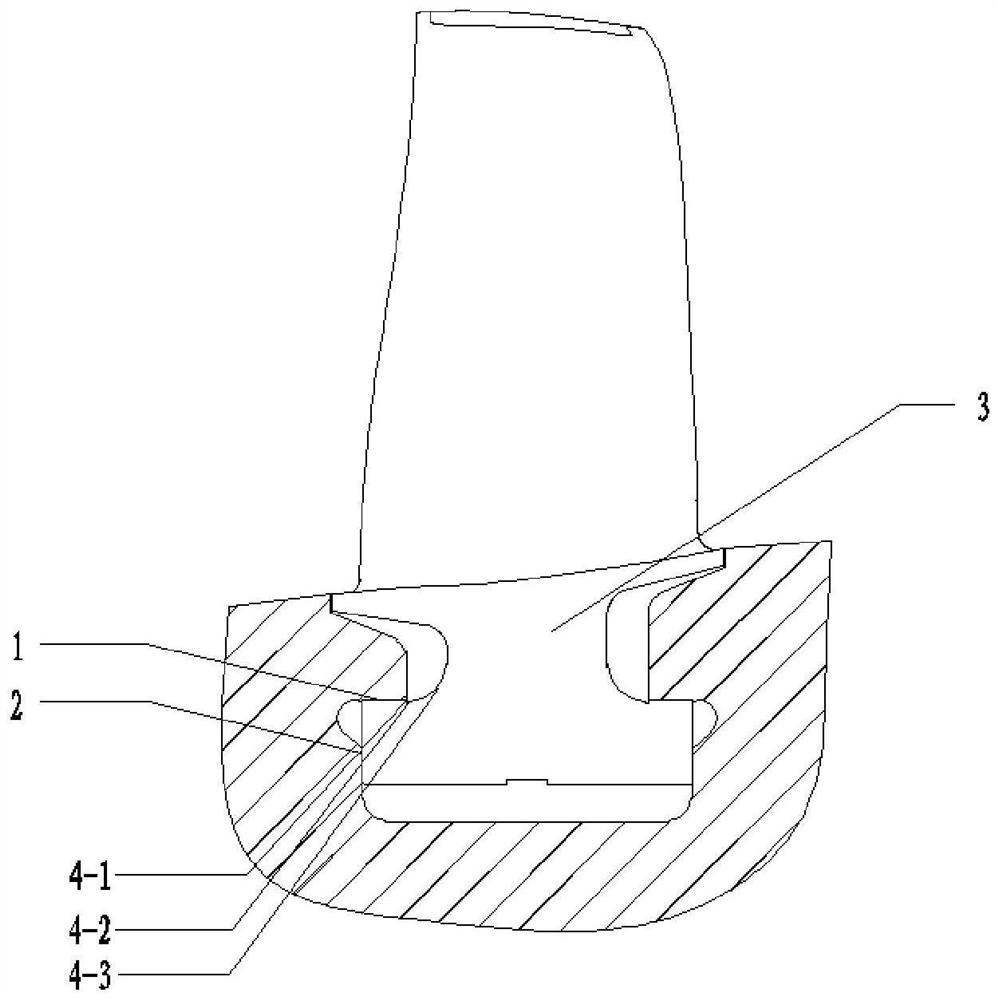

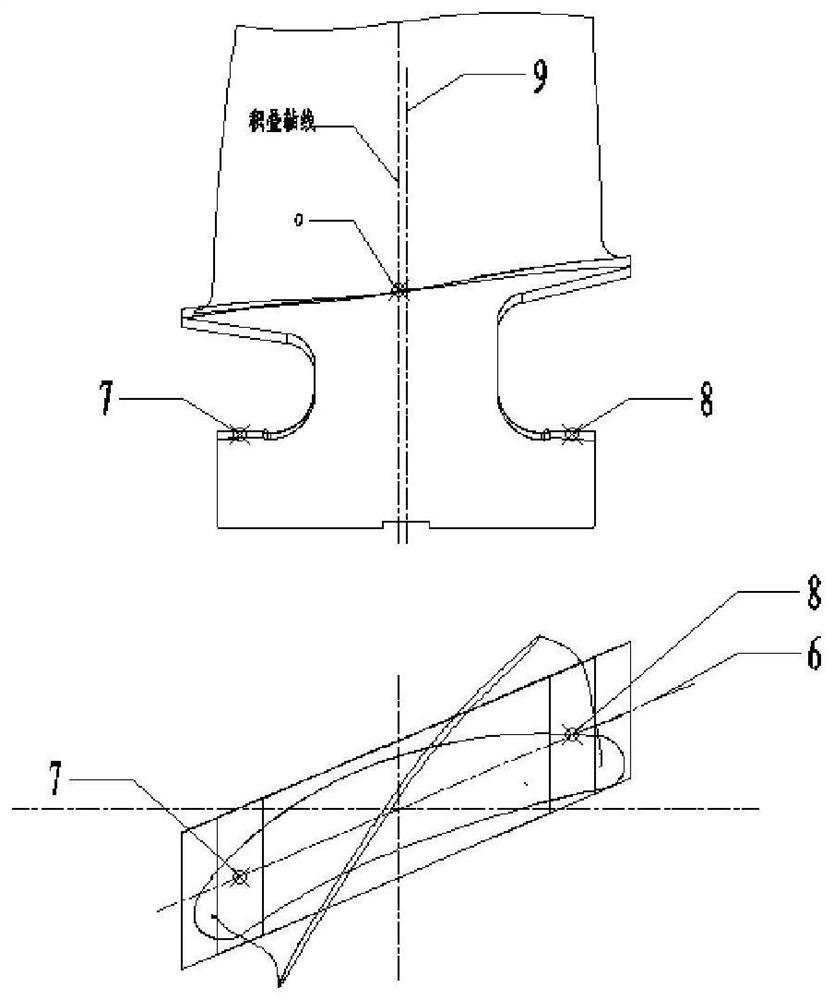

Blade circumferential arc hammer foot type tenon machining device and machining method thereof

A processing device and blade technology, which is applied to metal processing equipment, manufacturing tools, details of milling machine equipment, etc., can solve the problems of large deformation of the knife, high precision requirements for the height deviation of the two shoulders, and low processing efficiency, so as to meet the processing efficiency. and dimensional accuracy, solving poor surface quality, and improving the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

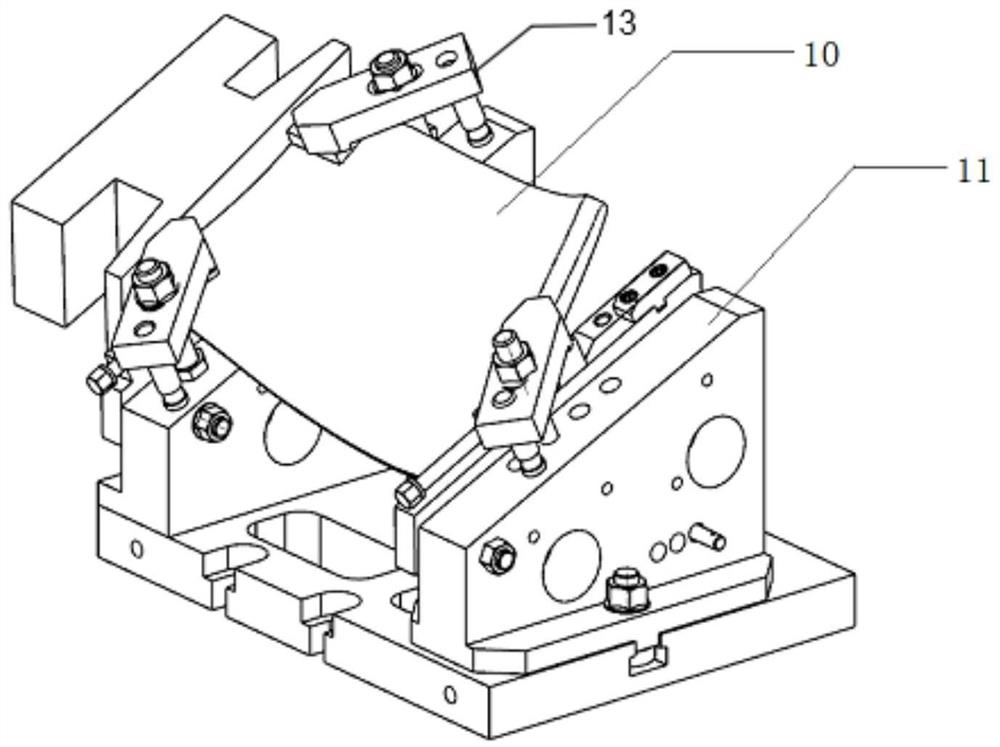

[0046] The present invention also provides a method for processing blade circumferential arc hammer foot type tenons, which includes the following steps:

[0047] S1: Clamp the blade blank 10 with the blade body and blade tip process platform through the first positioning seat 11-3 and the second positioning seat 11-4. After clamping, the front and rear end faces of the tenon are parallel to the plumb direction, and the back of the basin is inclined. On the horizontal plane; the inclination angle of the first positioning seat 11-3 and the second positioning seat 11-4 is 23°;

[0048] S2: Use a round blade universal milling cutter for rough machining, scan and mill the bottom surface and surroundings of the tenon, leaving a margin of 0.5-0.7mm;

[0049] S3: Use a helical toothed cylindrical milling cutter to mill the radial plane 3 on the back of the mortise basin. During milling, the tool passes along the oblique line to process the side surface. The machine speed is 200-300r / ...

Embodiment 2

[0054] The present invention also provides a method for processing blade circumferential arc hammer foot type tenons, which includes the following steps:

[0055] S1: Clamp the blade blank 10 with the blade body and blade tip process platform through the first positioning seat 11-3 and the second positioning seat 11-4. After clamping, the front and rear end faces of the tenon are parallel to the plumb direction, and the back of the basin is inclined. On the horizontal plane; the inclination angle of the first positioning seat 11-3 and the second positioning seat 11-4 is 25°;

[0056] S2: Use a round blade universal milling cutter for rough machining, scan and mill the bottom surface and surroundings of the tenon, leaving a margin of 0.5-0.7mm;

[0057] S3: Use a helical toothed cylindrical milling cutter to mill the radial plane 3 on the back of the mortise basin. During milling, the tool passes along the oblique line to process the side surface. The machine speed is 200-300r / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com