Process for preparing nano-starch powder

A nano-starch and powder technology, applied in the field of nano-materials and nano-materials, can solve the problems of biological characteristics of polluted raw starch, uneven particle size distribution, uneven hydrolysis rate, etc., and achieve easy industrialization, easy processing, and good uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

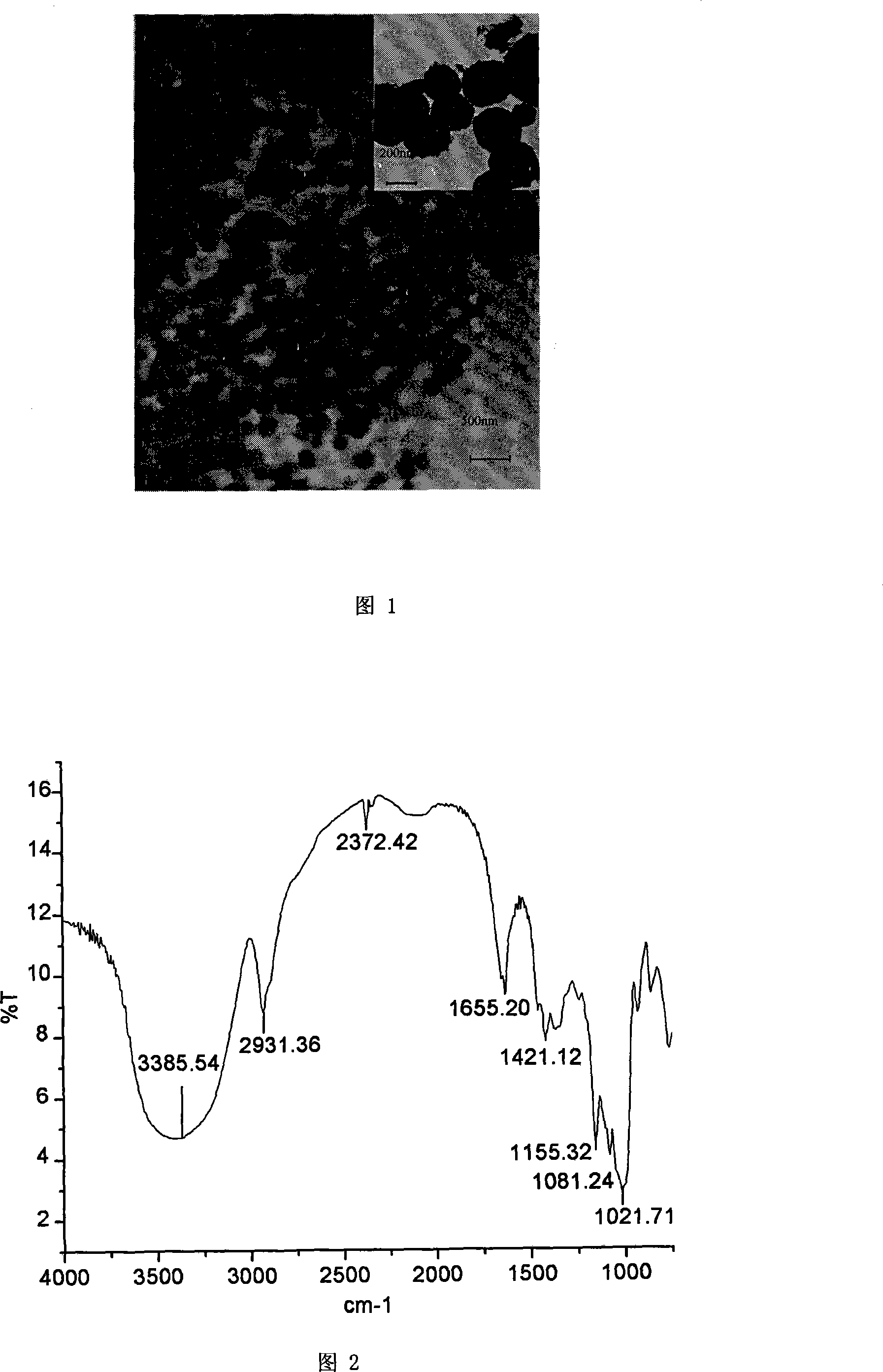

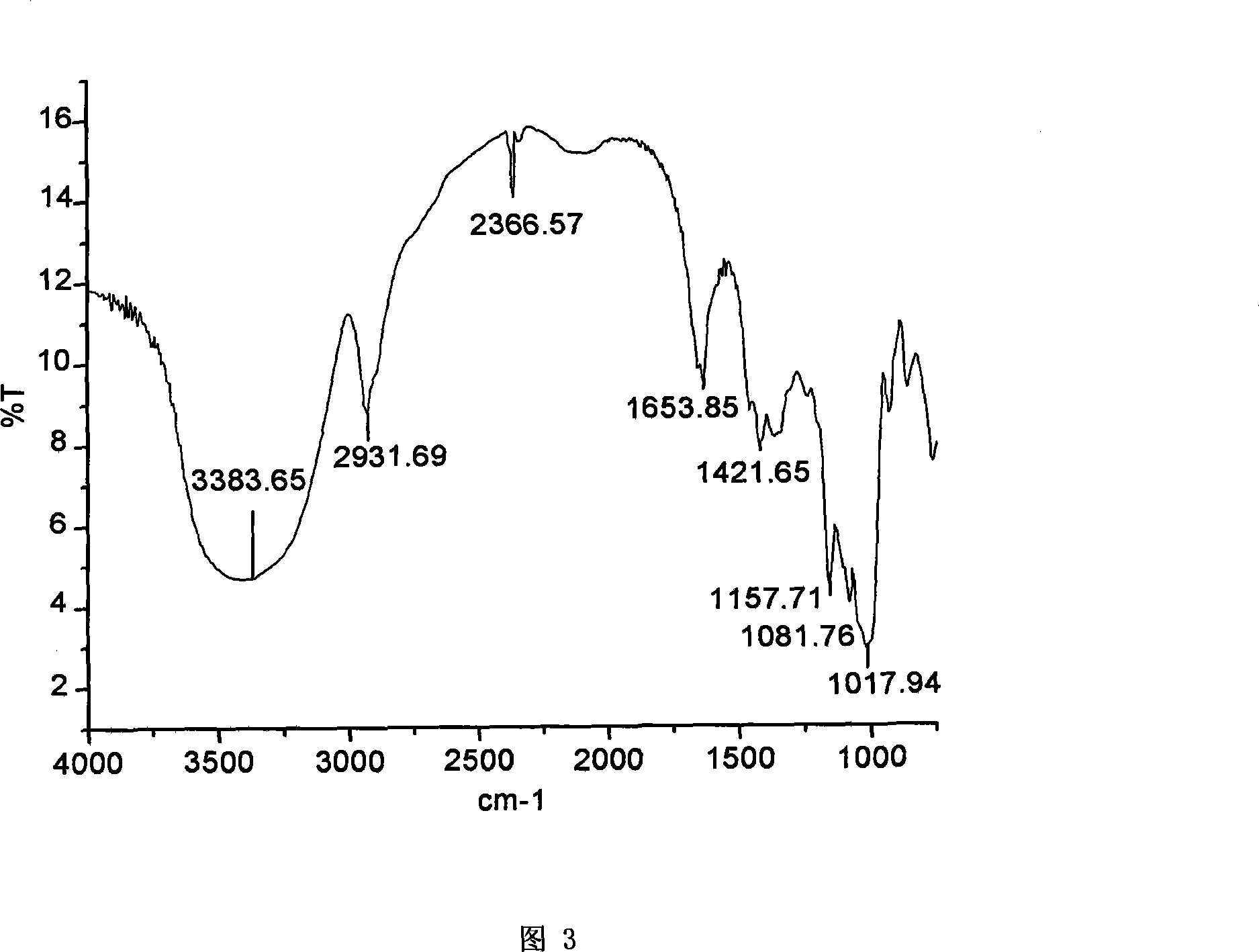

Image

Examples

Embodiment 1

[0022] (1) In a container containing deionized water, add 3‰ (mass percentage) of sodium lauryl sulfate to dilute evenly, then add corn starch and stir evenly, the starch concentration in the solution is 8%;

[0023] (2) Place the radiation head of the high-energy ultrasound in the middle of the starch solution, and set the program: high-energy ultrasound works for 5 seconds, intermittently for 3 seconds, and after continuous operation for 20 minutes, intermittently for 10 minutes to complete a cycle. During the treatment, the temperature in the solution should be observed to keep it below 50°C. The increase in temperature can extend the intermittent time. After completing 5 cycles of work in this way (the actual effect of ultrasound is about 1 hour, the whole process is about 4 hours), turn off the ultrasound and take out the solution;

[0024] (3) Place the above solution in a water bath at 45°C, slowly add 15% hydrochloric acid to make the concentration of hydrochloric acid in ...

Embodiment 2

[0028] (1) In a container with deionized water, add 5‰ (mass percentage) of sodium lauryl sulfate to dilute evenly, then add corn starch and stir evenly, the starch concentration in the solution is 10%;

[0029] (2) Place the radiation head of the high-energy ultrasound in the middle of the starch solution, and set the program: high-energy ultrasound works for 3 seconds, intermittently for 2 seconds, and after continuous operation for 25 minutes, intermittently for 15 minutes to complete a cycle. During the treatment, the temperature in the solution should be observed to keep it below 50°C. The increase in temperature can extend the intermittent time. After completing 4 cycles of work (the actual effect of ultrasound is about 1 hour, the whole process is about 4 hours), turn off the ultrasound and take out the solution;

[0030] (3) Put the above solution in a water bath at 45°C, slowly add 12% sulfuric acid to make the concentration of sulfuric acid in the solution 8% under the s...

Embodiment 3

[0034] (1) In a container with deionized water, add 5‰ (mass percentage) of sodium lauryl sulfate to dilute evenly, then add corn starch and stir evenly, the starch concentration in the solution is 15%;

[0035] (2) Place the radiation head of the high-energy ultrasound in the middle of the starch solution, and set the program: high-energy ultrasound works for 4 seconds, intermittently for 2 seconds, after continuous working for 18 minutes, intermittently for 15 minutes to complete a cycle. During the treatment, the temperature in the solution should be observed to keep it below 50°C. The increase in temperature can extend the intermittent time. After completing 8 cycles of work (the actual effect of ultrasound is about 1.5 hours, the whole process is about 5 hours), turn off the ultrasound and take out the solution;

[0036] (3) Place the above solution in a water bath at 48°C, slowly add 15% nitric acid to make the concentration of nitric acid in the solution 10% under the stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com