Manufacturing and processing method of D-type copper pipe

A processing method, D-type technology, applied in the direction of manufacturing tools, metal processing equipment, metal extrusion control equipment, etc., can solve problems such as difficult production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

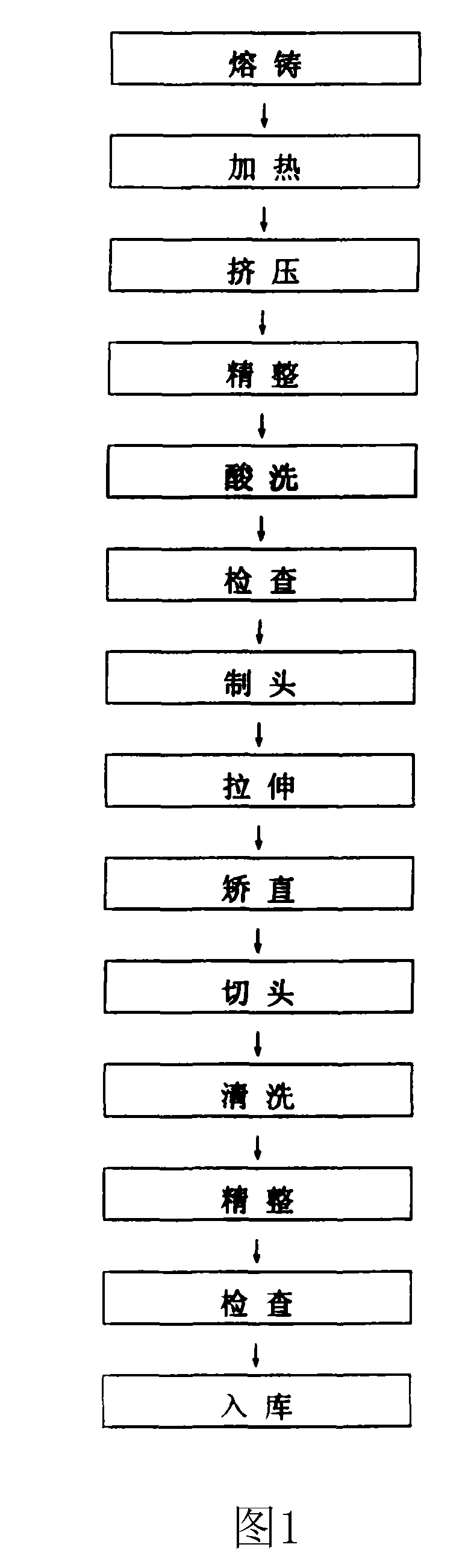

[0040] The processing and manufacturing process flow of the present invention is: melting and casting, heating, extrusion, finishing, pickling, inspection, head making, stretching, straightening, head cutting, cleaning, finishing, inspection, storage;

[0041]The specific processing technology is: 1. Melting and casting: melting and casting copper ingots by melting furnace; 2. Heating: heating ingots by heating furnace; The billet is subjected to transitional extrusion, directly extruded into a D-shaped tube billet, and made into a D-shaped tube billet; replacing the existing round extruded tube billet; wherein: the front end of the perforating needle is D-shaped, and the rear end is round , its diameter is consistent with the radius of the front end circle, and the front end of the piercing needle has an arc chamfer. , to increase the stability of the perforating needle; the arcs of the sizing section and the outlet section of the extrusion die are concentric with the outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com