Continuous extrusion method and equipment for producing large-width copper strip base from noncircular rod material

A technology of extrusion equipment and extrusion method, which is applied in the direction of metal extrusion, metal processing equipment, metal extrusion dies, etc., can solve the problems of inability to extrude width-thickness ratio, etc., achieve easy operation, improve processing efficiency, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

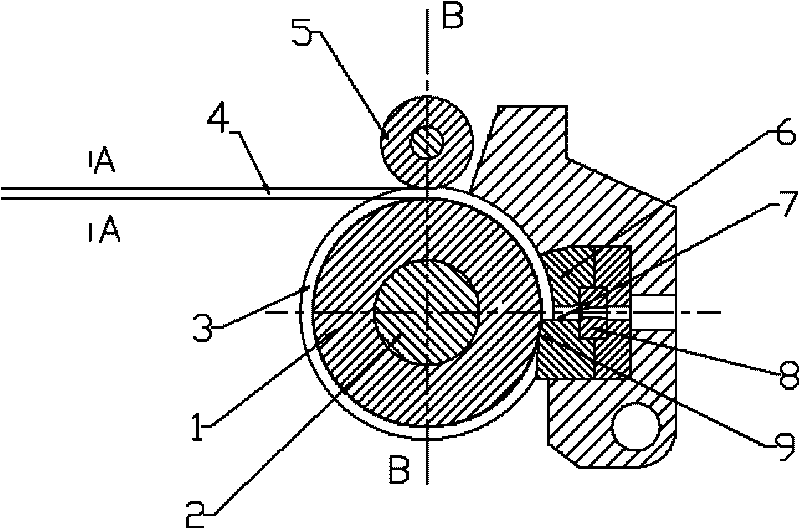

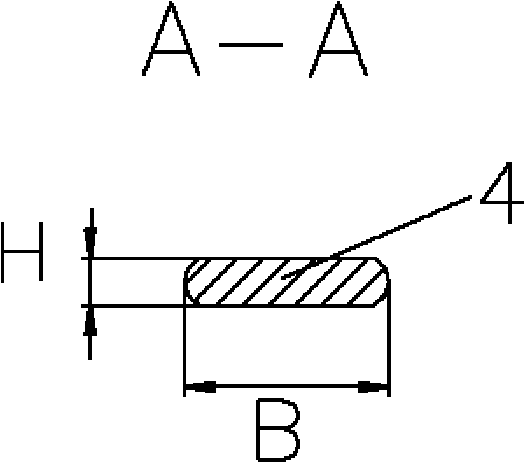

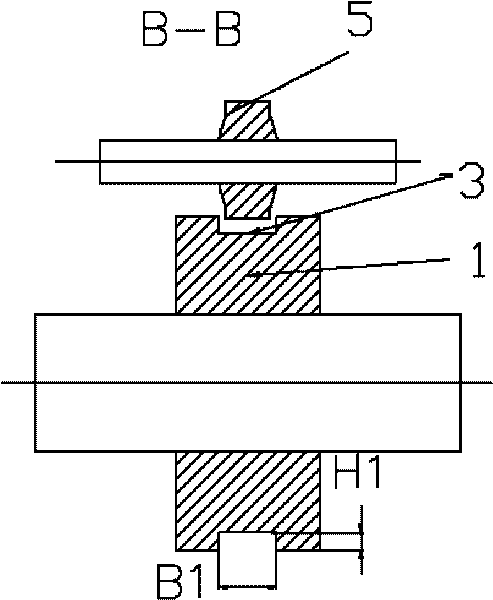

[0022] Such as Figure 1-7 The shown continuous extrusion equipment adopts a non-circular billet, the rotary extrusion wheel 1 is installed on the rotating shaft 2, and the rotary extrusion wheel 1 has an annular groove 3 in the circumferential direction, and the entrance width of the groove 3 is larger than or equal to the width of the non-circular blank, at image 3 Among them, the groove width B1 of the extrusion wheel is the width B of the slab plus (0-10mm), that is, B1=B+(0-10mm), and the depth H1 of the groove of the extrusion wheel is the thickness H of the slab plus (0 -5mm), that is, H1=H+(0-5mm).

[0023] The cross-sectional shape of the block on the cavity 6 depends on the cross-sectional shape and size of the extrusion wheel groove 3. Figure 4-6 Among them, the cross-sectional shape of the material blocking block 9 of the cavity is a non-circular section with rounded corners, and the width B2 of the material blocking block 9 is the extrusion wheel groove width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com