Device and method capable of measuring liquid-liquid diffusion coefficient at different temperatures

A diffusion coefficient and width technology, which is applied in the field of devices and methods that can measure liquid-liquid diffusion coefficients at different temperatures, can solve the problems of failure to consider Raman laser heating disturbance, inability to realize diffusion coefficient measurement, and low measurement accuracy. Achieve the effect of eliminating laser thermal effect, realizing continuous measurement and high measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: the diffusion coefficient measurement (method of the present invention) of toluene and hexanaphthene

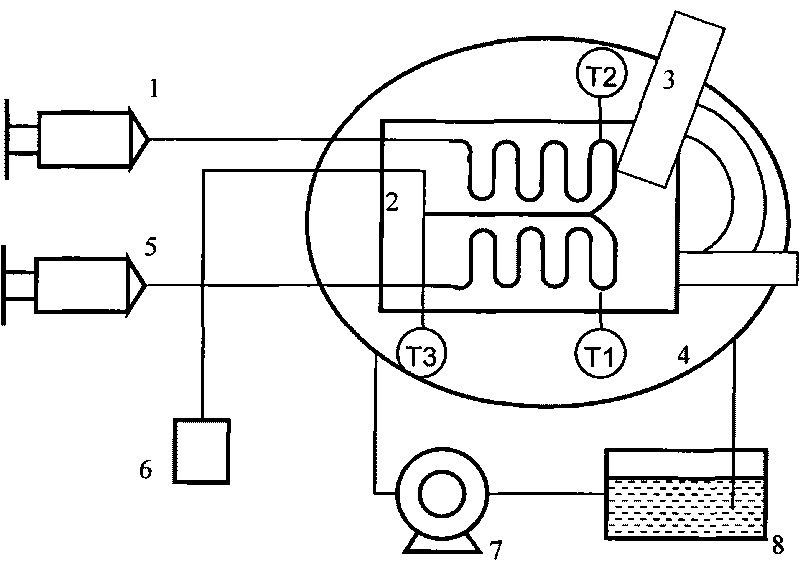

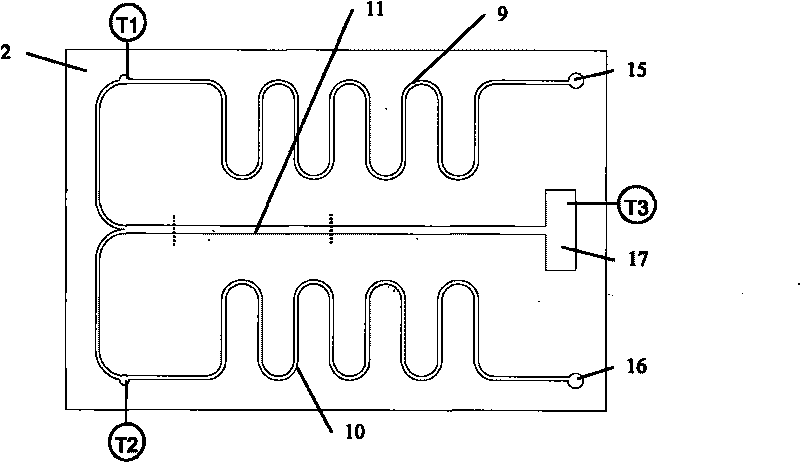

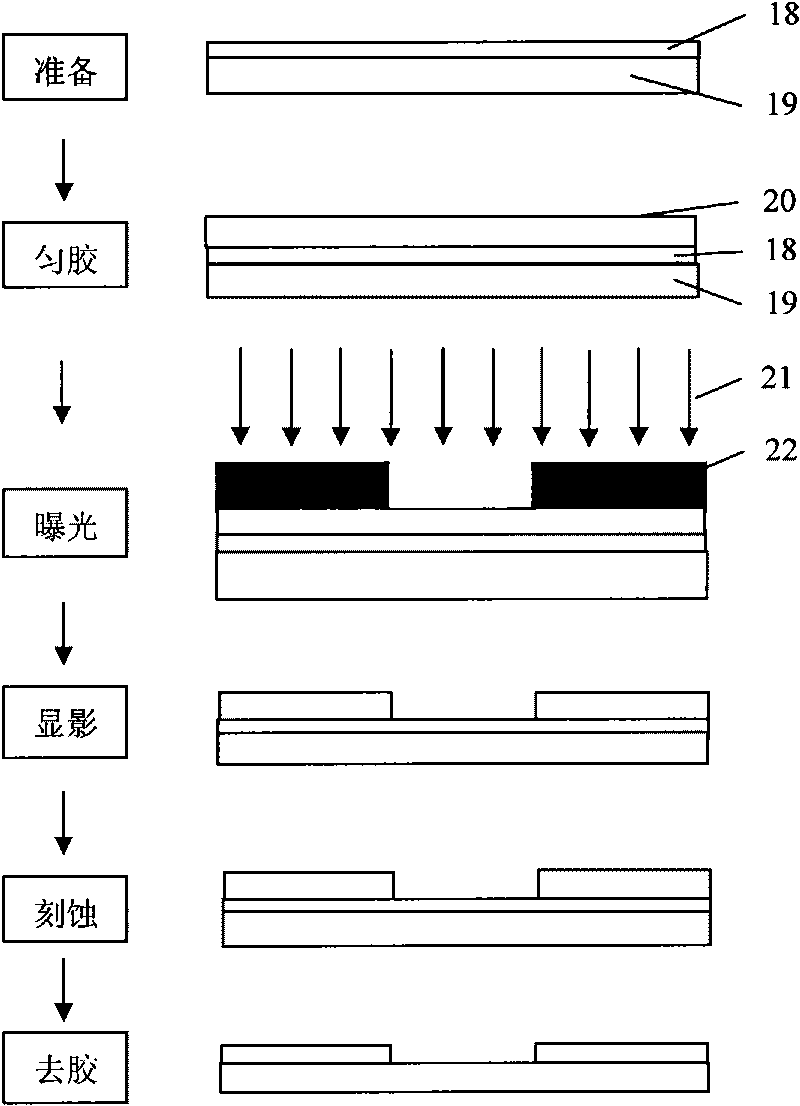

[0056] Silicon-based microfluidic chip, first obtained by deep silicon etching with such figure 2 The silicon substrate with the pattern shown in the figure is then left with a 200nm-thick aluminum film at the bottom of the flow channel by using the negative glue process, and finally bonded with the glass anode. Stick the chip on the surface of the soaking copper block. The cross-sectional size of the main diffusion straight channel is 800 μm wide and 30 μm deep.

[0057] Toluene-cyclohexane solutions with mole fractions of toluene of 0.247 and 0.447 were prepared, and the solutions of the two concentrations were respectively injected at 10 μL min by syringe pump. -1 Inject the two entrances of the chip, select the section at a distance of 1cm downstream of the intersection point as the measurement section, and take 30μm as the transverse scanning inter...

Embodiment 2

[0064] Example 2: Measurements with a silicon-glass chip with an aluminum thin film

[0065] The silicon-glass chip with aluminum thin film is the chip used in Example 1. The chip is glued to the surface of the soaking copper block. The cross-sectional size of the main diffusion straight channel is 800 μm wide and 30 μm deep.

[0066] Prepare toluene-cyclohexane solutions with mole fractions of toluene of 0.609 and 0.811, respectively. -1 The two entrances of the injection chip were injected, and the section at a distance of 1 cm downstream of the intersection point was selected as the measurement section, and the horizontal scanning interval was 30 μm. The Raman spectrum was scanned seven times at each position, and the data was the average value of the seven concentration measurements. The Raman spectrum uses a 514.5nm argon ion laser with a power of 25mW and a single sampling scan time of 10s. For the data obtained after fitting, see Figure 8 , the deviation from the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com