Processing process for black tea

A processing technology and technology for black tea, applied in the field of processing technology of black tea, can solve the problems of long time consumption, breakthrough, complicated processing steps, etc., and achieve the effect of stable tea quality and dark color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

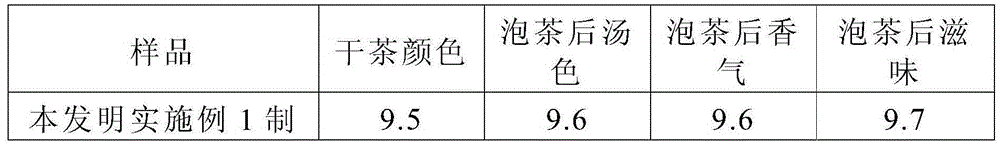

Embodiment 1

[0030] Select white leaf tea fresh leaves with white leaves and tenderness of 1 bud and 1-3 leaves, and spread them in a cool and ventilated condition for 15 minutes. The thickness of the fresh leaves is less than 3cm when spread. Afterwards, the cooled tea leaves are withered at a temperature of 20°C and a humidity of 50%. When withering, the thickness of the tea leaves is less than 1 cm, and the liquid leaf volume ratio is 1:10. A mixed enzyme preparation with a concentration of 250u / mL made by mixing pectinase preparations, in which the content of cellulase preparations accounts for 65%, is withered until the tea leaves are in a shriveled state, and the tea leaves are kneaded by hand but the tea juice does not come out. Afterwards, the tea leaves can be placed in a shaking cage, and the tea leaves account for 75% of the shaking cage, and the fragrance is shaken for 3 minutes. After that, pour the shaken tea leaves into the kneading cylinder for kneading. First, knead with l...

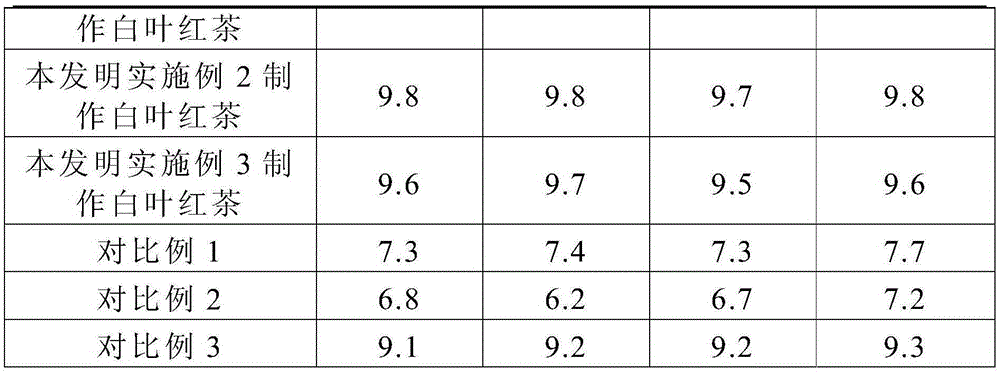

Embodiment 2

[0032] Select fresh leaves of white leaf tea with white leaves and a tenderness of 1 bud and 1-3 leaves, and spread them for 50 minutes in a cool and ventilated condition. The thickness of fresh leaves is less than 2cm when spread. Afterwards, the cooled tea leaves are withered at a temperature of 25°C and a humidity of 60%. When withering, the thickness of the leaves is less than 1 cm, and the liquid leaf volume ratio is 1:10. A mixed enzyme preparation with a concentration of 250u / mL made by mixing pectinase preparations, in which the content of cellulase preparations accounts for 65%, is withered until the tea leaves are in a shriveled state, and the tea leaves are kneaded by hand but the tea juice does not come out. Afterwards, the tea leaves can be placed in a shaking cage, and the tea leaves account for 80% of the shaking cage, and the fragrance is shaken for 5 minutes. Afterwards, pour the shaken tea leaves into the kneading cylinder for kneading. First, knead with ligh...

Embodiment 3

[0034] Select white leaf tea fresh leaves with white leaves and tenderness of 1 bud and 1-3 leaves, and spread them for 100 minutes in a cool and ventilated condition. The thickness of fresh leaves is less than 3cm when spread. Afterwards, the cooled tea leaves are withered at a temperature of 30°C and a humidity of 70%. When withering, the thickness of the leaves is less than 1 cm, and the liquid leaf volume ratio is 1:10. A mixed enzyme preparation with a concentration of 250u / mL made by mixing pectinase preparations, in which the content of cellulase preparations accounts for 65%, is withered until the tea leaves are in a shriveled state, and the tea leaves are kneaded by hand but the tea juice does not come out. Afterwards, the tea leaves can be placed in a shaking cage, and the tea leaves account for 85% of the shaking cage, and the fragrance is shaken for 10 minutes until the aroma of the tea leaves is revealed. After that, pour the shaken tea leaves into the kneading cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com