Female die hydro-drawing device

A technology of hydraulic deep drawing and concave die, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of many defective products, low work efficiency, uneven wall thickness of parts, etc., and achieve uniform wall thickness and tensile strength Effects of increased strength and reduced thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

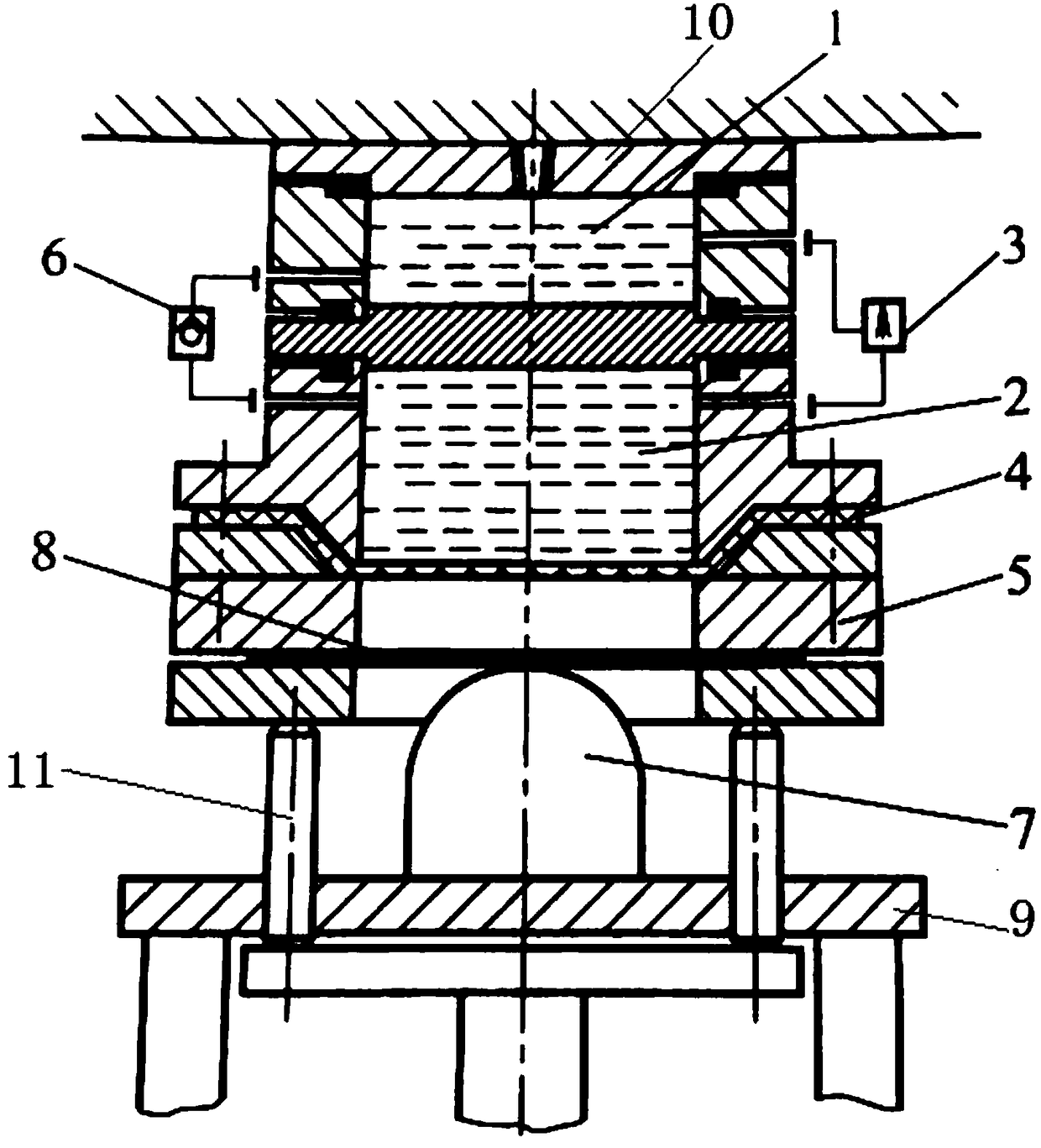

[0023] The rubber layer 4 with a thickness of 12mm to 15mm is fixed on the blank holder 5 below the lower cylinder 2, the sheet material 8 is stuck in the blank holder 5, and the upper cylinder 1 and the lower cylinder 2 are filled with hydraulic oil. When the punch When the seat 9 is upward, it drives the punch 7 to move upward, and the sheet material 8 is pushed into the blank holder 5 by the punch 7. After the sheet material 8 contacts the rubber layer 4, the oil pressure in the lower oil cylinder 2 rises, and the pressure in the lower oil cylinder 2 increases. The hydraulic oil tightly wraps the sheet material 8 on the punch 7. At this time, the sheet material 8 gradually deforms. When the oil pressure of the lower cylinder 2 reaches the limit value, the hydraulic oil is discharged from the overflow valve 3 into the upper cylinder 1 to maintain The oil pressure in the lower oil cylinder 2 is a constant value. When the punch 7 reaches the limited stroke, the sheet 8 is pulle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com