Pre-cleaning and moisturizing composition of medical apparatuses and method of preparing disinfectant by using same

A medical device and pre-cleaning technology, applied in the direction of disinfectants, detergent compositions, chemical instruments and methods, etc., can solve problems such as excessive foam and corrosive metals, achieve good stability, extend storage period, reduce Effect of time of manual or mechanical cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add 0.2 g of fatty alcohol polyoxyethylene ether and 0.2 g of nonylphenol polyoxyethylene ether into 96 g of water, stir to dissolve; add 0.02 g of alkaline protease, 0.02 g of lipase, 0.01 g of cellulase, and 0.01 g of amylase , while controlling the solution temperature below 30°C. After stirring and dissolving evenly, immediately add 0.5 g of glycerin, 0.3 g of propylene glycol, and 0.05 g of ethylene glycol and stir to dissolve; 3 g of dipropylene glycol methyl ether acetate and 0.5 g of p-chloro-m-xylenol are pre-dissolved in appropriate amount of purified water respectively. Then add and dissolve while stirring to obtain the pre-cleaning moisturizing agent.

Embodiment 2

[0042] Add 0.5 g of fatty alcohol polyoxyethylene ether and 0.5 g of nonylphenol polyoxyethylene ether into 94 g of water, stir to dissolve; add 0.1 g of alkaline protease, 0.1 g of lipase, 0.05 g of cellulase, and 0.05 g of amylase , while controlling the solution temperature below 30°C. After stirring and dissolving evenly, immediately add 1.3 grams of glycerin, 0.9 grams of propylene glycol, and 0.2 grams of ethylene glycol and stir to dissolve; 4 grams of dipropylene glycol methyl ether acetate and 0.75 grams of p-chloro-m-xylenol are pre-dissolved in appropriate amount of purified water respectively. Then add and dissolve while stirring to obtain the pre-cleaning moisturizing agent.

Embodiment 3

[0044] Add 1.0 g of fatty alcohol polyoxyethylene ether and 1.0 g of nonylphenol polyoxyethylene ether into 90 g of water, stir to dissolve; add 0.2 g of alkaline protease, 0.2 g of lipase, 0.1 g of cellulase, and 0.1 g of amylase , while controlling the solution temperature below 30°C. After stirring and dissolving evenly, immediately add 2.0 grams of glycerin, 1.5 grams of propylene glycol, and 0.4 grams of ethylene glycol and stir to dissolve; 5 grams of dipropylene glycol methyl ether acetate and 1.5 grams of p-chloro-m-xylenol are pre-dissolved in appropriate amount of purified water respectively. Then add and dissolve while stirring to obtain the pre-cleaning moisturizing agent.

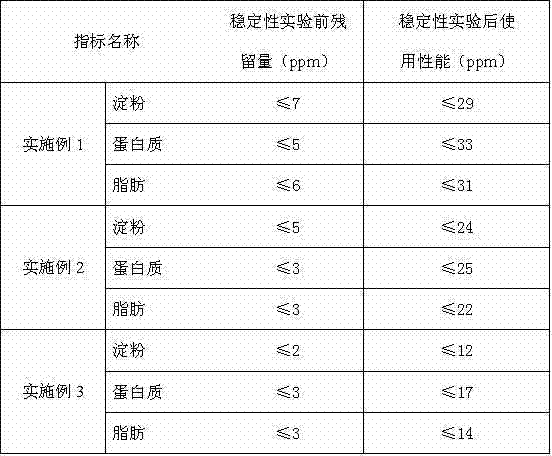

[0045] The pre-cleaning and moisturizing agents of the above examples were continuously soaked for 14 days on stainless steel sheets, carbon steel sheets, copper sheets, and aluminum sheets, and no corrosion was found. Surgical forceps were used to soak starch solution, protein solution, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com