Expanding ring type fixed extrusion pad for aluminium extrusion machine

An extrusion pad, aluminum extrusion technology, applied in metal extrusion, indenter/punch, metal processing equipment, etc., can solve the problems of poor manufacturing and processing technology, easy breakage and damage of expanding rings, complex structure of fixed pads, etc. , to achieve good press performance, improve reliability, and reduce cycle time without extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

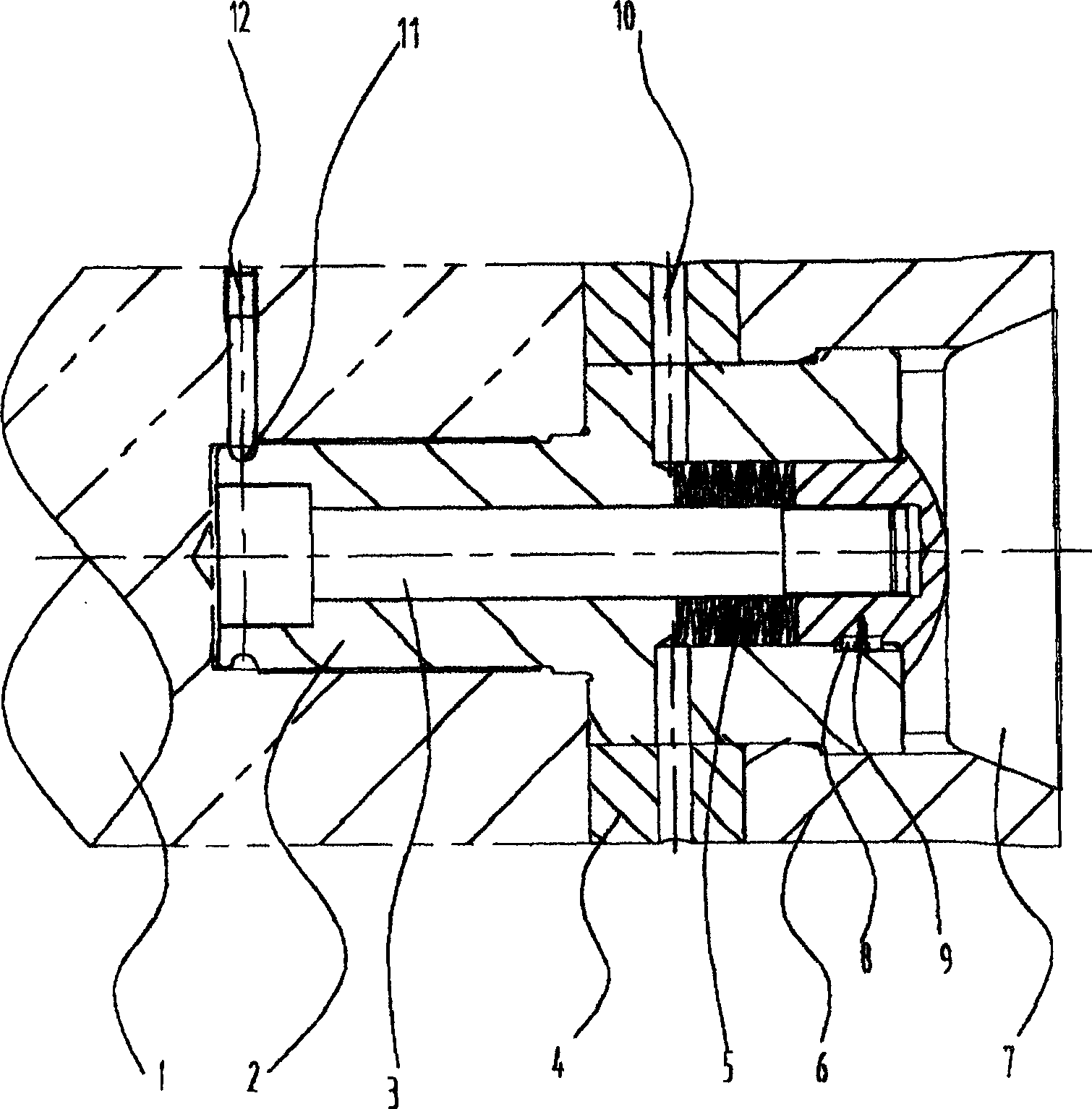

[0016] figure 1 Shown is a structure of an expanding ring-type fixed extrusion pad for an aluminum extrusion machine. The expansion ring type fixed extrusion pad includes a connecting body 2, a bolt 3, a ring pad 4, a spring 5, an expanding ring 6 and a cone pad 7 which are threaded on the extrusion rod 1; There is a spring inside, and the bolt connects the extrusion pad connecting body with the cone pad. The expansion ring is installed outside the extrusion pad connecting body. The inner cone surface of the expansion ring matches the cone surface of the cone pad, and the tail of the expansion ring matches the connecting body. ; The expansion ring is separated from the connecting body; the ring pad is installed between the extrusion rod and the expansion ring. The matching part between the middle hole of the connecting body and the cone pad is provided with a key 8 to prevent the rotation of the cone, and the key is fixed on the cone pad by a screw 9. Mounting holes 10 are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com