhase shiftedWavefront

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com