Wiring Board for Light-Emitting Element

a light-emitting element and wiring board technology, applied in the direction of printed circuit aspects, electrical apparatus construction details, electric connection formation of printed elements, etc., can solve the problems of high process cost, inability to cope with problems, deterioration of connection reliability, etc., to suppress cracks, increase adhesion strength, and suppress cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[Wiring Board for Light-Emitting Element]

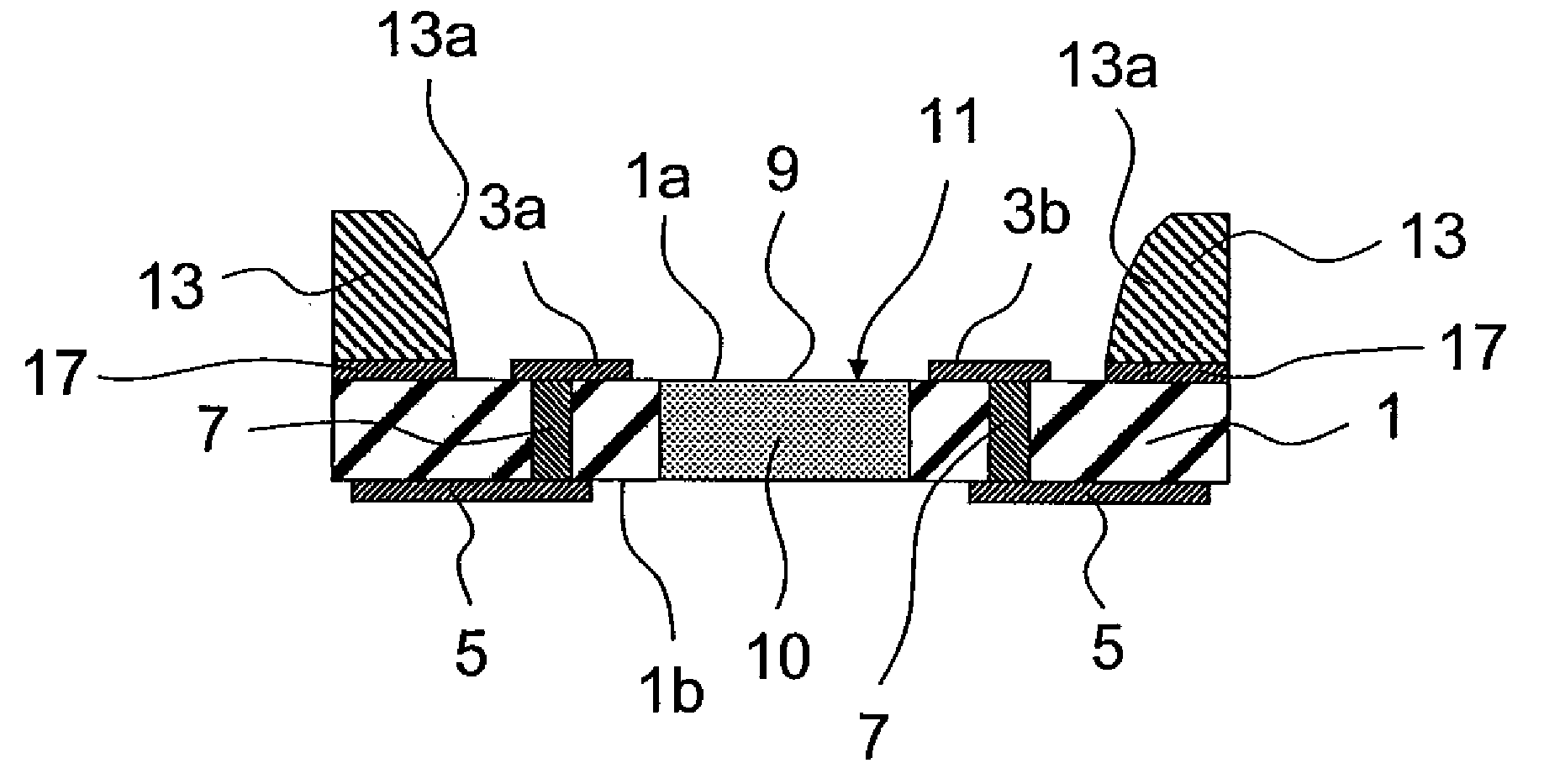

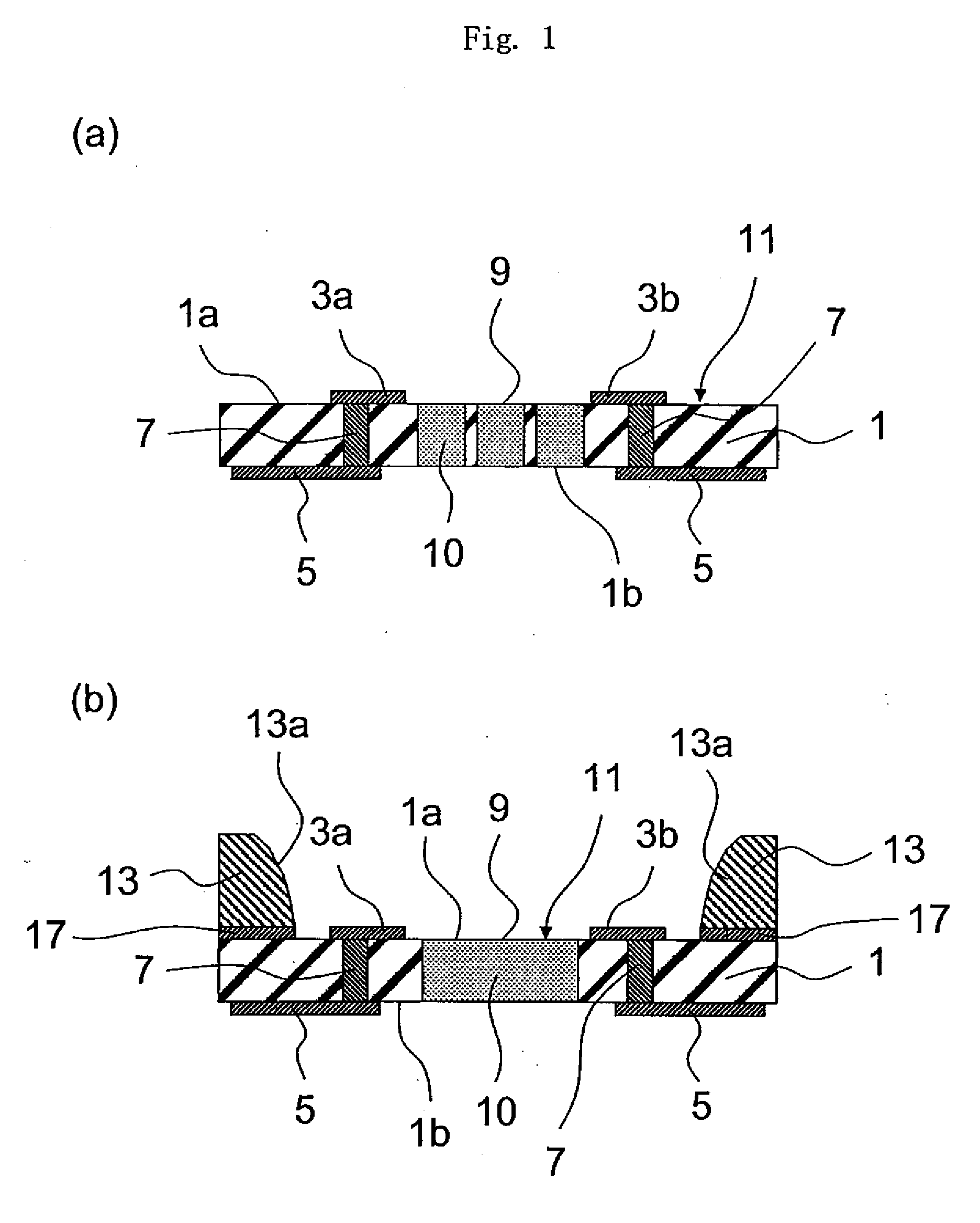

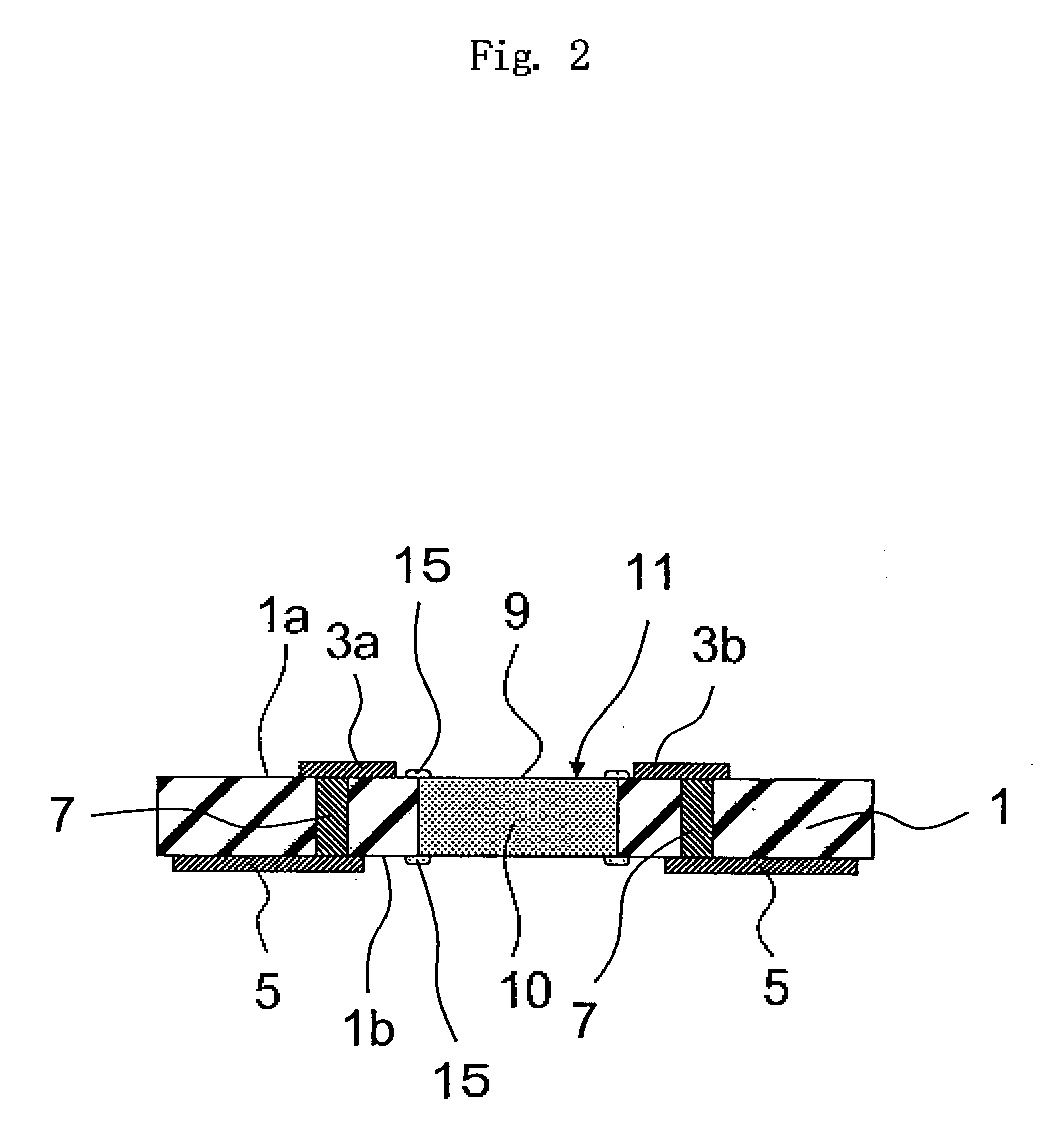

[0035] In FIGS. 1(a) and 1(b) illustrating a representative structure of a wiring board for light-emitting element of the present invention, the wiring board generally designated at 11 includes a ceramic insulating substrate 1, conductor layers (connection terminals) 3a and 3b formed on one surface 1a of the insulating board 1, conductor layers (external electrode terminals) 5 formed on the other surface 1b of the insulating substrate 1, and via-conductors 7 formed through the insulating substrate 1 so as to electrically connect the conductor layers 3a, 3b to the conductor layers 5.

[0036] On the surface 1a of the insulating substrate 1, there is formed a mounting region 9 between one conductor layer 3a and another conductor layer 3b for mounting a light-emitting element that will be described later. That is, the conductor layers 3a and 3b are electrically connected to the light-emitting element (not shown in FIGS. 1(a) and 1(b)) mounted on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com