Patents

Literature

86 results about "Powdered egg" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Powdered eggs are fully dehydrated eggs. They are made using spray drying in the same way that powdered milk is made. The major advantages of powdered eggs over fresh eggs are the reduced weight per volume of whole egg equivalent and the shelf life.

Egg Products Containing Microalgae

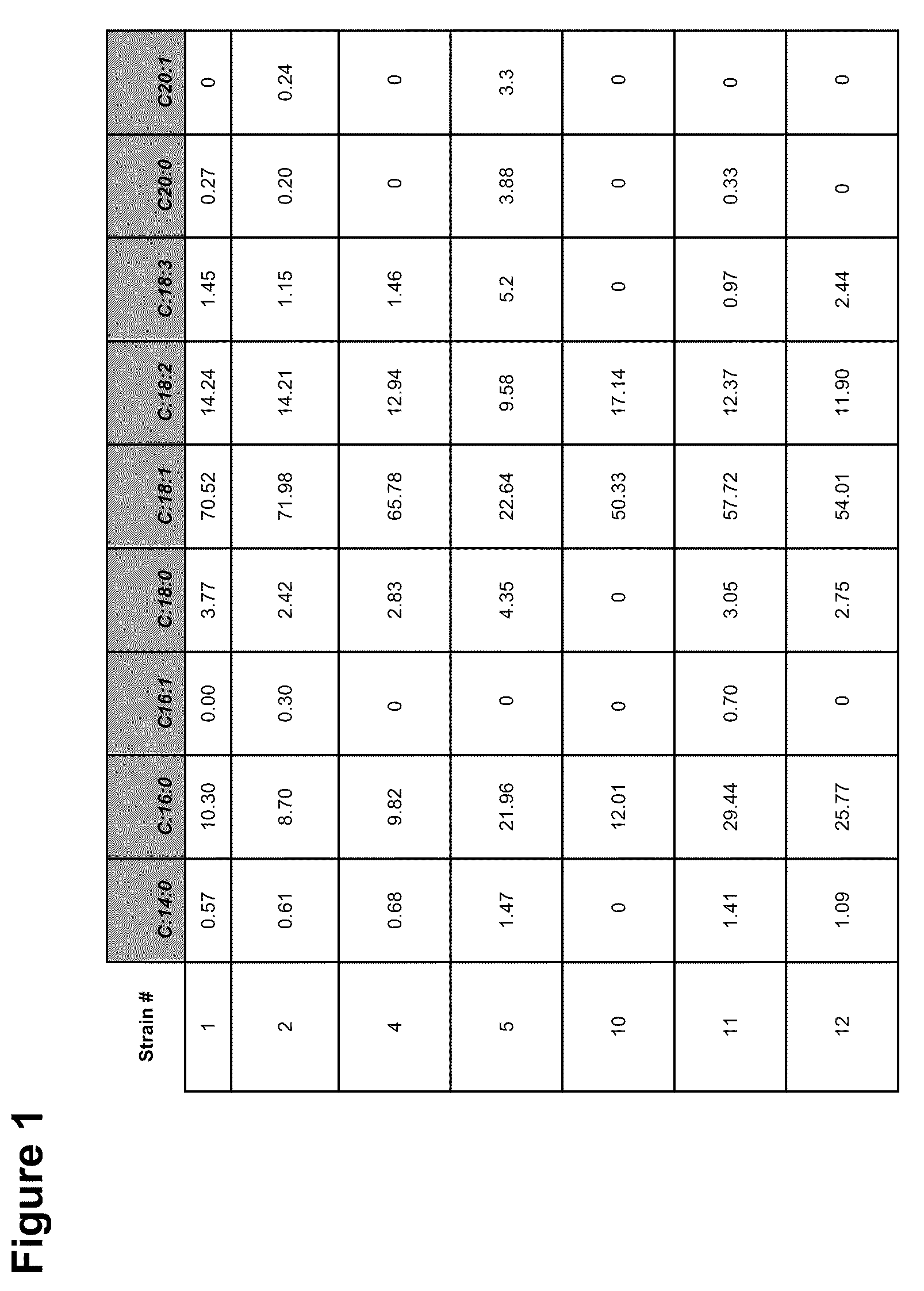

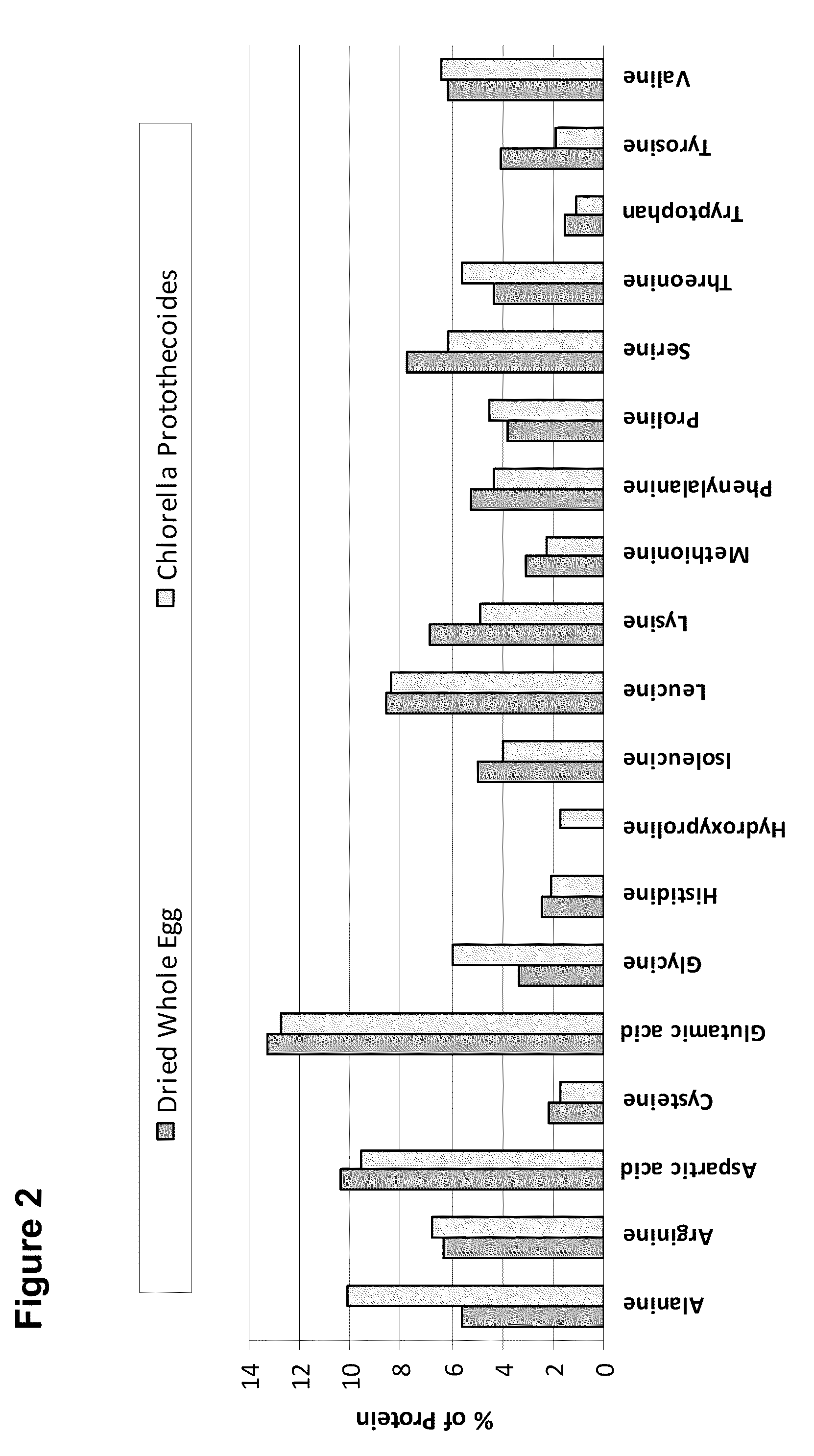

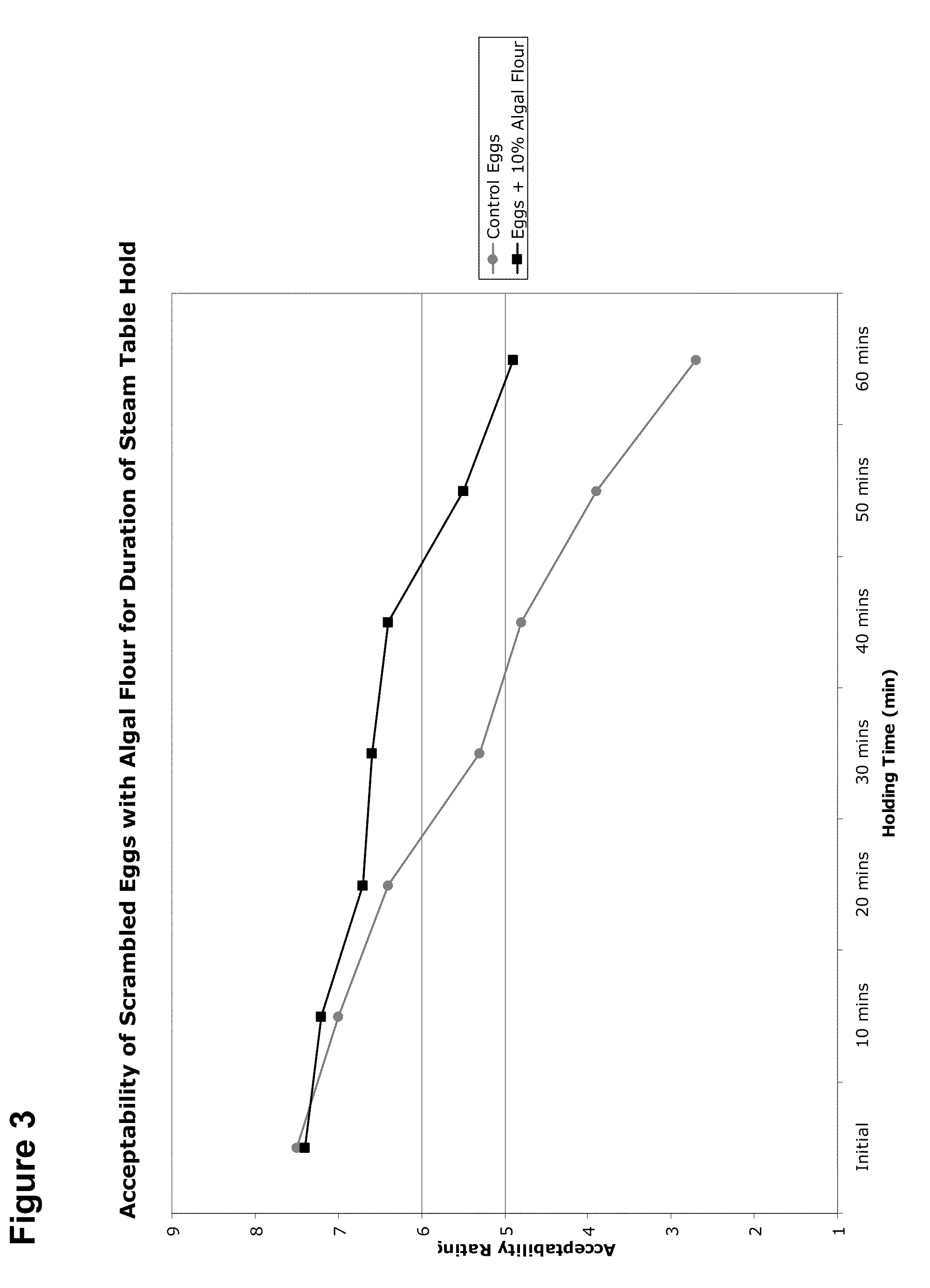

The compositions and methods of the invention relate to the creation of food products based on eggs, wherein the productions contain various raw materials made from microalgae in different forms. Some forms include high levels of monounsaturated oil, dietary fiber, carotenoids, and digestible crude protein. Provided herein are methods and compositions for enhancing food stability at elevated temperature during extended periods of storage in hydrated egg products. The microalgae-derived materials are provided as dry or hydrated homogenates made from heterotrophically produced microalgae of varying genera, species and strain. Weight / weight levels of saturated fats and cholesterol are reduced in egg products of the invention, while dietary fiber is increased. Blends of liquid or dried egg with liquid or dried algae are provided, as well as methods of manufacturing and formulating the blends. Unique combinations of egg whites and microalgae are also provided for manufacture of very low cholesterol egg products. In some embodiments, the textural characteristics of powdered eggs are altered to be more like the textural characteristics of liquid eggs through the inclusion of dietary fiber and other moisture-retaining properties of microalgal biomass.

Owner:TERRAVIA HLDG INC

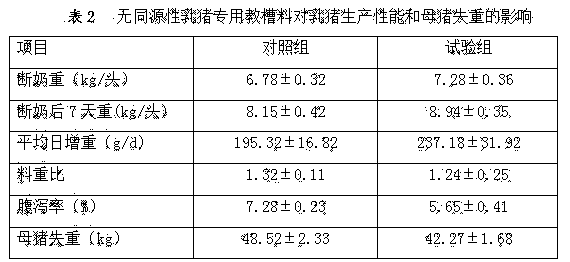

Complete feed for promoting lactation and development of mammary gland of sow and preparation method for complete feed

InactiveCN104397466AReasonable and innovative formulaMeet growth and developmentAnimal feeding stuffBiotechnologySodium bicarbonate

The invention relates to a complete feed for promoting lactation and development of the mammary gland of a sow. The complete feed comprises the following raw material components: corns, soybean meal, egg powder, wheat bran, fish meal, flaxseed flour, collagen powder, red sugar powder, stone powder, calcium hydrogen phosphate, sodium bicarbonate, sodium chloride, L-threonine, L-valine, L-methionine, L-tryptophan, lysine hydrochloride, choline chloride, composite vitamin and composite minerals. The formula of the feed provided by the invention is reasonable and novel; the feed adapts to the physiological characteristics of a lactating sow; after the feed is applied, the complete feed can promote lactation and development of the mammary gland of the sow, is low in cost and can meet the practical production of a pig farm.

Owner:GUANGXI SHANGDA TECH

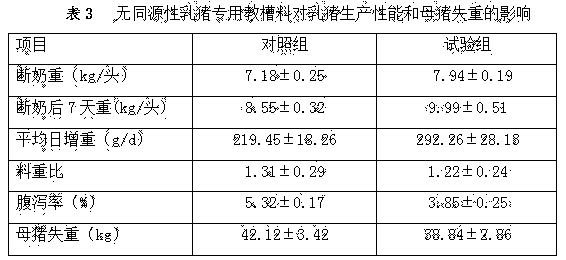

Creep feed specially used for piglet and preparation method thereof

InactiveCN104186934AReduce disease riskImprove digestion utilizationAnimal feeding stuffSucroseNutrition

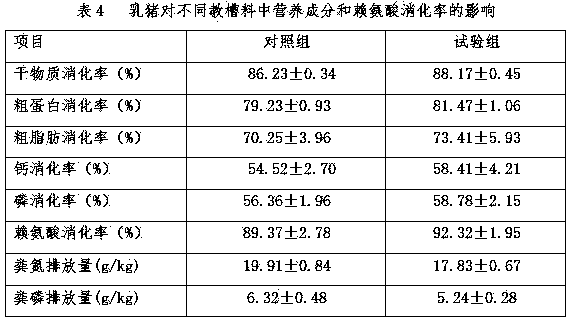

The invention discloses a creep feed specially used for piglets and a preparation method thereof and belongs to the field of feed production. The creep feed is prepared from following non-thermal-sensitive raw materials and thermal-sensitive raw materials through a two-stage mixing process and a two-stage granulation process, wherein the raw materials includes, by weight, 30-60 parts of corn, 5-12 parts of four, 3-10 parts of puffed soya bean, 3-10 parts of soybean protein concentrate, 1-7 parts of rice protein powder, 8-20 parts of fermented soybean meal, 0.5-3 parts of calcium hydrophosphate, 0.1-0.8 parts of salt, 1.5-5 parts of soybean oil, 3-7 parts of egg powder, 3-10 parts of wheat protein, 5-20 parts of whey powder, 1-5 parts of sugar, 1-5 parts of glucose, 0.3-1.5 parts of lysine, 0.05-0.4 parts of methionine, 0.05-0.5 parts of threonine and 0.5-3 parts of a composite pre-mixed material. Compared with a creep feed in the prior art, the creep feed specially used for the piglets can stop porcine disease transmission caused by plasma protein powder of diseased pigs, is comprehensive in nutrition, is easy to digest and absorb, and is quite good in value of popularization and application.

Owner:SHANDONG HEKANGYUAN GROUP

High-fiber low-carbon high-fat ketogenic cookie and making method thereof

InactiveCN108703180ACompatibility is scientific and reasonableCrispy tasteDough treatmentModified nutritive productsFiberPea protein

The invention relates to high-fiber low-carbon high-fat ketogenic cookie and a making method thereof. The high-fiber low-carbon high-fat ketogenic cookie is mainly made from, by weight, 10-50 parts ofinulin, 10-55 parts of pea fiber, 25-50 parts of MCT (medium-chain triglyceride) oil, 25-50 parts of gamma-linolenic acid oil, 2-15 parts of egg powder, 2-10 parts of pea protein, and 2-10 parts of hemp seed protein. The high-fiber low-carbon high-fat ketogenic cookie has accurate ratio, is convenient to calculate and consume, is crispy and fluffy, has crispy and fragrant taste, and is convenientto eat; commercially available materials are used to make the cookie, the production method is simple, and the cost is low; the high-fiber low-carbon high-fat ketogenic cookie is suitable for peoplerequiring ketogenic diets, and is also suitable for ordinary people having the pressing need for supplementary dietary fiber and for controlling weight and health by ketogenic dieting .

Owner:XIAN HERB REFINE BIOLOGIC PRODS

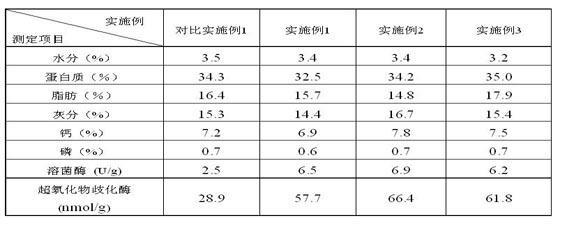

Egg meal beneficial to intestinal health of breeding animals and preparation method thereof

ActiveCN102132771AStrong sense of flowNutritional diversityAnimal feeding stuffAccessory food factorsBiotechnologyAquaculture industry

The invention discloses an egg meal beneficial to intestinal health of breeding animals, which comprises the following compositions in percentage by weight: 3-5 percent of water, 30-35 percent of crude protein, 14-18 percent of crude fat, 14-18 percent of ash content, 5-9 percent of calcium, 0.4-0.1 percent of phosphorus and the balance of active enzyme. A preparation method of the egg meal beneficial to the intestinal health of the breeding animals comprises the steps of washing egg, sterilizing, spraying, crushing eggs, mixing with film coating agents, emulsifying homogeneity, and spraying and drying, thereby obtaining the egg meal. The egg meal is characterized by being complete in nutrition, high in activity ingredient protection rate, convenient to use and store, and can be applicable to both aquaculture industry and poultry culture industry.

Owner:KUSN BEIRUIKANG BIOLOGICAL TECH

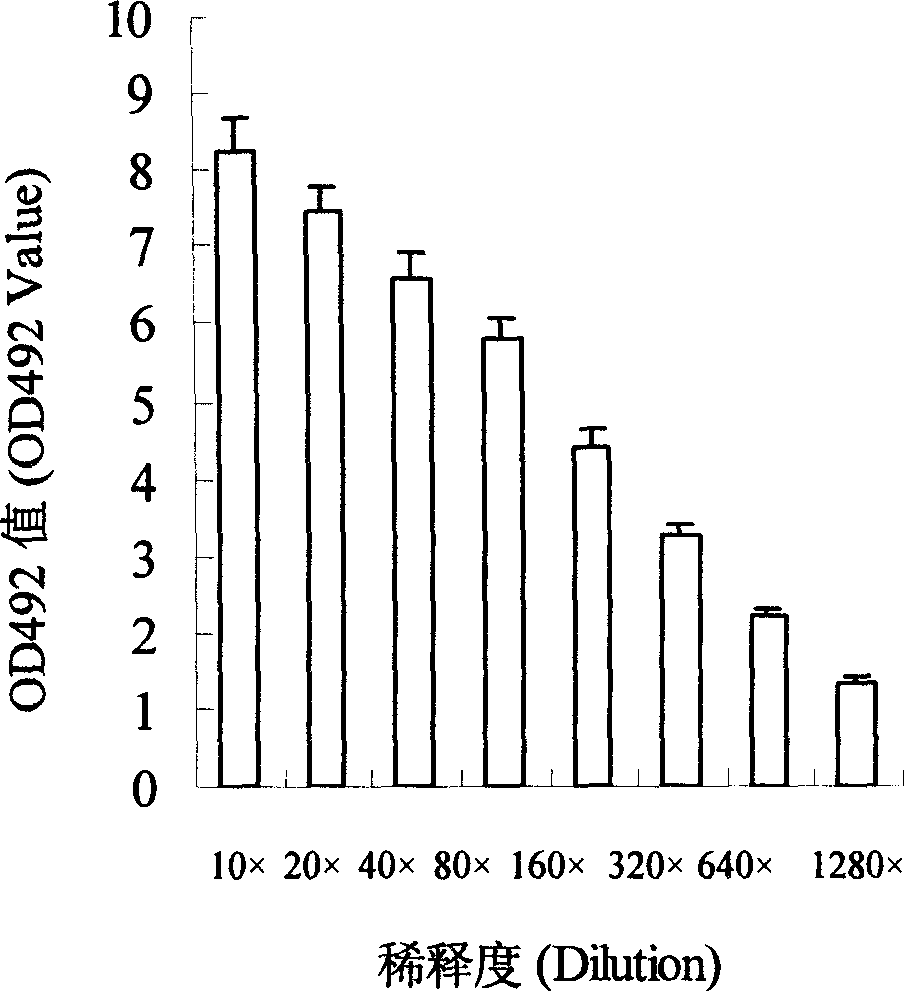

Method for preparing powdered egg yolk coating agent containing anti-aeromonas hydrophila yolk immunoglobulin

The present invention discloses preparation process of enveloped hydrophilic aeromonad resisting immunoglobulin yolk powder preparation. The preparation process includes collecting yolk liquid of hydrophilic aeromonad resisting yolk egg of titer in 1 to 640 and over, mixing beta-cyclodextrin and water through stirring to obtain beta-cyclodextrin aqua, adding the yolk liquid slowly into the beta-cyclodextrin aqua with the volume ratio between the yolk liquid and water being 2.8-5.6, mixing with starch with water content lower than 8 % through stirring to obtain mixture, pelletizing the mixture in 60 mesh screen, drying in a horizontal drier and sieving in a 80 mesh sieve. The enveloped preparation product has high bioactivity of immunoglobulin yolk, slow releasing characteristic, less influence of pepsin and good taste.

Owner:ZHEJIANG UNIV

Cooked wheaten food

InactiveCN107969617AUniform tasteHigh nutritional valueFood ingredient functionsNutritive valuesSucrose

The invention discloses a cooked wheaten food. The food comprises the following components in parts by weight: 100 parts of flour, 0.2-1 part of chlorella powder, 0.2-2 parts of salt, 20-35 parts of water, 0-2 parts of yeast, 0-5 parts of sucrose, 0-10 parts of concentrated juice, 0-20 parts of bean powder, 0-10 parts of egg powder and 0-2 parts of natural pigments. The food is balanced in nutrients, and particularly the chlorella powder has high nutritive value and simple source, contains rich vitamins and mineral elements, and can enhance human immunity. Meanwhile, on the one hand, the concentrated juice can play a role of dissolving the flour, and on the other hand, the concentrated juice can evenly distribute nutrients into the cooked wheaten food so as to enable the taste of the cooked wheaten food to be balanced and the flavor of the cooked wheaten food to be faint fragrant. The bean powder and the egg powder are added for increasing the protein content of the cooked wheaten food, so that nutrients are more balanced, and flavor is unique at the same time. The food is particularly suitable for infants and middle-aged and elderly people. Besides, various nutrient components arewrapped by the flour so as to reduce the loss of the nutrient components.

Owner:王星星 +1

Synthesized nutritious food vermicelli

InactiveCN103202421APromote absorptionMeet intake requirementsFood preparationBiotechnologyPotato starch

The invention relates to synthesized nutritious food vermicelli, in particular to four-in-one nutritious food vermicelli. A method for making the food vermicelli includes: matching raw materials including sweet potato starch, rice starch, soybean meal and egg powder according to a weight percentage; and mixing the mixed raw materials with water and making the product to be strip-shaped, drying or ageing at high temperature prior to drying to obtain a finished product. The synthesized nutritious food vermicelli has the advantages that the raw materials are reasonable in matching and high in utilization rate, the finished product is balanced in nutrition, safe and reliable, and amino acid in optimal amount is matched according to needs of human bodies to promote uptake, of amino acid, by people, improve nutrition absorbing capability of the people and improve immunity of the human bodies. The nutritious food vermicelli is simple in production process and low in cost.

Owner:WUHAN YUANZHAO TECH IND

Microwave processed egg product and preparation method thereof

InactiveCN102987446AImprove aestheticsIncrease nutritionFood preparationBiotechnologyMonosodium glutamate

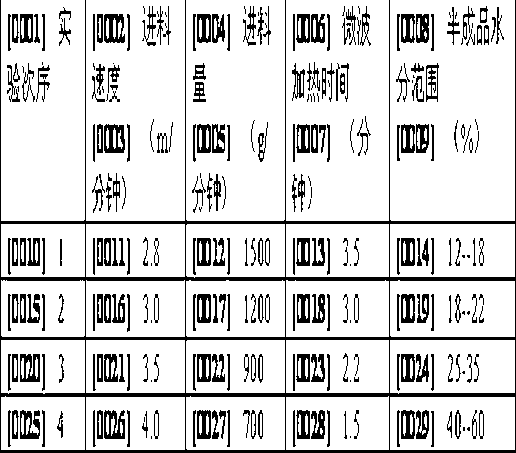

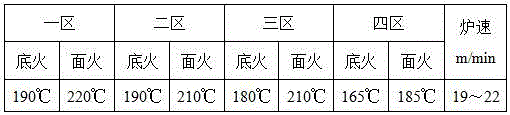

The invention relates to a microwave processed egg product which uses egg powder, starch, white granulated sugar, vegetable oil, sorbitol, phosphate, xanthan gum, edible salt, monosodium glutamate, soy powder, 5-flavor nucleotide, vitamin E and baking powder as main materials and prepared by microwave processing and drying and a preparation method of the microwave processed egg product. The preparation method comprises the steps of: mixing uniformly the egg powder and starch powder; adding liquid charging stock of the vegetable oil; mixing; adding tap water; mixing as paste; preparing wet particles / or extruding and forming; heating by a microwave production line; palletizing secondarily; drying by hot air; packaging; and continuously heating by the microwave production line. The egg product is convenient to produce, high in work efficiency, and environment-friendly and sanitary. Uniform microporous channels from inside to outside are formed in the prepared product after microwave processing. After hot water or soup base is added into the product, the product absorbs water quickly and expands and floats on the hot water or soup base, so that the inherent color, flavor and taste of fried egg are well represented, the attractiveness and nutrition of a main foot are improved, and the microwave processed egg product is suitable for an ingredient of a convenient food.

Owner:ZHENGZHOU GUANGHEYUAN AGRI TECH

Roxburgh rose crisp or filling rich in natural vitamin C component and preparation method of roxburgh rose crisp or filling

ActiveCN103989104AHas health effectsTo overcome the shortcomings of the applicationYeast food ingredientsFood coatingBiotechnologyVitamin C

The invention discloses a roxburgh rose crisp or filling rich in natural vitamin C component, and a preparation method of the roxburgh rose crisp or filling. The roxburgh rose crisp or filling is prepared from the following raw materials in parts by weight: 3-5 parts of roxburgh rose filling, 12-16 parts of wax gourd filling, 1-2 parts of maltose, 0.5-1 part of egg powder and 0.5-1 part of cream. The preparation of the roxburgh rose filling comprises the steps of enzymolysis, grinding, fermentation and the like; the wax gourd filling is prepared by removing the peel of a wax gourd, removing seeds, slicing, putting the sliced wax gourd into a pot with boiled water, cooking for 15-20 minutes, fishing out, wrapping by gauze, squeezing water until the water is completely squeezed out, and chopping the sliced wax gourd. According to the roxburgh rose crisp or filling and the preparation method, the roxburgh rose is used as main health care raw material for preparing the baked food; compared with the existing Taiwan food pineapple cake, the roxburgh rose crisp or filling has an obvious health care effect, and is proved to be better in flavor and mouth feel after being tasted by people, thus having very high competitiveness in the traditional food.

Owner:贵州华南理工生物工程有限公司

Soft-shelled turtle fodder and preparation method thereof

InactiveCN104171568AHigh in nutrientsEnsure basic nutritionAnimal feeding stuffBiotechnologyAnimal science

The invention discloses a soft-shelled turtle fodder and a preparation method thereof. The fodder comprises the following components in parts by weight: 5-10 parts of soybean cake meal, 3-5 parts of bone meal, 10-15 parts of egg powder, 10-15 parts of seaweed powder, 3-5 parts of corn protein meal, 3-5 parts of fish meal, 5-10 parts of wheat bran, 3-5 parts of rice bran, 0.5-1 part of edible salt, 0.01-0.02 part of DL-methionine, 0.05-0.1 part of betaine, 0.1-0.2 part of multiple vitamins for fish and 0.1-0.2 part of choline chloride. The preparation method comprises the steps of (1) preparing a premix; (2) crushing; and (3) preparing the soft-shelled turtle fodder. The fodder disclosed by the invention has comprehensive and balanced nutritional ingredients according to a formula; simultaneously, no pollutants are produced in the whole preparation process, the preparation process is clean and environmentally friendly, the immunity of soft-shelled turtles is improved and diseases and insect pests are reduced.

Owner:JURONG SOUTHERN AQUATIC PROD FARMING PROFESSIONAL COOP

Extruded and puffed syrup-coated food prepared by using germinated brown rice as raw material and preparation method thereof

InactiveCN104957344AHigh nutritional valueComprehensive and balanced nutritionConfectionerySweetmeatsBiotechnologyNutrition

The invention relates to extruded and puffed syrup-coated food prepared by using germinated brown rice as a raw material and a preparation method thereof. The extruded and puffed syrup-coated food is prepared according to a method which comprises the following steps: (1) performing germination treatment to brown rice; (2) preparing germinated brown rice raw material powder; (3) uniformly mixing the germinated brown rice raw material powder with egg powder and glucose to obtain mixed powder; (4) pouring the mixed powder into a twin-screw extruder production line to perform extrusion and puffing; (5) preparing and decocting syrup prepared by using isomaltulose, xylitol and white granulated sugar as main raw materials; (6) pouring the hot extruded and puffed semi-finished product into a basin and mixing the semi-finished product with the decocted syrup; (7) pouring the hot mixture into a mold for extrusion molding; (8) cutting the molded product to obtain finished products. The extruded and puffed syrup-coated food prepared by using germinated brown rice as the raw material and the preparation method thereof have the advantages that the operation method is simple, the fat content of the food can be reduced by adopting an extrusion and puffing manner instead of oil frying manner, and no pollution caused by other heavy metals is not caused during processing. Not only can the food be guaranteed to have a good external shape and be nutritious and healthy, but also the safety of food processing is improved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Anti-enteritis functional protein powder for feeds and production method thereof

InactiveCN103988990AInhibition of reproductionEliminate Excessive Immune ResponseAnimal feeding stuffAccessory food factorsBiotechnologyPROTEIN S HEERLEN

The invention discloses an anti-enteritis functional protein powder for feeds and a production method thereof. Fermented soybean meal, probiotics, an activated egg powder, cell-wall-broken yeast and chitosan oligosaccharide are used as main raw materials. The product has the characteristics of high protein content, less anti-nutritional factors, body immunity enhancement, and prominent anti-enteritis effect, generates no drug resistance, has no toxicity and no residue, can be mixed with other drugs for use, and is suitable for being added in various animal breeding feeds.

Owner:WEIHAI GOLD FEED

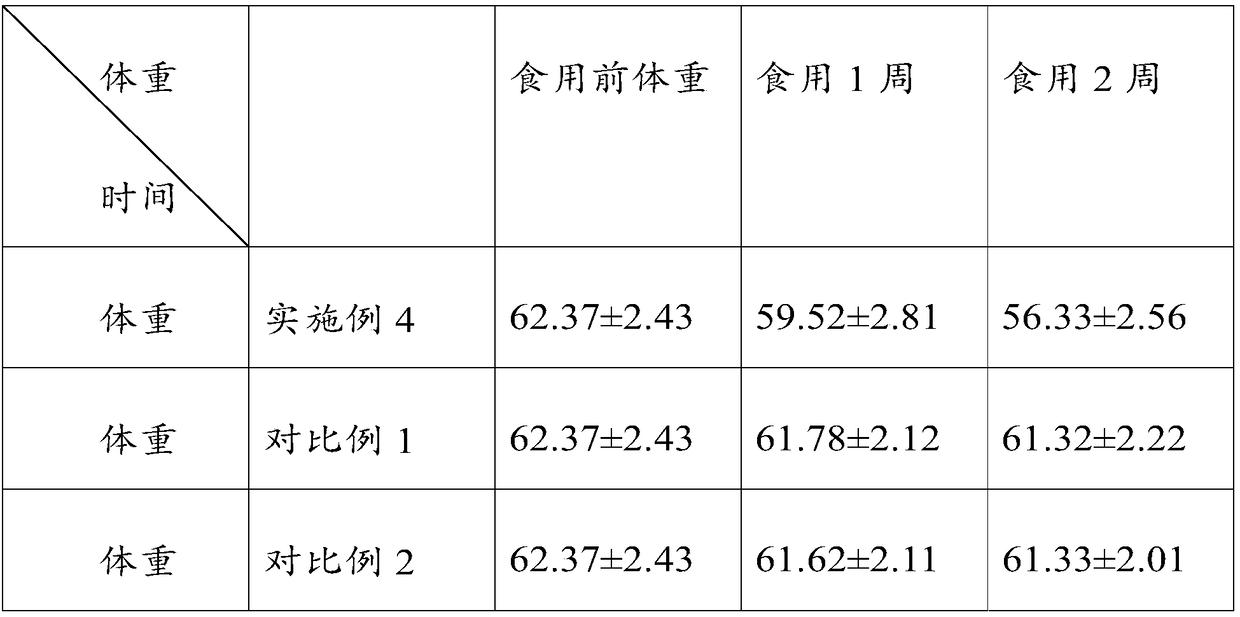

Raising method for producing sows

InactiveCN105192378AIncrease production capacityEnhance physical fitnessAnimal feeding stuffBiotechnologyAnimal science

The invention relates to a raising method for producing sows. The raising method includes the following steps: feeding feed composed of Pennisetum sinese roxb, corn, egg powder, wheat bran, soybean meal, fish meal, meat and bone meal, 20-30 parts of linseed meal, soybean oil, histidine, arginine, sucrose powder and vitamin, wherein a feeding method includes: feeding 3-4kg for each sow each day before delivery, feeding 1-2kg for each sow at the day of delivery, gradiently adding 0.5kg for each sow each of four days after delivery, and allowing the sows to ingest freely after 3-5 days; regularly feeding extract prepared with poria cocos, astragalus, aniseed and Corydalis saxicola each mouth, wherein feeding interval is a week. By the raising method, physique of the producing sows can be enhanced effectively, productivity of the producing sows can be improved, and nutrition yield and quality of breast milk can be improved.

Owner:陆川县英平畜牧业有限责任公司

Fresh soft cream and preparation thereof

InactiveCN1644071AAccurate measurementWide variety of sourcesCheese manufactureButtermilkSoybean proteinToned milk

A fresh soft cheese is prepared from concentrated milk, butter, milk powder, edible soybean fibre powder, egg, soybean protein, starch, salt, sodium tripolyphosphate, and VC sodium through proportional mixing, emulsifying, degassing, loading in containers, high-temp and -pressure sterilizing, and cooling. Its advantage is low storage period (12 months at 0-10 deg.C).

Owner:骆承庠 +1

Pollution-free aquatic feed additive using ginkgo leaves as base stock

The invention relates to a pollution-free aquatic feed additive using ginkgo leaves as a base stock. The pollution-free aquatic feed additive is prepared from the following materials in parts by weight: 150-200 parts of ginkgo leaves, 100-120 parts of potatoes, 30-50 parts of lotus leaves, 15-20 parts of common andrographis herbs, 8-12 parts of Chinese mosla herbs, 5-7 parts of Chinese rhubarb, 7-12 parts of mangnolia officinalis, 3-5 parts of negundo chastetree fruits, 50-80 parts of chlorella powder, 50-80 parts of egg powder, 5-10 parts of medical stones and 20-30 parts of corn starch. The feed additive disclosed by the invention completely adopts natural components, is not extracted and treated by any harmful chemical reagent and pollution-free to an aquaculture environment, and completely satisfies green, safe and pollution-free requirements of modern aquaculture industry.

Owner:广东恒旺饲料有限公司

Egg-contained dry food

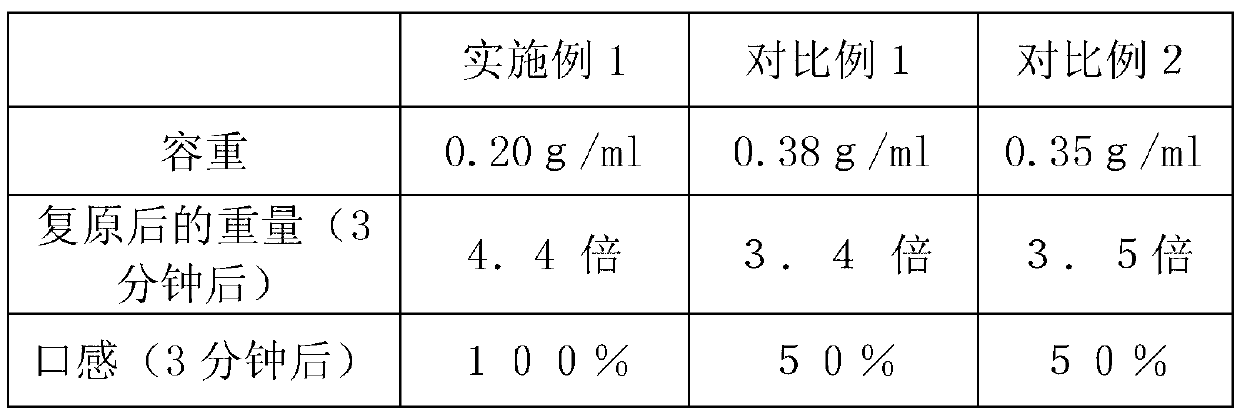

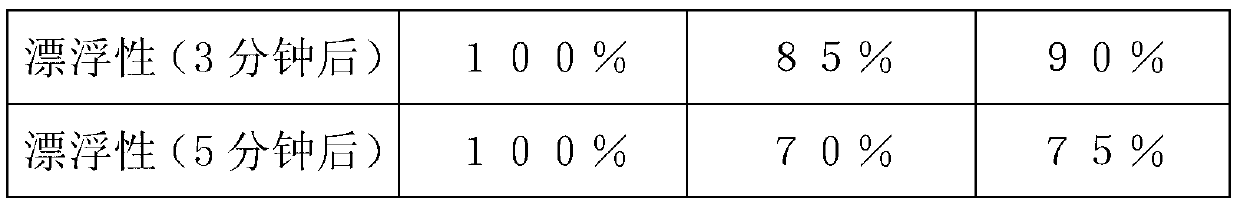

InactiveCN103125980AUniform recoverySufficient water absorptionFood preparationVegetable oilMicrowave

The invention relates to an egg-contained dry food and aims to solve the problems of poor water absorption and expansibility, poor taste, poor floatability and high product price of the traditional egg-contained dry food. The egg-contained dry food is prepared by the following steps of: mixing the following components in parts by weight: 1500-3500 parts of egg powder, 1000-3000 parts of starch, 500-1500 parts of granulated sugar, 200-400 parts of vegetable oil, 250-350 parts of table salt, 50-150 parts of gourmet powder and 1-5 parts of carotene; then, stirring by using water with the mass concentration of 1-10% and the temperature of 0-30 DEG C to form a dough with the water content of 10-40%, wherein the water internally contains a swelling agent; then, forming by using a granulator to prepare grains, heating the grains to over 85 DEG C at the microwave strength of 500-3000J / g within 10-60s, and drying the grains until the water content is up to 8-20%; and then, drying the grains under hot air of 50-80 DEG C until the water content is up to 1-8% and the volume weight is up to 0.20-0.30g / ml to obtain the egg-contained dry food, wherein the egg-contained dry food is porous, the weight of the egg-contained dry food is increased by 4-8 times when the egg-contained dry food restores because of absorbing water in hot water or soup with the temperature over 80 DEG C for 2-5 min, and the restored food floats on the surface of boiling water or soup after 5min.

Owner:KAIFENG TAIYO KINMEI FOOD CO LTD

Low-fat arrowroot flour biscuits and preparation method for same

InactiveCN105918412AOvercome the defect of rough tasteGreat tasteDough treatmentBakery productsBiotechnologySodium bicarbonate

The invention discloses low-fat arrowroot flour biscuits and preparation method for the same. The arrowroot flour biscuits comprise the following components in parts by mass: 200 to 250 parts of low-quality wheat flour, 40 to 50 parts of powdered white granulated sugar, 30 to 40 parts of whole arrowroot flour, 10 to 20 parts of arrowroot starch, 20 to 30 parts of bran, 10 to 12 parts of egg powder, 2.0 to 3.0 parts of edible salt, 2.0 to 3.0 parts of ammonium bicarbonate, 1.0 to 2.0 parts of sodium bicarbonate, 0.1 to 0.3 part of enzymes special for short biscuits, 40 to 60 parts of palm oil, 5 to 10 parts of glucose syrup and 60 to 70 parts of water, wherein the mass ratio of the whole arrowroot flour to the arrowroot starch is (1.5-4):1. When the arrowroot flour biscuits are prepared by virtue of the formula and the preparation method, the mouth-feel and the high quality of the biscuits can be ensured, the using amount of fat can also be reduced, and positive significance for production and popularization of the healthy arrowroot flour biscuits and popularization and application of arrowroot flour is achieved.

Owner:广州鹰金钱食品集团有限公司

Child formula milk powder capable of promoting height development, and preparation method of child formula milk powder capable of promoting height development

InactiveCN111528282APromote child developmentImprove developmentMilk preparationBiotechnologyNutrition

The invention discloses child formula milk powder capable of promoting height development, and a preparation method of the child formula milk powder capable of promoting height development. The formula milk powder contains whole-fat milk powder, desalinated whey powder, skimmed milk powder, isomaltooligosacharide, solid corn syrup, maltose powder, fructo-oligosaccharide, hydrolyzed powdered egg yolk, whey protein powder, docosahexaenoic acid powder, arachidonic acid powder, composite mineral substances, complex vitamins, calcium carbonate and bifidobacterium animalis. The formula milk powder not only provides rich nutrients for growth and development of children but also can directly and effectively promote skeleton growth and height development of the children.

Owner:广州市美素力营养品有限公司

Dietary-fiber biscuits capable of relaxing bowels and production process thereof

InactiveCN105767096AGood laxative effectHas laxative effectDough treatmentBakery productsDiseaseVegetable oil

The invention discloses dietary-fiber biscuits capable of relaxing the bowels and a production process thereof. The dietary-fiber biscuits is produced by, by weight, 100-150 parts of whole-wheat flour, 30-50 parts of corn flour, 12-15 parts of milk powder, 15-20 parts of anhydrous dextrose, 10-15 parts of egg powder, 5-7 parts of pectin, 15-20 parts of vegetable oil, 12-16 parts of butter, 0.5-1.5 parts of yeast, 8-10 parts of bamboo shoot dietary fibers, 10-20 parts of yam, 10-20 parts of black sesame, 20-30 parts of unpolished rice, 10-20 parts of semen juglandis and an appropriate amount of water. The production process includes the steps of firstly, premixing auxiliary materials; secondly, preparing dough; thirdly, baking; fourthly, cooling, finishing and packaging. The dietary-fiber biscuits capable of relaxing the bowels have the advantages that the biscuits are rich in dietary fibers, capable of preventing constipation and intestinal system diseases and changing intestine and stomach weakness, good in the bowel relaxing effect and free of side effect on human bodies.

Owner:安徽凯宇果胶食药配料有限公司

Composite balancing nutritional agent

The invention relates to a composite balancing nutritional agent with convenient eating. The nutritional mixture combines several foods with high nutrition into a whole for the first time to realize comprehensive balanced nutrition and is matched with a convenient preparation form for convenient use. The nutritional mixture is prepared by mixing raw materials comprising the following components: milk powder, egg powder, soybean meal, fish meal, Chinese wolfberry, Chinese date and a flavoring component, wherein the weight ratio of the milk powder to the egg powder to the soybean meal to the fish meal to the Chinese wolfberry to the Chinese date to the flavoring component is sequentially 10 to 95:5 to 90:5 to 90:5 to 90:5 to 90:5 to 90:1 to 30:1 to 30. The nourishing and flavoring component is one or multiple of lentinus edodes, garlic, ginger, capsicum, onion, zanthoxylum, essence of chicken and brown sugar. The nutritional mixture has comprehensive and abundant nutrition and convenient use. The invention is suitable for serving as a nutritional beverage and an instant diet or is matched with other instant diets for use.

Owner:胥永贵

Probiotic and egg nutritional powder and preparation method thereof

The present invention discloses probiotic and egg nutritional powder. The probiotic and egg nutritional powder comprises the following raw materials in parts by mass: 40-60 parts of egg powder, 20-40parts of inulin, 1-10 parts of citrus fibers, 1-10 parts of resistant dextrin, 0.5-15 parts of compound probiotic powder, 0.5-5 parts of stachyose, 0.5-5 parts of hydrolyzed egg yolk powder and 0.5-5parts of blueberry fruit powder. The present invention also discloses a preparation method of the probiotic and egg nutritional powder. The preparation method comprises the following steps of preparing egg powder, preparing compound probiotic powder and preparing probiotic and egg nutritional powder. The probiotic and egg nutritional powder is a solid drink having functions of preventing oxidation, nourishing intestinal flora, supplementing dietary fibers, moistening intestines and relaxing bowels, enhancing immunity, and improving sub-health, and can significantly alleviate increasingly striking sub-health problems of intestinal disorders, constipation, low immunity, etc. in long-term drinking.

Owner:四川伟康生物科技有限公司

Egg powder

An egg food product is provided that when mixed with baby food and given regularly to a baby will reduce the likelihood of the baby developing a food allergy to eggs. The egg food product is produced by taking whole eggs or egg whites and mixing or whipping them, either by themselves or with other ingredients such as rice, tapioca, wheat, corn, nut flours, soy flour, or bean flour. An acid or acid salt containing food product such as citric acid, lemon juice, and cream of tartar may be added while mixing or whipping the eggs in order to help firm the eggs or egg whites and allow them to retain more air. The resulting batter is then baked in order to produce a cake-like product. The resulting cake is then dried in order to remove substantially all moisture. The dried cake is then ground or milled into a powder.

Owner:LIL MIXINS LLC

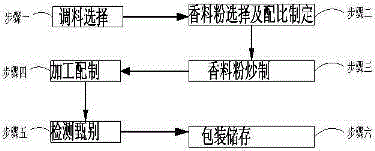

Multi-flavor barbecue ingredient production method

InactiveCN104824608AStrong thermal energy conductionHigh composition densityFood ingredientsFood preparationBiotechnologySodium bicarbonate

The present invention discloses a multi-flavor barbecue ingredient production method, which comprises: 1, seasoning selecting, 2, perfume selecting and ratio determining, 3, perfume powder frying, 4, processing preparing, 5, detecting screening, and 6, packaging storing, wherein the seasoning selecting comprises 10 parts of disodium 5'-ribonucleotide, 14 parts of edible sodium bicarbonate, 0.4 part of tenderizer containing a papain component, 10 parts of crude cuminum cyminum powder, 30 parts of corn starch, 14 parts of edible sodium bicarbonate, 0.4 part of tenderizer containing a papain component, 5 g of dehydrated egg powder, 10 ml of a grain baijiu, and 400 ml of drinking water, and the perfume ratio selection comprises 7% of coriandrum sativum seed, 0.2% of rosmarinus officinalis, 2.98% of black sesame, 41% of foeniculum vulgare mill, 13% of cuminum cyminum, 25% of zanthoxylum bungeanum, 10% of illicium verum hook, and 1% of black pepper. According to the present invention, under the catalysis of the papain, the meat structure is quickly loosened, the lean meat tissue is expanded and opened, Sodium Inosinate, sodium guanylate and sodium chloride (salt) rapidly permeate into the inner layer, and the meat is expanded and loose, such that the baking time is effectively reduced.

Owner:UNIV OF JINAN

Maize puffed fine cake and its preparing process

The present invention discloses a corn puffed fine cake and its preparation process. The raw material of said corn puffed fine cake (sesame flavour) comprises (by every Kg of raw material) refined puffed corn fluor 400-800g, white granulated sugar 150-500g, milk powder 10-50g, egg powder 5-50g, sesame 5-50g, perfume 0.1-10g, vegetable oil 5-25g, edible salt 5-25g, tea-polyphenol 0.1-10g, yeast extract 5-50g and water 5-150g. Said invention also provides the concrete steps of its preparation method.

Owner:冯华君

Milk replacer for squabs and preparation method for milk replacer

InactiveCN103766670AHigh nutritional valueSolve industrialization problemsAnimal feeding stuffBiotechnologyAnimal science

The invention specifically discloses a milk replacer for squabs and a preparation method for the milk replacer, and solves the problem of restrictions of lactation of conventional 1 to 10-day aged squabs to squab intensification and industrialization. The milk replacer for the squabs is prepared from the following air-dried solid raw materials in parts by weight: 250 to 300 parts of egg powder, 150 to 200 parts of fish meal, 150 to 200 parts of soybean meal, 100 to 150 parts of whole milk powder, 80 to 100 parts of vegetable oil, 50 to 80 parts of corn gluten meal, 40 to 80 parts of lactic acid powder, 6 to 8 parts of calcium hydrogen phosphate, 2 to 3 parts of edible salt, 0.8 to 1 part of composite trace element, 0.6 to 1 part of composite vitamin and 0.1 to 0.2 part of an antioxidant. The prepared milk replacer is nutritionally balanced, high in palatability and easy to digest and absorb and accords with gastrointestinal digestion characteristics of the squabs, and has the advantages of convenience in storage and preparation and capability of meeting squab intensive-feeding production requirements, and requirements of 1 to 10-day aged squabs on nutrition are met.

Owner:山西省生态畜牧产业管理站 +3

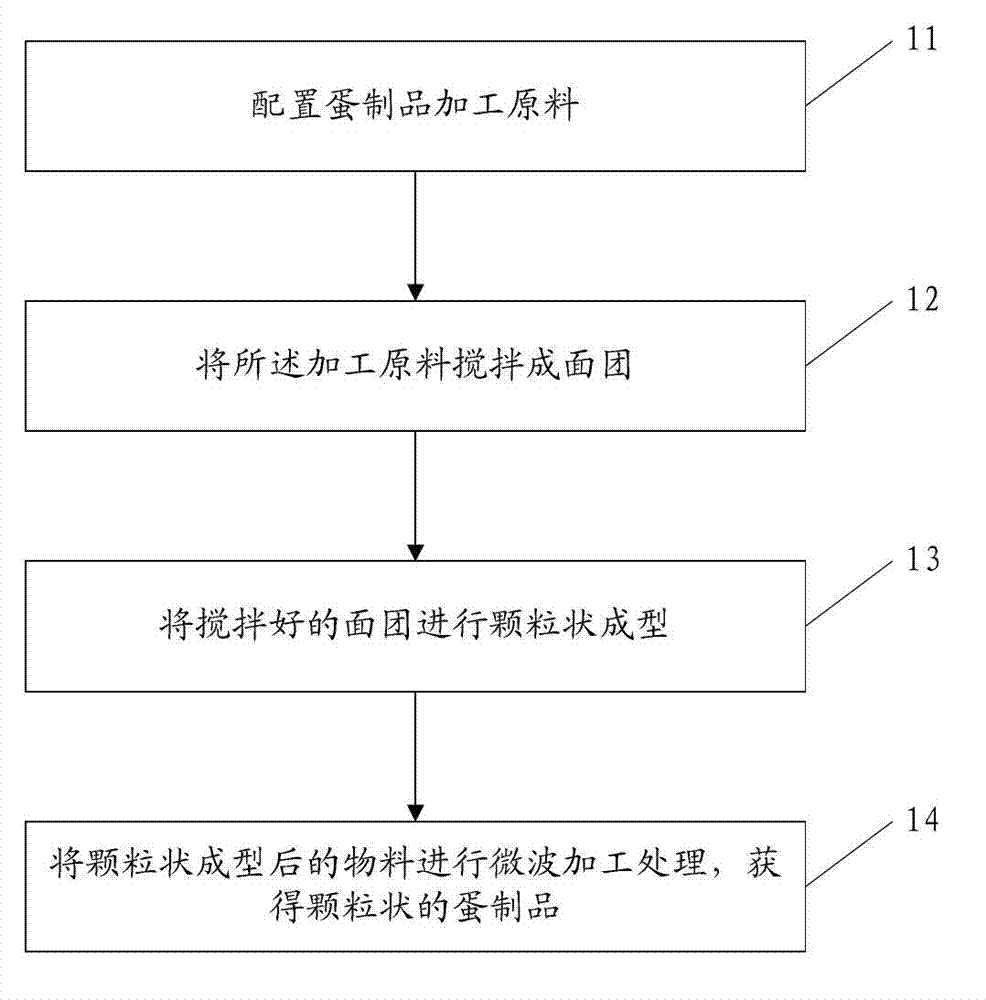

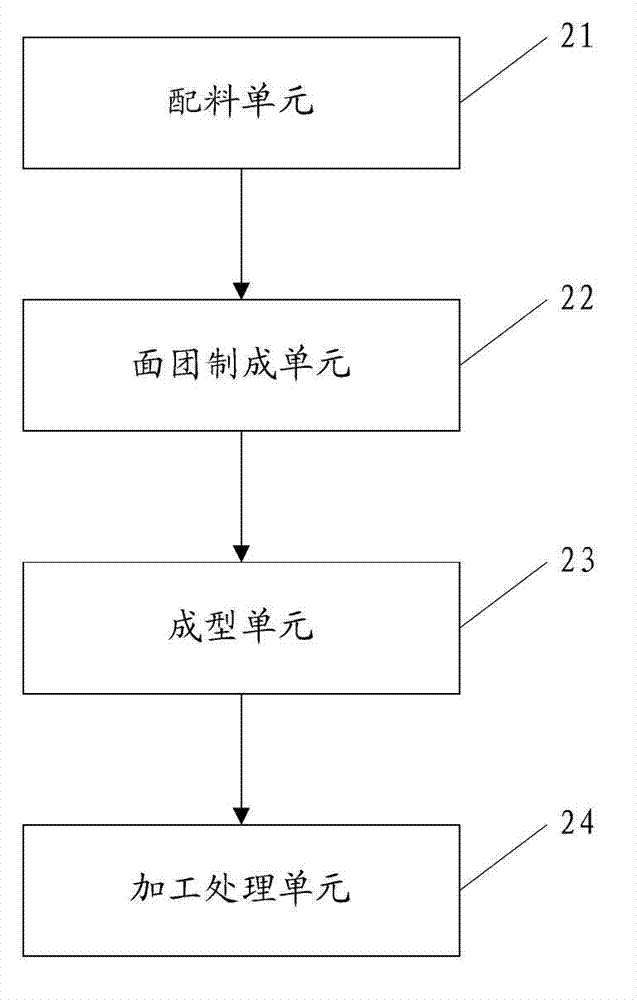

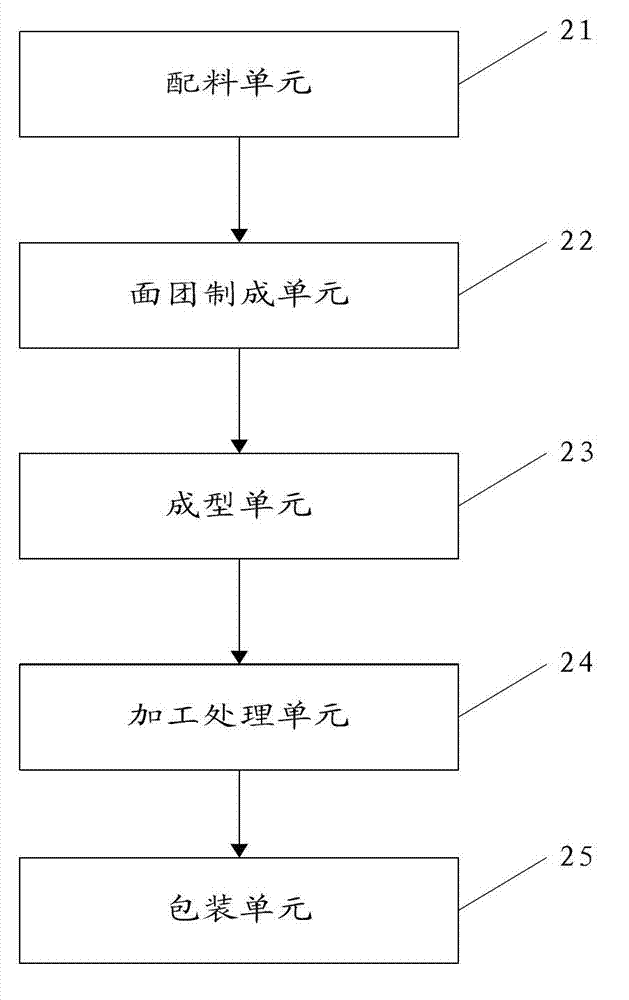

Egg product as well as processing method and device thereof

InactiveCN102960778ANutrients gain and maintainPromote recoveryFood shapingFood preparationAnimal scienceMicrowave

The invention discloses an egg product as well as a processing method and device thereof, relating to the technical field of deep processing of egg products and being invented for ensuring that the egg product meets the requirements for convenience and rapidness and the nutritional components of the egg product can be effectively increased and remained. The method comprises the following steps of: preparing egg product processing raw materials, wherein the processing raw materials include egg powder, starch, edible oil, seasoning and water, the egg powder and the starch are 60% of the total weight of the processing raw materials, the edible oil, the seasoning and the water are 40% of the total weight of the processing raw materials; the egg powder is 20-50% of the total weight of the processing raw materials, the starch is 10-30% of the total weight of the processing raw materials, the edible oil is 1-3% of the total weight of the processing raw materials, the seasoning is 15-25% of the total weight of the processing raw materials and the water is 12-24% of the total weight of the processing raw materials; stirring the processing raw materials into dough; forming the stirred dough into granules; and carrying out microwave processing on the formed granulated materials to obtain a granulated egg product.

Owner:JILIN JINYI FOOD CO LTD

Well cooked egg powder

ActiveUS11154081B1Easy for an infant or baby to eat and digestFood thermal treatmentEggs preservation by heatingBiotechnologyNutrition

A nutritional or dietary egg supplement or food product is provided that may be eaten by children or adults. The food product is made solely of whole hen's eggs or egg whites that have been heat treated to selectively denature allergenic proteins s compared to a natural hen's egg.

Owner:LIL MIXINS LLC

Preparation method of high-activity yoghurt powder

The invention discloses a preparation method of high-activity yoghurt powder. The high-activity yoghurt powder is prepared from the following raw materials in parts by weight: 90-100 parts of fresh milk, 20-25 parts of cherries, 1-3 parts of white granulated sugar, 8-10 parts of trehalose and 2-4 parts of egg powder. According to the preparation method of the high-activity yoghurt powder, by adding cherries, trehalose and egg powder, the survival rate of beneficial bacteria in the high-activity yoghurt powder is higher, the requirement for the amount of iron elements in a human body can be metthrough the iron elements in the cherries, which promotes hemoglobin regeneration, and meanwhile the taste of the redissolved yoghurt powder is better.

Owner:黄鹏

Cultivation method for worm grass containing high amount of cordycepin and growth medium used by method

InactiveCN106171529AIncrease productivityShorten the production cycleAnimal corpse fertilisersNitrogenous fertilisersCell culture mediaAdenosine

The invention discloses a cultivation method for worm grass containing high amount of cordycepin and a growth medium used by a method. The method comprises following steps: (a) making the growth medium, wherein components and mass percents of components of the growth medium are as follows: 75%-100% of egg powder, 0%-20% of maltodextrin, 0%-5% of adenosine; wherein the sum of the components for the growth medium is 100%; (b) inoculating cordyceps militaris strains on the growth medium; (c) harvesting and obtaining required cordyceps militaris under cultivation in a certain environment condition. The cultivation method for worm grass containing a high amount of cordycepin and the growth medium used by the method have following beneficial effects: production efficiency of cordyceps militaris is increased so that production cycle is shortened; production equipment is easy; production condition is easy to control; cost of manufactured production is low; and amount of cordycepin for worm grass is up to 1.5-4.0%.

Owner:吴剑翔

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com