Microwave processed egg product and preparation method thereof

A production method and microwave technology, applied in food preparation, application, food science and other directions, can solve the problems of strict equipment requirements, poor molding, unfavorable promotion, etc., and achieve good moisturizing performance, high work efficiency, increased emulsification and moisturizing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

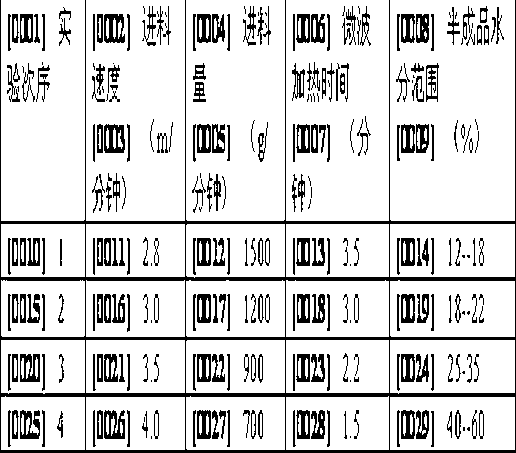

Examples

Embodiment 1

[0048] Example 1, specific formula: 500 grams of egg powder, 100 grams of acetate starch, 100 grams of white sugar, 100 grams of vegetable oil, 100 grams of sorbitol solution, 5 grams of edible salt, 5 grams of monosodium glutamate, 10 grams of phosphate, soy sauce powder 5 grams, 5 grams of baking powder, 5 grams of xanthan gum, 1 gram of 5-flavor nucleotide, 0.1 gram of vitamin E.

Embodiment 2

[0049] Embodiment 2, specific formula: 300 grams of egg powder, 300 grams of acetate starch, 100 grams of white sugar, 100 grams of vegetable oil, 100 grams of sorbitol solution, 5 grams of edible salt, 5 grams of monosodium glutamate, 10 grams of phosphate, soy sauce powder 5 grams, 5 grams of baking powder, 5 grams of xanthan gum, 1 gram of 5-flavor nucleotide, 0.1 gram of vitamin E.

Embodiment 3

[0050] Example 3, specific formula: 300 grams of egg powder, 100 grams of acetate starch, 200 grams of white sugar, 100 grams of vegetable oil, 100 grams of sorbitol solution, 5 grams of edible salt, 5 grams of monosodium glutamate, 10 grams of phosphate, soy sauce powder 5 grams, 5 grams of baking powder, 5 grams of xanthan gum, 1 gram of 5-flavor nucleotide, 0.1 gram of vitamin E.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com