Reciprocating forming equipment for fuel cell metal polar plate

A metal plate and forming equipment technology, applied in metal processing equipment, metal rolling, metal rolling, etc., can solve the problems affecting the life and safety of the stack, inaccurate hole shape alignment, poor consistency, etc., to achieve The effect of improving the forming accuracy of the pole plate, reducing the damage of the pole plate, and improving the filling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

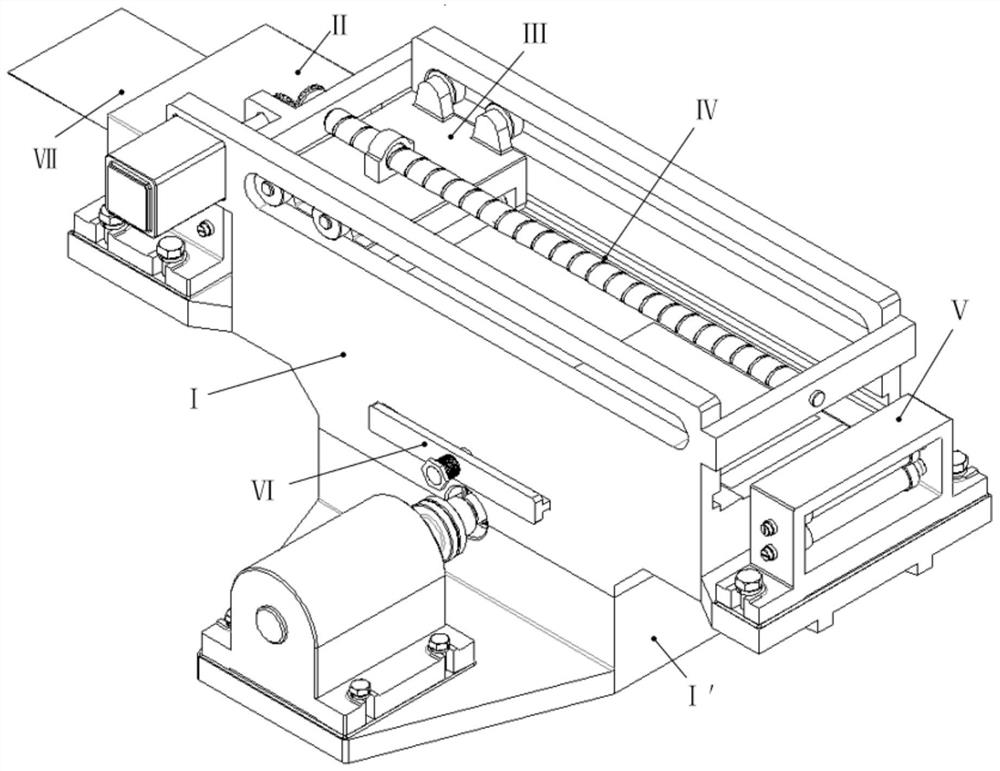

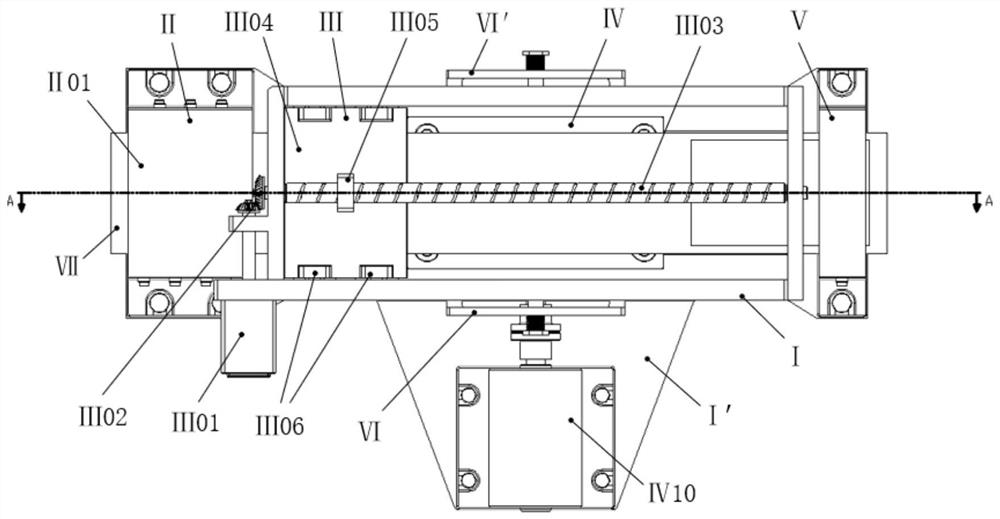

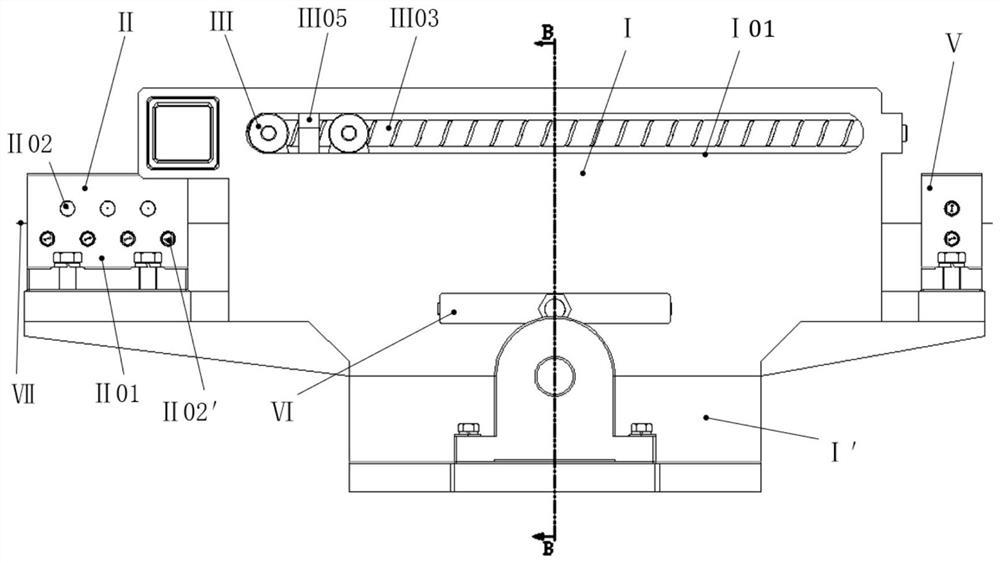

[0016] A fuel cell metal plate reciprocating forming equipment, such as figure 1 , 2 , 3, 4, and 5, when the metal blank needs to be processed and produced, the metal forming blank VII is straightened by the pole plate straightening device II, and then enters the forming station of the plane hard mold IV01 to stop, and the plane hard mold moves The motor Ⅳ10 drives the eccentric on the eccentric shaft Ⅳ05 to rotate upwards by 180°, pushing the flat dura mater Ⅳ01 to move upwards to the forming station; The nut Ⅵ02 is powered off, and the compression spring Ⅵ04 pushes the U-shaped limit pin Ⅵ01 to move into the frame, and the support platform Ⅳ03 is stuck, so that the flat dura mater Ⅳ01 stops at the forming station; the plate moving forming mechanism Ⅲ is installed on the The mobile forming motor Ⅲ01 on the upper left end of the upper frame Ⅰ drives the lead screw Ⅲ03 installed in the upper frame Ⅰ through the bevel gear Ⅲ02, and the lead screw Ⅲ03 drives the mobile platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com