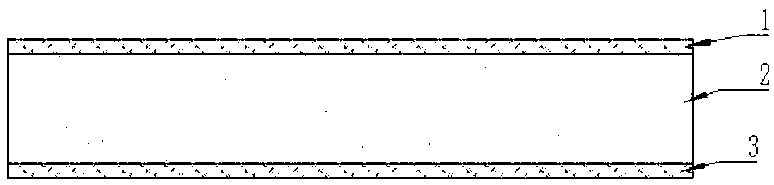

Waterproof, fireproof, mildew-proof and high-strength glass fiber felt gypsum board and preparation method thereof

A technology of glass fiber felt and gypsum board, which is applied in the field of building materials, and can solve problems such as the decline in waterproof performance of glass fiber felt gypsum board, difficulty in applying glass fiber felt gypsum board to building exterior walls, and easy moisture absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] By weight, 100 parts of gypsum, 70 parts of water, 0.15 parts of hydrogen-containing silicone oil, 0.15 parts of FUNGIPOL 458 FL, 0.22 parts of chopped glass fiber, 0.04 parts of sodium trimetaphosphate, 0.3 parts of fly ash, Huijiang naphthalene-based water reducer 0.37 parts, 0.27 parts of modified starch, 0.07 parts of sodium lauryl sulfate.

Embodiment 2

[0036] By weight, 100 parts of gypsum, 75 parts of water, 0.30 parts of hydrogen silicone oil, 0.22 parts of FUNGIPOL 458 FL, 0.30 parts of chopped glass fiber, 0.06 parts of sodium trimetaphosphate, 0.4 parts of silica fume, 0.22 parts of Wanbang naphthalene-based water reducer , 0.30 parts of modified starch, 0.06 parts of sodium lauryl sulfate.

Embodiment 3

[0038]By weight, 100 parts of gypsum, 80 parts of water, 0.37 parts of hydrogen-containing silicone oil, 0.30 parts of FUNGIPOL 458 FL, 0.37 parts of chopped glass fiber, 0.07 parts of sodium trimetaphosphate, 0.5 parts of Portland cement, BASF naphthalene-based superplasticizer 0.30 parts, 0.37 parts of modified starch, 0.04 parts of sodium lauryl sulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com