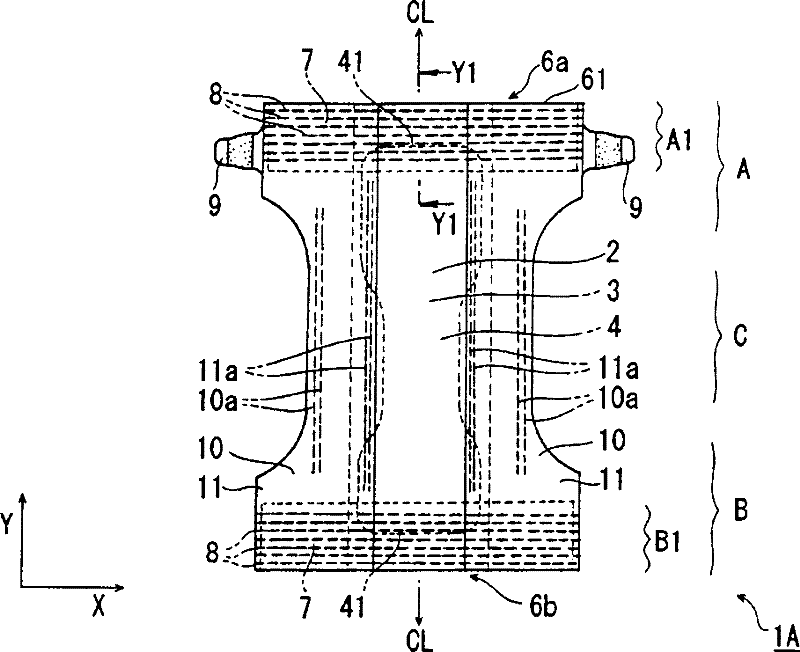

Absorbent article

An absorbent, disposable technology, applied in the direction of absorbent pads, medical science, bandages, etc., can solve the problems of increased long fiber distance, reduced mobility, and difficulty in following expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

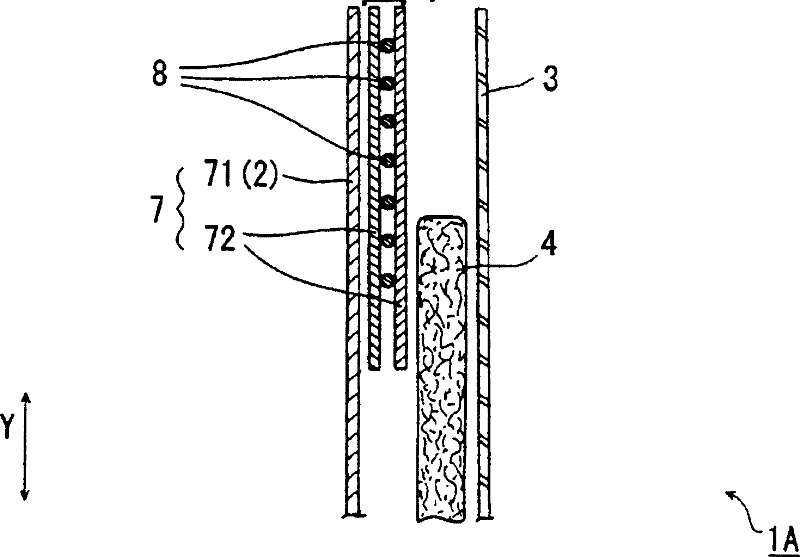

Embodiment 1

[0111] Embodiment 1, use the hydrophilic hot air (air-through) non-woven fabric (25g / m2) that PP / PE and PET / PE fiber constitute as inner hydrophilic sheet 2 , width 60mm × width 100mm), as the outer hydrophilic sheet using 2 pieces of hydrophilic spunbonded non-woven fabrics made of PP fibers (10g / m 2 , 60mm in length and 120mm in width). In addition, 10 strands of natural rubber (470dtex) were used as waist elastic members. In Example 1, the inner hydrophilic sheet was placed on a flat surface, one of the outer hydrophilic sheets was placed on the inner hydrophilic sheet, and one of the outer hydrophilic sheets was placed side by side at intervals of 5 mm and stretched. For 10 waist elastic members with a stretch ratio of 200%, these waist elastic members are sandwiched, another outer hydrophilic sheet is provided, and one outer hydrophilic sheet and The other outer hydrophilic sheet is bonded all over, thereby forming the pleats.

[0112] The liquid spreading area of ea...

Embodiment 2

[0114] Embodiment 2, use the weakly hydrophilic spun-bonded non-woven fabric (19g / m2) that PP fiber constitutes as the inside hydrophilic sheet 2 , width 60mm×width 100mm), as the outer hydrophilic sheet, use hydrophilic SMMS (spunbond / meltblown / meltblown / spunbond) composed of PP fibers (10g / m 2 , 60 mm in length x 120 mm in width), except that, in the same manner as in Example 1, pleats were produced.

[0115] The liquid diffusion area of each of the inner hydrophilic sheet and the outer hydrophilic sheet used was measured in the same manner as in Example 1. The measured values obtained are shown in Table 1. The measured value is the average value of n=5.

Embodiment 3

[0117] Embodiment 3, use the hydrophilic air-through non-woven fabric (36g / m 2 , width 60mm × width 100mm), as the outer hydrophilic sheet using a hydrophilic spun-bonded non-woven fabric composed of PP fibers (10g / m 2 , 60 mm in length x 120 mm in width), except that, in the same manner as in Example 1, pleats were produced.

[0118] The liquid diffusion area of each of the inner hydrophilic sheet and the outer hydrophilic sheet used was measured in the same manner as in Example 1. The measured values obtained are shown in Table 1. The measured value is the average value of n=5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com