Patents

Literature

31results about How to "Increase amino acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Meat flavor hot flavorings and production method thereof

InactiveCN101455323AReduce spicinessHighlight aromaFood preparationMonosodium glutamateIllicium verum

The invention discloses a meat scent savoury and pungent flavoring, containing the following raw materials: vegetable oil, dried pimiento, zanthoxylum bungeanum, star anise, salt, sugar, monosodium glutamate, starch, meat reaction solution, fresh increasing flavoring agent. A production method of the meat scent savoury and pungent flavoring includes: heating the vegetable oil to 150-200 DEG C; respectively adding the dried pimiento zanthoxylum bungeanum and anise tree and frying for 30-60 seconds, quickly removing, draining the oil, and then coarse crushing and mixing the dried pimiento zanthoxylum bungeanum and anise tree; adding salt, sugar, monosodium glutamate, starch, meat reaction solution in the mixture, mixing uniformly; and then adding the fresh increasing flavoring agent, and then mixing uniformly; performing ultramicro crushing after microwave drying, and then obtained the completed product by hermetic package. The invention uses a short time fried mode to alleviate the biting taste of the pimiento and prominent the fragrant flavor of the pimiento; and matches with flavoring made up by different meat reaction solutions, so that the invention contains not only the meat flavor, but also an increase of essential amino acids of human body, minerals and so on.

Owner:浙江正道生物科技有限公司

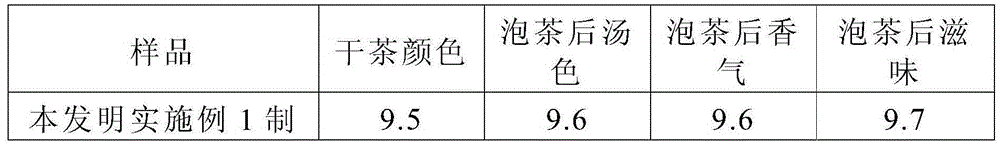

Processing process for black tea

The invention relates to a processing process for black tea, and belongs to the technical field of tea leaf processing. The processing process mainly includes the steps of selecting fresh leaves and conducting withering, rolling, fermenting and drying, wherein enzymic preparations are added in the withering process, fragrance rocking is conducted after withering, and enzyme killing is conducted after fermentation. In the processing process for black tea, enzymes are added in the withering process, and therefore the content of fresh leaf tea polyphenol, amino acid, lutein, water extract and the like is increased; fragrance rocking is added after withering is conducted, enzyme killing is added after fermentation, and therefore white-leaf black tea can form the quality characteristics such as the unique fragrance, the unique taste and the like.

Owner:宁波市海曙凯达纸制品厂

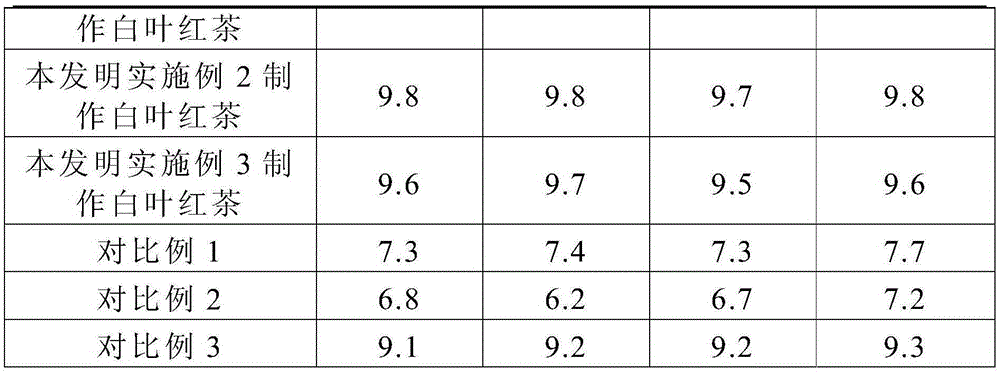

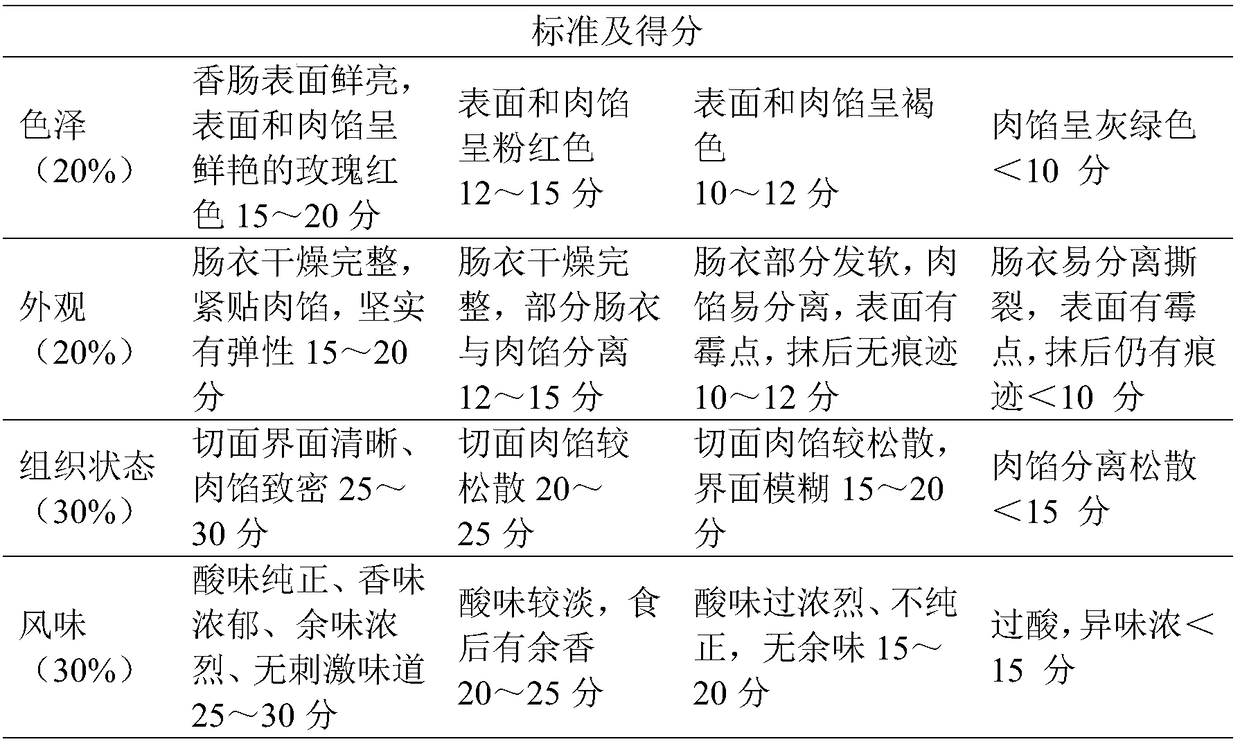

Fermented small sausages and preparation method thereof

InactiveCN109363097ARealize long-term storage at room temperatureImprove product qualityMeat/fish preservation using chemicalsFood ingredient as mouthfeel improving agentLactic acid bacteriumAdditive ingredient

The invention relates to fermented small sausages. The fermented small sausages are prepared from the following ingredients in parts by weight: 50-80 parts of lean pork, 0-40 parts of streaky pork, 5-20 parts of fat, 2-2.5 parts of edible salt, 0.3-0.5 part of acerola cherry powder, 0.05-0.2 part of D-sodium isoascorbate, 0.3-0.6 part of glucose, 0.25-0.8 part of seasonings for fermented sausages,0.005-0.03 part of a lactic acid bacterium fermentation agent, and 0.005-0.05 part of spice extracts. According to spoilage-preventing and quality-guaranteeing requirements of fermented small sausages, hurdle factors are designed and adjusted in the preparation method so as to realize long-term storage of the fermented small sausages at normal temperature, wherein the hurdle factors include curing, secondary sterilization, usage of the spice extracts as natural preservatives, low product acidity and low product water acidity. Thus, the hurdle factors interact so as to have product quality ofthe fermented small sausages improved.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

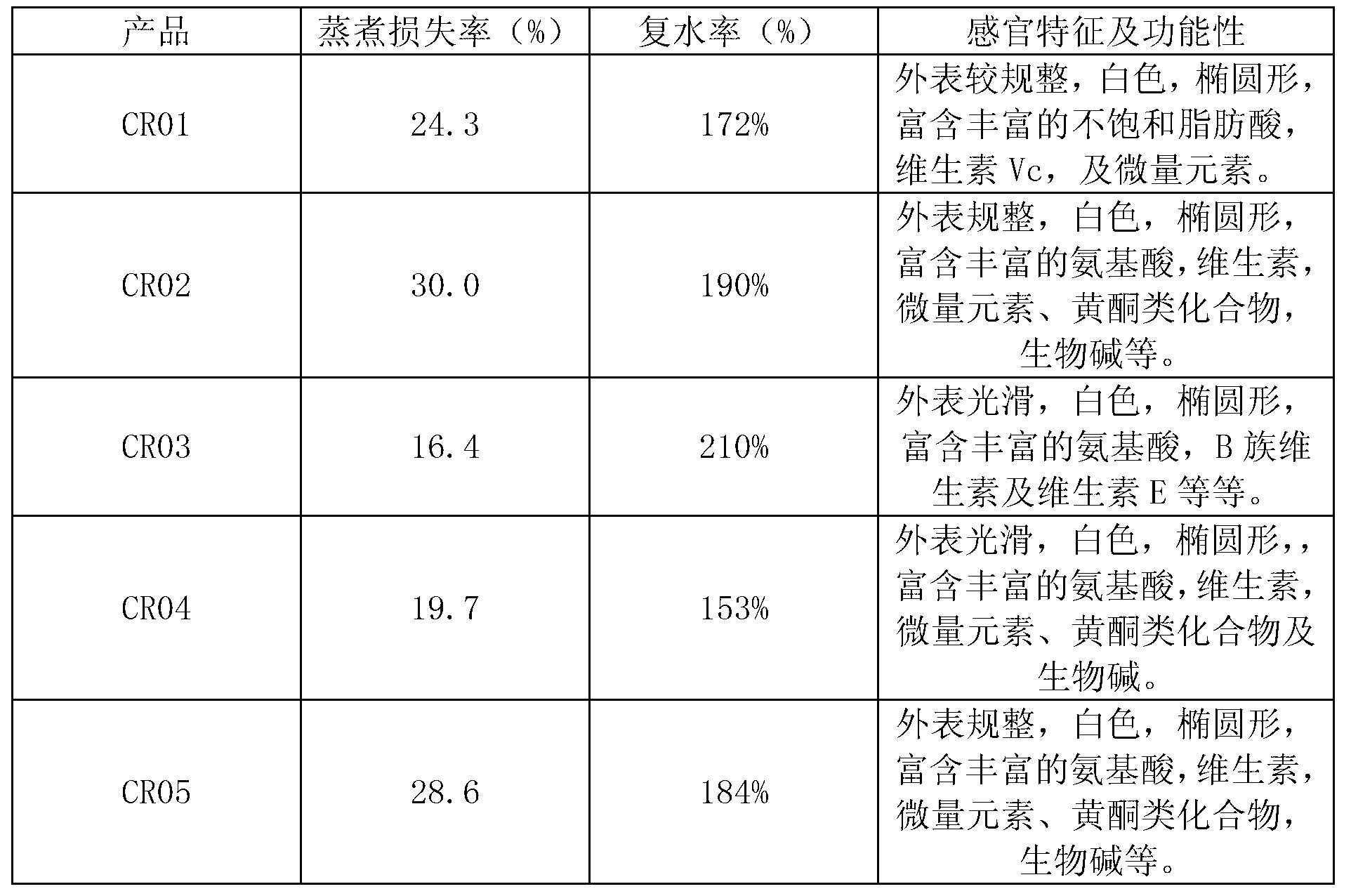

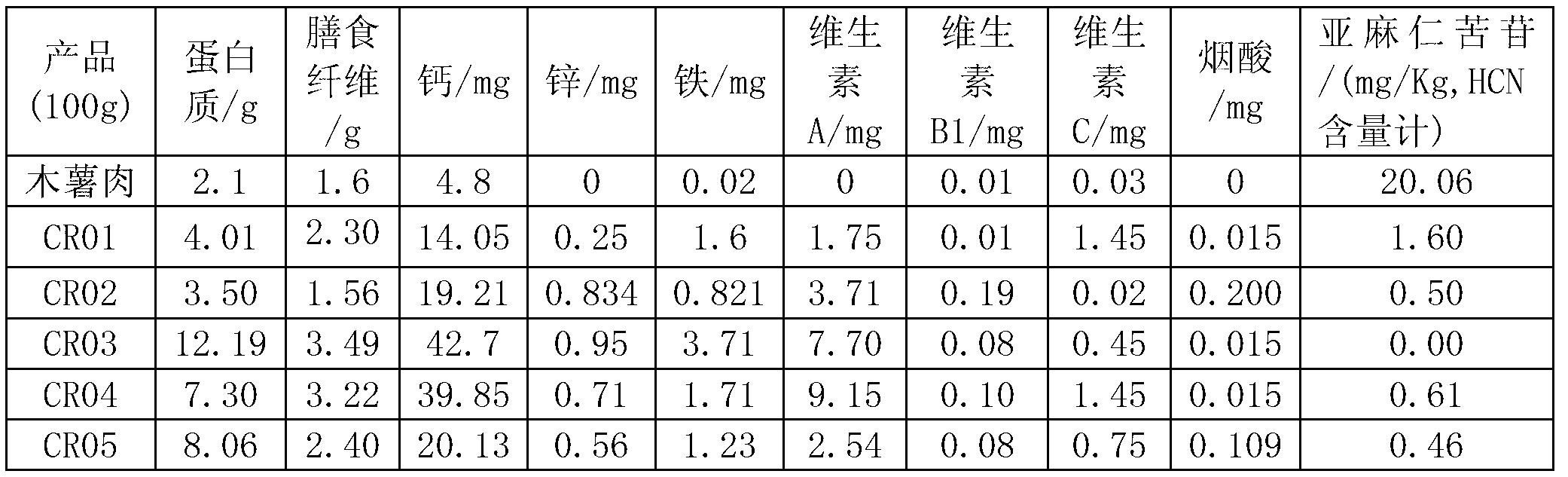

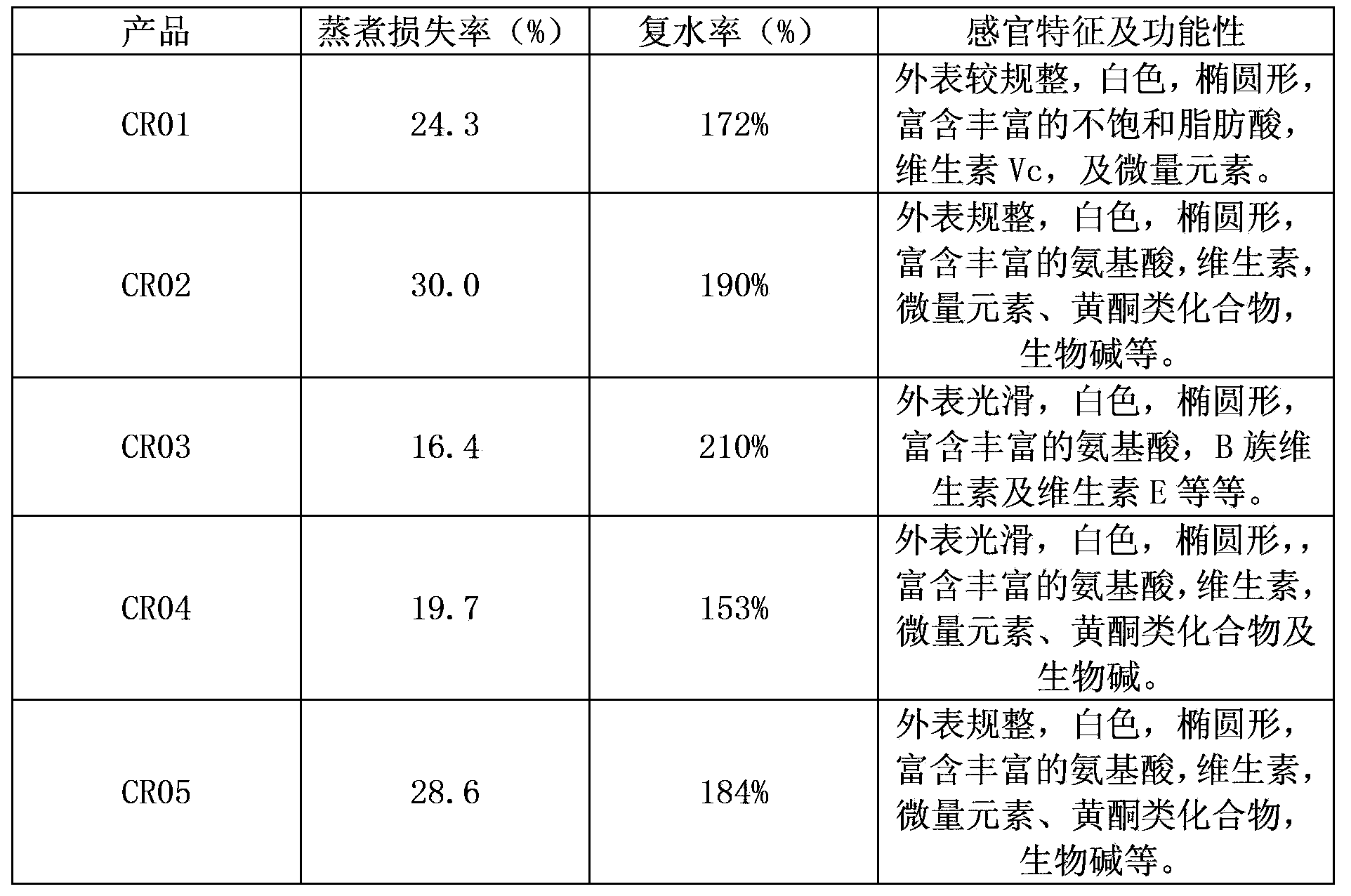

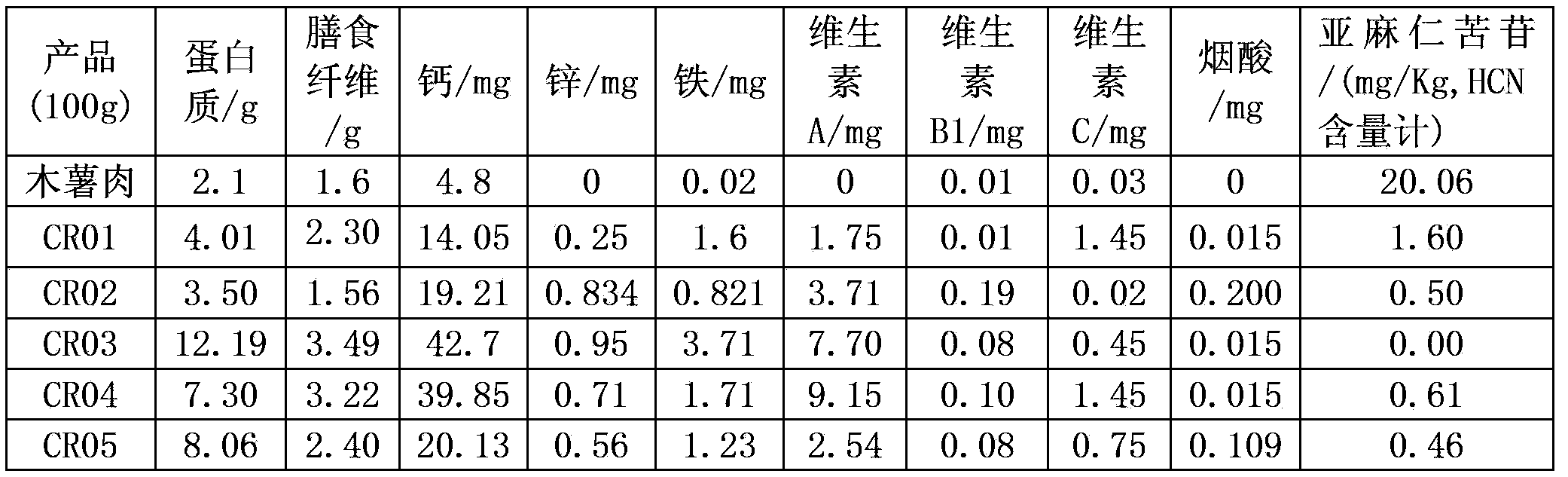

Cassava rice and processing method thereof

InactiveCN103156141AImprove eating effectIncrease the degree of staple foodFood preparationNutritive valuesEdible oil

The invention provides cassava rice which consists of raw powder and a mixture. The raw powder comprises the following components in percentage by weight: 30-60 percent of a component A, 30-60 percent of a component B and 5-10 percent of a component C, wherein the component A is cassava starch; the component B is one or a mixture of broken rice meal, corn starch and soybean meal; and the component C is one or a mixture of chestnut powder, yam flour, beautiful millettia root powder and banana meal. The mixture is a proper amount of edible oil, gelatin and edible alcohol. The cassava rice takes the cassava starch as a main raw material, is additionally provided with other side crops, the chestnut powder, the yam flour, the beautiful millettia root powder and the like an auxiliary mode, is convenient to eat, reasonable in formula, fine and smooth in mouthfeel, is easily cured and less prone to breakage in a cooking process, is enriched in vitamins, amino acid and trace metal elements, can improve the nutritive value of cassava and make non-food crops become principle foods, does not have odor and is neat in appearance and good in mouthfeel.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

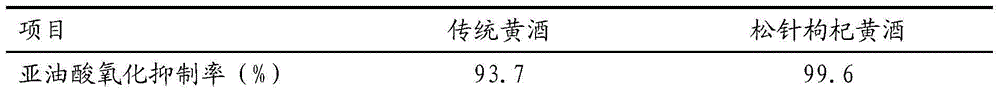

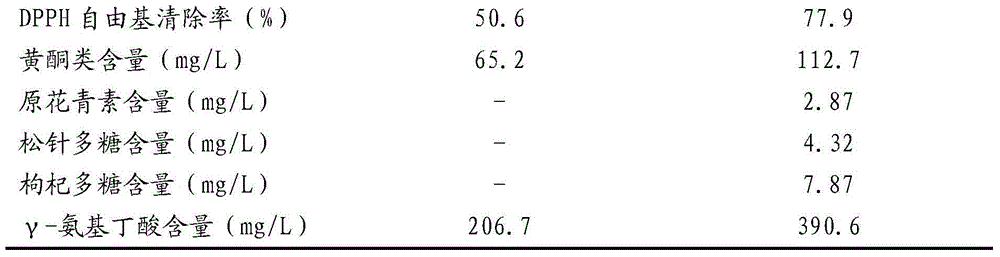

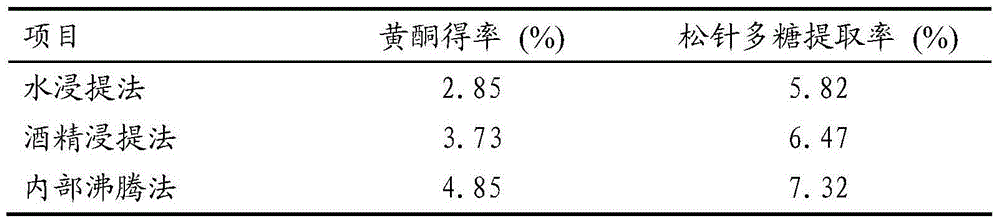

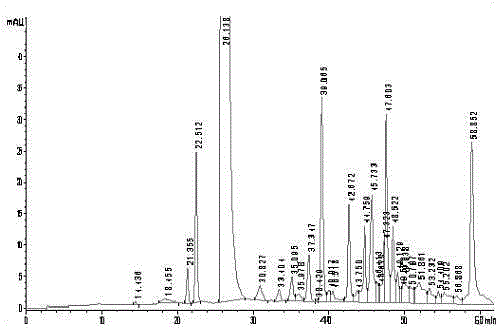

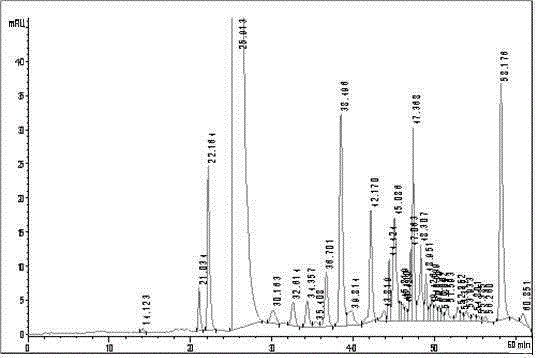

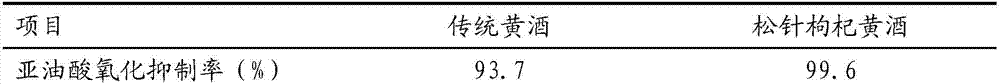

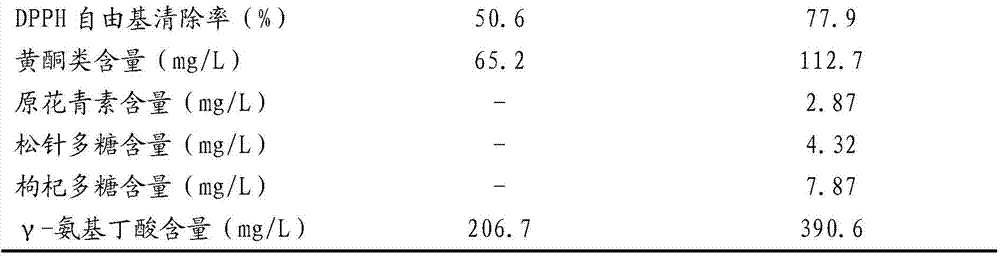

Preparation method of pine needle and Chinese wolfberry yellow rice wine

ActiveCN104946454ATroubleshoot graying issuesReduce bitternessMicroorganism based processesAlcoholic beverage preparationWine industryVitamin

The invention relates to the field of yellow rice wine brewing and particularly provides a preparation method of pine needle and Chinese wolfberry yellow rice wine. According to the preparation method, pine needle leach liquor and Chinese wolfberry clear liquid are added in the yellow rice wine brewing technology, the whole brewing technology is adjusted, novel compound barm is reselected for fermentation, and brand-new pine needle and Chinese wolfberry yellow rice wine is obtained finally. Pine needle and Chinese wolfberry are organically combined with production of yellow rice wine, and on the basis of the original nutrition of yellow rice wine, the contents of amino acids, mineral substances and vitamins are increased, and functionalized active substances including Chinese wolfberry polysaccharide, flavonoid and anthocyanin are provided, so that further development of the yellow rice wine industry is facilitated.

Owner:QILU UNIV OF TECH +1

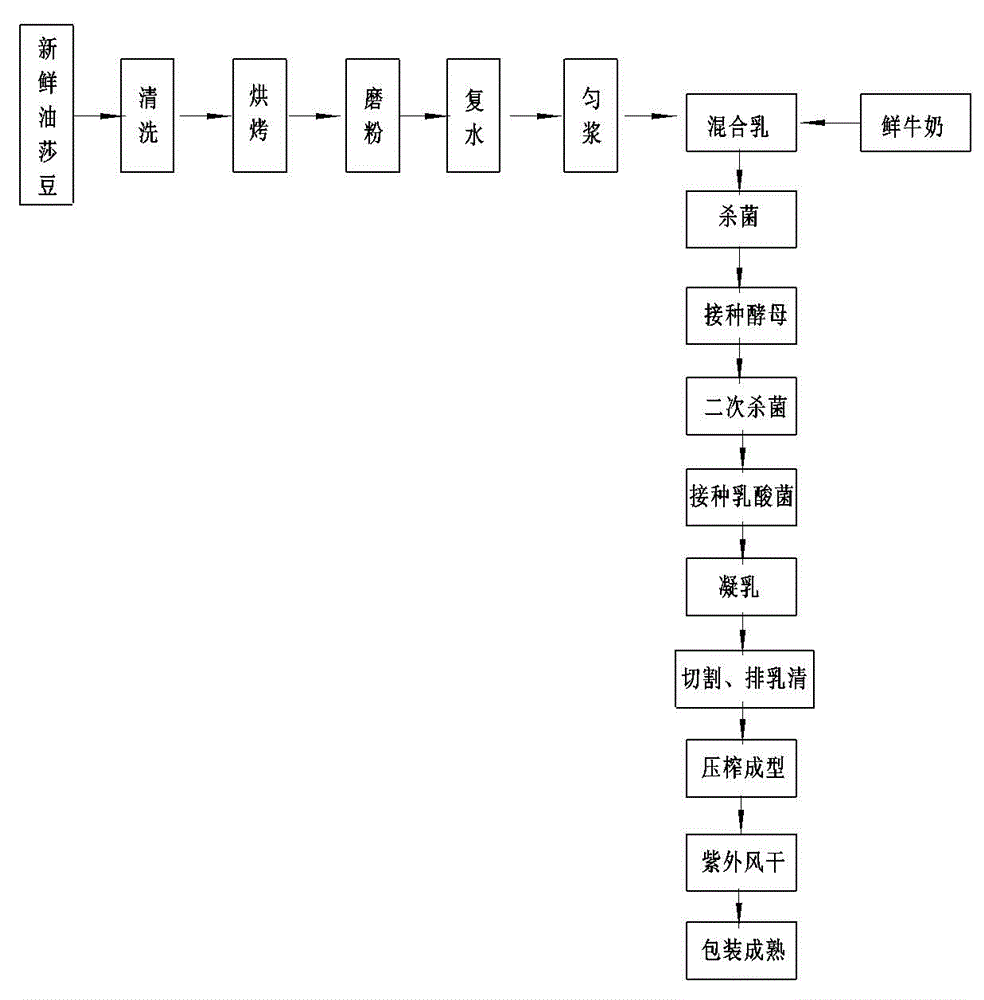

Method for preparing tigernut soft cheese

The invention relates to a method for preparing a soft cheese product, and particularly relates to a method for preparing tigernut soft cheese. The method for preparing the tigernut soft cheese is characterized by mainly comprising the following steps: preparing milk tigernut juice; standardizing mixed milk; sterilizing the mixed milk; inoculating saccharomycetes for first fermentation; sterilizing fermented milk; inoculating lactobacillus for second fermentation; curding milk; cutting the curded milk and draining whey; subjecting the obtained product to squeeze molding; drying the product with ultraviolet; and packaging and maturing the obtained product. The method disclosed by the invention is simple, economic and practical, is convenient to operate, is a method for preparing the tigernut soft cheese with mellow and good taste, which can effectively utilize the traditional Chinese medicine characteristics of tigernut and can greatly increase the digestion absorption rate of nutrients.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

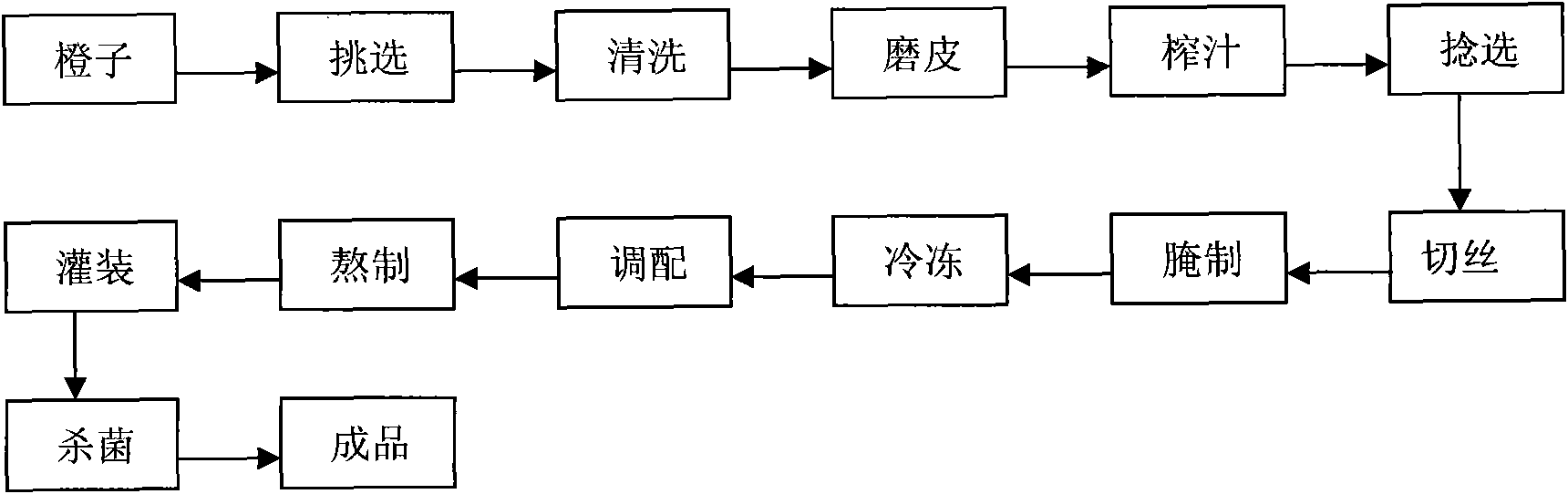

Production method of navel orange tea

InactiveCN101611750ABroaden the development pathIncrease incomeTea substituesFood preparationNutritive valuesNavel

The invention provides a production method of navel orange tea, comprising the following steps: selecting fresh navel orange fruits which are approximately the same in sizes and identical in maturity, have rinds without diseases and have no mechanical damages as processing materials, and obtaining the navel orange tea through the working procedures of cleaning, grinding rinds, juicing, twisting and selecting, shredding, debitterizing, sousing, freezing, mixing, boiling and the like. The production method provided by the invention preserves the nutritive value and the characteristic flavor of the natural navel oranges. The navel orange tea possesses the natural color of the navel oranges, full aroma and pleasant sweetness and sour. In addition, natural honey is added, thus enriching the nutritive value of the product and increasing the monose content, amino acid, vitamins, minerals and the like in the product. The production method broadens the development road of deep processing of the navel orange, mitigates the problem of difficult sale of surplus fresh navel oranges, increases the additional value of the navel orange products and the income of orange farmers and prompts the development of the citrus industry.

Owner:ZIGUI COUNTY QUGU FOOD

Feeding method of sheep oral formalin and feed thereof

InactiveCN101843227AIncreased ad libitum intakeImprove slaughter performanceAnimal feeding stuffProtozoaSmall intestine

The invention discloses a feeding method of sheep oral formalin, comprising the following steps: diluting formalin with a required amount into 50-100 times, mixing with feed (ration) to feed sheep or diluting the formalin with the required amount into 200-400 times, directly leading the diluted formalin to be taken by sheep orally, and feeding the feed (ration) at the same time. By the invention, the free feed intake of the sheep is increased, the number of protozoa in a sheep rumen is reduced, while the number of rumen bacteria is increased, amino acid and other substances reaching sheep small intestines are obvious increased, and the nutrient substances like amino acid absorbed by the sheep small intestines are obviously boosted. By the invention, the slaughtering performance of the sheep can be greatly improved. The methanal content in an oral formalin sheep texture is determined for the first time in the invention, which shows that the methanal content in the textures such as muscle, liver and the like of sheep which adopts the oral formalin of the invention in a long time is less than 2mg / Kg (the beer standard).

Owner:雒秋江 +1

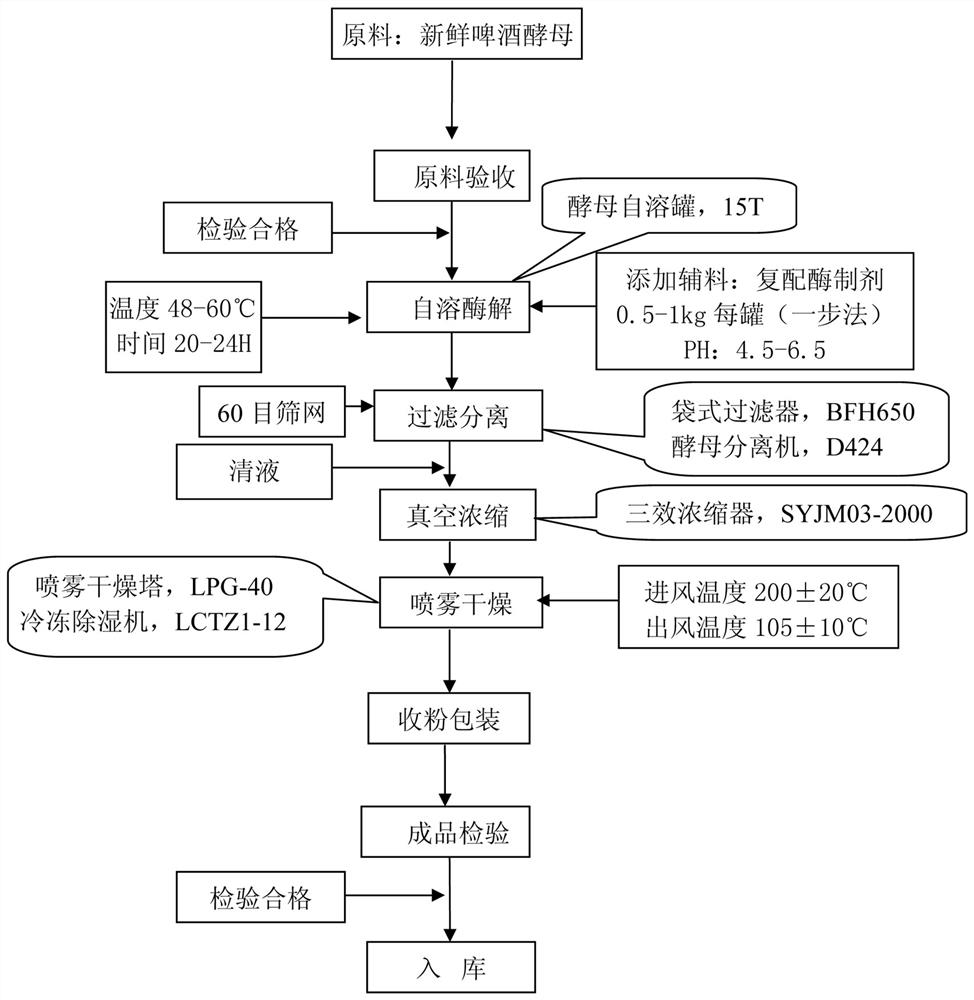

Production method of beer yeast extract

PendingCN112515159APromote autolysisThe autolytic enzymolysis step uses yeast cell autolysis to promoteFood ingredientsCartonProcess engineering

The invention discloses a production method of a beer yeast extract. The production method comprises the following steps that raw materials are checked and accepted, specifically, quality inspection is conducted on beer yeast; autolysis enzymolysis is conducted, specifically, qualified beer yeast is pumped into a yeast tank, a compound enzyme preparation is added into the yeast tank, and it is started to calculate the autolysis enzymolysis time; filtering and separating is conducted, specifically, the beer yeast is filtered and separated; vacuum concentration is conducted, specifically, vacuumconcentration is conducted on the filtered and separated beer yeast by adopting a triple-effect concentrator; spray drying is conducted, specifically, the beer yeast feed liquid subjected to vacuum concentration is dried; powder collecting and inner packaging are conducted, specifically, powder collecting operation is conducted once every 15-20 minutes, during powder collecting, an upper valve ofa powder collector is closed, a lower valve is opened, powdery finished products are collected and put into a polyethylene bag for food, weighing is conducted, a bag opening is sealed, and the products obtained after powder collecting and inner packaging are completed are placed in a temporary storage room; finished products are inspected, specifically, the finished products are sampled and inspected in a clean area by inspectors; and packaging and warehousing are conducted, specifically, the qualified finished products after being subjected to inner packaging and opening sealing are put intoa composite plastic woven bag or carton.

Owner:ZHEJIANG DEQING DONGLI BIOLOGICAL DEV

Lying silkworm pencil and preparation method and use method thereof

InactiveCN103860446AGood groomingIncrease amino acidCosmetic preparationsMake-upPolymer scienceMicrocrystalline wax

The invention discloses a lying silkworm pencil and a preparation method and a use method thereof. The lying silkworm pencil is prepared by the following components in percentage by weight: 85-95% of pearl powder, 10-35% of microcrystalline wax, 4-9% of beeswax, 10-20% of white oil, 2-5% of lanolin, 3-5% of titanium dioxide, 10-20% of amino acid, 5-15% of protein, 0.2-1% of essence, 5-15% of pigment, and 5-6% of glyceryl monostearate. The lying silkworm pencil disclosed by the invention has a whitening function of pearl, and can tighten skin by adding amino acid and protein components, makeup is not easily disturbed, the skin does not easily dry up, and the makeup clings to the skin better, accordingly, and a person without lying silkworm owns a pair of attractive eyes after smearing and modifying, especially, a double eye and a big eye, so that the modifying effect of lying silkworm is more obvious.

Owner:张小亚

Preparation method of ginkgo leaf feed additive

InactiveCN111528352AIncrease amino acidRich in vitaminsAnimal feeding stuffBiotechnologyRed yeast rice

The invention discloses a preparation method of a ginkgo leaf feed additive. The method comprises the following steps of weighing ginkgo leaves, mulberry leaves and broussonetia papyrifera leaves according to a weight ratio of 1: 1: 10, carrying out microwave drying, crushing and uniform mixing, adding red yeast rice powder accounting for 5% of the total weight and lactic acid bacteria freeze-dried powder accounting for 3% of the total weight, adding beer accounting for 60% of the total weight of the medicinal materials, carrying out uniform mixing, and performing fermentation at 30-32 DEG C for 16-18 hours; and performing fermentation at 26-28 DEG C for 60-70 days, and after the fermentation is finished, performing blow-drying with cold air in a shade place until the water content is lessthan or equal to 30% (by weight), thereby obtaining the ginkgo leaf feed additive product. The invention also provides a new method for development and application of the ginkgo leaves, the mulberryleaves and the broussonetia papyrifera leaves. The method has relatively good social effects for the development and utilization of enriched nutrients of the plant leaves as the feed additive, the efficient breeding and rapid growth of bred animals, the promotion of the development of the breeding industry and the improvement of the economic benefits.

Owner:XUZHOU SANNONG BIOTECH

Preparation method of ecological organic fertilizer

InactiveCN104211455AImprove fertilityImprove water retentionBio-organic fraction processingOrganic fertiliser preparationFiberPlant roots

The invention discloses a preparation method of an ecological organic fertilizer. The preparation method comprises the following steps: (1) grinding collected greening wastes into wood fiber raw materials with a diameter not larger than 5 millimeters; (2) placing the raw materials in a fermentation tank to carry out fermentation for 30 to 40 days; (3) delivering the fermented raw materials to a sunshine room to carry out aging, and carrying out secondary heating; (4) turning over the raw material for every 10 days, and repeating the turning treatment for three times; (5) screening the raw materials according to the particle size after 60 to 70 days of aging, and finally carrying out an ecological treatment without any chemical product so as to obtain the qualified ecological fertilizer. After the high-temperature aging treatment, the fertilizer does not contain any weed seed, insect egg or harmful chemical component, and moreover the fertilizer can improve the fertilizing performance and water-retaining performance of the soil, improves the growth situation of plants, increases the content of beneficial microorganisms in the soil, assists the plant root growth and nutrition absorption, and strengthens the disease resistant performance of the plants.

Owner:KUNSHAN LILIN ENERGY SAVING & EMISSION REDUCTION SCI & TECH

Instant artificial rice and processing method thereof

InactiveCN107048342AImprove eating effectIncrease the degree of staple foodFood scienceLevel ivBanana powder

The invention discloses a method for processing instant artificial rice. The method comprises the following steps of: step 1, obtaining raw materials, wherein a first group of raw materials comprises 30-60 parts of potato whole powder, a second group of raw materials comprises 3-6 parts of rice flour, 10-20 parts of corn flour and 15-25 parts of soybean flour, a third group of raw materials comprises 5-10 parts of chestnut powder, 15-20 parts of Chinese yam flour and 20-30 parts of banana powder, and a fourth group of raw materials comprises 3-5 parts of edible oil, 5-10 parts of potato starch and 80-100 parts of water; step 2, blending the fourth group of raw materials evenly, adding the mixture into the third group of raw materials, and blending the mixture evenly; step 3, blending the first group of raw materials and the second group of raw materials evenly, mixing the mixture evenly with material obtained in step 2, extruding the mixture to obtain primary product of rice-like artificial rice, wherein a single screw extruder is adopted for performing extrusion forming, a first-stage barrel temperature of the single screw is 50-70 DEG C, a second-stage barrel temperature is 60-80 DEG C, a third-stage barrel temperature is 70-100 DEG C, a fourth-stage barrel temperature is 90-120 DEG C, and a fifth-stage barrel temperature is 80-95 DEG C; and step 4, performing puffing-drying to obtain the instant artificial rice.

Owner:钟静涛

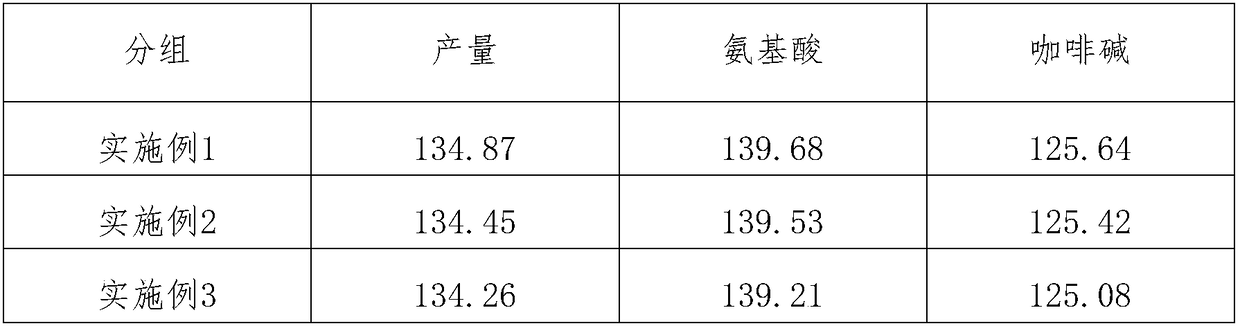

Application of nitrogen fixation bacterial manure to improvement of tea quality

InactiveCN108911909AIncrease productionIncrease amino acidCultivating equipmentsOrganic fertilisersCaffeineAzorhizobium

The invention relates to application of nitrogen-fixation bacterial manure to improvement of tea quality. The nitrogen fixation bacterial manure is characterized by being prepared from mixing nitrogen-fixation bacteria and a carrier with a weight ratio of 0.1 to 1%, the nitrogen-fixation bacteria is prepared by mixing azorhizobium caulinodans, azomonas winogradsky, A.lipoferum according to a weight ratio of (3 to 5) to (2 to 4) to (1 to 2). according to the invention, the nitrogen-fixation bacterial manure is applied to the planting of tea, the content of amino acid and caffeine in tea can beimproved and the quality of tea is obviously improved.

Owner:贵州省普定县黔龙茶业有限公司

Preparation method of living oyster mushroom culture material

ActiveCN112136603AIncrease fruitingShorten germination cycleAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersLychee fruitOyster

A preparation method of a living oyster mushroom culture material is characterized by comprising the following steps of taking corncob, isatis root straw, okra straw, mangosteen shells, passion fruitshells, litchi shells and longan shells according to parts by weight, then crushing raw materials into particles being 5-15 mm, adding water for pre-wetting, standing for 10-16 hours, then conductingstirring and turning, and adding cottonseed hulls and large bran in parts by weight during stirring; taking an amino acid nutrient solution, total nutrients, a resistance increasing agent, a compoundfertilizer and monopotassium phosphate which serve as auxiliary materials in parts by weight, and adding water for full melting, wherein the weight part ratio of the materials to the water is 1:1.6-1.8; sub-packaging prepared compost into cultivation bags, then putting the bagged fungus bags into a sterilization pot for sterilization, keeping the temperature for 3-4 hours when the temperature rises to about 100 DEG C, and taking the fungus bags out of the pot after cooling, wherein sterilization is the same as conventional oyster mushroom sterilization; and inoculating the cooled fungus bags taken out of the pot after cooling according to a conventional oyster mushroom inoculation method.

Owner:郑州市蔬菜研究所

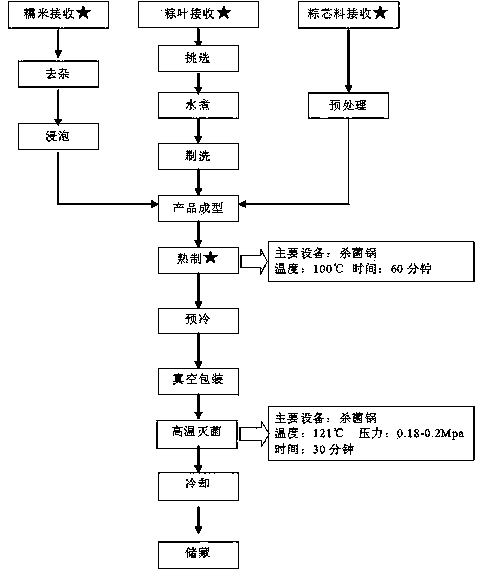

Waxy corn rice dumplings and preparation method thereof

InactiveCN104273445AIncrease profitIncrease added valueFood ingredient functionsFood preparationWaxy cornPreservative

The invention relates to the technical field of processing of foods and particularly discloses waxy corn rice dumplings and a preparation method thereof. The waxy corn rice dumplings are characterized by being prepared from the following raw materials in parts by weight through adding water and bamboo leaves: 20-30 parts of waxy corn kernels, 40-50 parts of glutinous rice, 10-15 parts of white granulated sugar and 10-20 parts of stuffing. The waxy corn rice dumplings are suitable for standardized, mechanical and modern industrial production; the addition value of the product is high, the profit is great and the technological content is high; and any chemical coloring agent and preservative are not added and the products meet national food sanitation monitoring standards.

Owner:济南金王食品股份有限公司

Preparation method of ecological organic fertilizer

InactiveCN112552086AImprove fertilityImprove water retentionBio-organic fraction processingOrganic fertiliser preparationEnvironmental resource managementPlant roots

The invention discloses a preparation method of an ecological organic fertilizer. The preparation method comprises the steps of 1) crushing collected greening garbage into a wood fiber raw material ofwhich the diameter does not exceed 5mm; 2) fermenting the raw material in a fermentation tank for 30 to 40 days; 3) feeding the fermented raw material into a sunlight room for decomposing and aging,and carrying out secondary heating; 4) turning over the raw material once every 10 days, wherein the raw material is turned over for three times in total; and 5) decomposing and aging the raw materialfor 60 to 70 days and then carrying out ecological treatment such as fineness screening, and meanwhile, without any chemical product, acquiring the qualified ecological organic fertilizer. The organic fertilizer product does not contain weed seeds and worm eggs after high-temperature decomposition, harmful chemical components are not added, the soil fertility and the drought resistance and waterretention capacity can be improved, the plant growth condition can be improved, the content of beneficial microorganisms in soil is increased, plant root growth and nutrient absorption are facilitated, and the disease resistance of botany is improved.

Owner:张永良

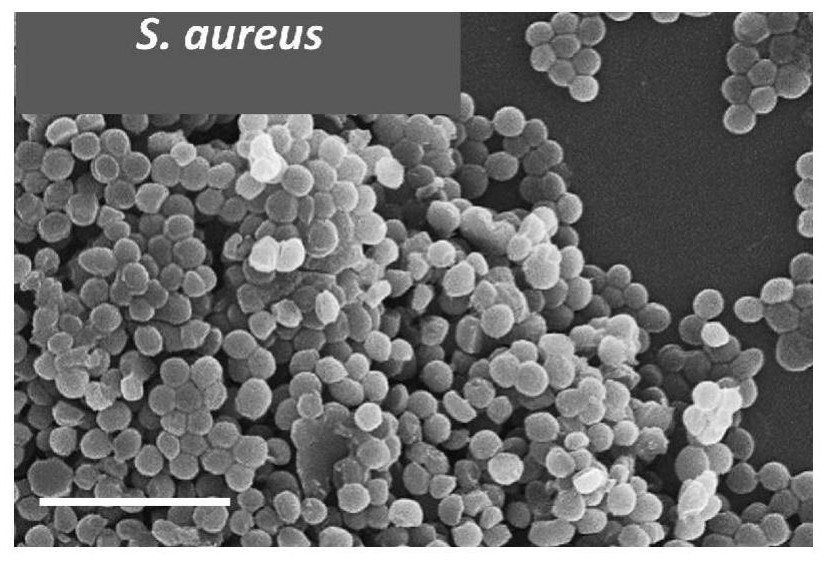

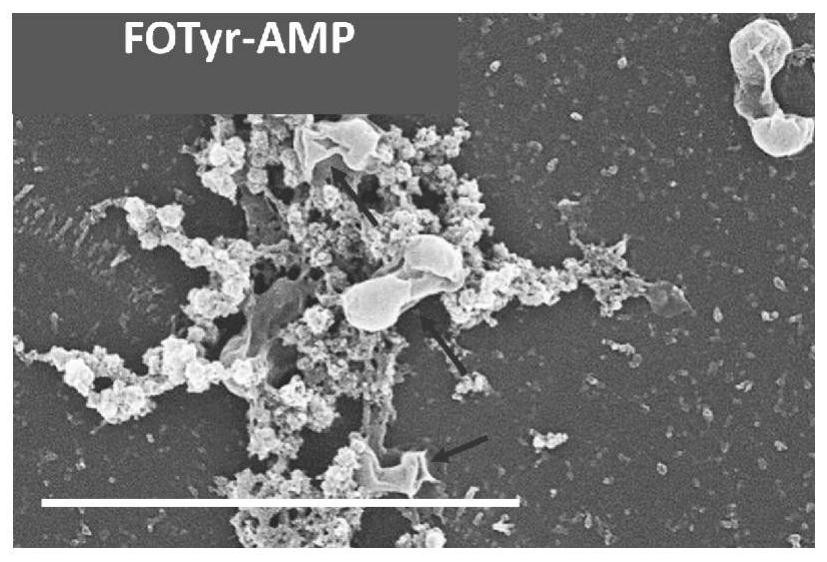

A kind of polypeptide antibiotic and its preparation method and application

ActiveCN111471093BImprove the bactericidal effectStable structureAntibacterial agentsPeptide/protein ingredientsBiofilmAntimicrobial peptides

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

A kind of preparation method of pine needle wolfberry rice wine

ActiveCN104946454BFully fermentedTargetedAlcoholic beverage preparationMicroorganism based processesYeastWine industry

Owner:QILU UNIV OF TECH +1

Pesticide containing notoginseng polysaccharide

PendingCN110150286AIncrease resistanceImprove defensePlant growth regulatorsBiocidePANAX NOTOGINSENG ROOTDrug content

The invention relates to the technical field of pesticide preparation, in particular to a pesticide containing notoginseng polysaccharide. The pesticide comprises a panax notoginseng polysaccharide raw drug containing notoginseng polysaccharide as the main component, a preparation and a pesticide chemically acceptable auxiliary material, wherein the panax notoginseng polysaccharide pesticide raw drug content is 80-99.9 percent, the weight percentage of the raw drug in the panax notoginseng polysaccharide pesticide preparation is 0.1-80 percent, and the rest is auxiliary material. Aiming at thedeficiency of the prior art, the invention provides a pesticide containing notoginseng polysaccharide with reliable performance, which not only has good disease control effect, but also has the advantages of low toxicity, low residue and the like. Compared with chemical pesticides, the invention has the advantages of high safety, small influence on ecological environment and good disease controleffect.

Owner:云南绿戎生物产业开发股份有限公司

High-activity chelated protein peptide fertilizer

InactiveCN105175133AHigh organic matterHigh in mineral nutritionBio-organic fraction processingOrganic fertiliser preparationHigh activityGlutamic acid

The invention discloses a high-activity chelated protein peptide fertilizer which is prepared from the following raw materials in parts by weight: 48-52 parts of cottonseed hull, 5-6 parts of ammonium bicarbonate, 8-10 parts of fly ash, 8-10 parts of actinolite powder, 1-3 parts of ferric citrate, 2-3 parts of honey, 88-92 parts of almond residue, 1-2 parts of ferrous chloride, 1-2 parts of glutamic acid, 4-6 parts of sodium silicate, 0.8-1.2 parts of calcium chloride and a right amount of water. The fertilizer contains higher organic matters and mineral nutrients. The added fly ash, ferric citrate, honey and the like greatly enhance the active functional effects of amino acids, lignin and the like in fertilizer. The fertilizer middle chelated layer is matched to greatly improve the absorptivity of the fertilizer, so that the fertilizer has excellent chemical activity and bioactivity, and can enhance multiple tolerances of crops and improve the crop quality after long-term usage.

Owner:ANHUI LUHU BIOTECH

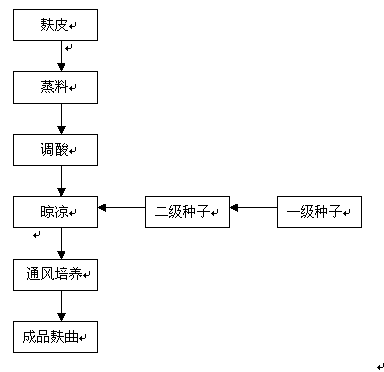

Method for preparing aspergillus niger mouldy bran for brewing wine

ActiveCN103215158BIncrease profitIncrease reaction rateMicroorganism based processesAlcoholic beverage preparationWater bathsYeast

The invention provides a method for preparing aspergillus niger mouldy bran for brewing wine, comprising the following steps of: a. a first-grade seed: adding water into crushed barley malt, saccharifying in a water-bath boiler to obtain a saccharification liquid, filtrating the saccharification liquid by gauze, regulating PH value of the saccharification liquid to be 6-7, regulating pol to be 2-8 Be, obtaining an inclined plane medium after disinfection, inoculating aspergillus niger M-002 to the inclined plane medium, and then culturing in a constant temperature incubator, to obtain the first-grade seed; b. secondary seed: adding bean cake powder, water and caproic acid solution to wheat bran, moistening grains to obtain a medium, then disinfecting to obtain a secondary seed medium, inoculating by the first-grade seed, covering with a bottle after culturing in the constant temperature incubator, and then continuously culturing, to obtain a secondary seed; and c. ventilation and enlargement culture: adding water in wheat bran, adjusting acidity with vinasse after steaming grains, adding a secondary seed, seeding it to a ventilation bed in a yeast house after uniformly mixing, controlling temperature to culture, to obtain aspergillus niger M-002 mouldy bran.

Owner:JINAN GUOLI BIOLOGICAL SCI & TECH

Preparation method of multi-element mineral water-soluble silicon fertilizer

InactiveCN103553745BIncrease the number of microorganismsSimple structureFertilizer mixturesPotassiumStone dust

The invention relates to a preparation method of a multi-element mineral water-soluble silicon fertilizer. The water-soluble silicon fertilizer consists of the following components in parts by weight: 3-5 parts of diopside, 3-5 parts of potassium feldspar, 82-85 parts of wormcast and 5-7 parts of plant ash. The preparation method comprises the following steps: respectively smashing and grinding diopside and potassium feldspar to obtain powder; passing the diopside powder and the potassium feldspar powder through an 80-mesh sieve, for later use; weighing the standby diopside powder and the standby potassium feldspar powder according to the ratio of component parts by weight, evenly mixing the powder in a mixer; calcining the evenly-mixed powder in a smelting furnace; cooling a discharged material to obtain a diopside and potassium feldspar water-soluble multi-element crystal; smashing and grinding the multi-element crystal to obtain powder for later use; evenly mixing 3-5 parts of standby multi-element crystal powder, 82-85 parts of wormcast and 5-7 parts of plant ash by weight in the mixer; performing granulation by a granulator, performing baking by a baking machine and performing sieving by a sieving machine to obtain the multi-element mineral water-soluble silicon fertilizer. The multi-element mineral water-soluble silicon fertilizer can promote the production increase of crops, enhance the quality of the crops, improve the structure of soil and ensure the safe consumption of the crops.

Owner:范志伟

Nutritional oatmeal

InactiveCN107897711APromote body growthPrevent agingFood ingredient functionsNutrientPhysiological function

The invention discloses a nutritious oatmeal, which is composed of wheat flour, corn flour, rice flour, creamer, sucrose, vanillin and other components. %, corn flour 4‑7%, rice flour 3‑5%, maltose 3‑5%, anhydrous butter 1‑3%, salt 0.1‑0.5%, whole milk powder 2‑4%, refined sucrose 23‑34% , non-fat creamer 22‑34%, vanillin 0.2‑0.5%, guar gum 0.1‑0.5%, honey 1‑2 parts, mixed vitamins 0.5‑1 part, processed into wheat germ nutrition cereal. The nutritional oatmeal provided by the present invention, after adding wheat germ powder to the original oatmeal, adds protein, amino acid, multiple vitamins, various minerals, and trace elements to the oatmeal, so that the nutritional oatmeal with wheat germ is rich in nutrition and can be used for a long time. Amount of consumption can promote the growth of the body, the balance of the human body, prevent aging and beauty, adjust physiological functions, improve blood circulation, prevent cholesterol deposition, and prevent cardiovascular diseases such as arteriosclerosis.

Owner:帅娟

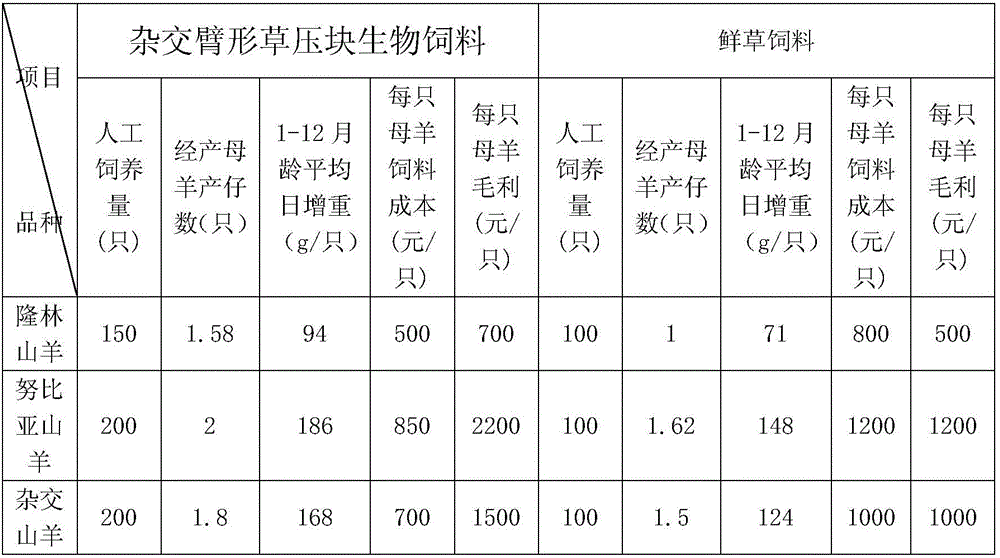

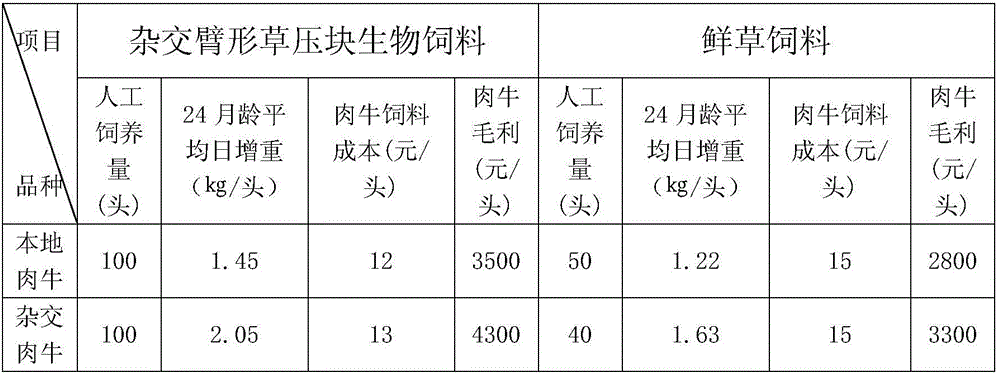

Bachiaria-hybrid cattle-and-sheep blocked biological feed and preparing method thereof

InactiveCN106071152ASimple manufacturing methodLow costFood processingAnimal feeding stuffDiseaseAnimal science

The invention discloses a bachiaria-hybrid cattle-and-sheep blocked biological feed and a preparing method thereof. The preparing method includes the steps of physical processing, micro-storage processing and cassava straw formula feed preparing, and the cassava straw formula feed is obtained. The bachiaria-hybrid cattle-and-sheep blocked biological feed and the preparing method thereof have the advantages that the daily ration nutritional requirements in different stages can be met, the nutrition is comprehensive, the disease resistance of herbivorous animals is greatly enhanced, the digestion rate is high, the feed utilization rate is remarkably increased, waste is reduced, and the large-scale breeding feed cost is greatly reduced.

Owner:广西壮族自治区牧草工作站

Meat flavor hot flavorings and production method thereof

InactiveCN101455323BReduce spicinessHighlight aromaFood preparationMonosodium glutamateZanthoxylum bungeanum

The invention discloses a meat scent savoury and pungent flavoring, containing the following raw materials: vegetable oil, dried pimiento, zanthoxylum bungeanum, star anise, salt, sugar, monosodium glutamate, starch, meat reaction solution, fresh increasing flavoring agent. A production method of the meat scent savoury and pungent flavoring includes: heating the vegetable oil to 150-200 DEG C; respectively adding the dried pimiento zanthoxylum bungeanum and anise tree and frying for 30-60 seconds, quickly removing, draining the oil, and then coarse crushing and mixing the dried pimiento zanthoxylum bungeanum and anise tree; adding salt, sugar, monosodium glutamate, starch, meat reaction solution in the mixture, mixing uniformly; and then adding the fresh increasing flavoring agent, and then mixing uniformly; performing ultramicro crushing after microwave drying, and then obtained the completed product by hermetic package. The invention uses a short time fried mode to alleviate the biting taste of the pimiento and prominent the fragrant flavor of the pimiento; and matches with flavoring made up by different meat reaction solutions, so that the invention contains not only the meat flavor, but also an increase of essential amino acids of human body, minerals and so on.

Owner:浙江正道生物科技有限公司

Feeding method of sheep oral formalin and feed thereof

InactiveCN101843227BIncreased ad libitum intakeImprove slaughter performanceAnimal feeding stuffProtozoaMedicine

The invention discloses a feeding method of sheep oral formalin, comprising the following steps: diluting formalin with a required amount into 50-100 times, mixing with feed (ration) to feed sheep or diluting the formalin with the required amount into 200-400 times, directly leading the diluted formalin to be taken by sheep orally, and feeding the feed (ration) at the same time. By the invention,the free feed intake of the sheep is increased, the number of protozoa in a sheep rumen is reduced, while the number of rumen bacteria is increased, amino acid and other substances reaching sheep small intestines are obvious increased, and the nutrient substances like amino acid absorbed by the sheep small intestines are obviously boosted. By the invention, the slaughtering performance of the sheep can be greatly improved. The methanal content in an oral formalin sheep texture is determined for the first time in the invention, which shows that the methanal content in the textures such as muscle, liver and the like of sheep which adopts the oral formalin of the invention in a long time is less than 2mg / Kg (the beer standard).

Owner:雒秋江 +1

Preparation process of baking-flavor pecan fermented beverage

InactiveCN110800903AChange flavorNo greasy feelingFood ingredient functionsBiotechnologyLactic acid bacterium

The invention particularly discloses a preparation process of a baking-flavor pecan fermented beverage. The process provided by the invention comprises the following steps: stir-frying pecan to obtaincooked pecan, baking the cooked pecan to obtain baking-flavor pecan kernels, adding purified water according to a relationship that the weight ratio of the kernels to the purified water is 1:(5-10) to prepare slurry, performing sterilizing at 105 DEG C for 30-35 minutes, and inoculating a lactic acid bacteria starter with a weight of 10-12% of the slurry, wherein the lactic acid bacteria starteris prepared by compounding streptococcus lactis and bifidobacteria according to a weight ratio of 1:1; and performing sealing for slow fermentation at a fermentation temperature of 26+ / -0.5 DEG C for90-100 hours, and then performing blending and homogenizing to obtain an active baking-flavor pecan fermented beverage with active lactic acid bacteria; or further performing short-time sterilizing at128-136 DEG C for 6-8 minutes on the homogenized beverage, and performing cooling and filling to prepare an inactive baking-flavor pecan fermented beverage. The invention provides a new processing technology for processing and utilizing pecans, enriches the product market of fermented beverages, and further promotes development of the pecan industry.

Owner:JIANGSU QIANYAOTANG GUOYI RES INST CO LTD

Ginseng and Pseudostellaria composite health drink and preparation method thereof

The invention relates to a plant drink, namely a compound health drink of ginseng and heterophylla, and a preparation method thereof. Ginseng is used as raw material, and ginseng juice is obtained through water extraction. The ginseng juice is used as the main raw material and Pseudostellariae juice, which has health effects, is added to make ginseng and Pseudostellariae compound beverage. The processing technology of ginseng and Taizi ginseng does not destroy the original nutritional characteristics, taste and effective functions of the raw materials, which ensures the naturalness of the beverage.

Owner:通化百泉保健食品有限公司

A kind of cassava rice and processing method thereof

InactiveCN103156141BImprove eating effectIncrease the degree of staple foodFood preparationBiotechnologyBanana powder

The invention provides cassava rice which consists of raw powder and a mixture. The raw powder comprises the following components in percentage by weight: 30-60 percent of a component A, 30-60 percent of a component B and 5-10 percent of a component C, wherein the component A is cassava starch; the component B is one or a mixture of broken rice meal, corn starch and soybean meal; and the component C is one or a mixture of chestnut powder, yam flour, beautiful millettia root powder and banana meal. The mixture is a proper amount of edible oil, gelatin and edible alcohol. The cassava rice takes the cassava starch as a main raw material, is additionally provided with other side crops, the chestnut powder, the yam flour, the beautiful millettia root powder and the like an auxiliary mode, is convenient to eat, reasonable in formula, fine and smooth in mouthfeel, is easily cured and less prone to breakage in a cooking process, is enriched in vitamins, amino acid and trace metal elements, can improve the nutritive value of cassava and make non-food crops become principle foods, does not have odor and is neat in appearance and good in mouthfeel.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com