Method for preparing superparamagnetic micron starch

A technology of superparamagnetic and magnetic nanoparticles, which is applied in the fields of magnetism of organic materials/organic magnetic materials, medical preparations of non-active ingredients, pharmaceutical formulations, etc., and can solve problems such as destroying porous structures and reducing starch adsorption and drug loading capacity. , to achieve the effects of simple preparation process, improved bioavailability, and reduced side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

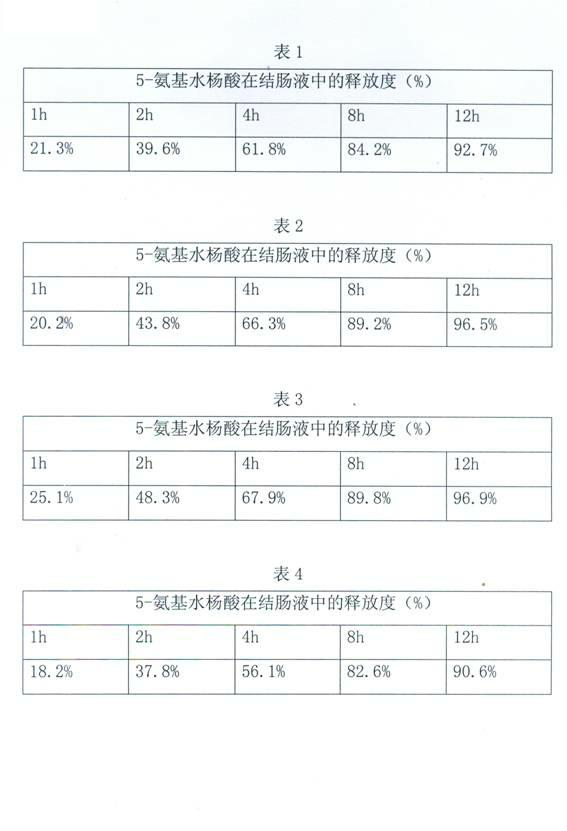

Embodiment 1

[0026] Preparation of Superparamagnetic Japonica Rice Starch

[0027] Accurately weigh 8.1 g of ferric trichloride hexahydrate and dissolve in 142.5 ml of deionized water, transfer to a three-necked flask, stir and heat to 70°C. Weigh 4.4 g of ferrous chloride tetrahydrate, dissolve it in 10 ml of deionized water, filter, and take 7.5 ml into a three-neck flask. Under the condition of vigorous stirring, 18 ml of concentrated ammonia water (25%, w / v) was quickly added, and after 1 min, 4.66 g of oleic acid was added dropwise, and the rapid stirring was continued at 70°C for 1 h. After the reaction, a black sol-like substance was obtained, and the resulting precipitate was separated from the reaction system by applying an external magnetic field. Wash with alcohol twice to remove excess oleic acid, and then wash with deionized water to about pH=7. Then add 160 ml of KMnO at a concentration of 10 mg / ml 4 solution, KMnO 4 The solution oxidizes the oleic acid on the surface of ...

Embodiment 2

[0034] Preparation of Superparamagnetic Tapioca Starch

[0035] Accurately weigh 8.1 g of ferric chloride hexahydrate and dissolve in 142.5 ml of deionized water, transfer to a three-necked flask, stir and heat to 70°C. Weigh 4.4 g of ferrous chloride tetrahydrate, dissolve it in 10 ml of deionized water, filter, and take 7.5 ml into a three-necked flask. Under the condition of vigorous stirring, 18 ml of concentrated ammonia water (25%, w / v) was quickly added, and after 1 min, 4.66 g of oleic acid was added dropwise, and the rapid stirring was continued at 70°C for 1 h. After the reaction, a black sol-like substance was obtained, and the resulting precipitate was separated from the reaction system by applying an external magnetic field. Wash with alcohol twice to remove excess oleic acid, and then wash with deionized water to about pH=7. Then add 160 ml of KMnO at a concentration of 10 mg / ml 4 solution, KMnO 4 The solution oxidizes the oleic acid on the surface of the mag...

Embodiment 3

[0042] Preparation of Superparamagnetic Corn Starch

[0043] Accurately weigh 7 g of ferric chloride hexahydrate and dissolve in 140 ml of deionized water, transfer to a three-necked flask, stir and heat to 50°C. Weigh 4 g of ferrous chloride tetrahydrate and dissolve it in 8 ml of deionized water, filter, and take 7 ml into a three-necked flask. Under the condition of vigorous stirring, 15ml of concentrated ammonia water (25%, w / v) was quickly added, and after 3 minutes, 3.2g of oleic acid was added dropwise, and the rapid stirring was continued at 50°C for 30 minutes. After the reaction, a black sol-like substance was obtained, and the resulting precipitate was separated from the reaction system by applying an external magnetic field. Wash with alcohol 3 times to remove excess oleic acid, and then wash with deionized water to about pH=7. Then add 100 ml of KMnO at a concentration of 8 mg / ml 4 solution, KMnO 4 The solution oxidizes the oleic acid on the surface of the mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com