Backward extrusion forming device for miniature precision part

A precision parts, reverse extrusion technology, applied in the direction of metal extrusion, pressure head / punch, metal processing equipment, etc., to achieve the effect of reduced processing, high surface quality, and uniform thickness of the side wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

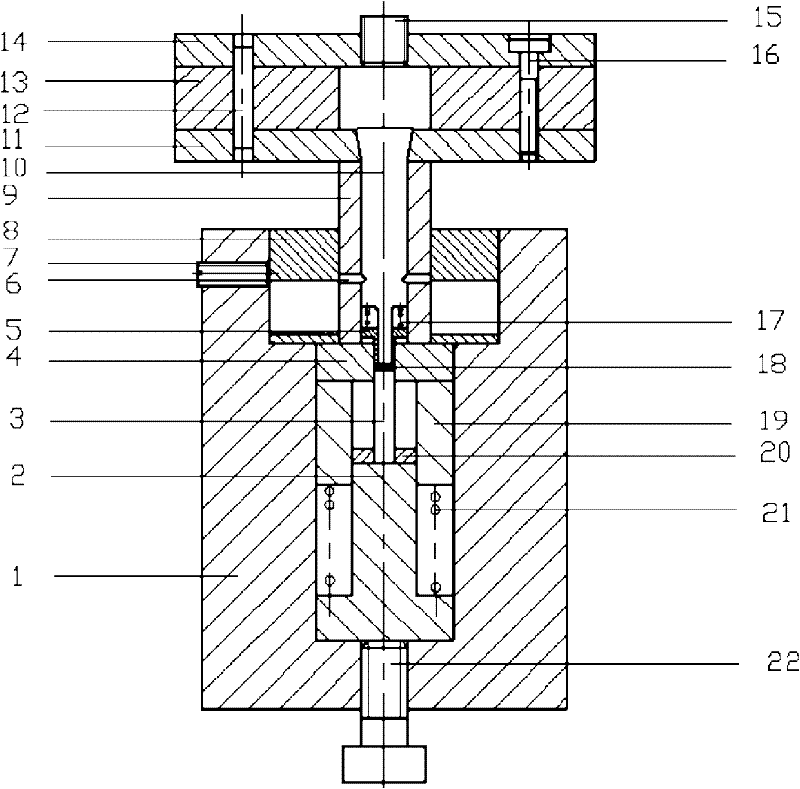

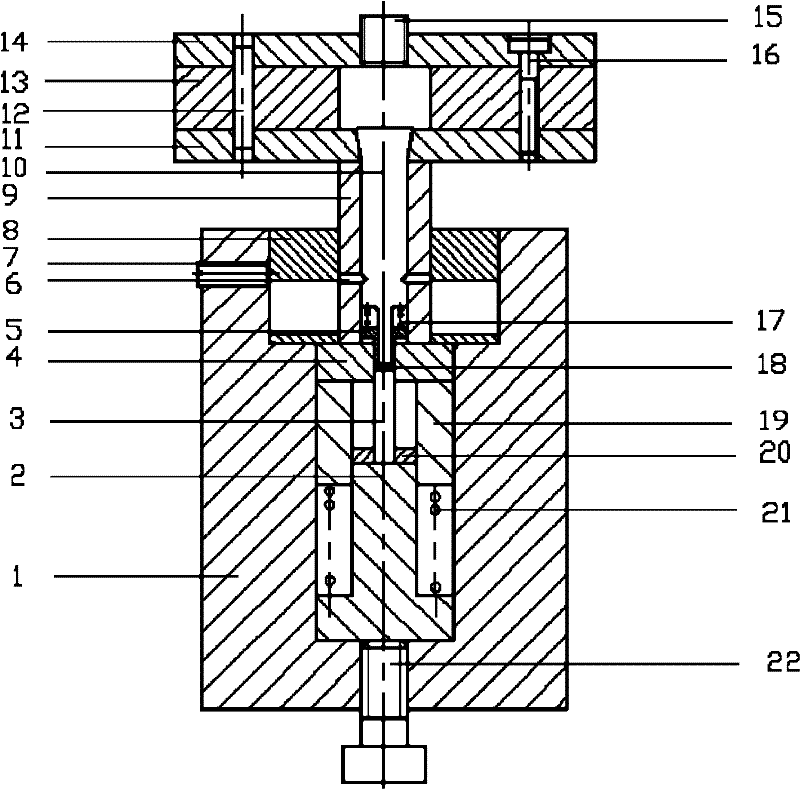

[0012] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail: present embodiment implements under the premise of technical solution of the present invention, has provided detailed implementation mode and operation process, but protection scope of the present invention is not limited to following Example.

[0013] Such as figure 1 As shown, this embodiment includes: mold base 1, support base 2, ejector rod 3, die 4, punch sleeve 5, pin 6, fastening screw 7, connecting seat 8, die press head 9, punch 10 , upper mold base 11, fixed pin 12, upper backing plate 13, upper template 14, fixed bolt 15, connecting bolt 16, sleeve spring 17, blank 18, die support 19, fixed block 20, support spring 21, mold unloading Bolt 22. Wherein support base 2, push rod 3, die 4, die support 19, fixed block 20, support spring 21 form floating device; Connecting seat 8, die press head 9, punch 10 and pin 6 form combination press head; Convex ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com