Patents

Literature

86results about How to "Curb productivity decline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

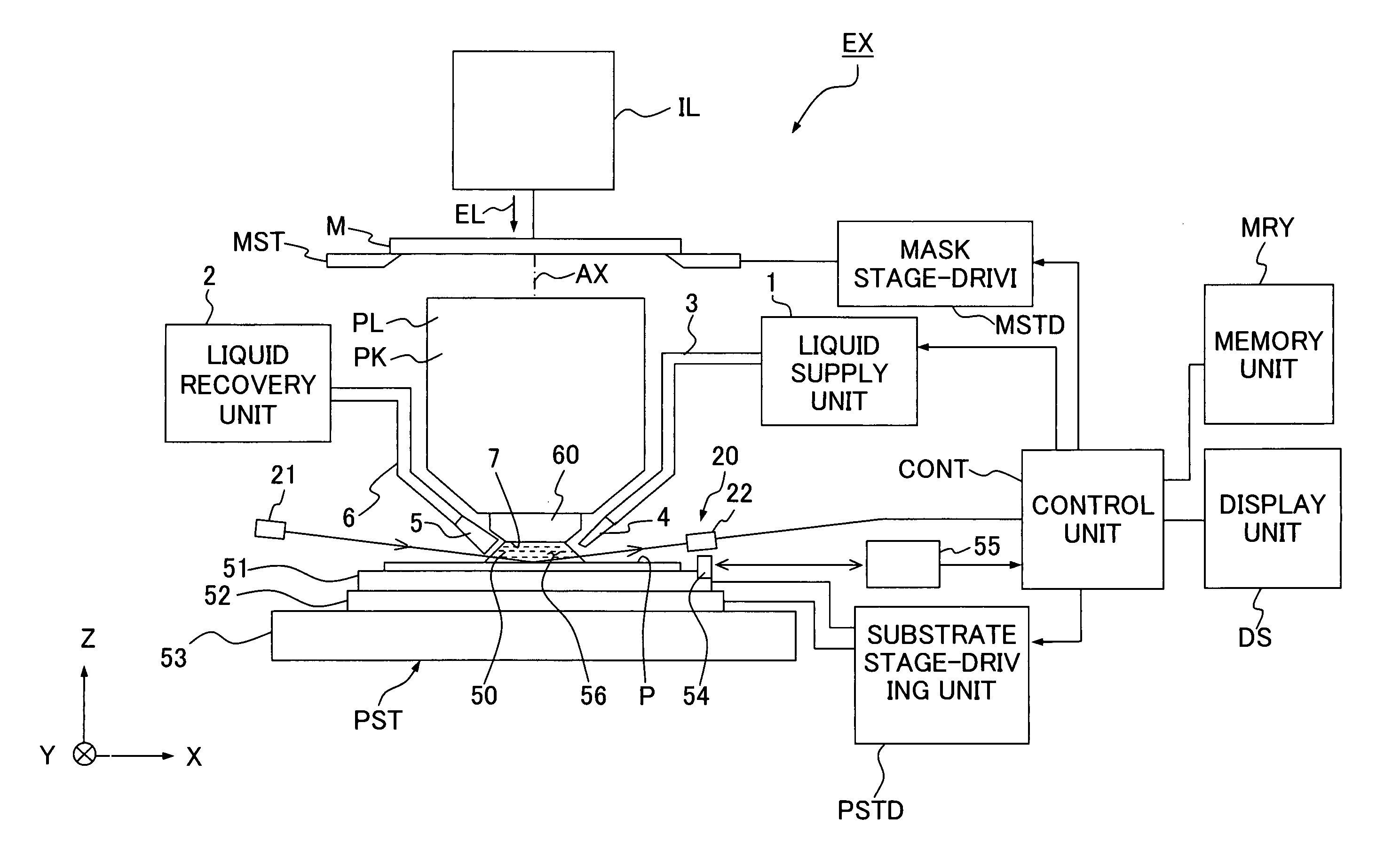

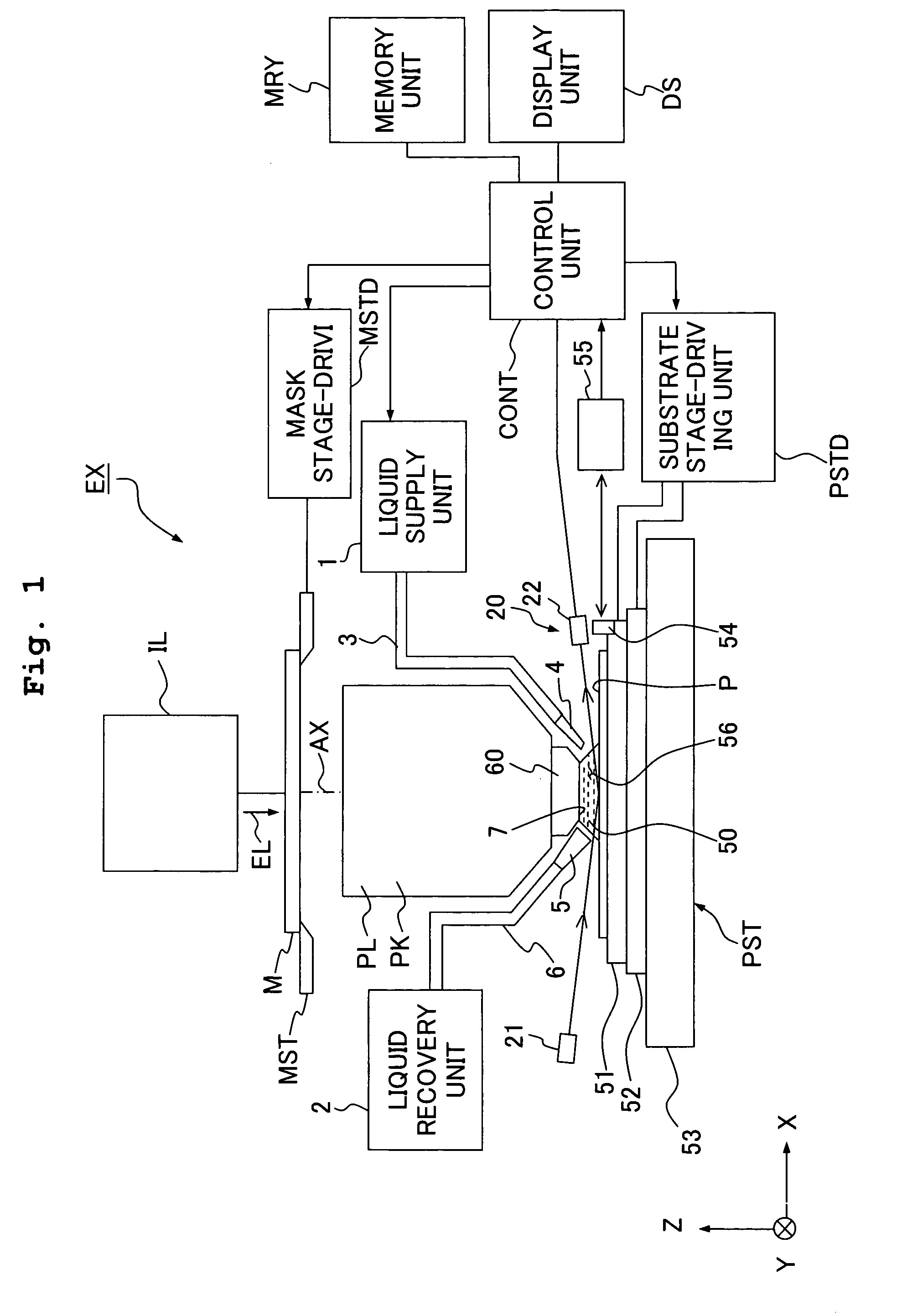

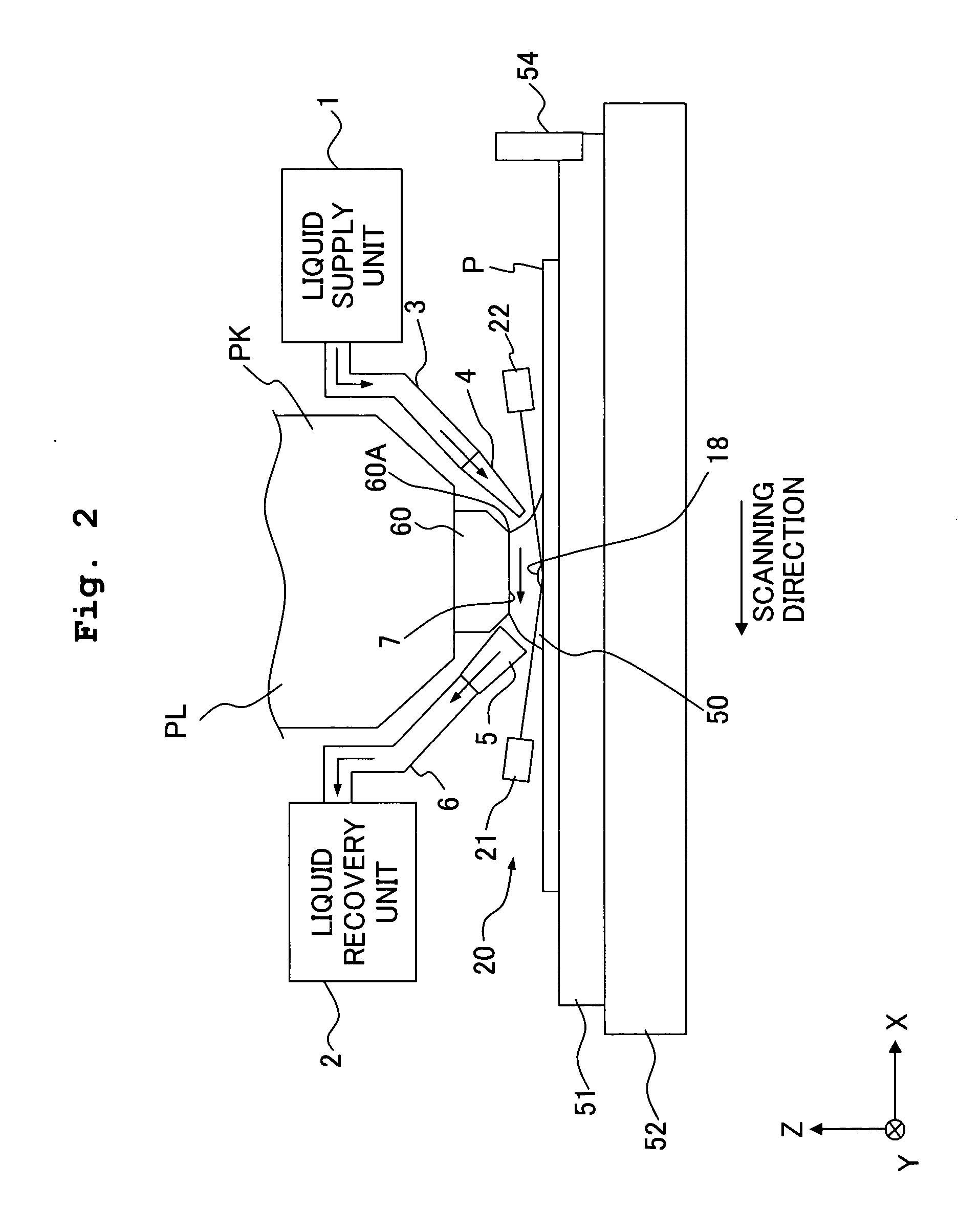

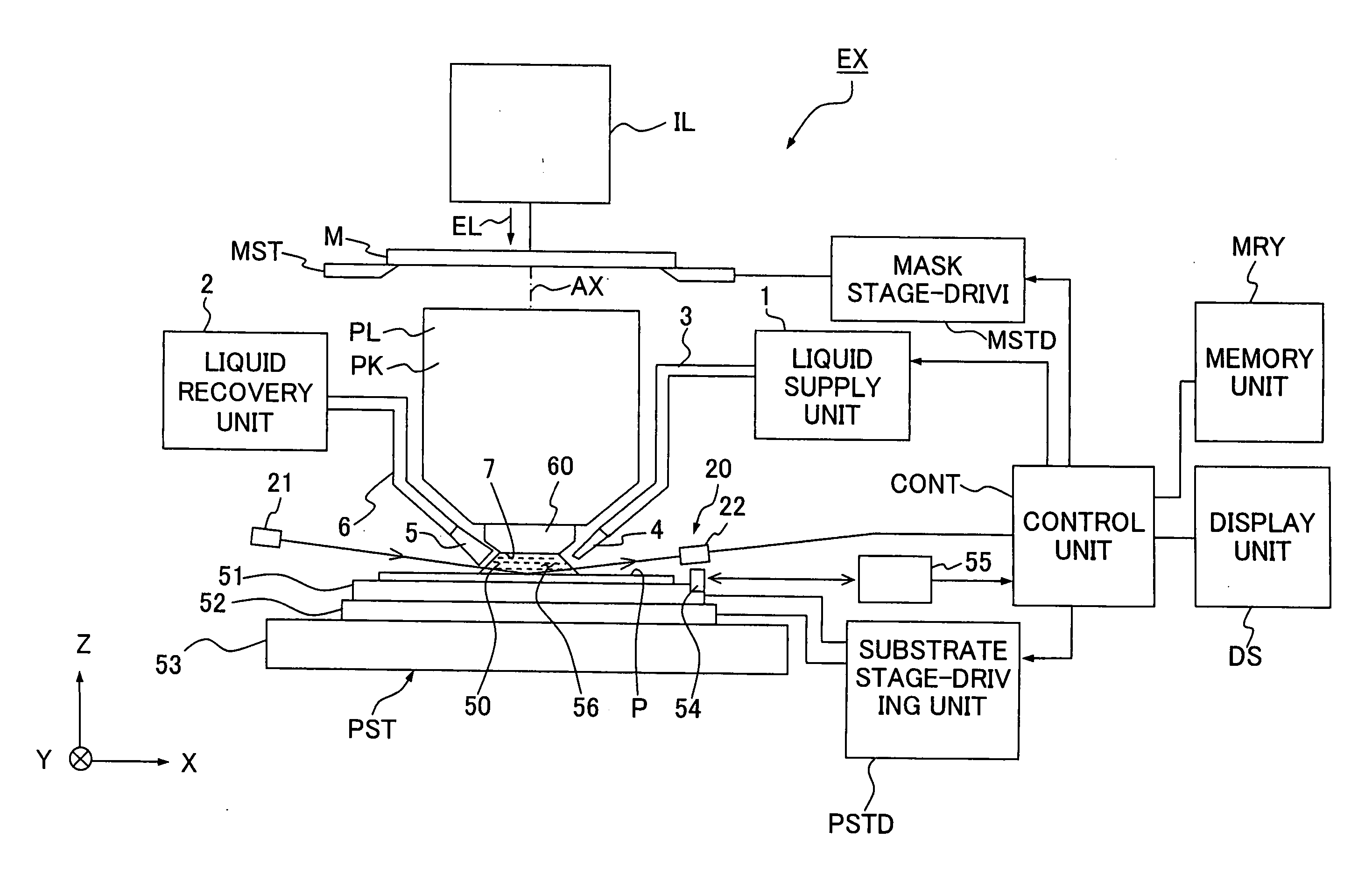

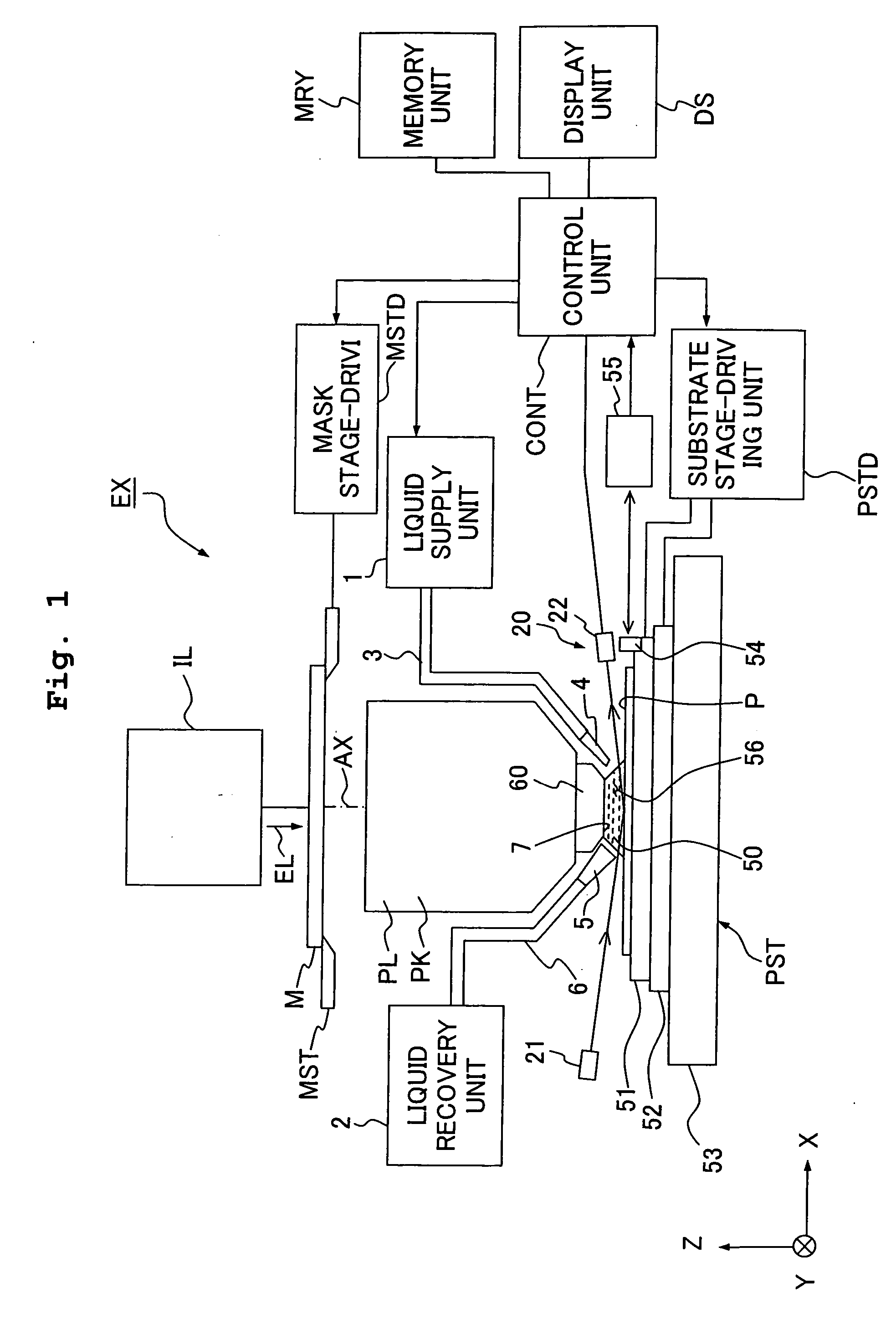

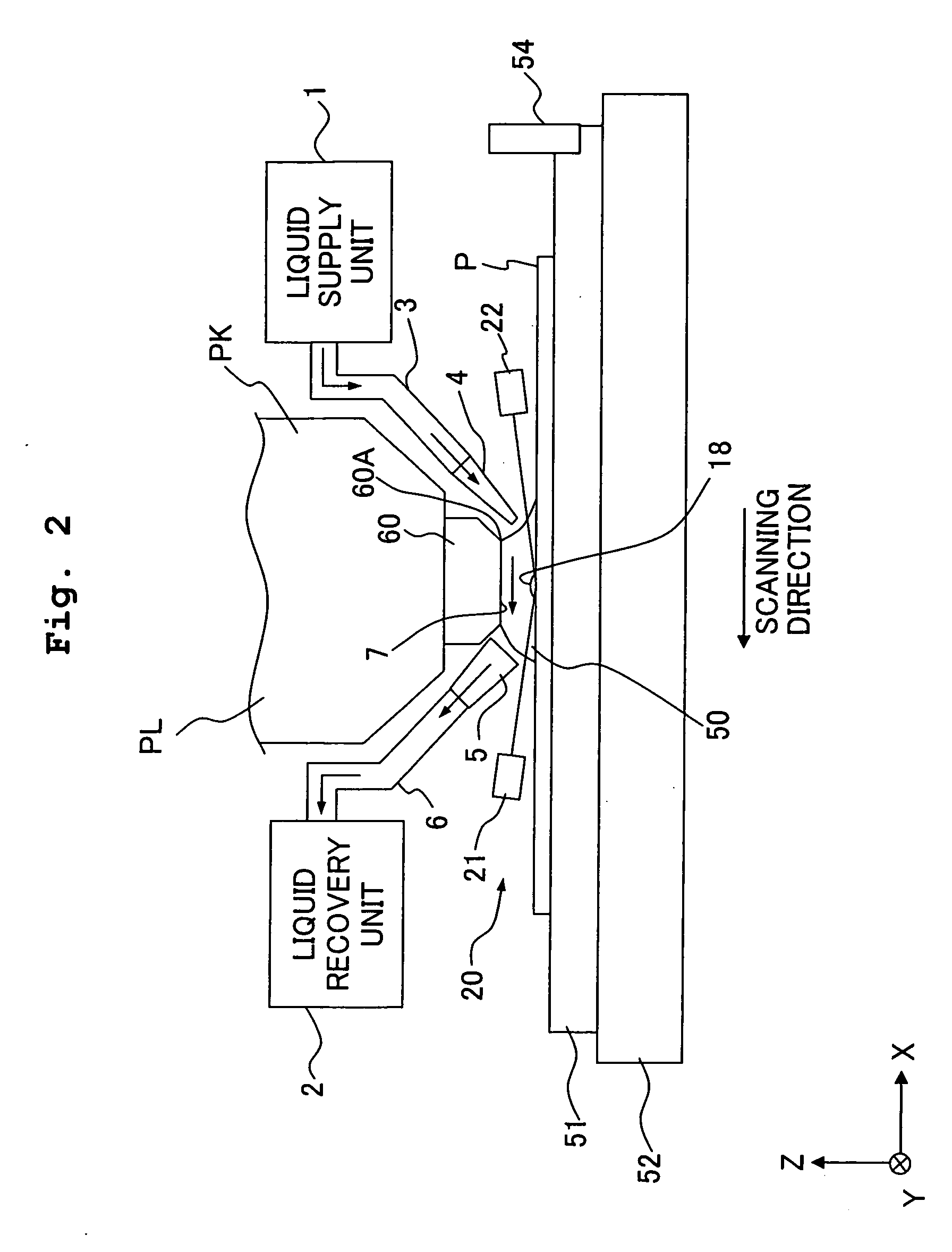

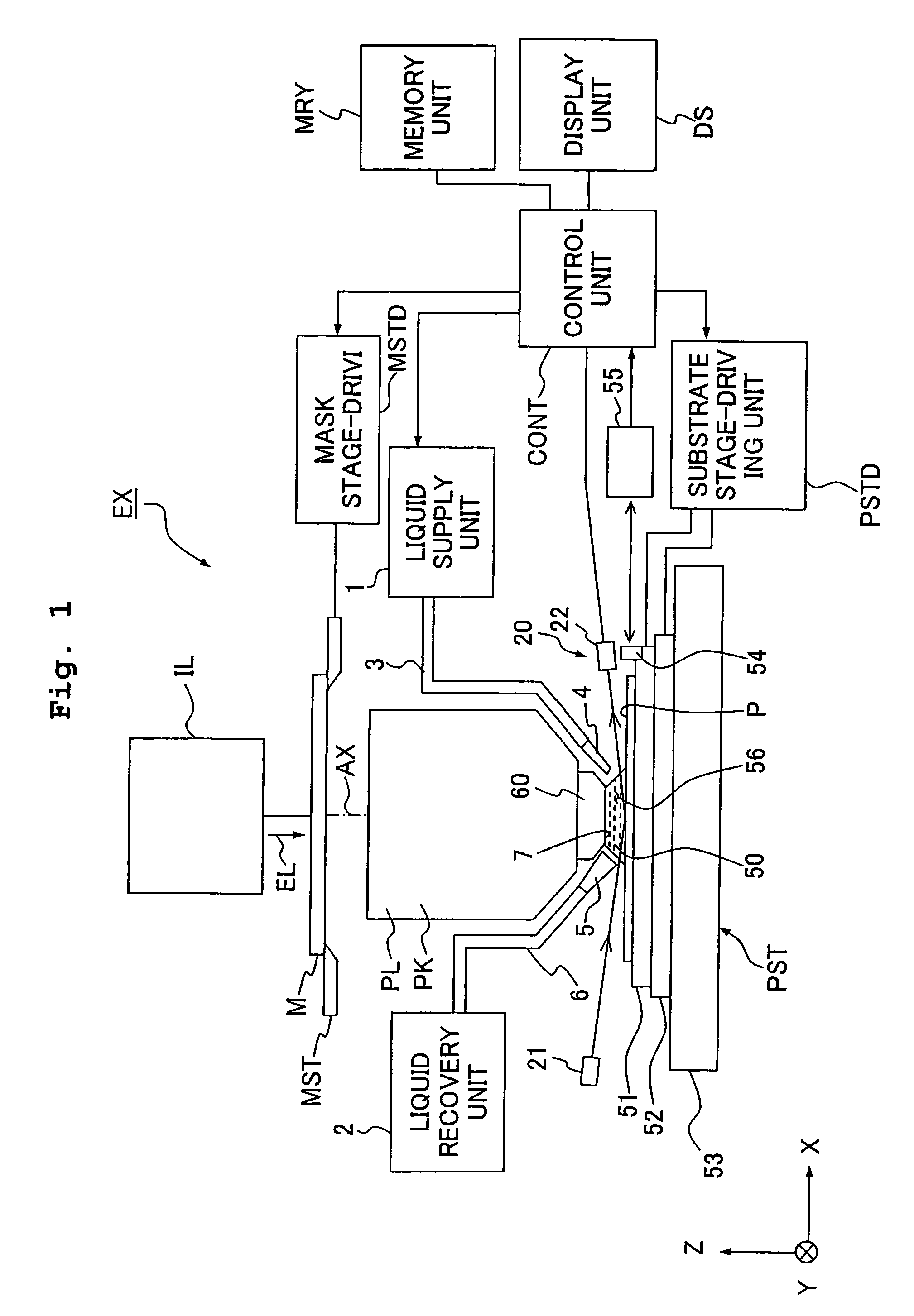

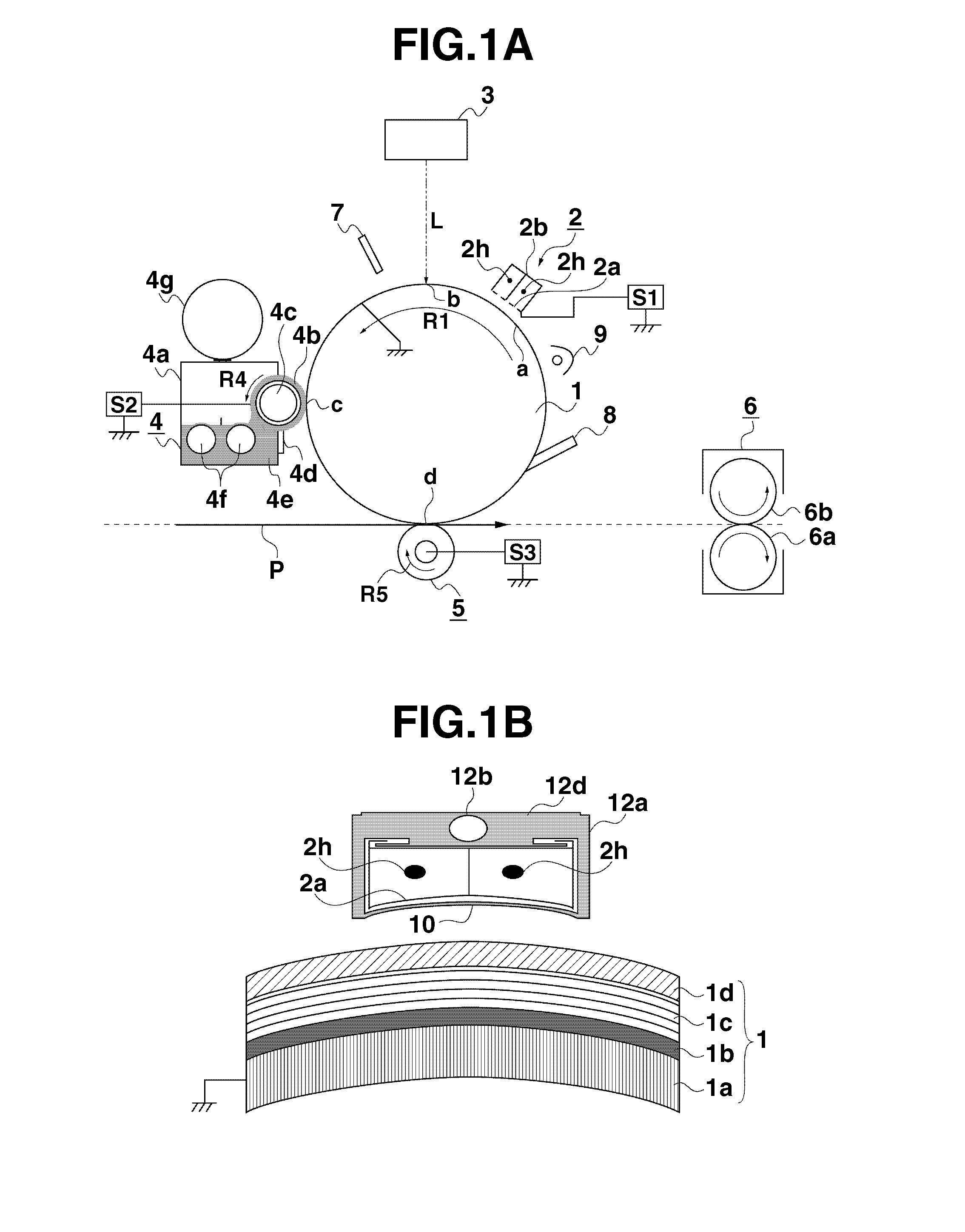

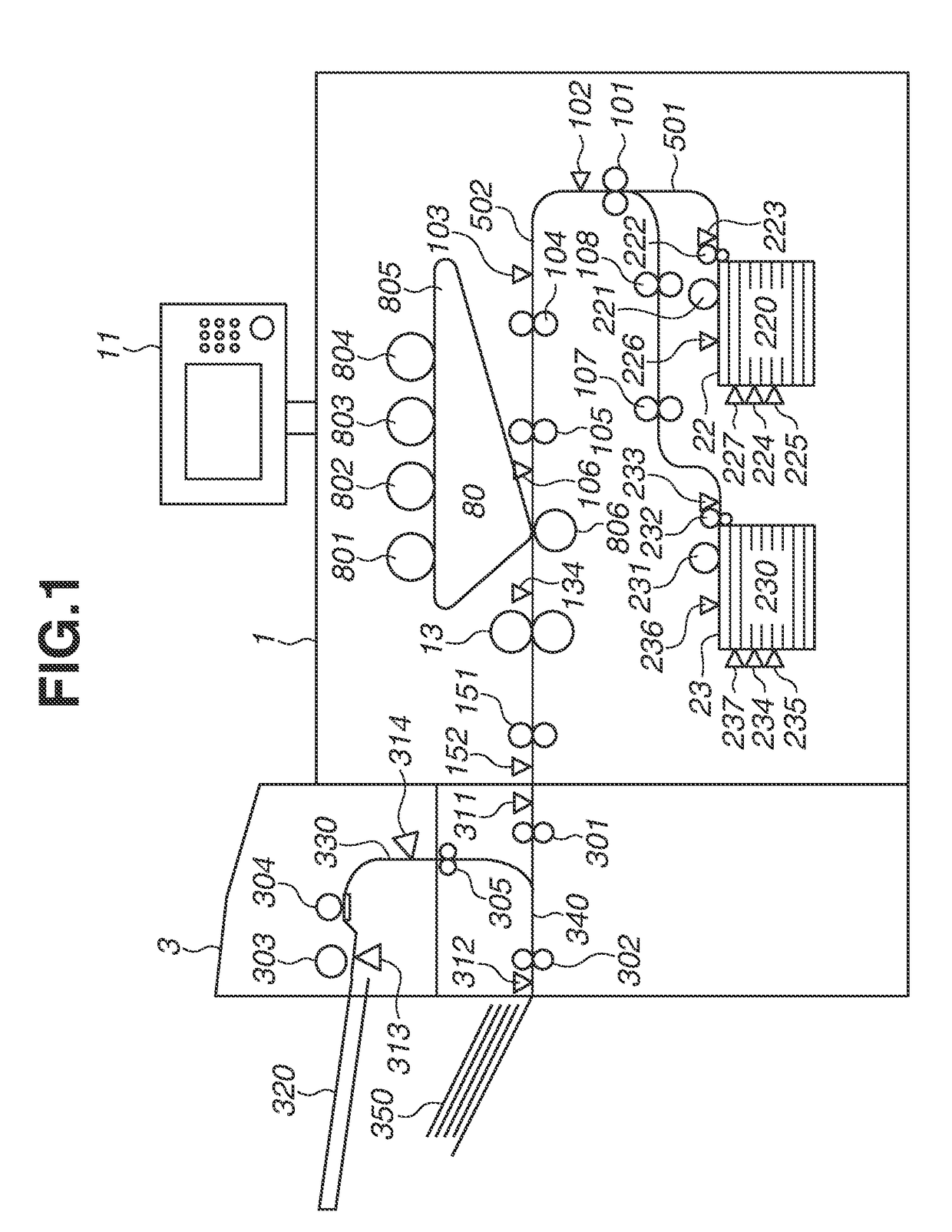

Exposure apparatus and method for producing device

InactiveUS20050264774A1Increase productivityCurb productivity declineInvestigating moving fluids/granular solidsScattering properties measurementsBubble DetectorAir bubble

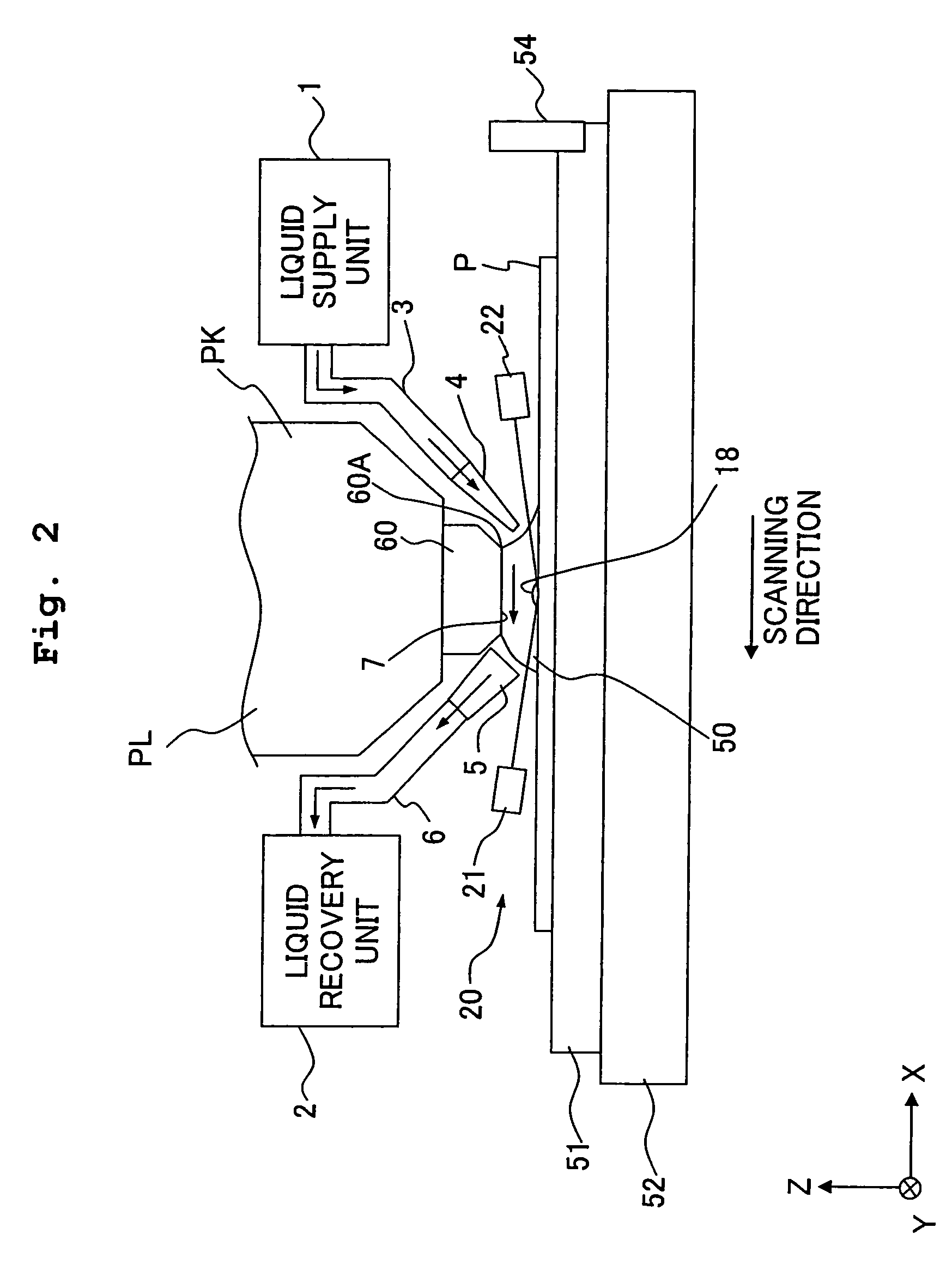

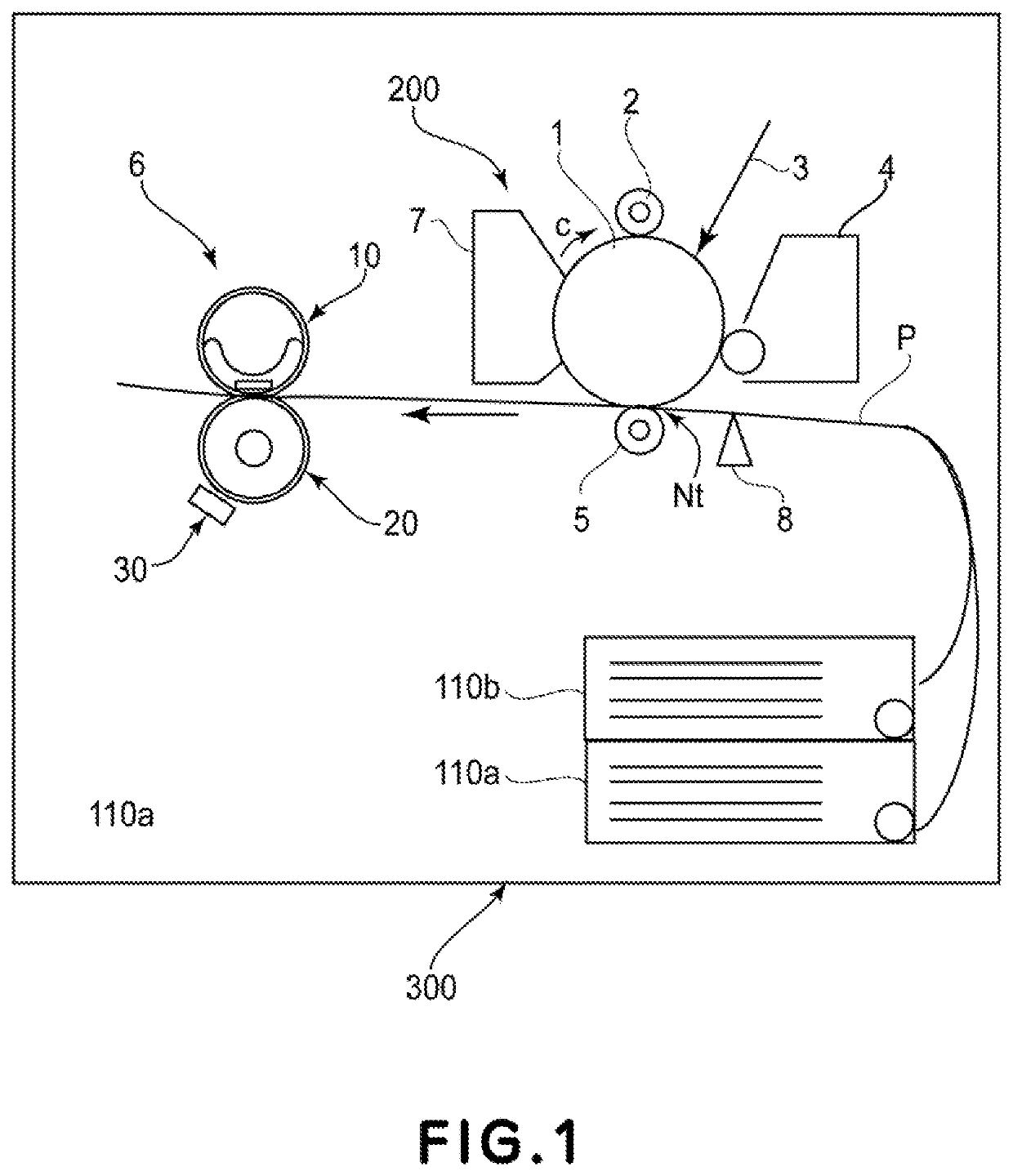

An exposure apparatus, wherein an exposure of a substrate (P) is carried out by filling at least a portion of the space between a projection optical system and the substrate (P) with a liquid and projecting an image of a pattern onto the substrate (P) via the projection optical system and the liquid, includes a bubble detector (20) which detects air bubble or bubbles in the liquid between the projection optical system and the substrate (P). Consequently, the exposure apparatus is capable of suppressing deterioration of a pattern image caused by bubbles in the liquid when an exposure is carried out while filling the space between the projection optical system and the substrate with the liquid.

Owner:NIKON CORP

Exposure apparatus and method for producing device

InactiveUS20060126043A1Curb productivity declineImprove productivityInvestigating moving fluids/granular solidsScattering properties measurementsBubble DetectorAir bubble

An exposure apparatus performs an exposure of a substrate by filling at least a portion of the space between a projection optical system and the substrate with a liquid and projecting an image of a pattern onto the substrate via the projection optical system and the liquid. The apparatus includes a bubble detector that detects air bubble or bubbles in the liquid between the projection optical system and the substrate. Consequently, the exposure apparatus is capable of suppressing deterioration of a pattern image caused by bubbles in the liquid when an exposure is carried out while filling the space between the projection optical system and the substrate with the liquid.

Owner:NIKON CORP

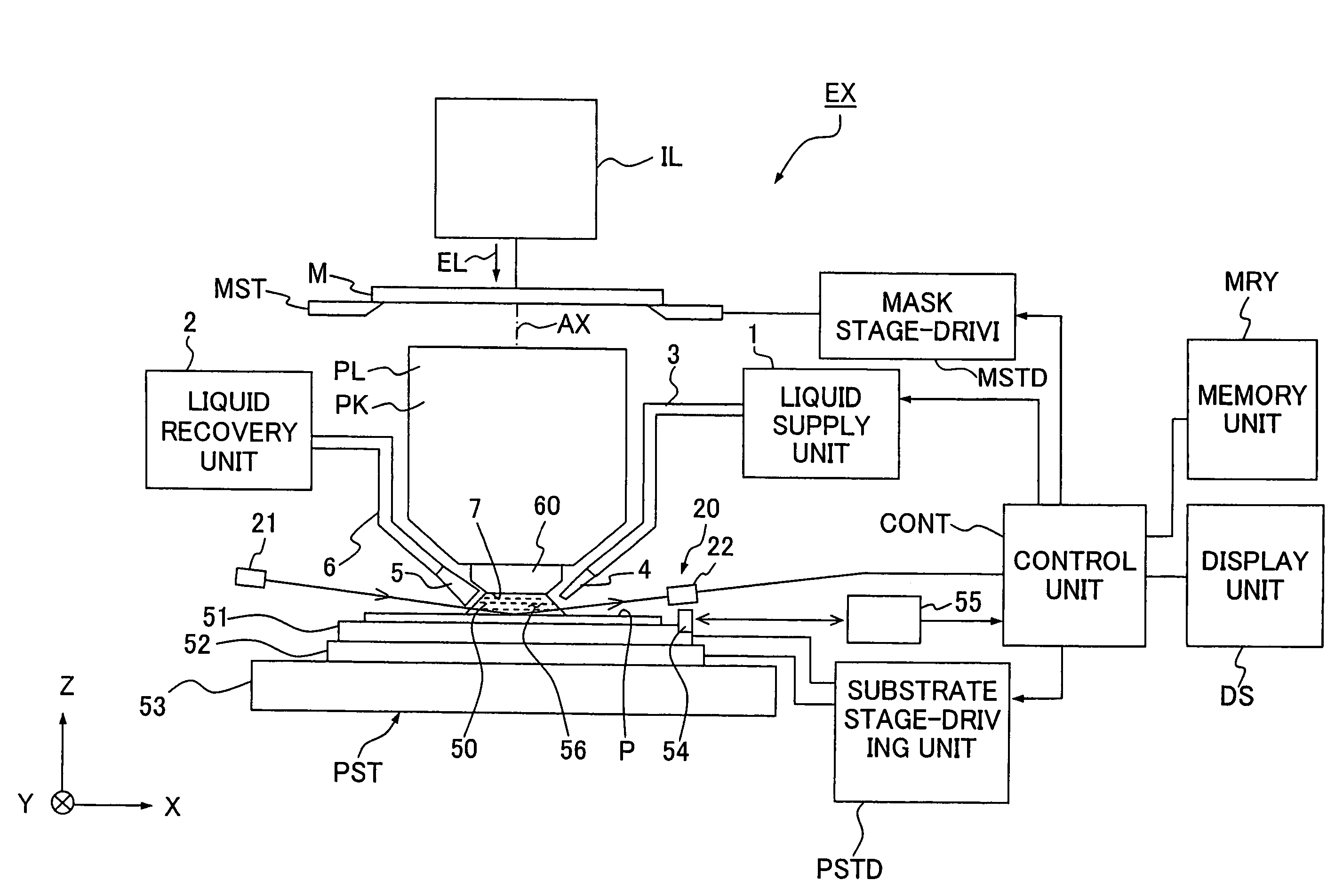

Exposure apparatus and method for producing device

InactiveUS7379158B2Curb productivity declineImprove productivityInvestigating moving fluids/granular solidsScattering properties measurementsPhysics

A liquid immersion type exposure apparatus includes a projection optical system for projecting a pattern of a mask onto a substrate, a liquid film forming system for forming a liquid film in a predetermined region between the projection optical system and the substrate, and a sensor for detecting disappearance of at least a portion of the liquid film in the predetermined region.

Owner:NIKON CORP

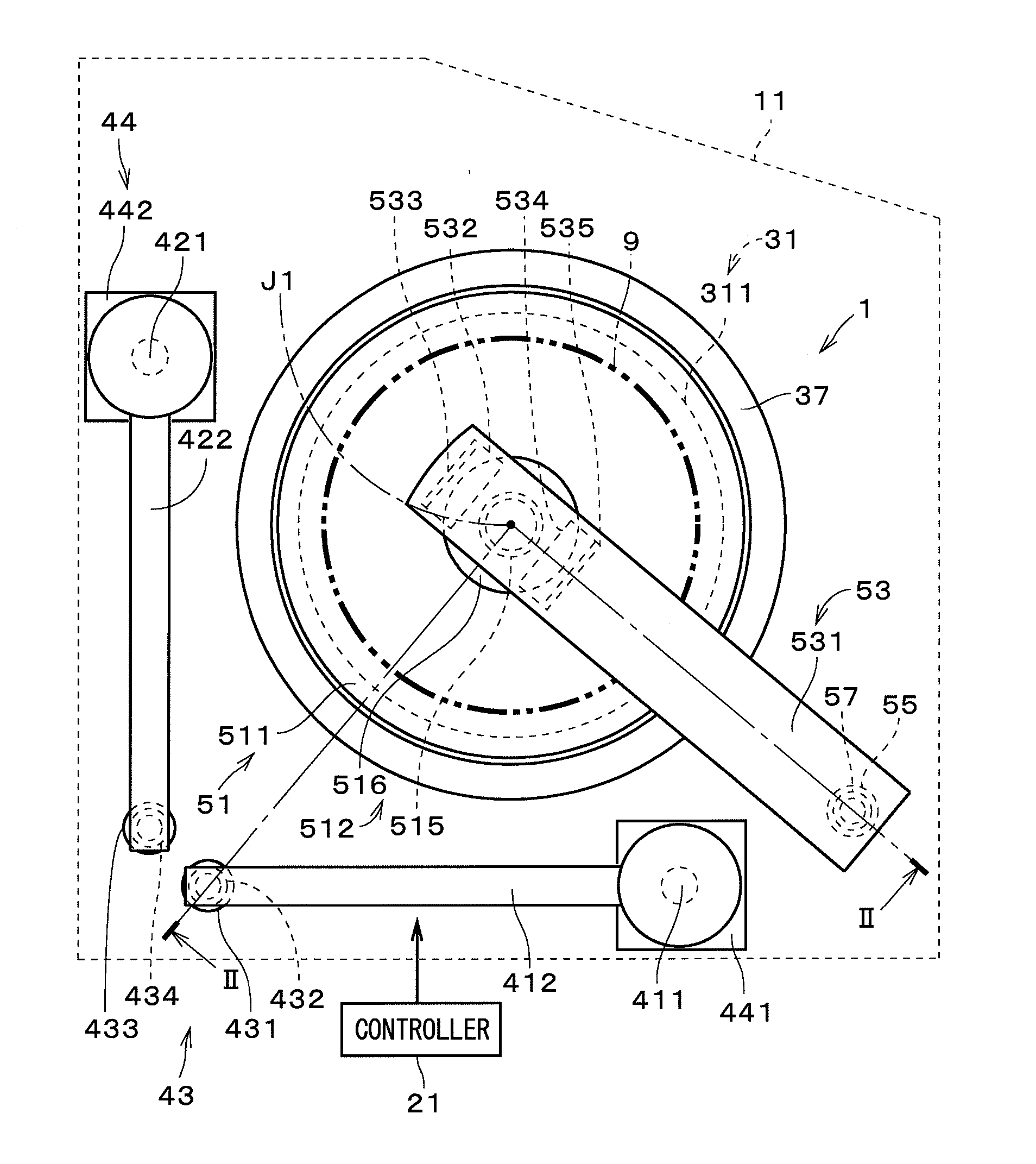

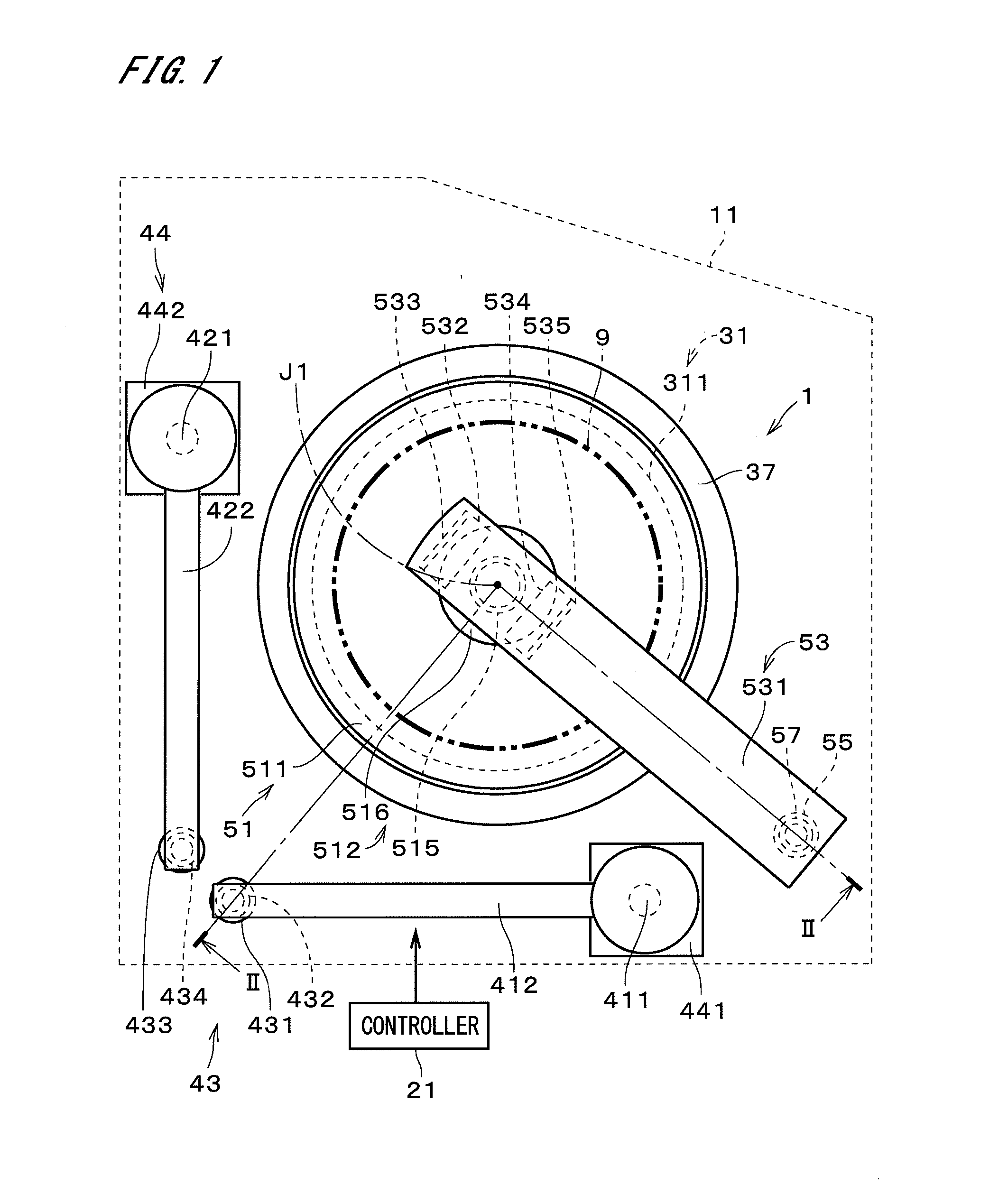

Optical shaping apparatus and optical shaping method

ActiveUS20150202805A1Increase productivityImprove accuracyAdditive manufacturing apparatusOptical articlesLight beamOptoelectronics

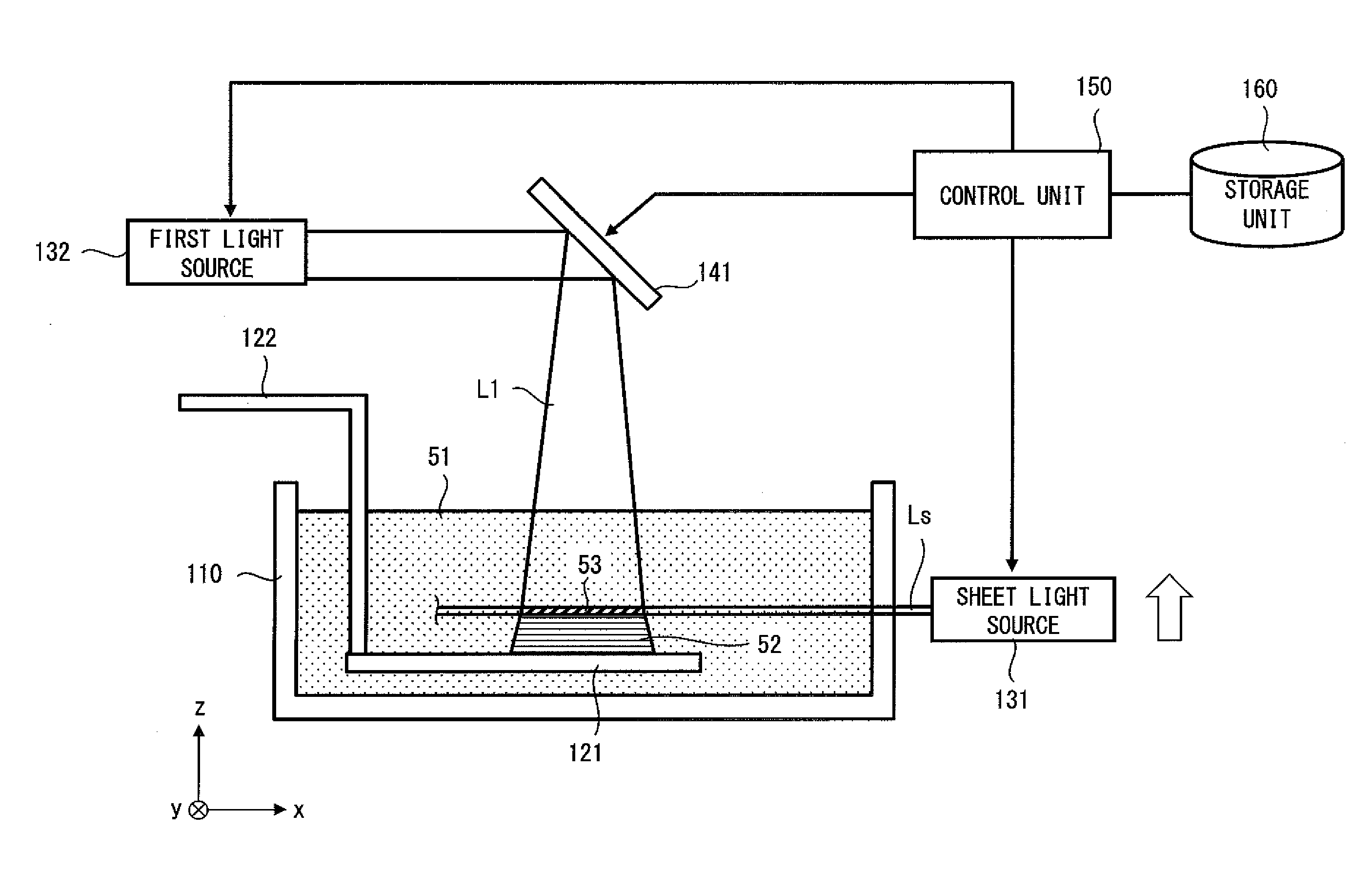

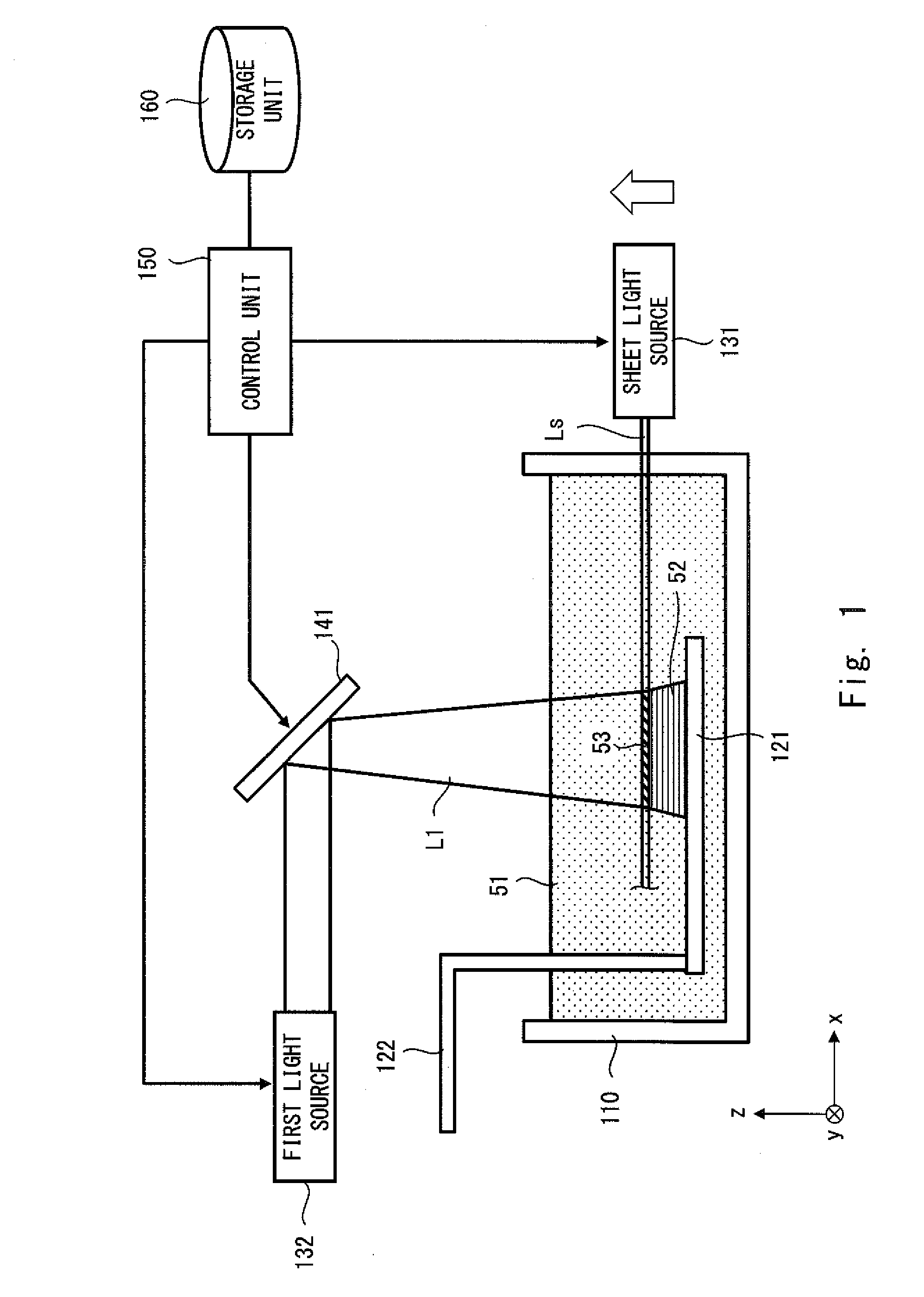

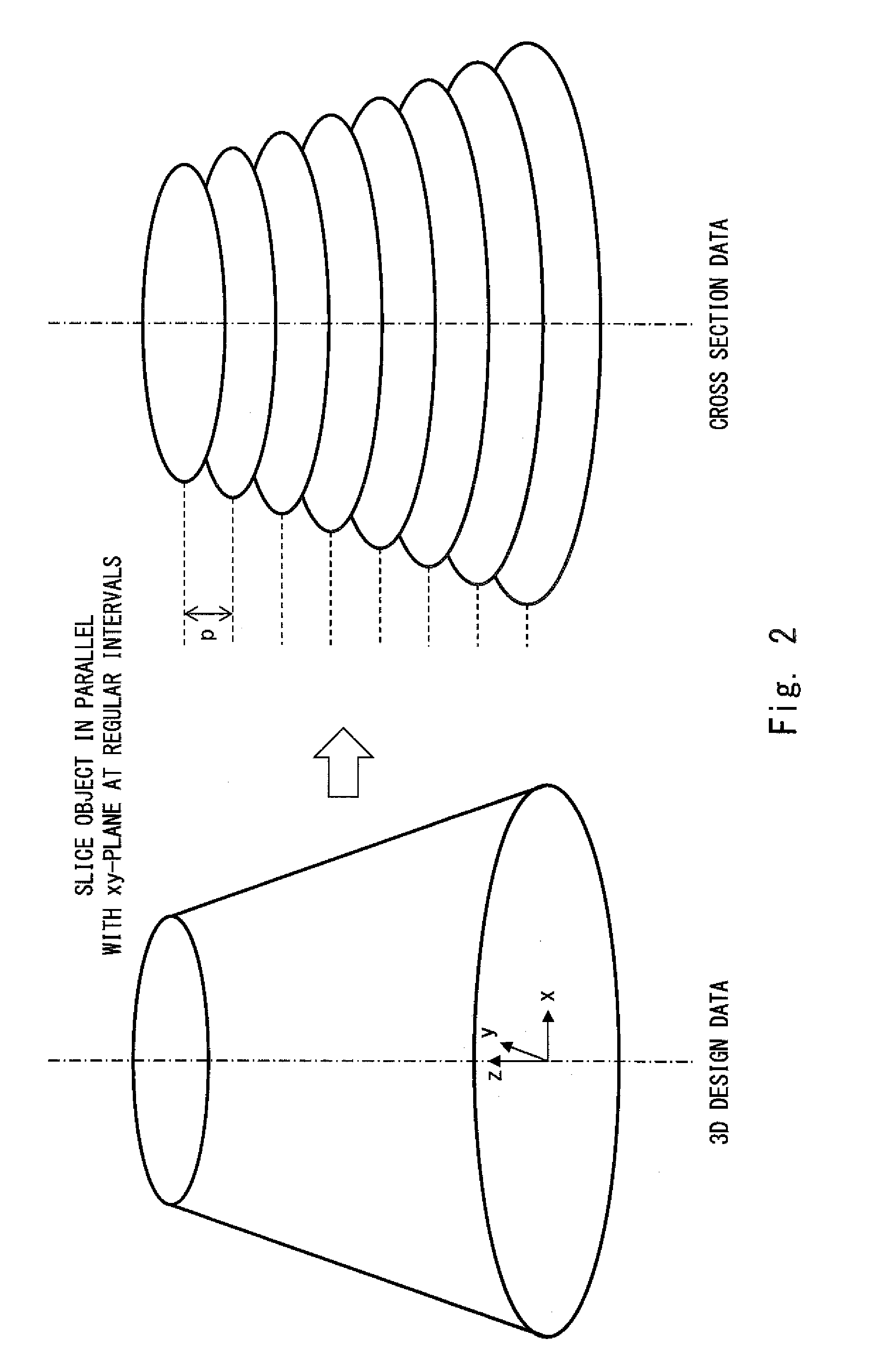

An optical shaping method according to the present invention is an optical shaping method for shaping a three-dimensional structure by repeating a process for forming a cured resin layer 53 by irradiating an optically curing resin liquid 51 with light so that cured resin layers 53 are laminated. The process for forming the cured resin layer 53 includes, while applying a sheet light Ls to the optically curing resin liquid 51, applying a first light beam L1 intersecting the sheet light Ls to this optically curing resin liquid, and thereby forming the cured resin layer 53 in an area where the sheet light Ls intersects the first light beam L1. The irradiation place of the sheet light Ls is moved and the process for forming the cured resin layer 53 is repeated.

Owner:TOYOTA JIDOSHA KK

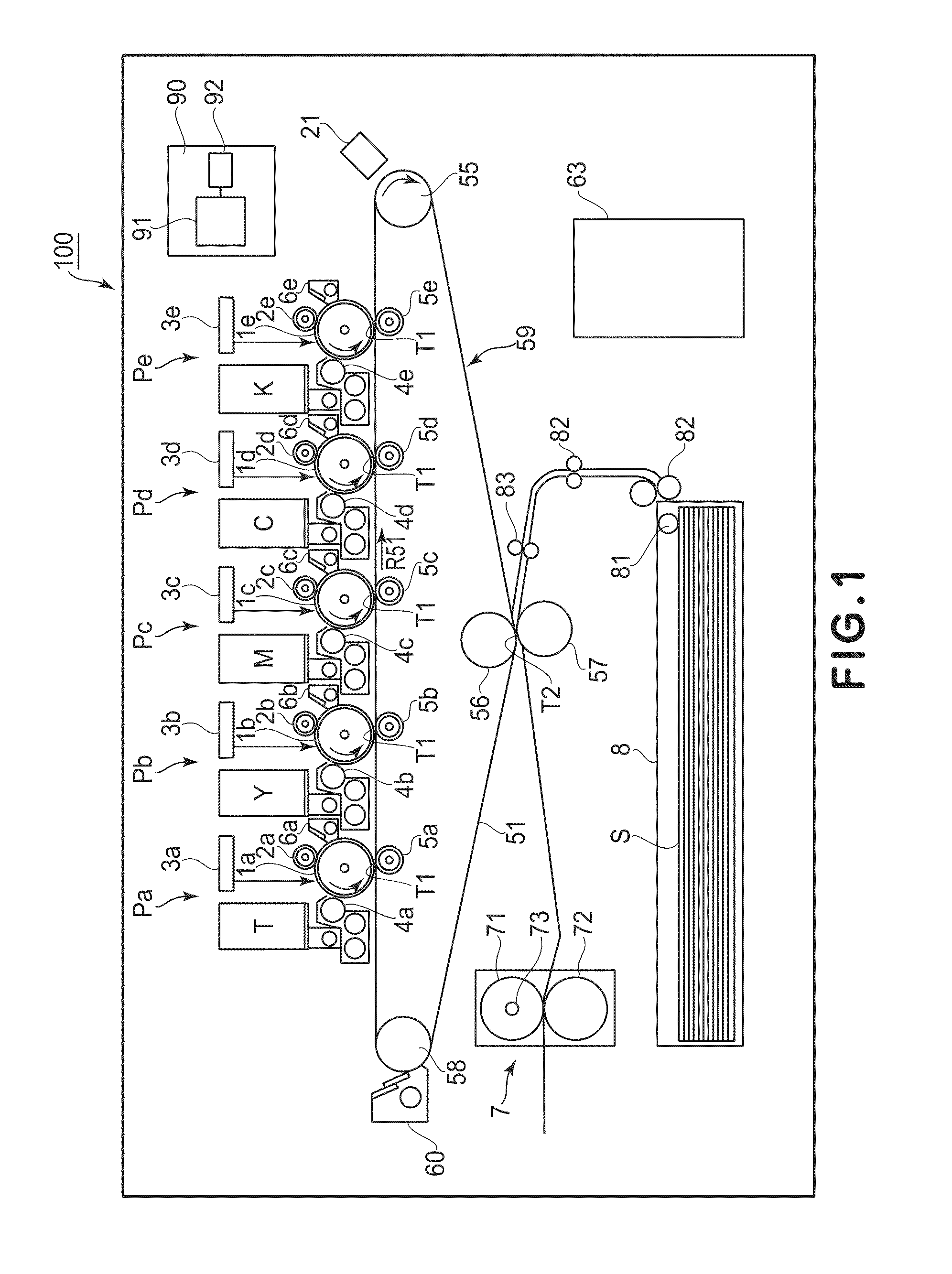

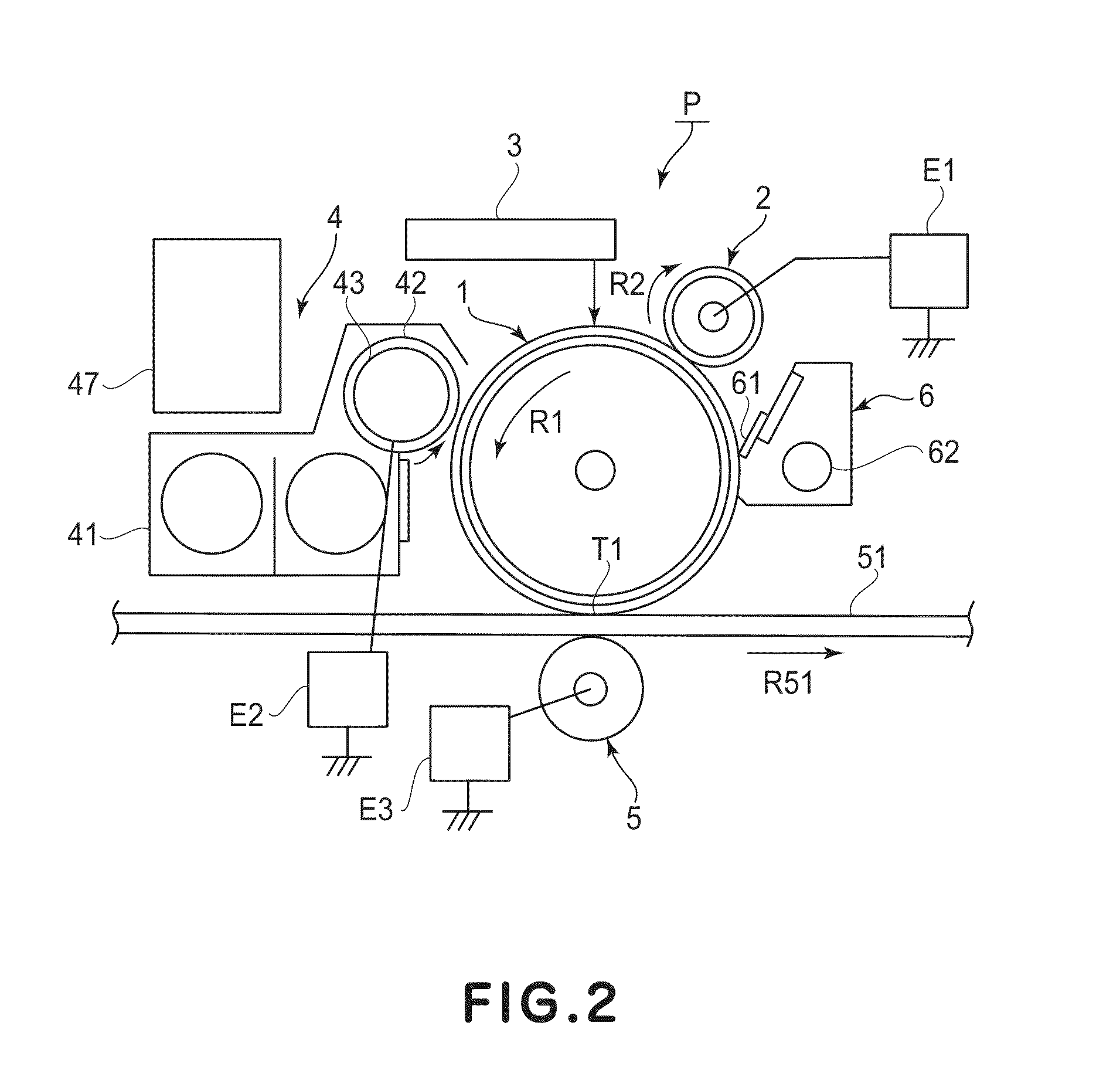

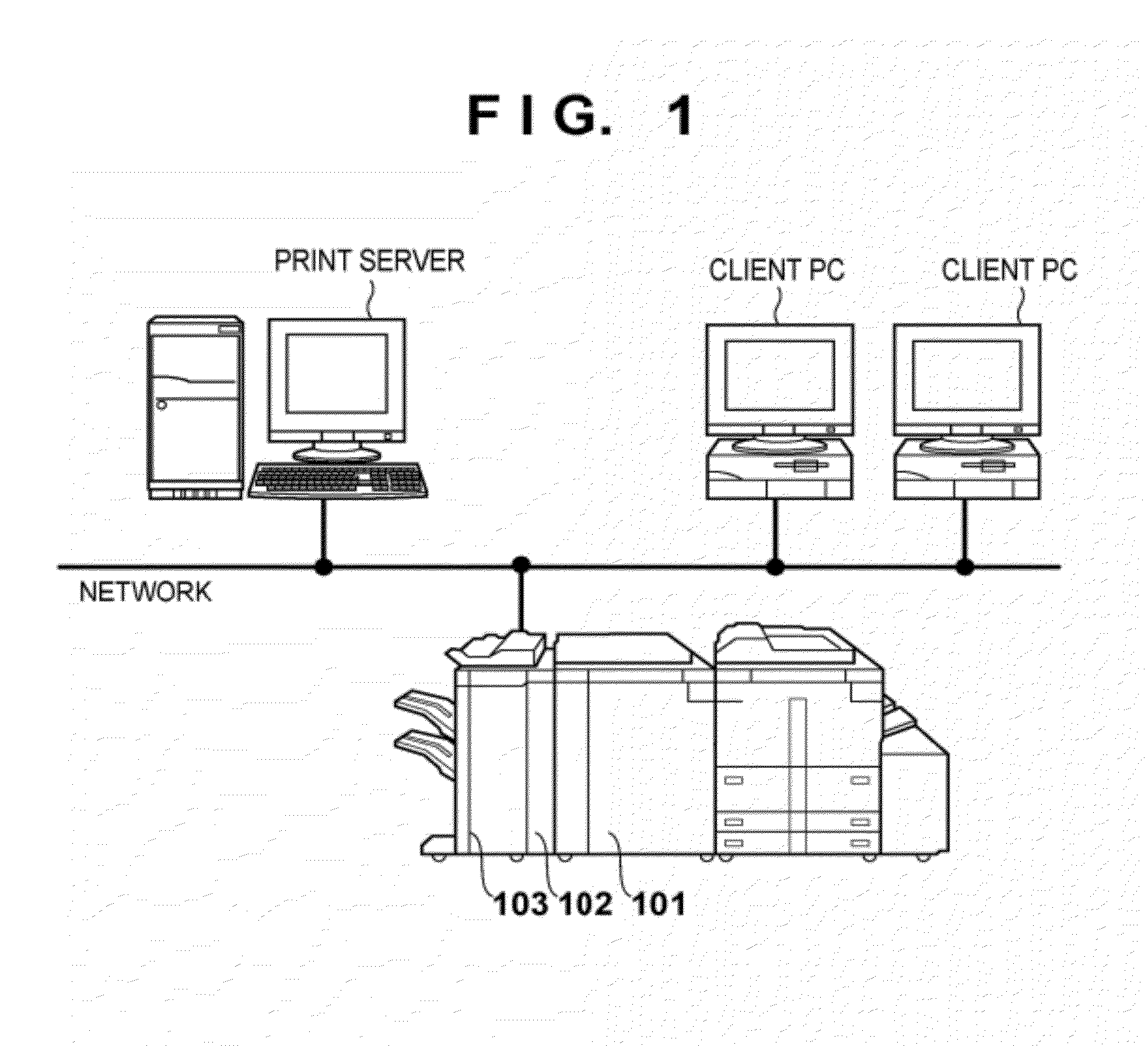

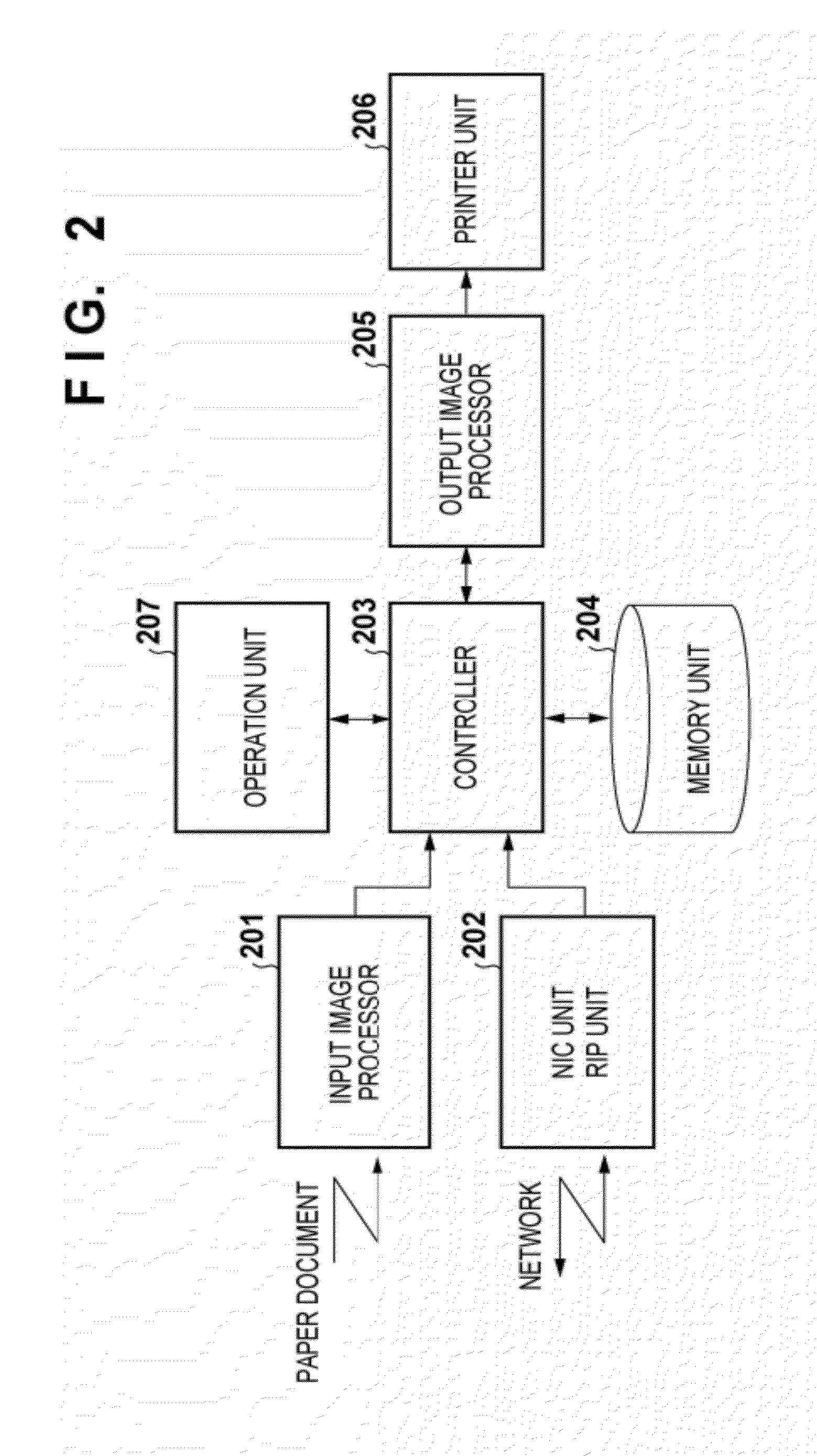

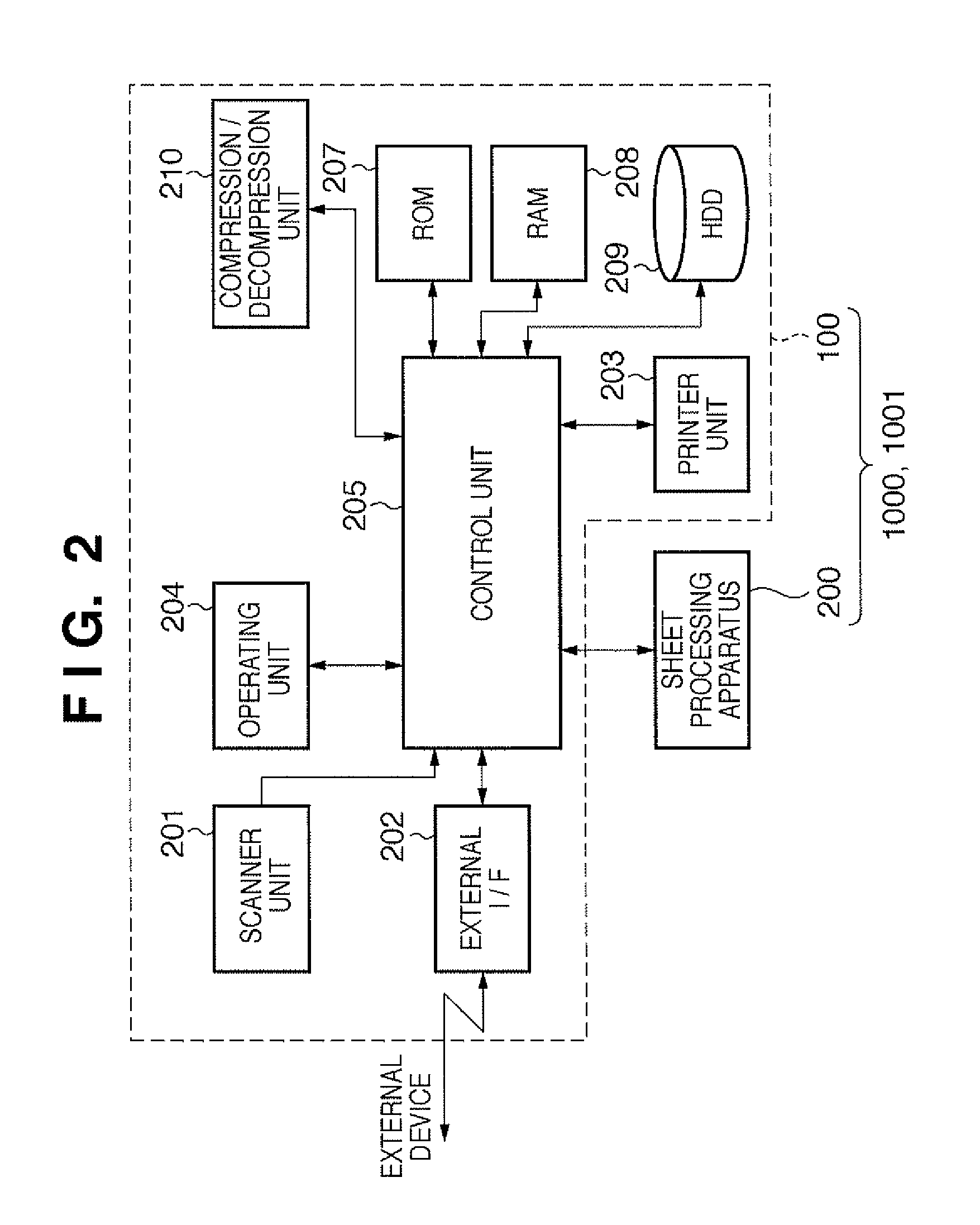

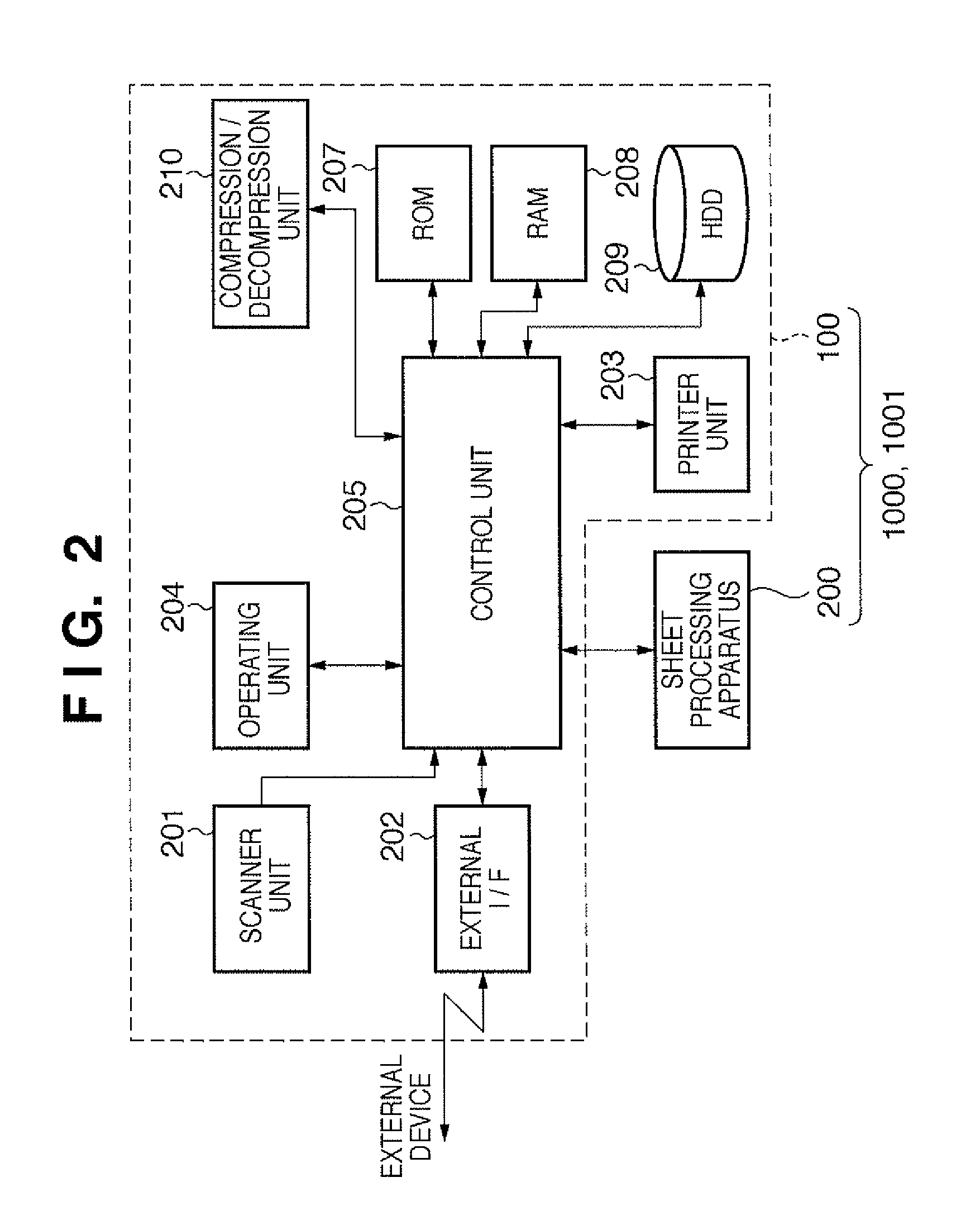

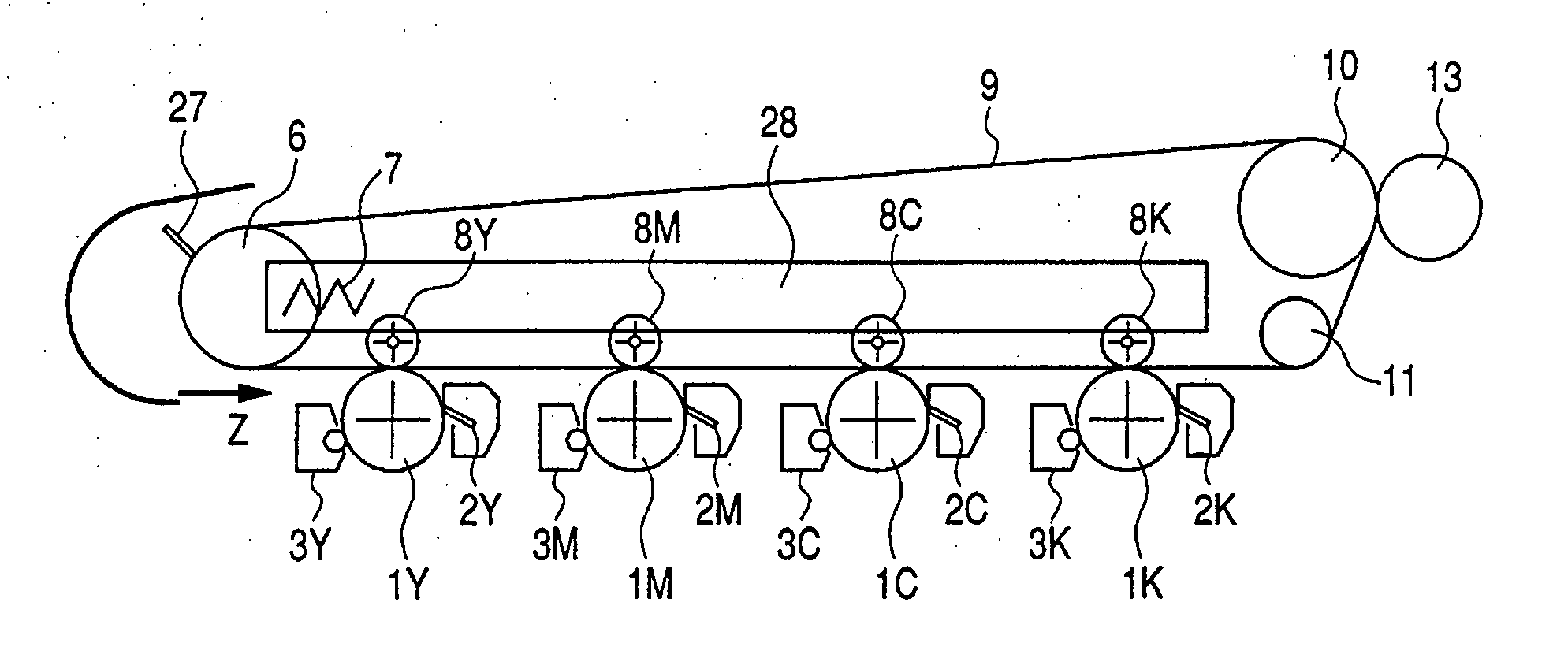

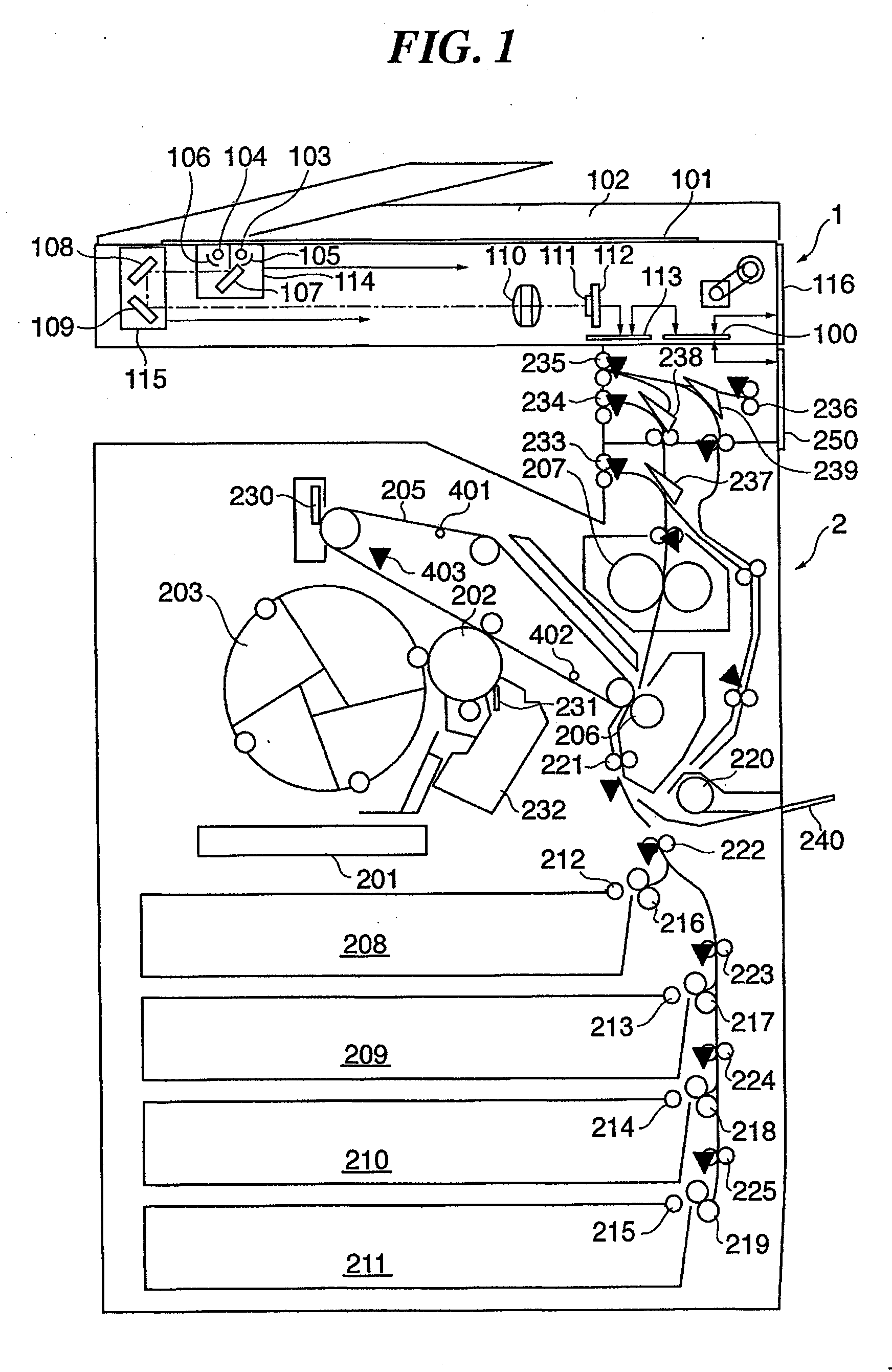

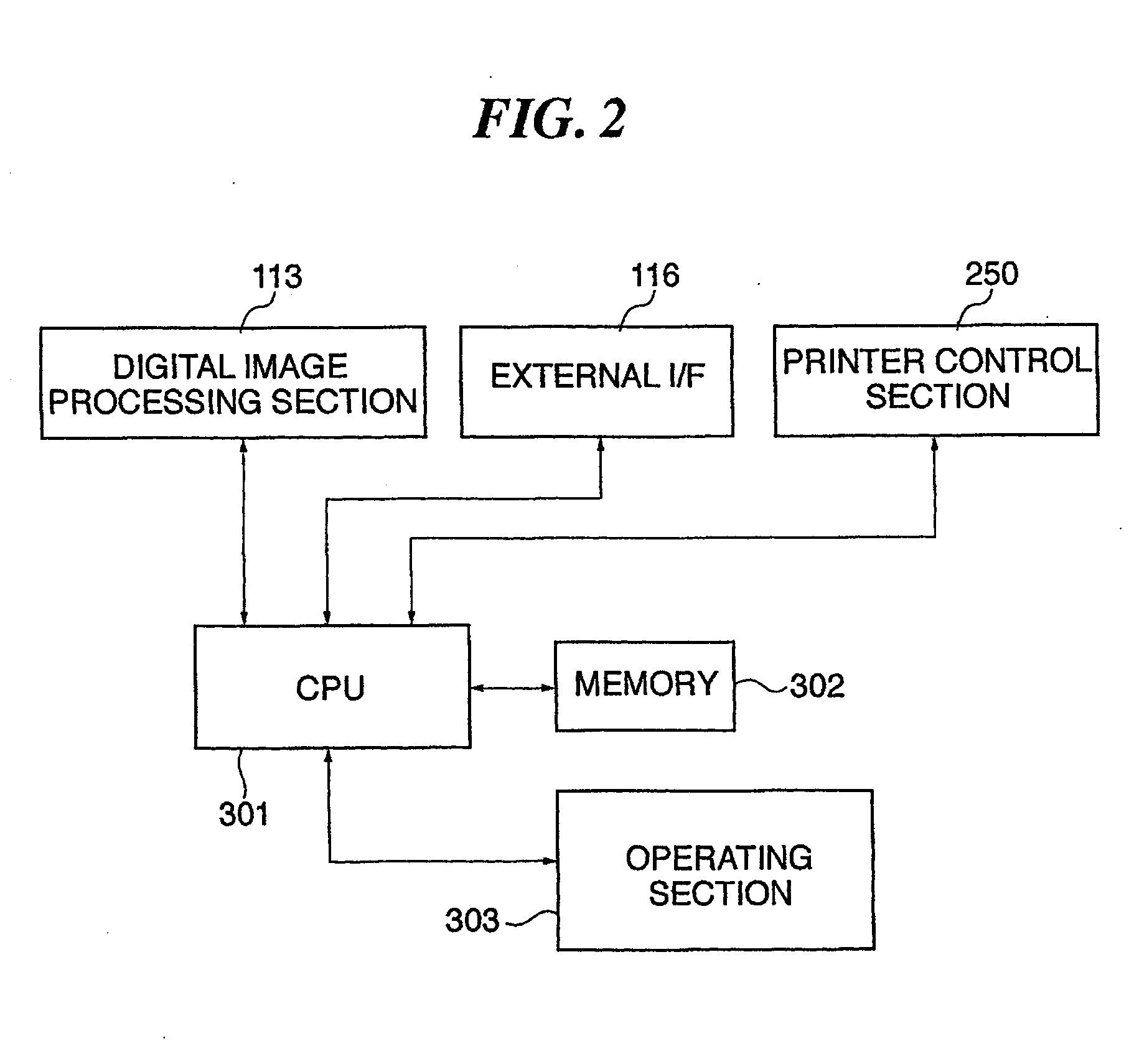

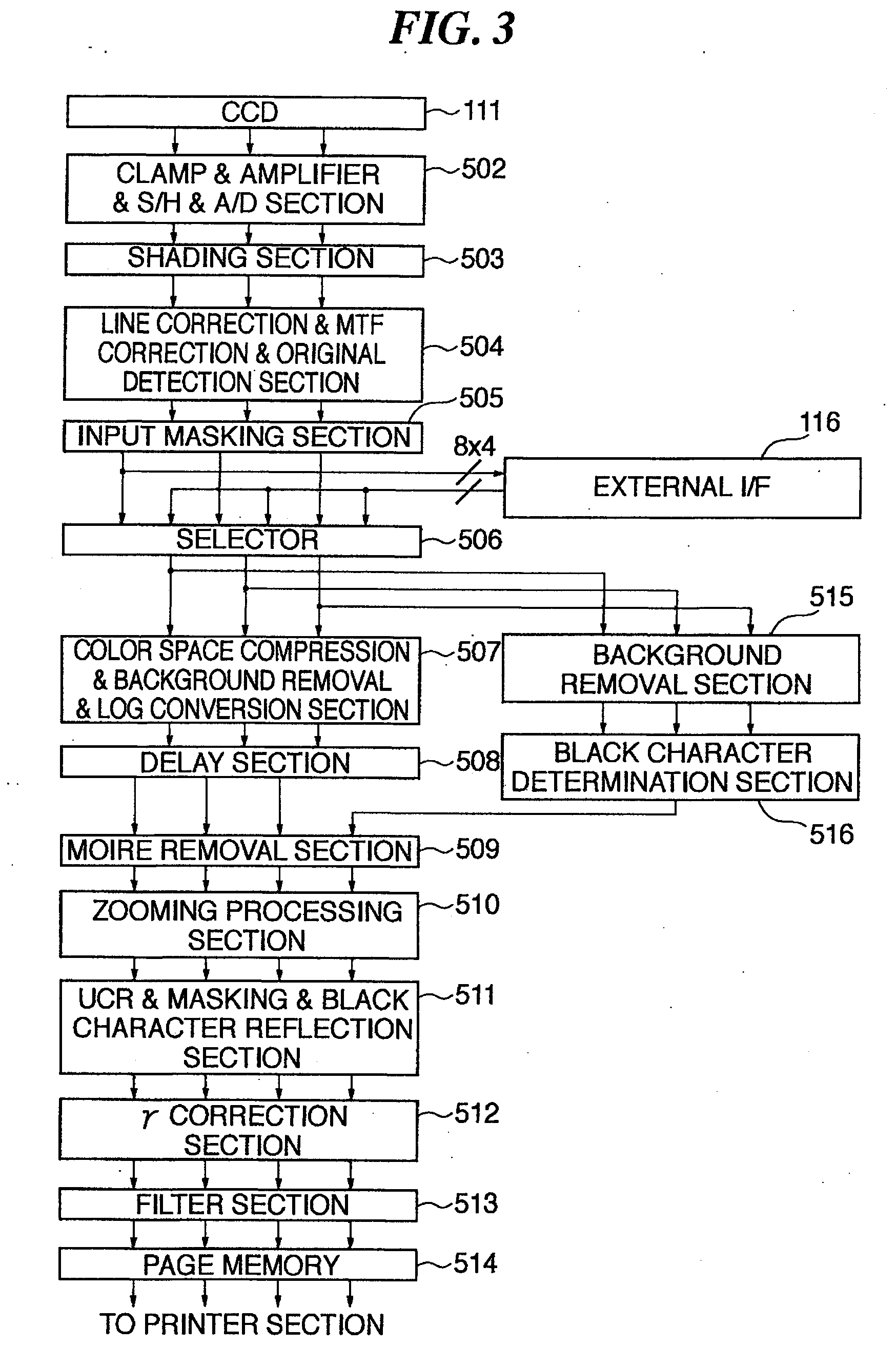

Image forming apparatus

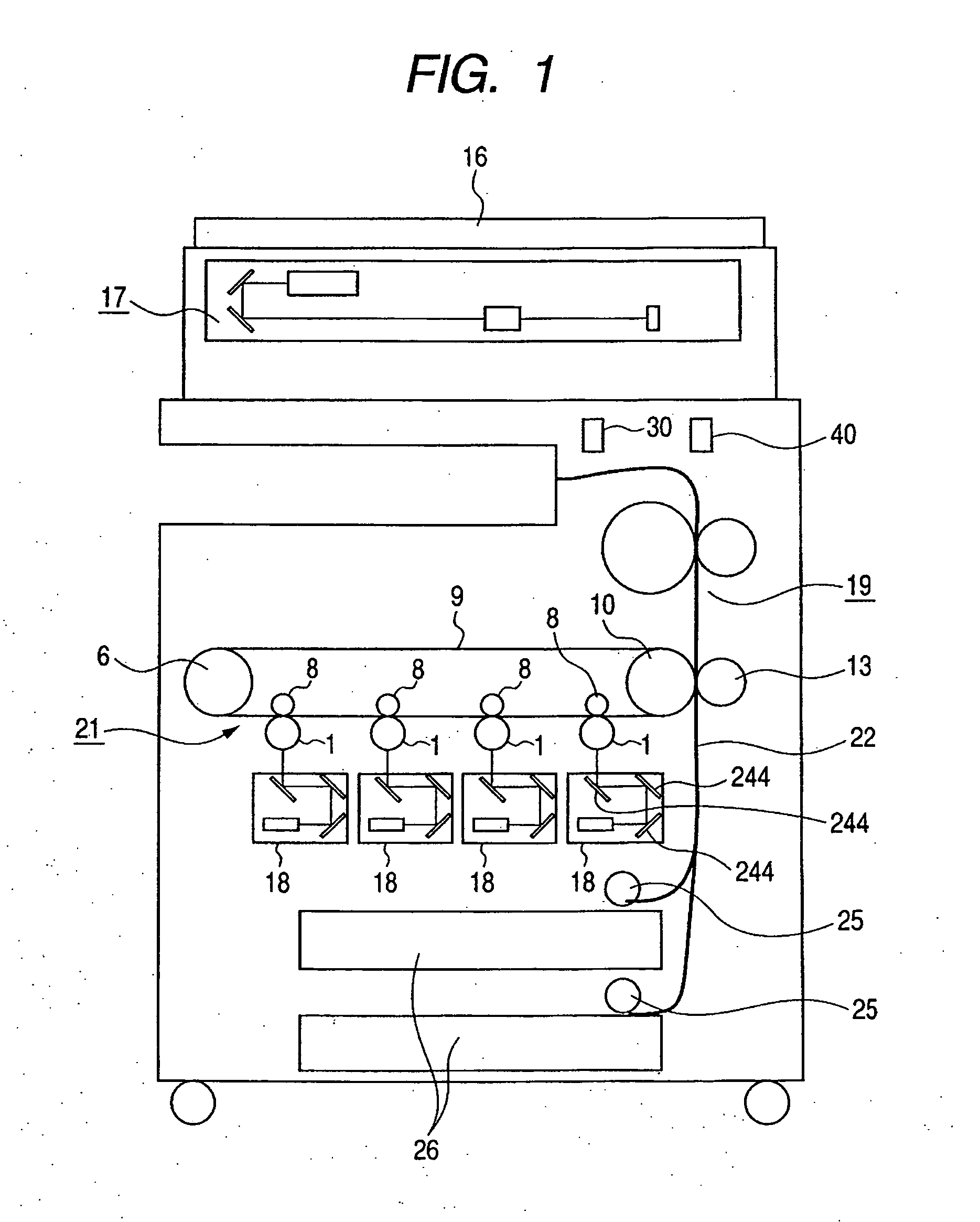

InactiveUS20100239286A1Increase productivityCurb productivity declineElectrographic process apparatusCorona dischargeImage formationElectrical current

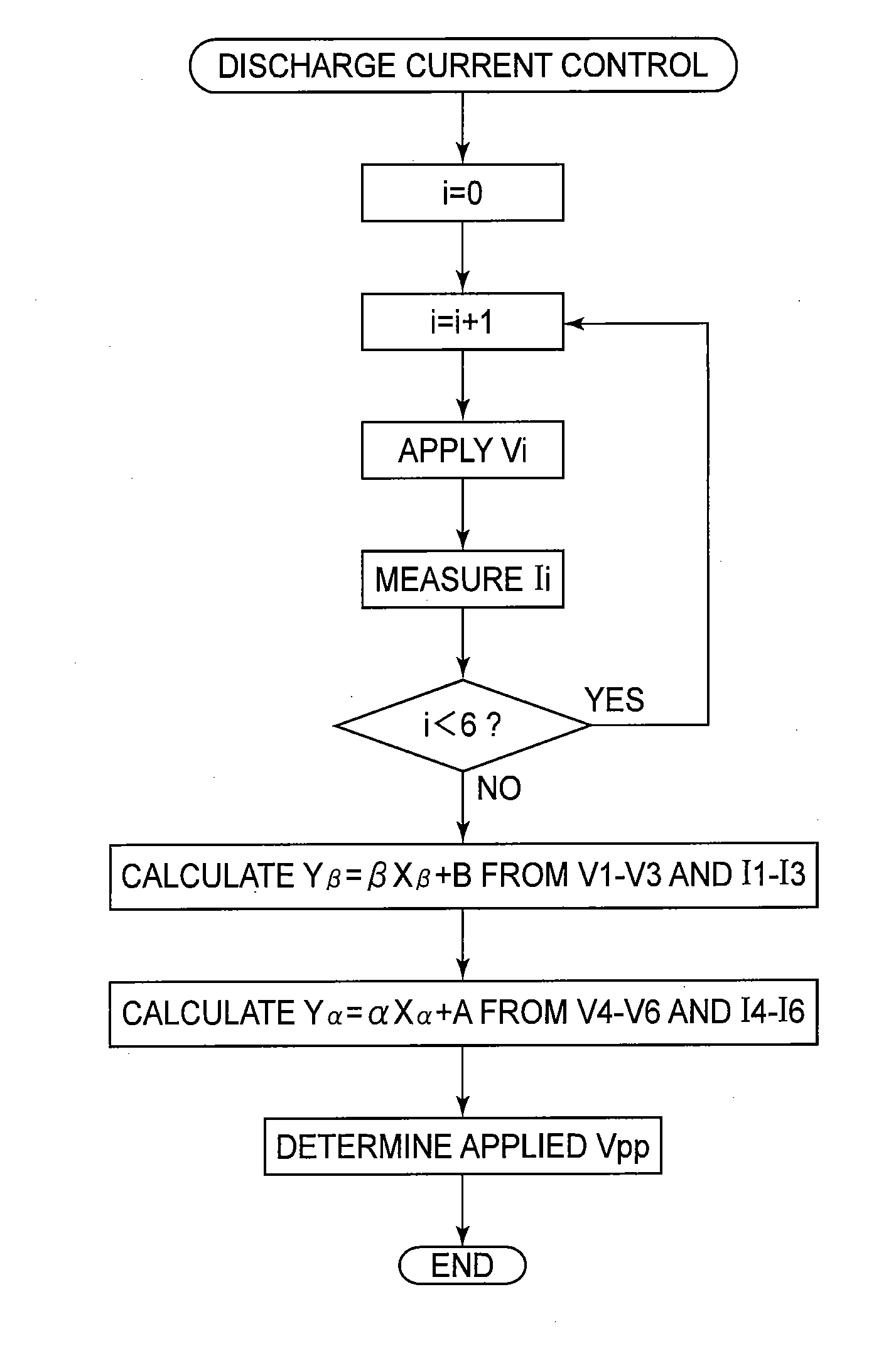

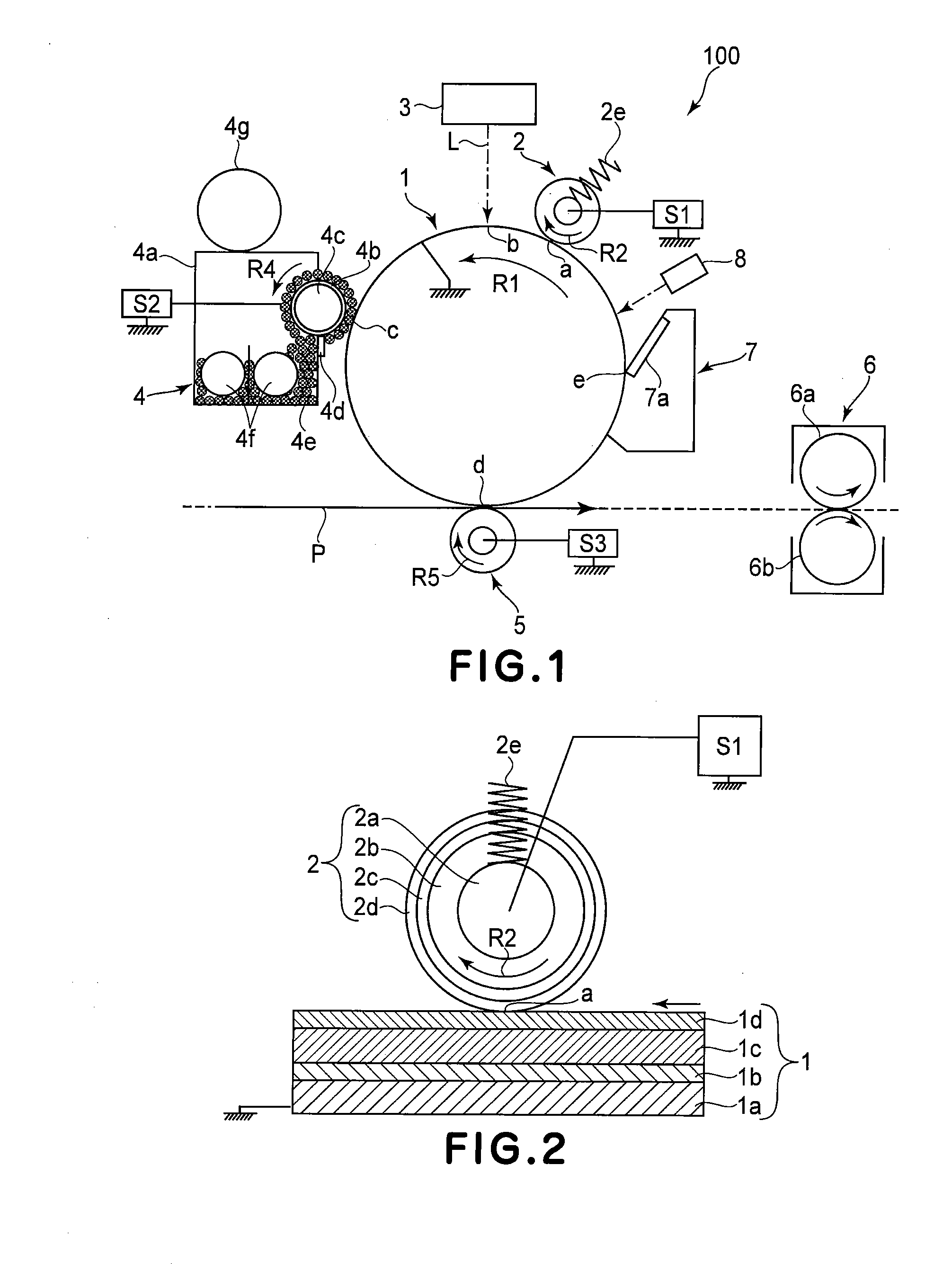

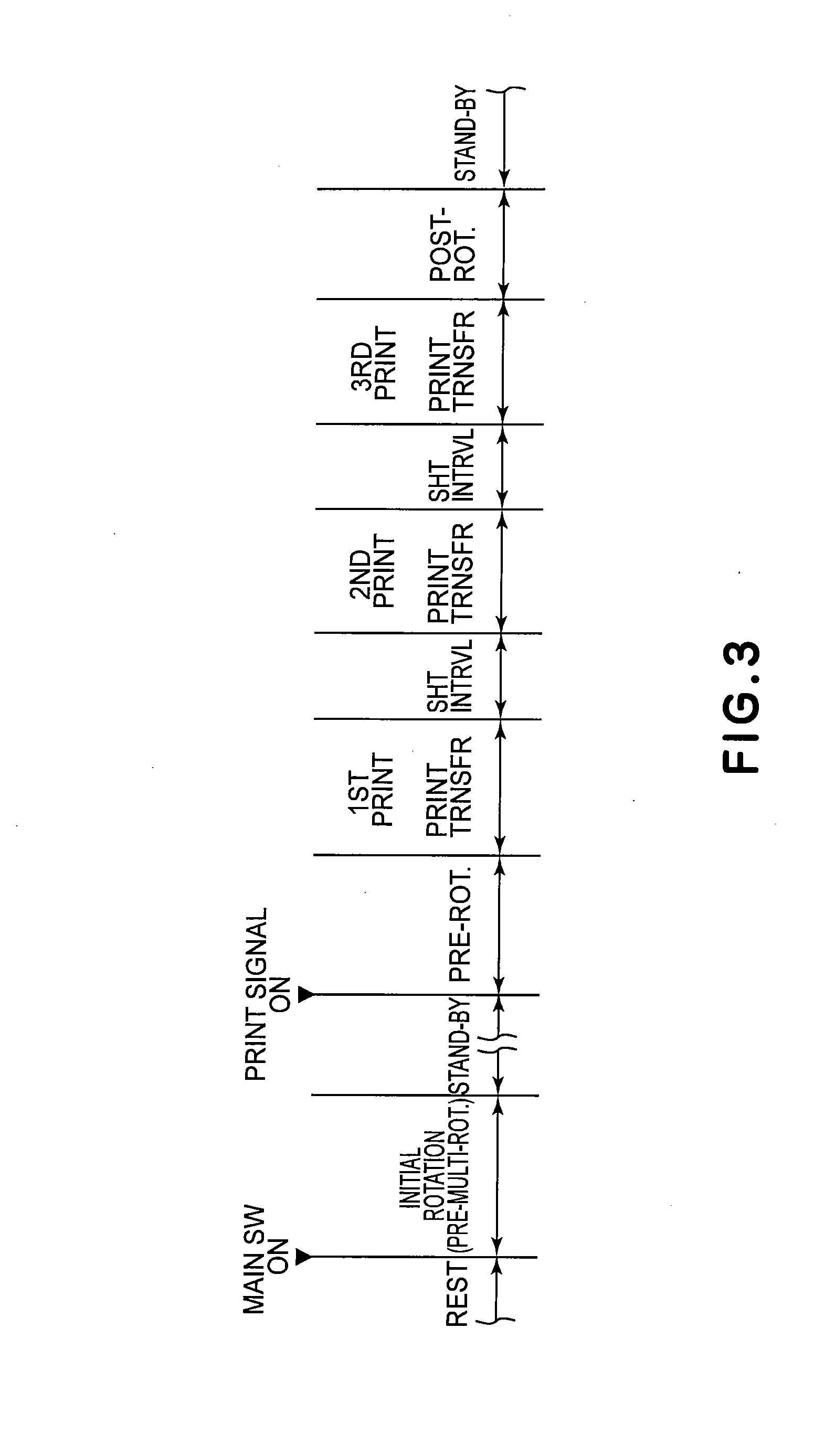

An image forming apparatus includes a drum; a charging member; a charging bias applying device; an image forming device; a detecting device for detecting a current passing between the charging member and the drum; an executing device for selectively executing a first mode in which the charging bias of a first frequency is applied to form the image on the drum rotated at a first speed and a second mode in which the charging bias of a second frequency is applied to form the image on the drum rotated at a second speed; a calculating device for calculating information indicating a relationship between an output of the detecting device when the AC voltage of the first frequency is applied and an output of the detecting device when the AC voltage of the second frequency is applied; and an adjusting device for adjusting a peak-to-peak voltage to be applied to the charging member in the first mode based on the output of the detecting device obtained by applying the AC voltage of the first frequency to the charging member and for adjusting a peak-to-peak voltage to be applied to the charging member in the second mode based on the output of the detecting device obtained by applying the AC voltage of the first frequency to the charging member and the information calculated by the calculating device.

Owner:CANON KK

Image forming apparatus

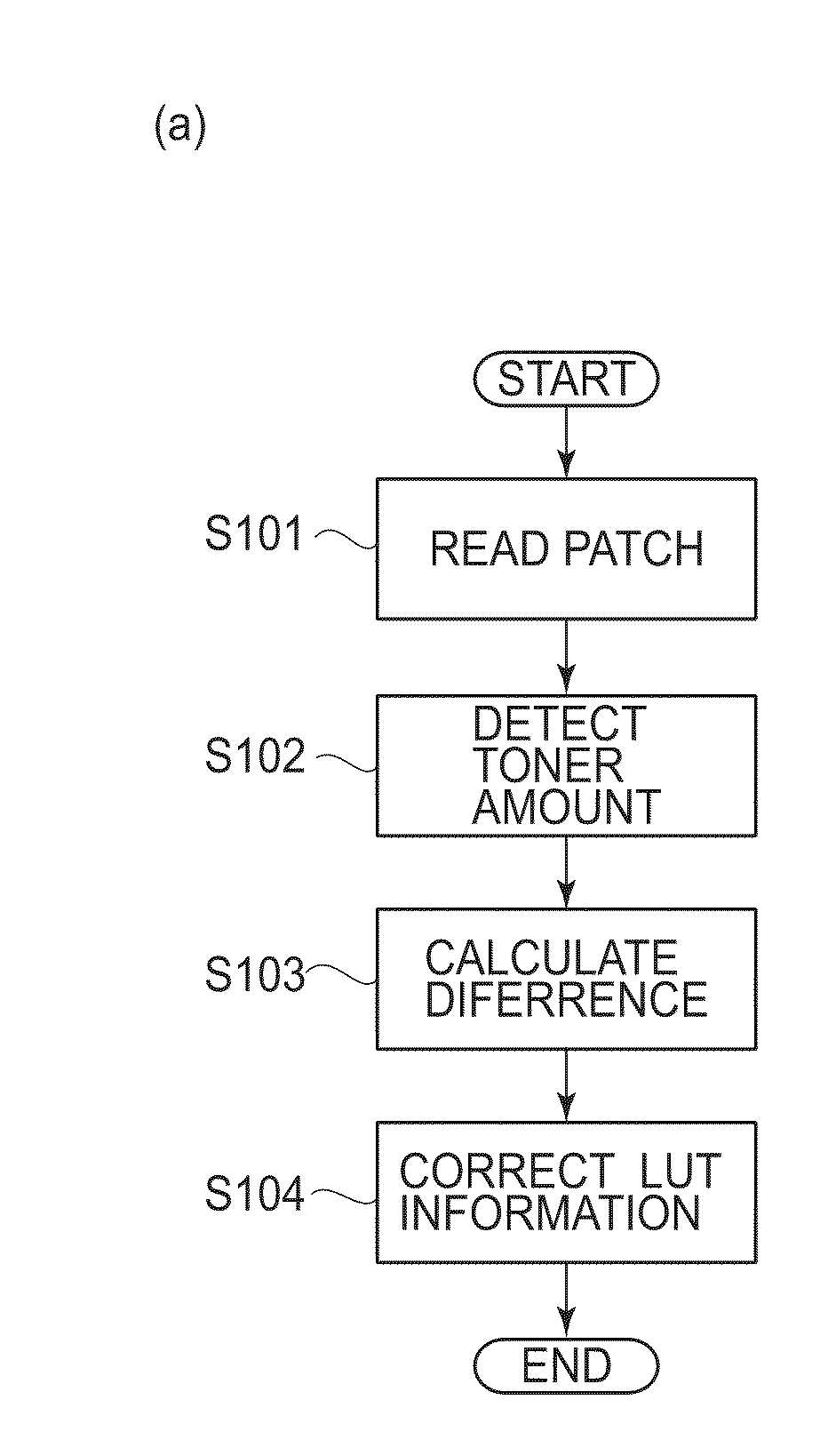

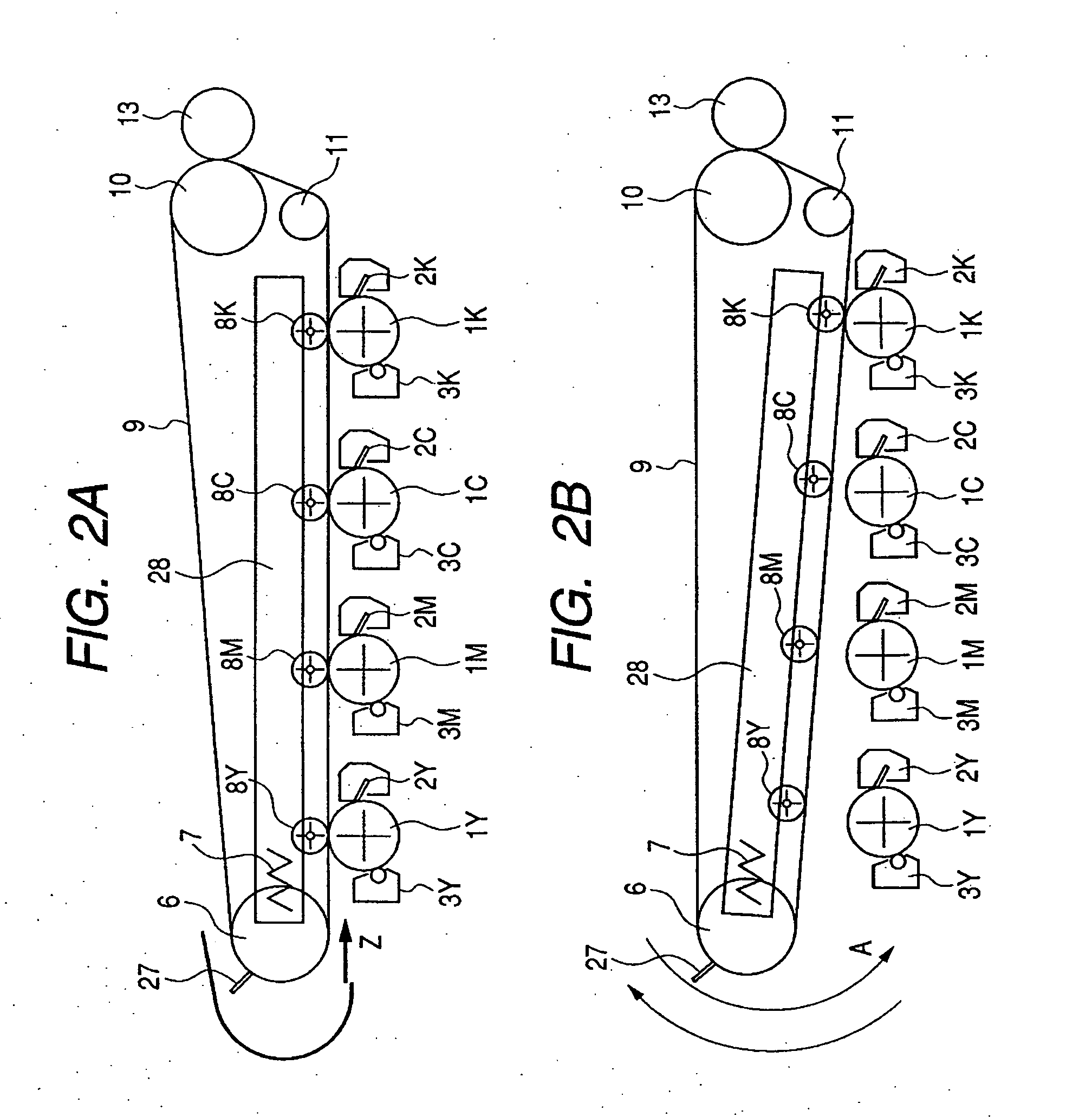

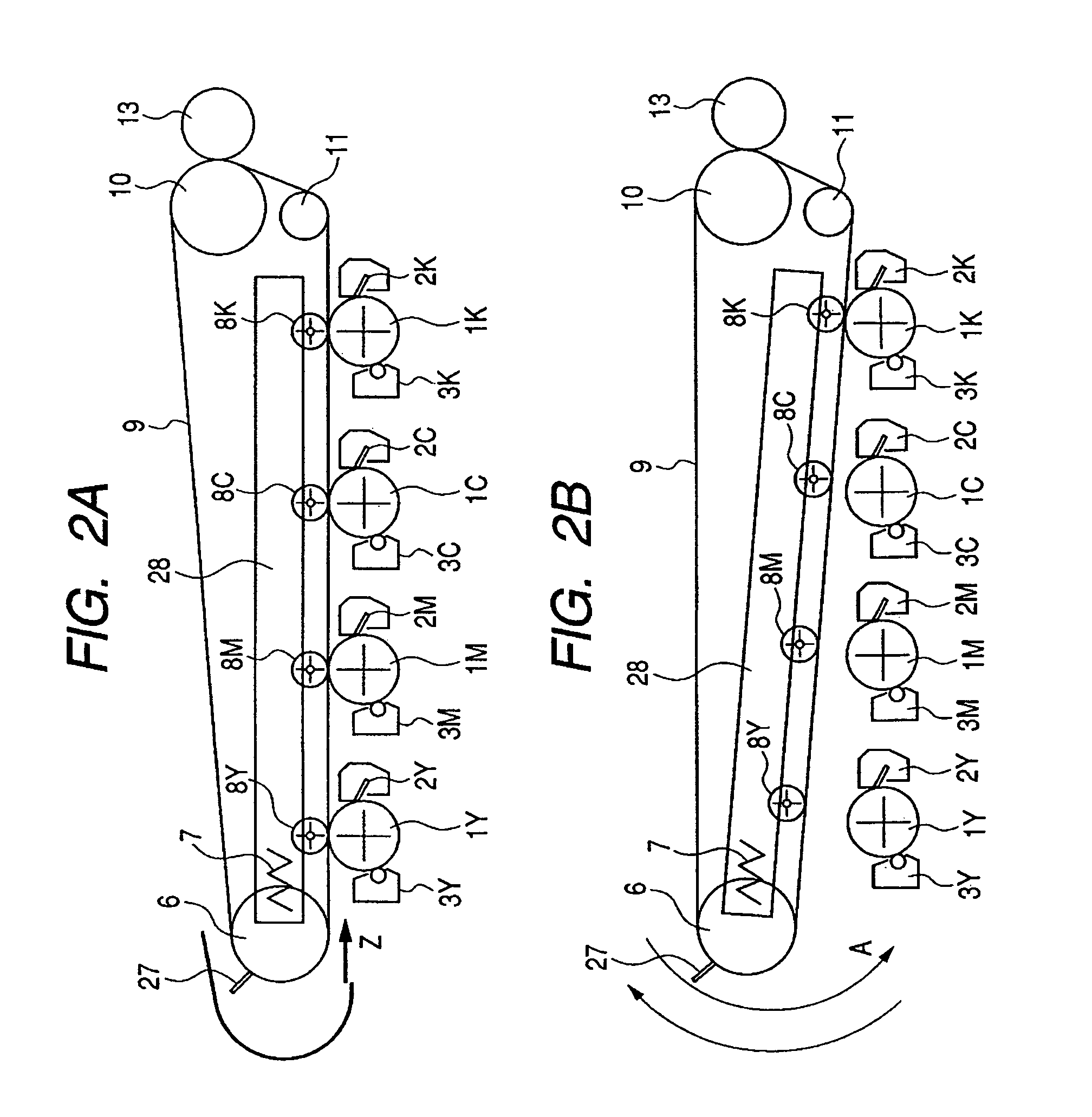

InactiveUS20110123209A1Decrease productivityIncrease in toner consumptionElectrographic process apparatusColor imageImage formation

An image forming apparatus includes a color image forming portion for forming a color toner image on an image bearing member; a transparent image forming portion for forming a transparent toner image on the image bearing member. The color image forming portion is capable of forming a test color toner image on the image bearing member, and the transparent image forming portion is capable of forming a test transparent toner image on the image bearing member. The apparatus further includes a detecting portion for detecting a density of each of the test color toner image and the test transparent toner image; and a control portion for controlling an image forming condition for an image to be formed on a recording material, on the basis of a result of detection of the density of each of the test color toner image and the transparent toner image. The test transparent toner image and the test color toner image are formed on the image bearing member by the transparent image forming portion and the color image forming portion between an operation for forming the image to be formed on the recording material and a subsequent operation for forming the image to be formed on the recording material. A frequency of formations of the test transparent toner images is lower than that of the formations of the test color toner images.

Owner:CANON KK

Image forming apparatus

ActiveUS20110222898A1Reduce generationDecrease productivityElectrographic process apparatusCorona dischargeImage formationEngineering

An image forming apparatus includes a corona charger having an opening, a shutter configured to open and close the opening of the corona charger, a humidity sensor configured to detect humidity, and a control unit configured to control the so that time from ending an image forming process to closing the opening using the shutter is reduced when the humidity detected by the humidity sensor increases.

Owner:CANON KK

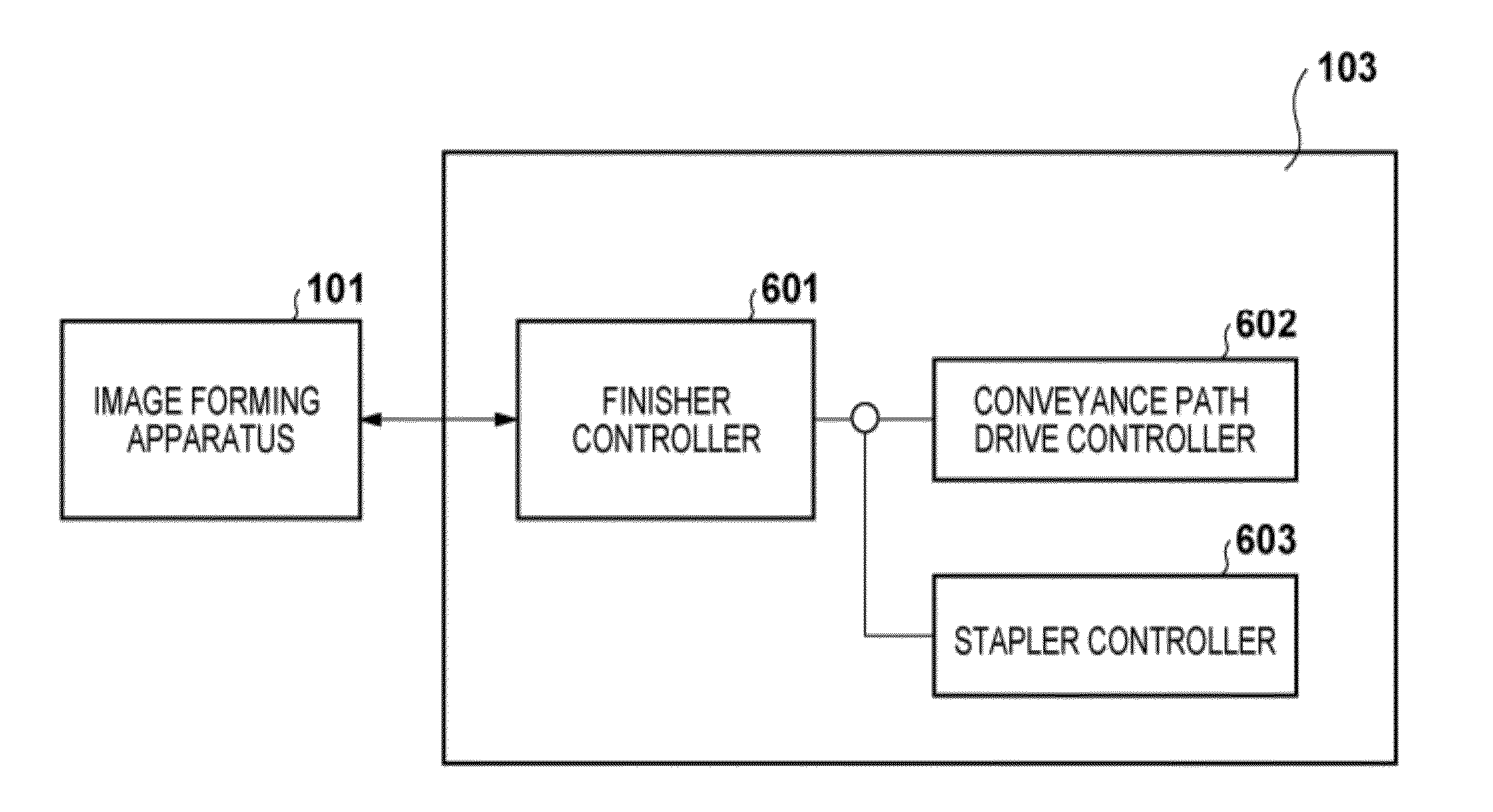

Print control apparatus and control method thereof

InactiveUS20120263483A1Curb productivity declineAvoid wastingElectrographic process apparatusComputer scienceControl equipment

A print control apparatus that controls a printing unit is provided. A determination unit determines print quality of a print image printed by the printing unit. A first counting unit counts the number of pages of each of sets whose print quality is determined by the determination unit not to satisfy a predetermined criterion. A second counting unit counts the number of same pages of the sets whose prnt quality is determined by the determination unit not to satisfy a predetermined criterion. A control unit stops printing by the printing unit if a count value counted by the first counting unit reaches a first predetermined value and stops printing by the printing unit if a count value counted by the second counting unit reaches a second predetermined value.

Owner:CANON KK

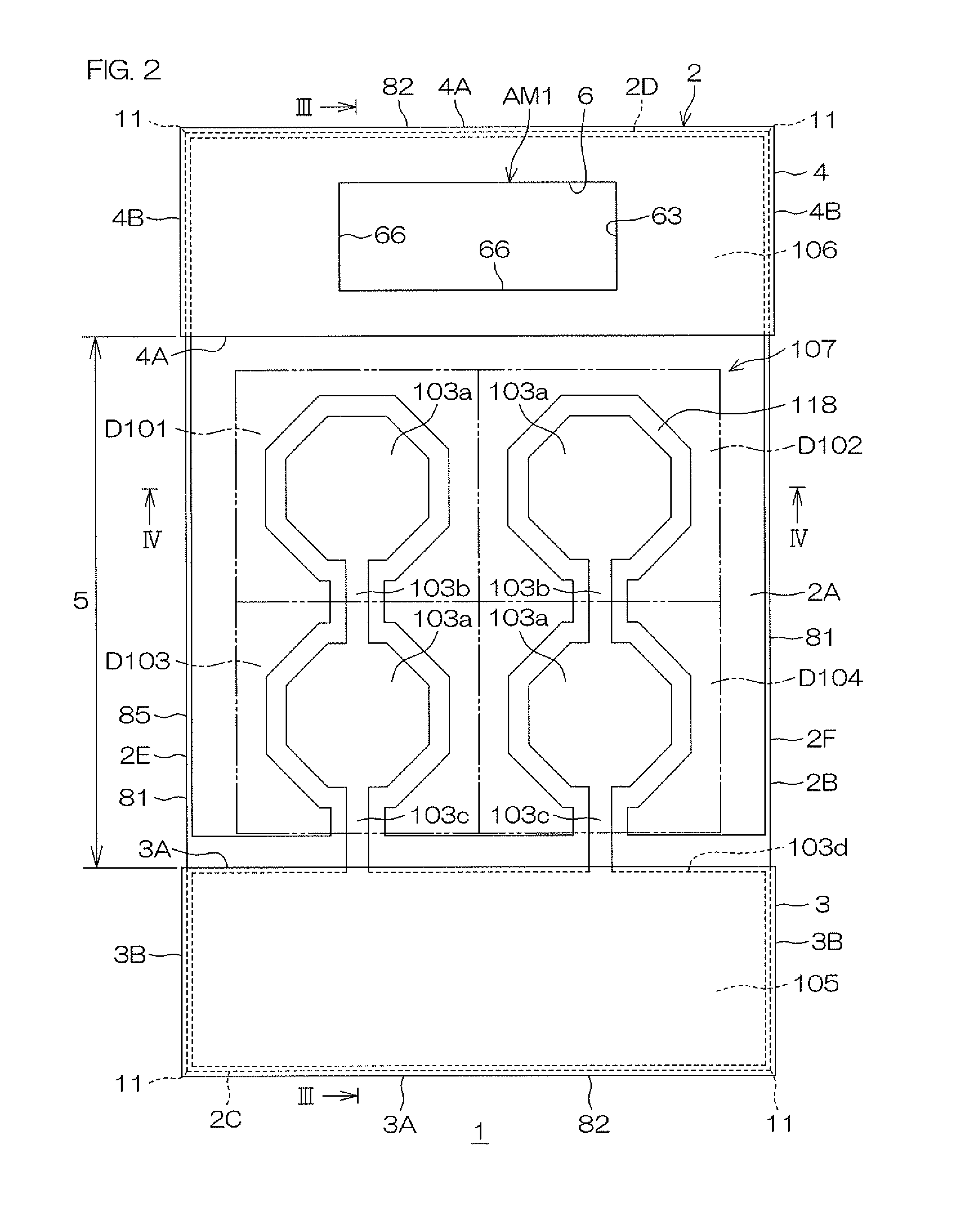

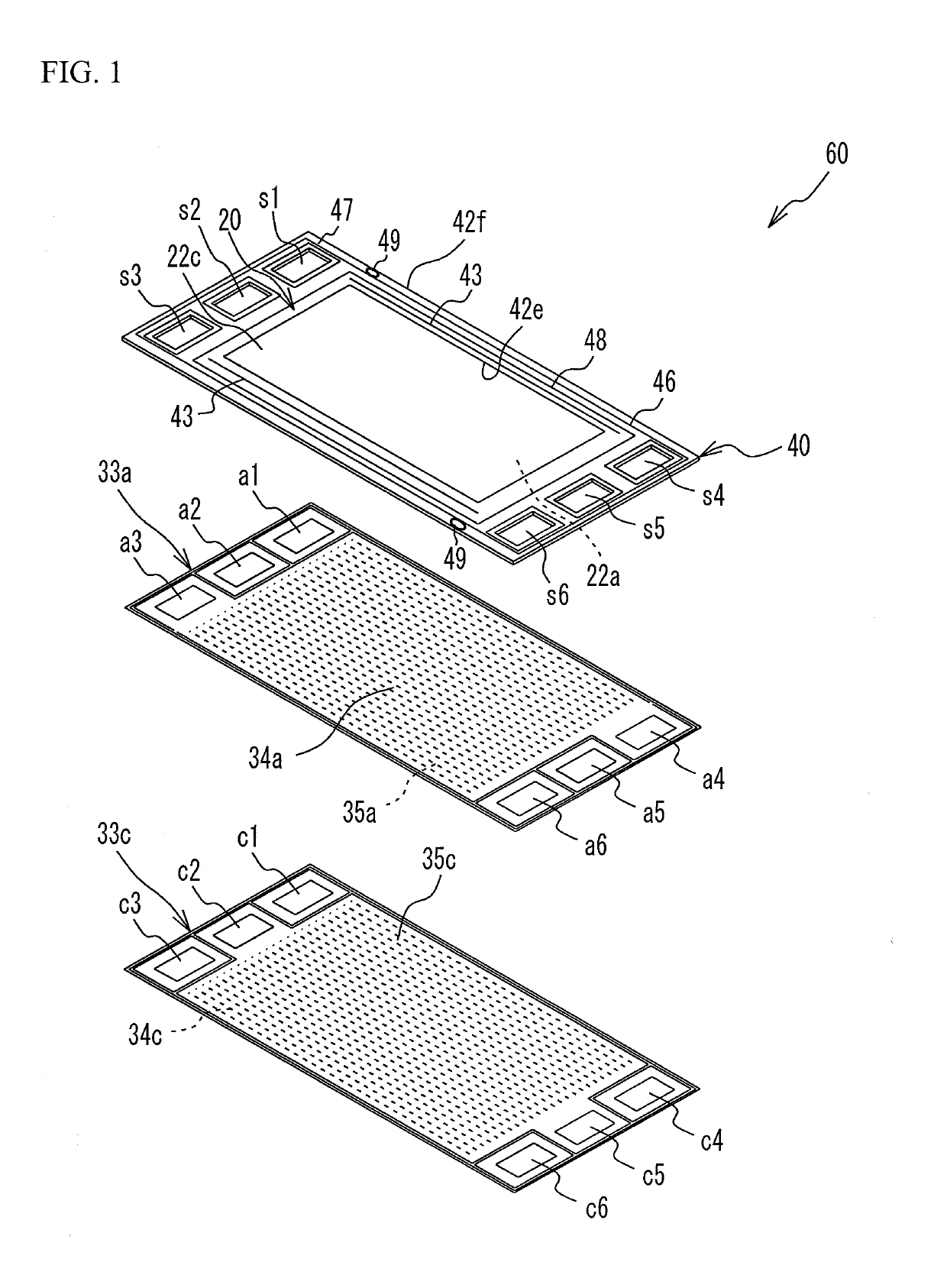

Chip parts and method for manufacturing the same, circuit assembly having the chip parts and electronic device

ActiveUS20150243612A1Inspection precision is improvedDecrease productivitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringElectrical and Electronics engineering

A chip part according to the present invention includes a substrate having a penetrating hole, a pair of electrodes formed on a front surface of the substrate and including one electrode overlapping the penetrating hole in a plan view and another electrode facing the one electrode, and an element formed on the front surface side of the substrate and electrically connected to the pair of electrodes.

Owner:ROHM CO LTD

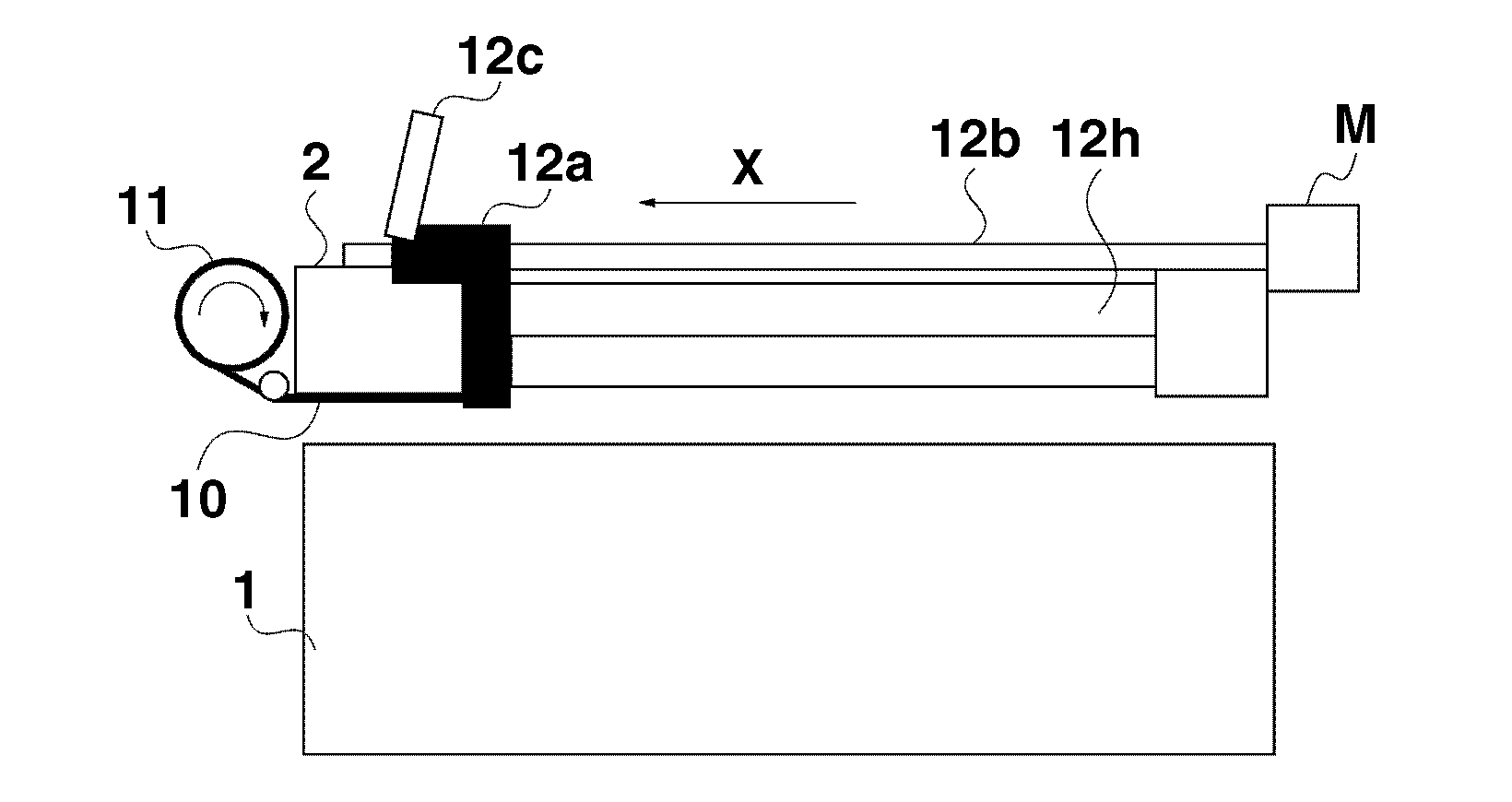

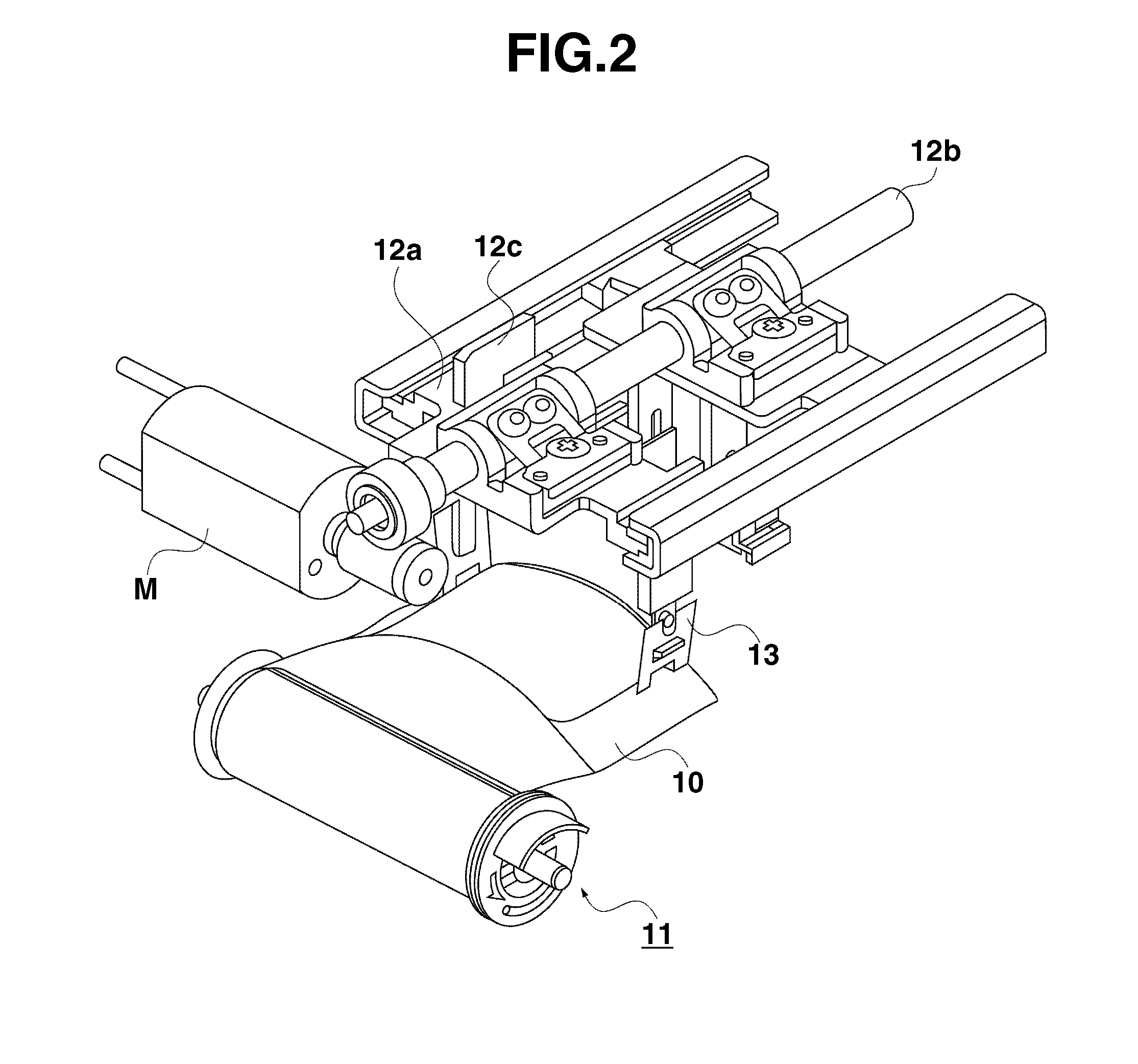

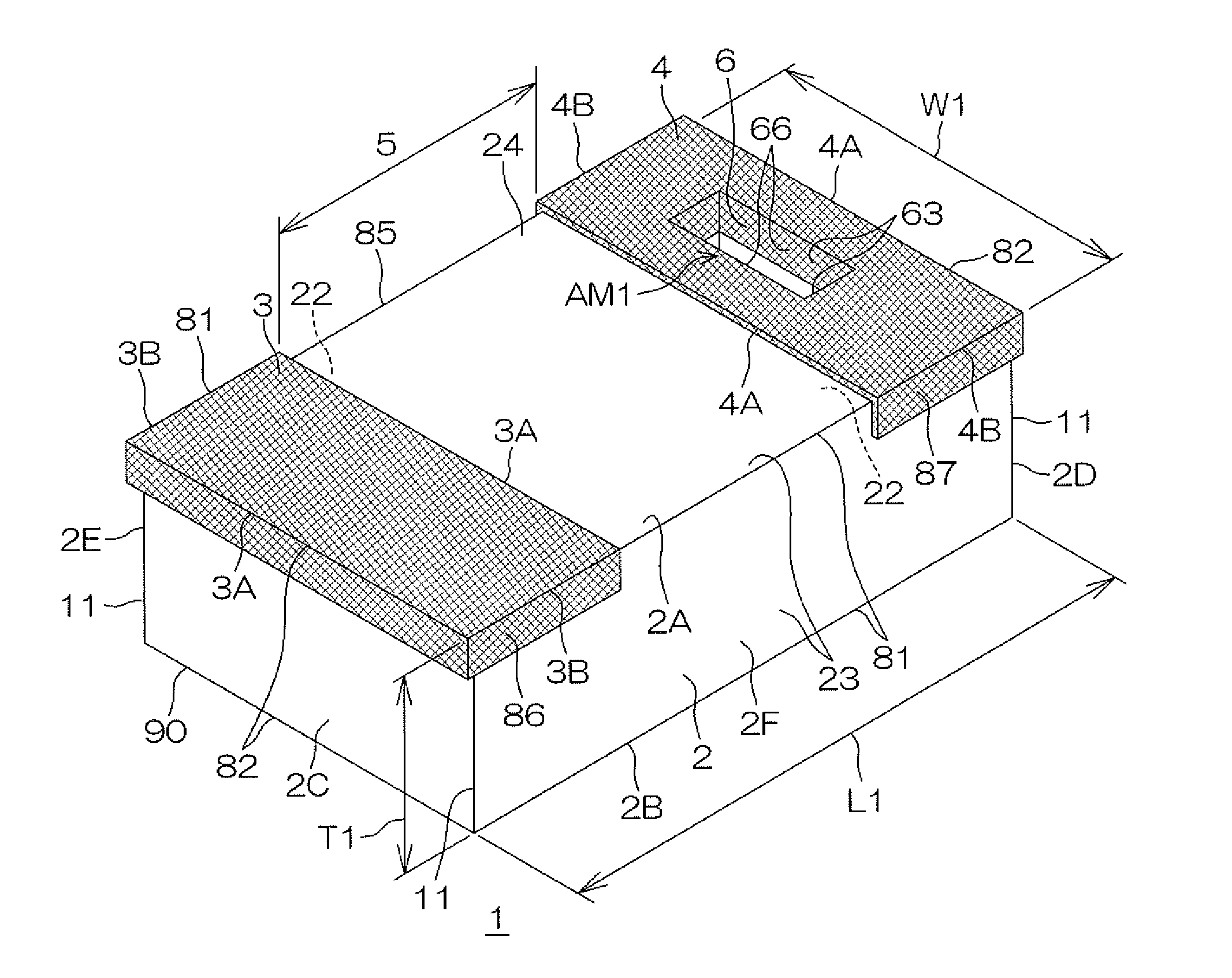

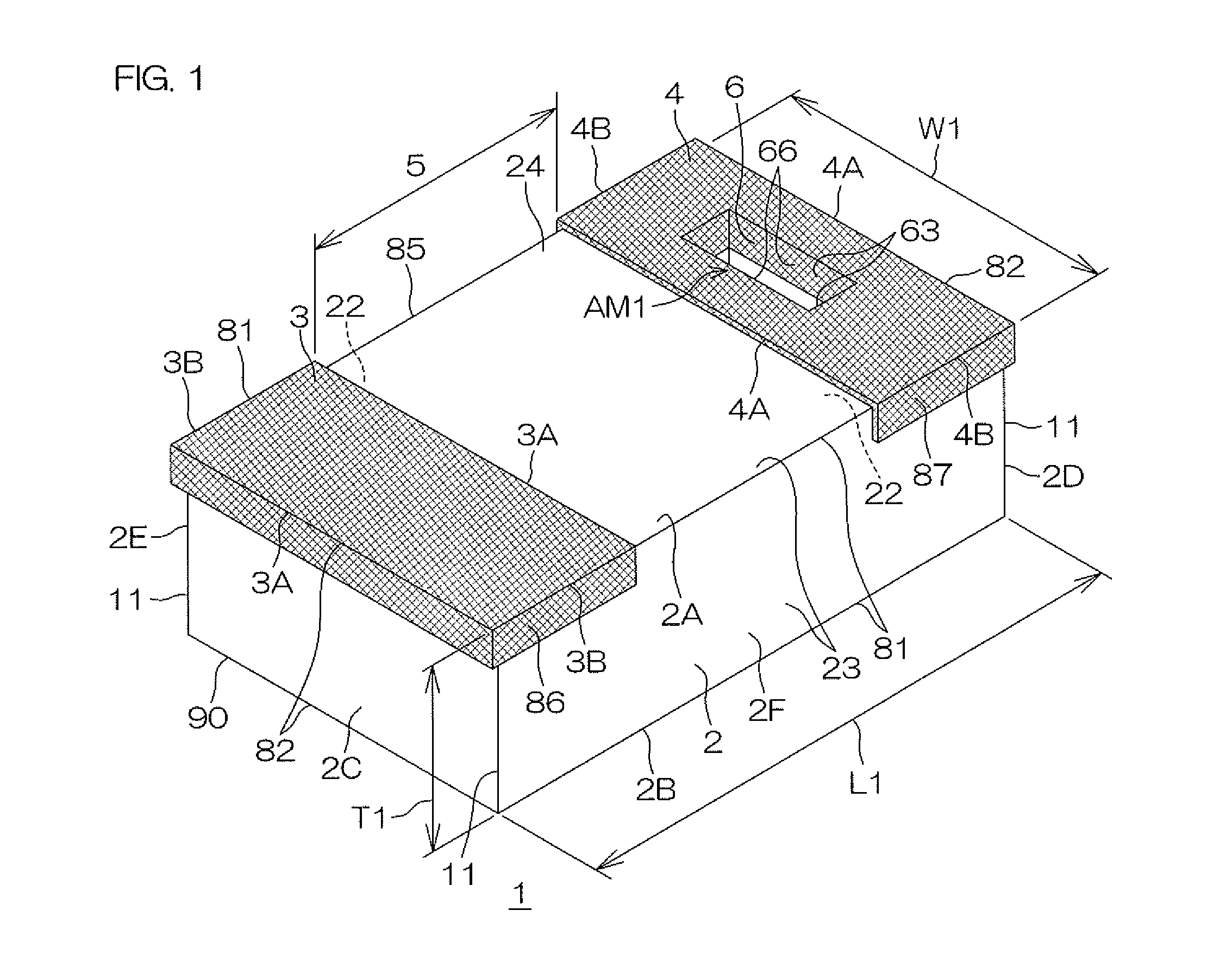

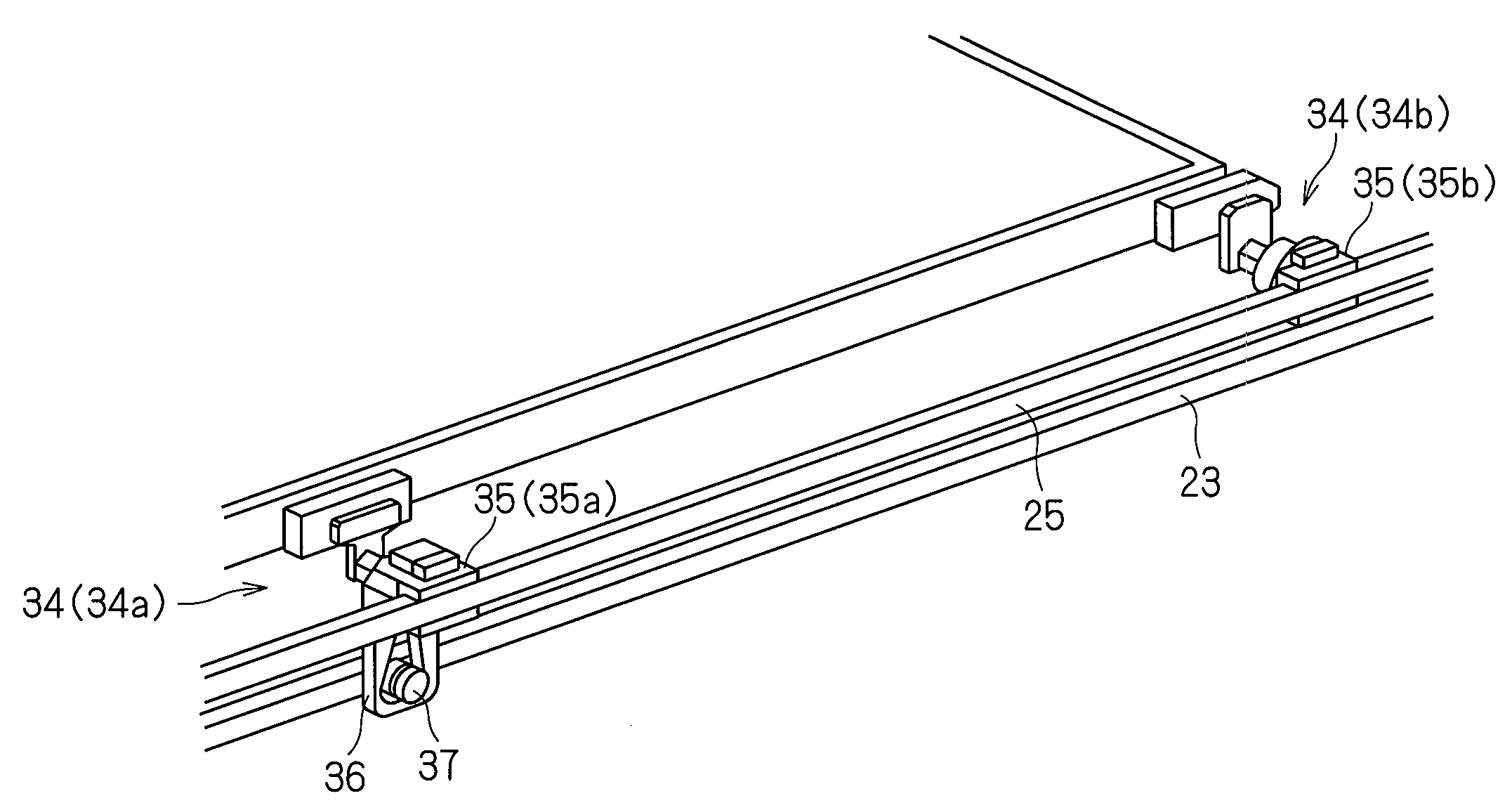

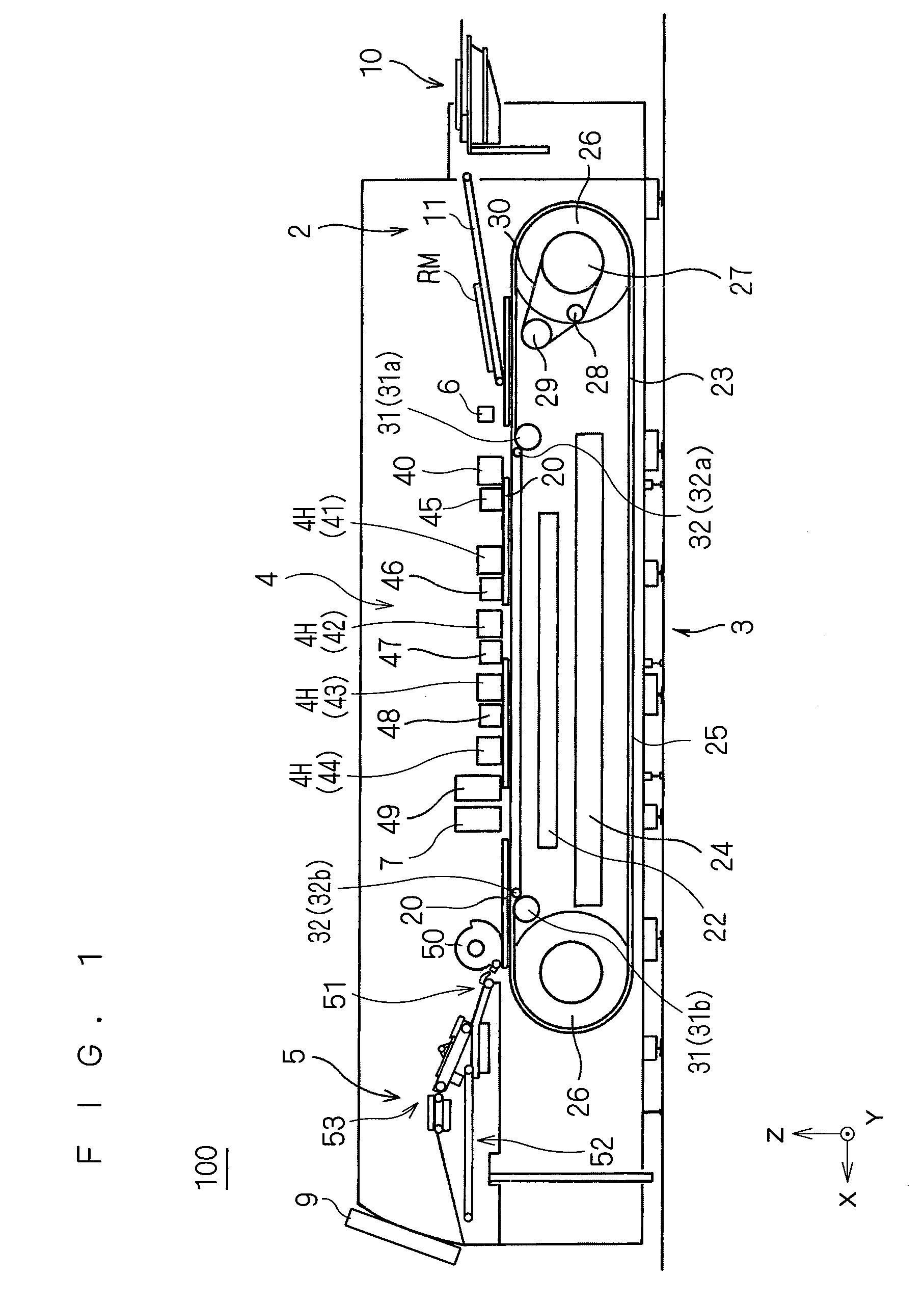

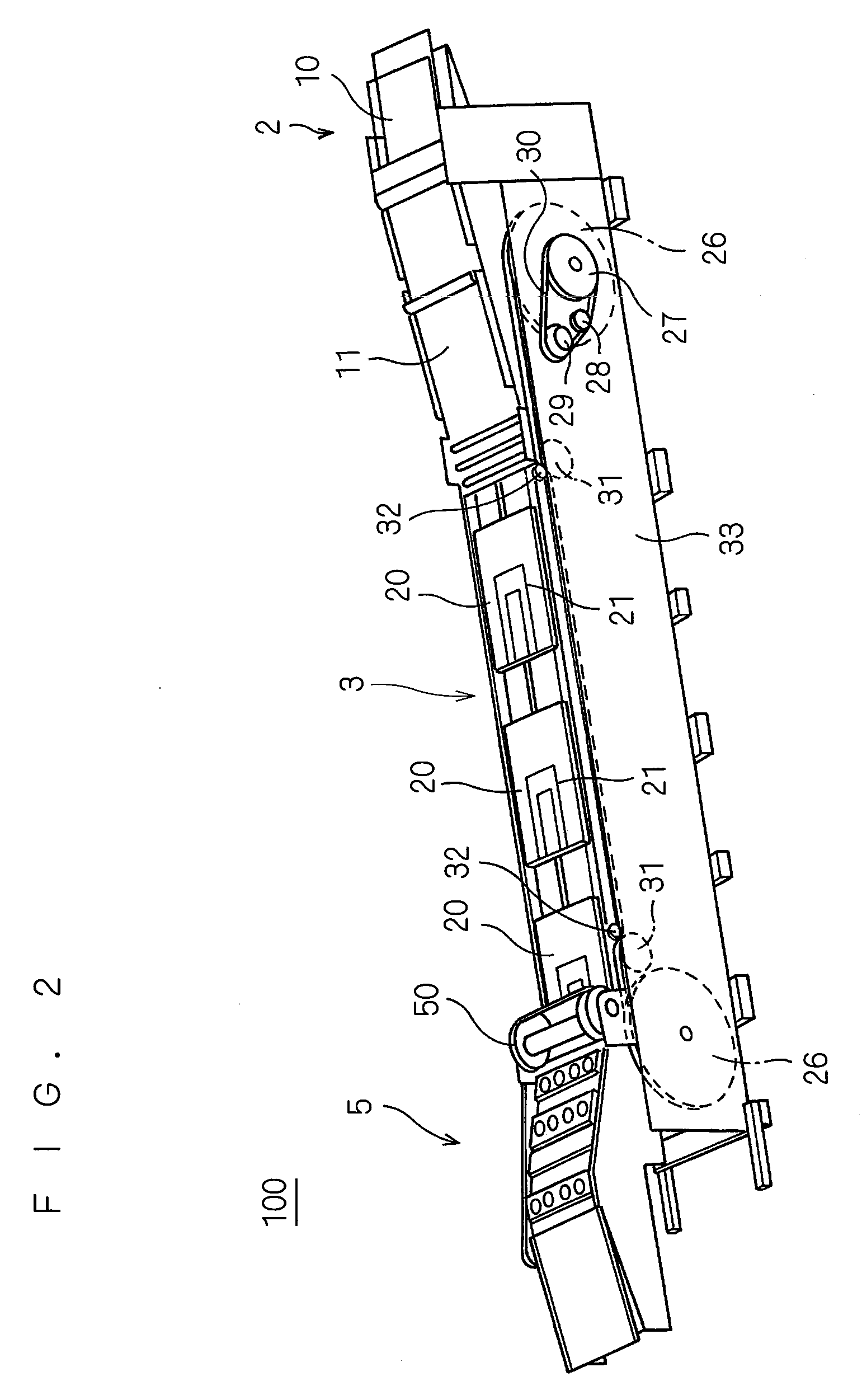

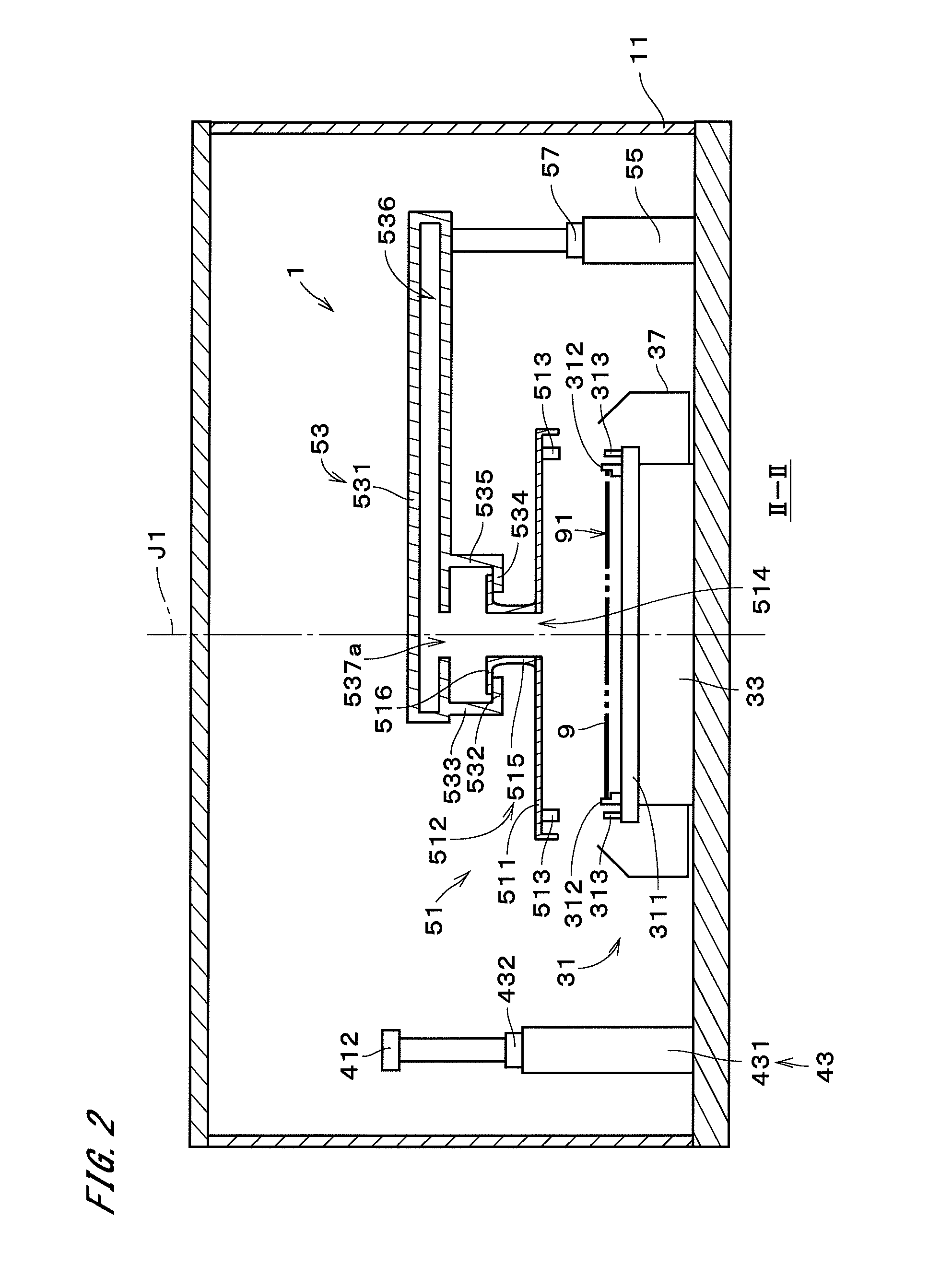

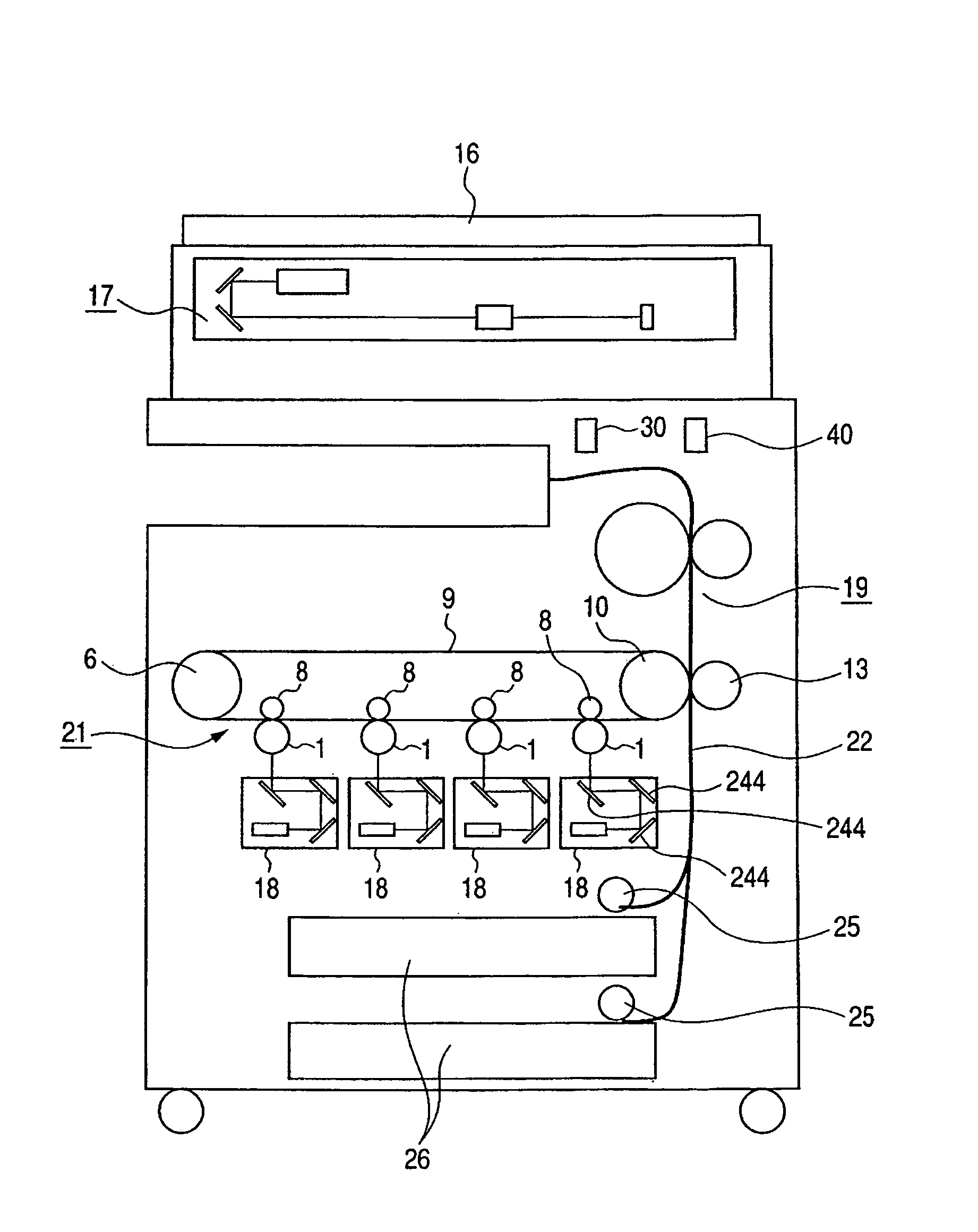

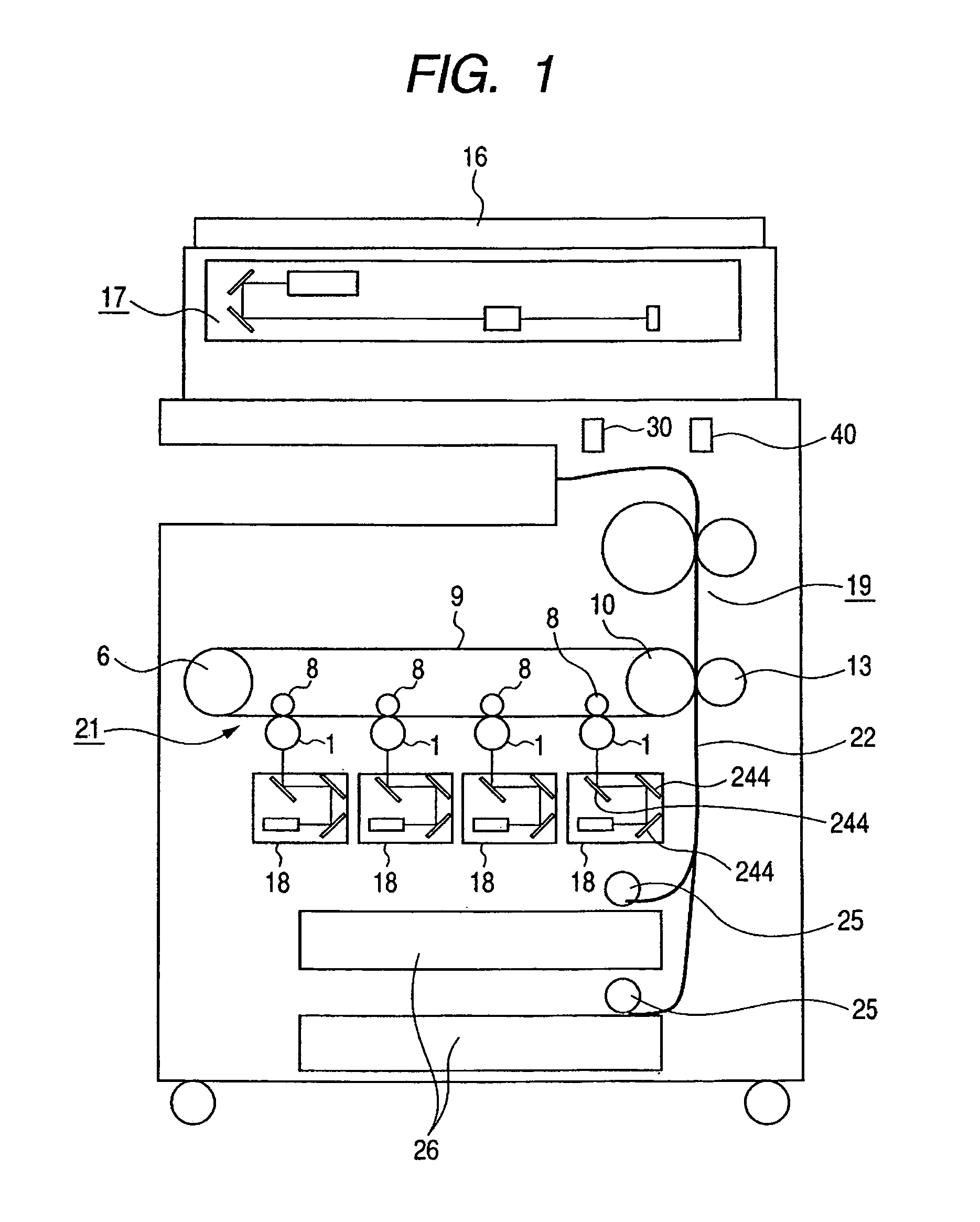

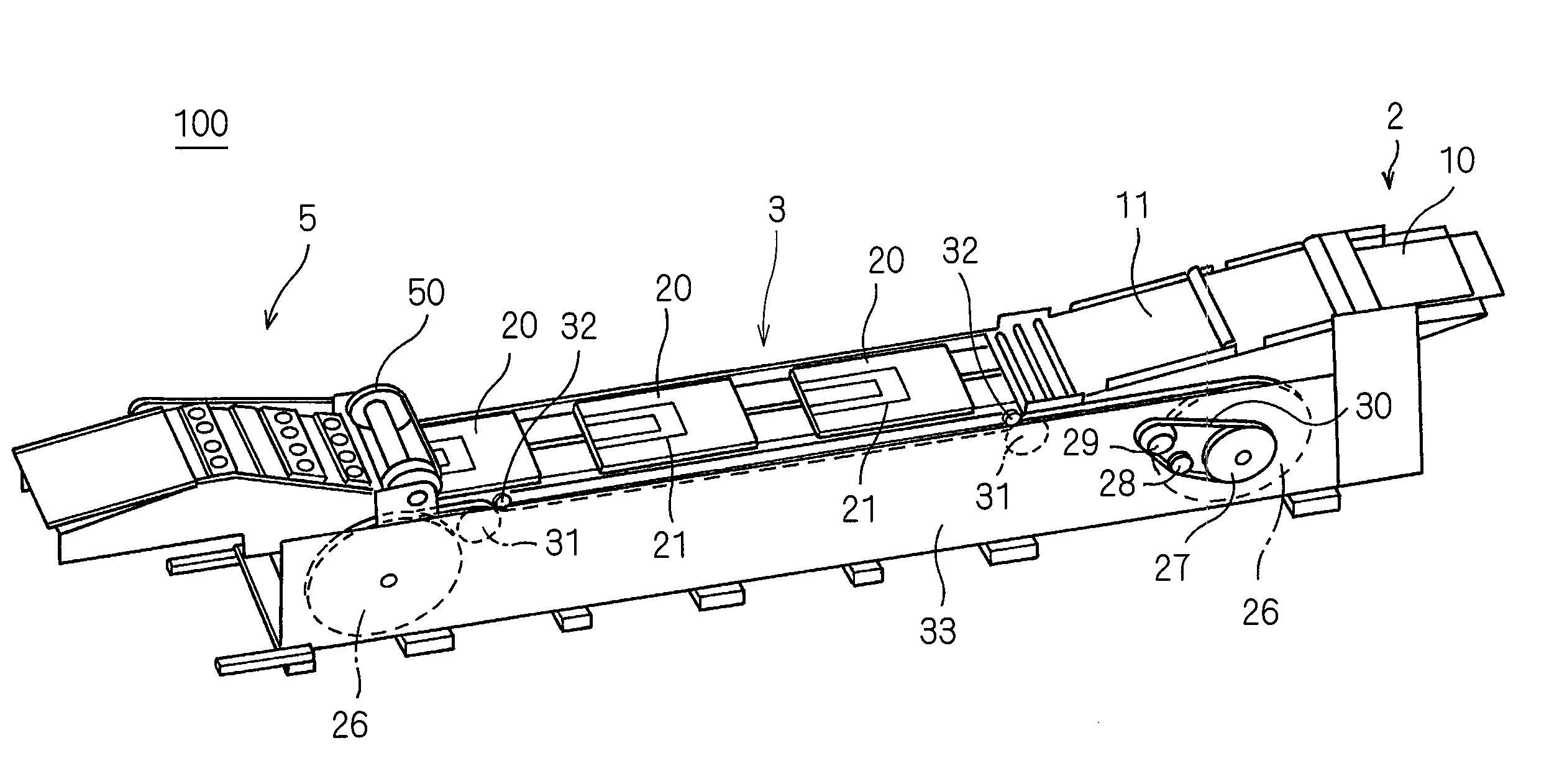

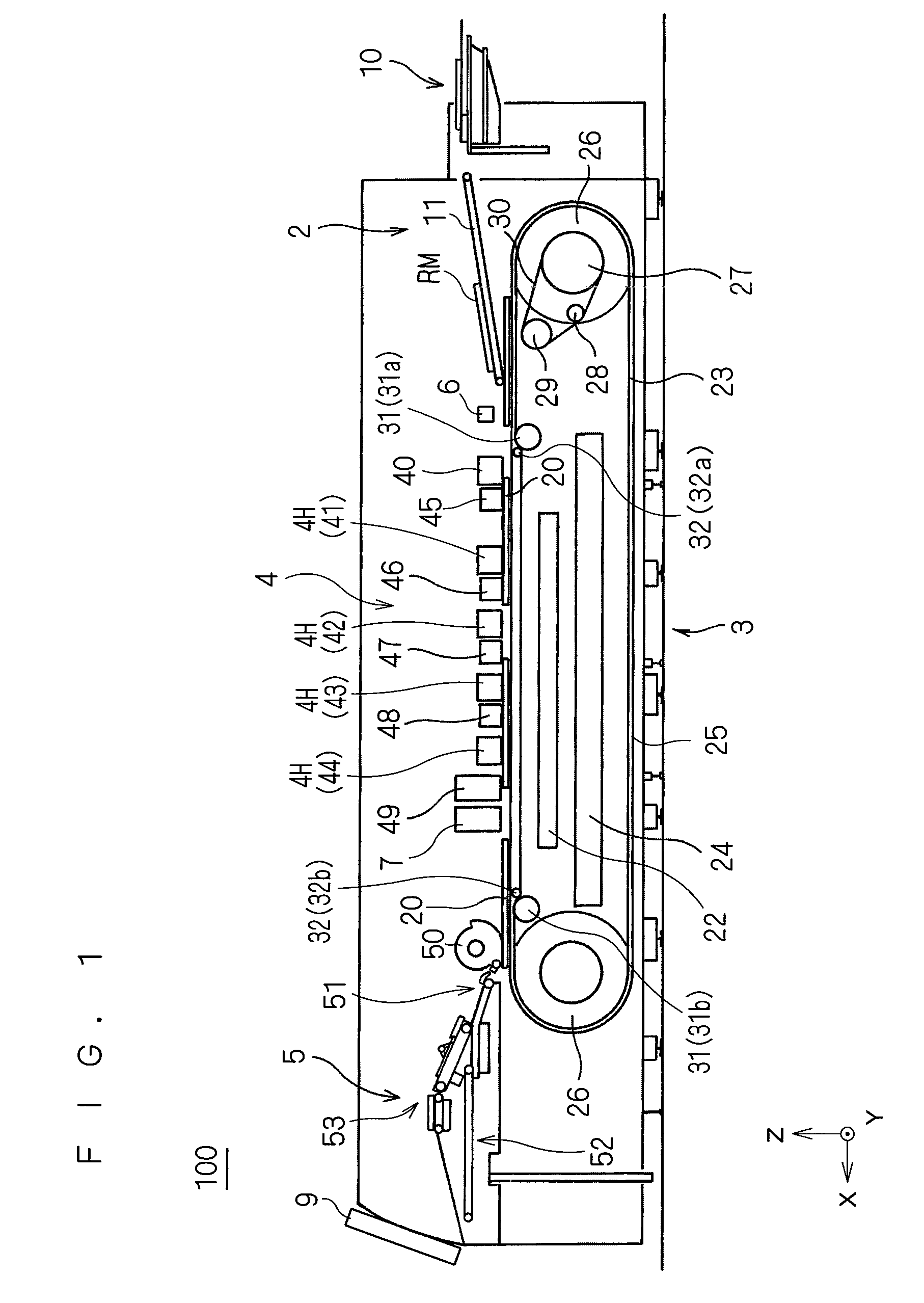

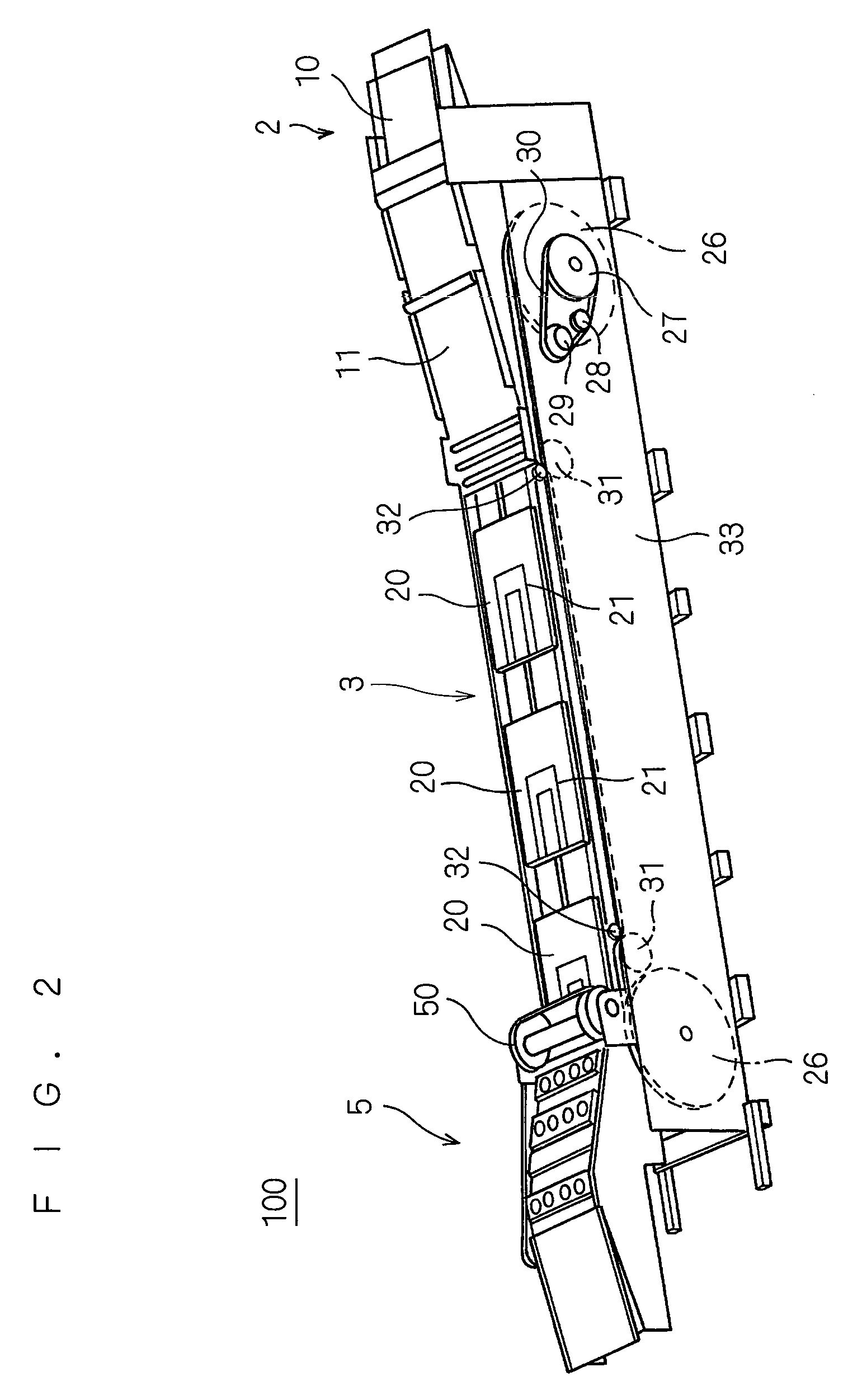

Recording medium transport device in image recording apparatus

InactiveUS20090295080A1Operation be interruptCurb productivity declineTypewritersOther printing apparatusImage recordingLinear motor

An image recording apparatus includes a plurality of linear motor mechanisms for transporting a plurality of tables in a first transport section including at least an area in which an image is recorded on recording media, and an endless transport mechanism for transporting the plurality of tables in at least a second transport section contiguous with the first transport section and capable of transporting the plurality of tables in the first transport section. The image recording apparatus further includes an unused linear motor mechanism determination part for determining an unused linear motor mechanism. When the unused linear motor mechanism is determined, the endless transport mechanism is used as an alternative to transport at least one of the tables which is to be transported in the first transport section but which is able to be transported by none of the plurality of linear motor mechanisms. If a malfunctioning linear motor mechanism is present because of a breakage, an operation anomaly and the like, the image recording apparatus achieves the image recording while maintaining the accuracy of the recorded image although the throughput thereof decreases.

Owner:DAINIPPON SCREEN MTG CO LTD

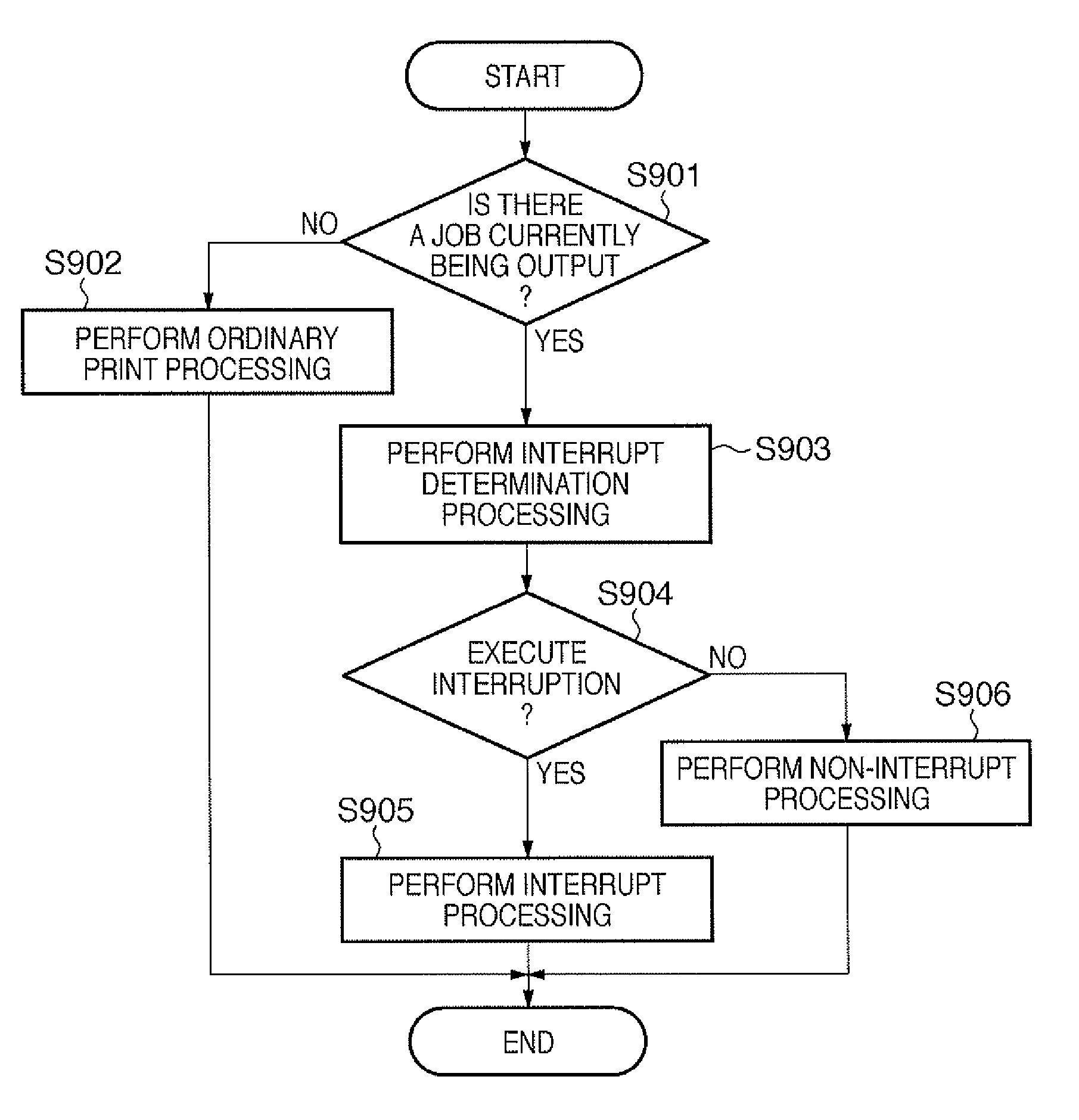

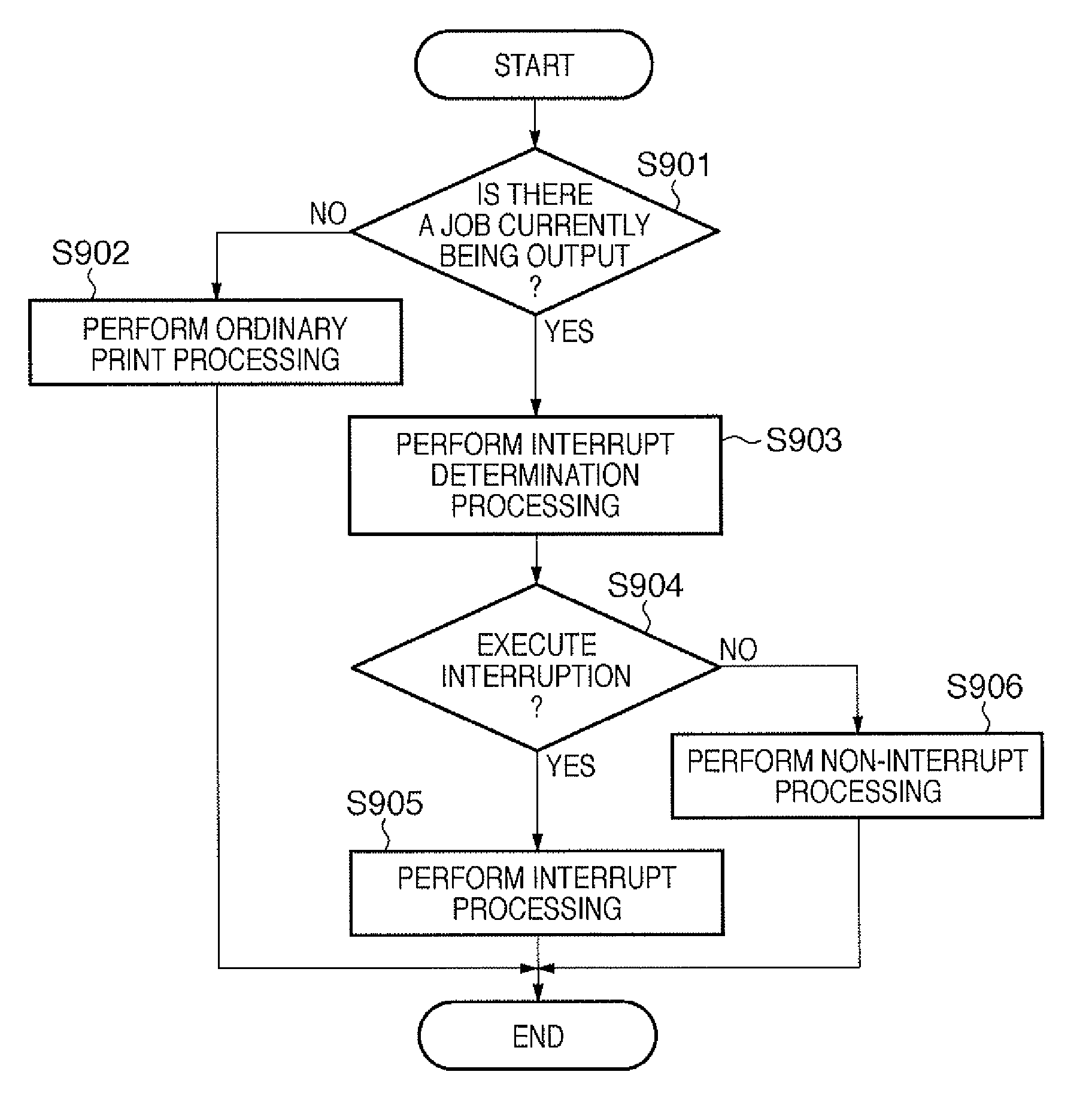

Printing control apparatus, printing control method, and program

InactiveUS20100196042A1Decrease productivityCurb productivity declineElectrographic process apparatusComputer engineeringControl unit

A printing control apparatus that causes printing by a printing unit having a fixing unit that fixes a recording agent on a sheet, the printing control apparatus including: a printing control unit configured to cause the printing unit to stop printing of a currently printing job, and print another job in a state that printing of the job has been stopped; and a determining unit configured to determine whether or not to permit execution of the other job in a state that the currently printing job has been stopped by the printing control unit, based on a fixing unit temperature necessary for printing of the currently printing job and a fixing unit temperature necessary for execution of the other job.

Owner:CANON KK

Image forming apparatus

ActiveUS20180157003A1Confirm effectCurb productivity declineElectrographic process apparatusMountingsImage formationEngineering

Owner:CANON KK

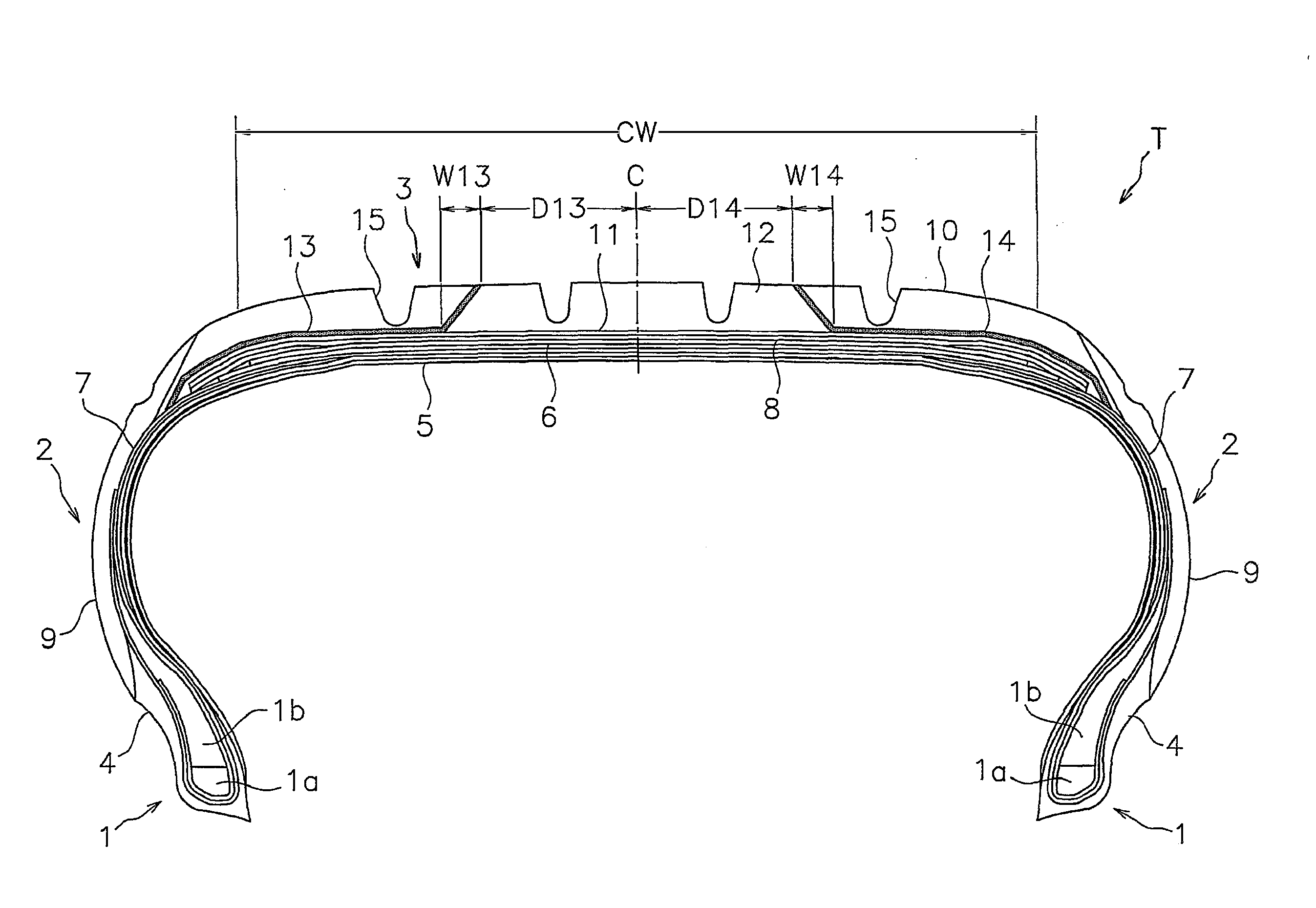

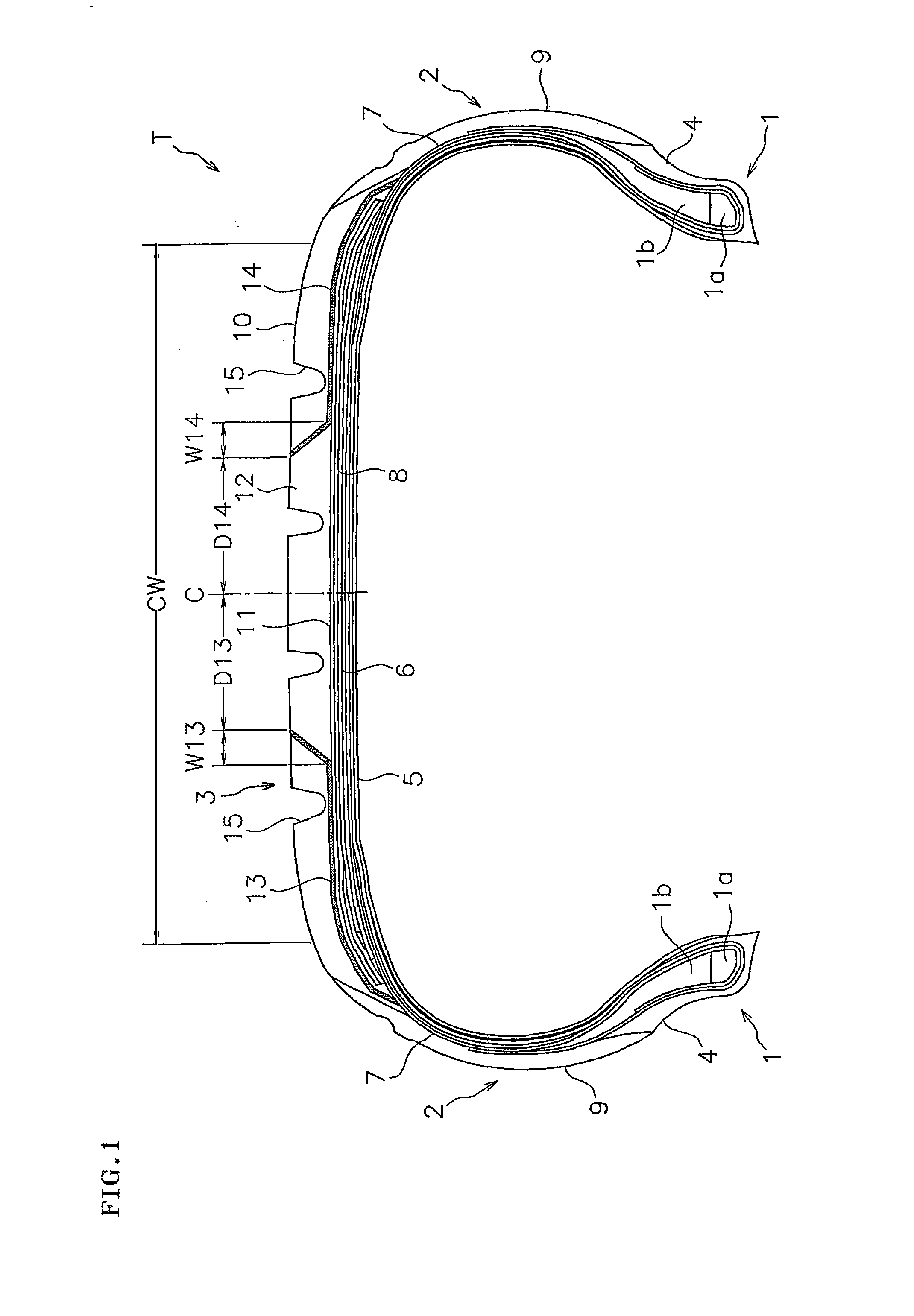

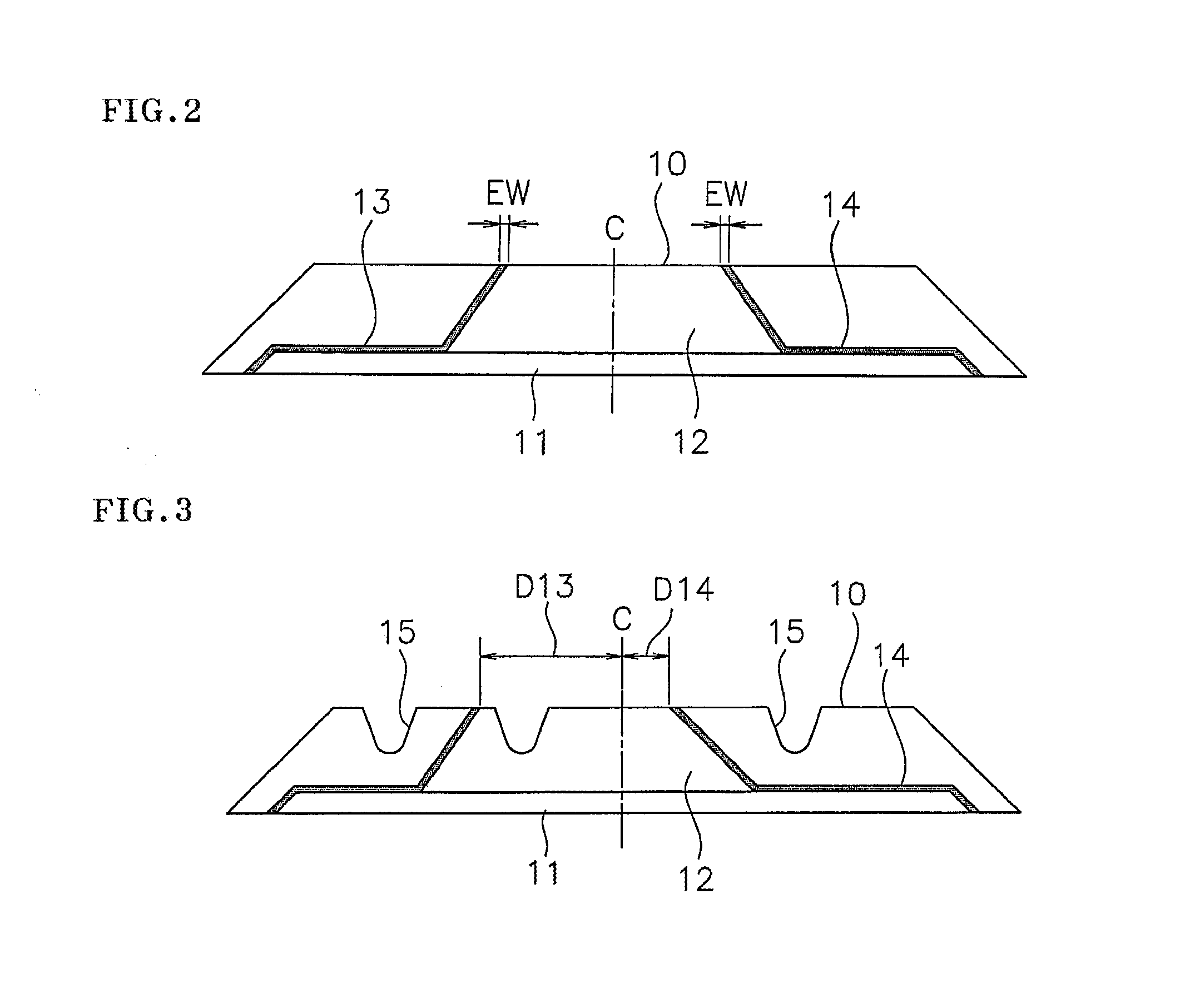

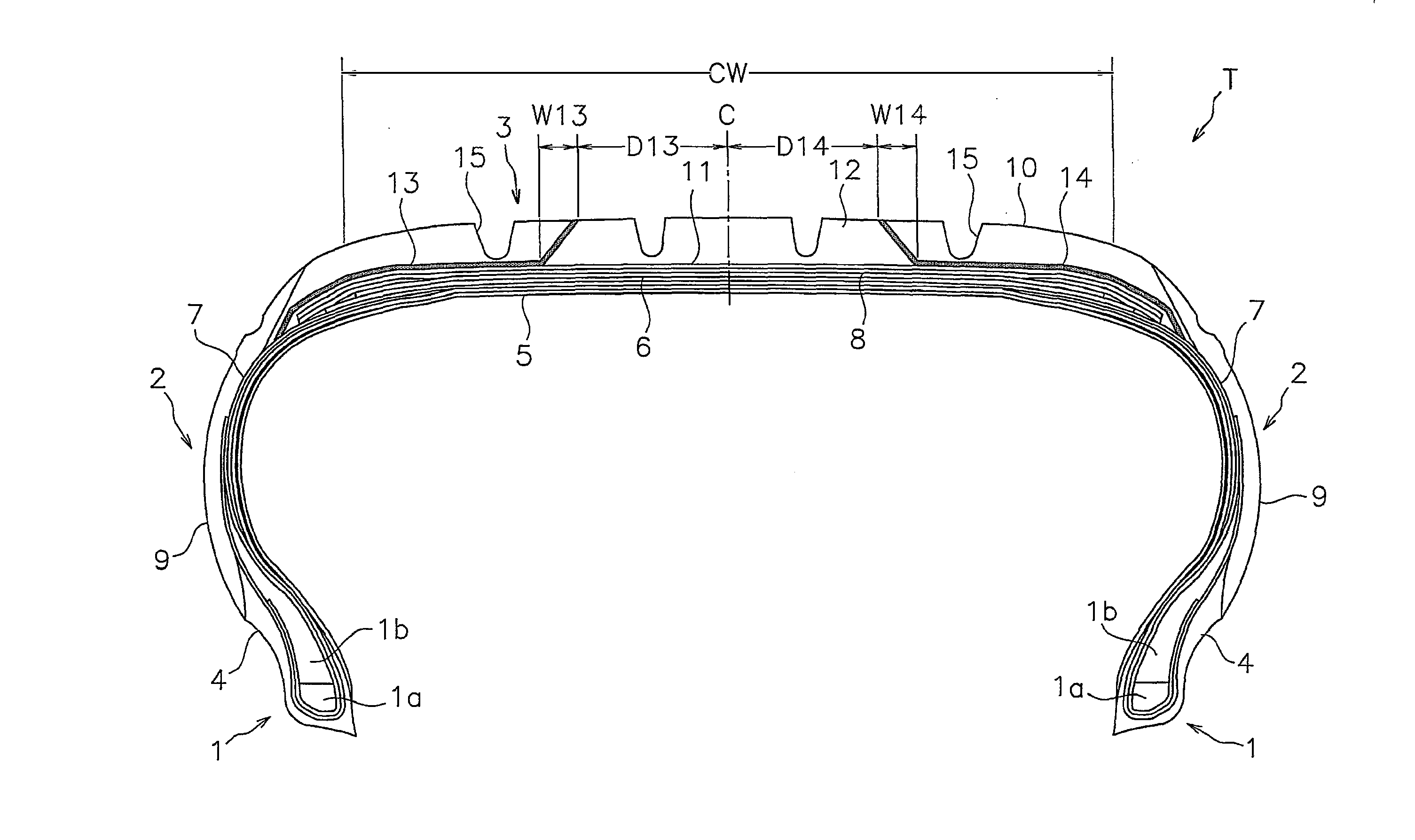

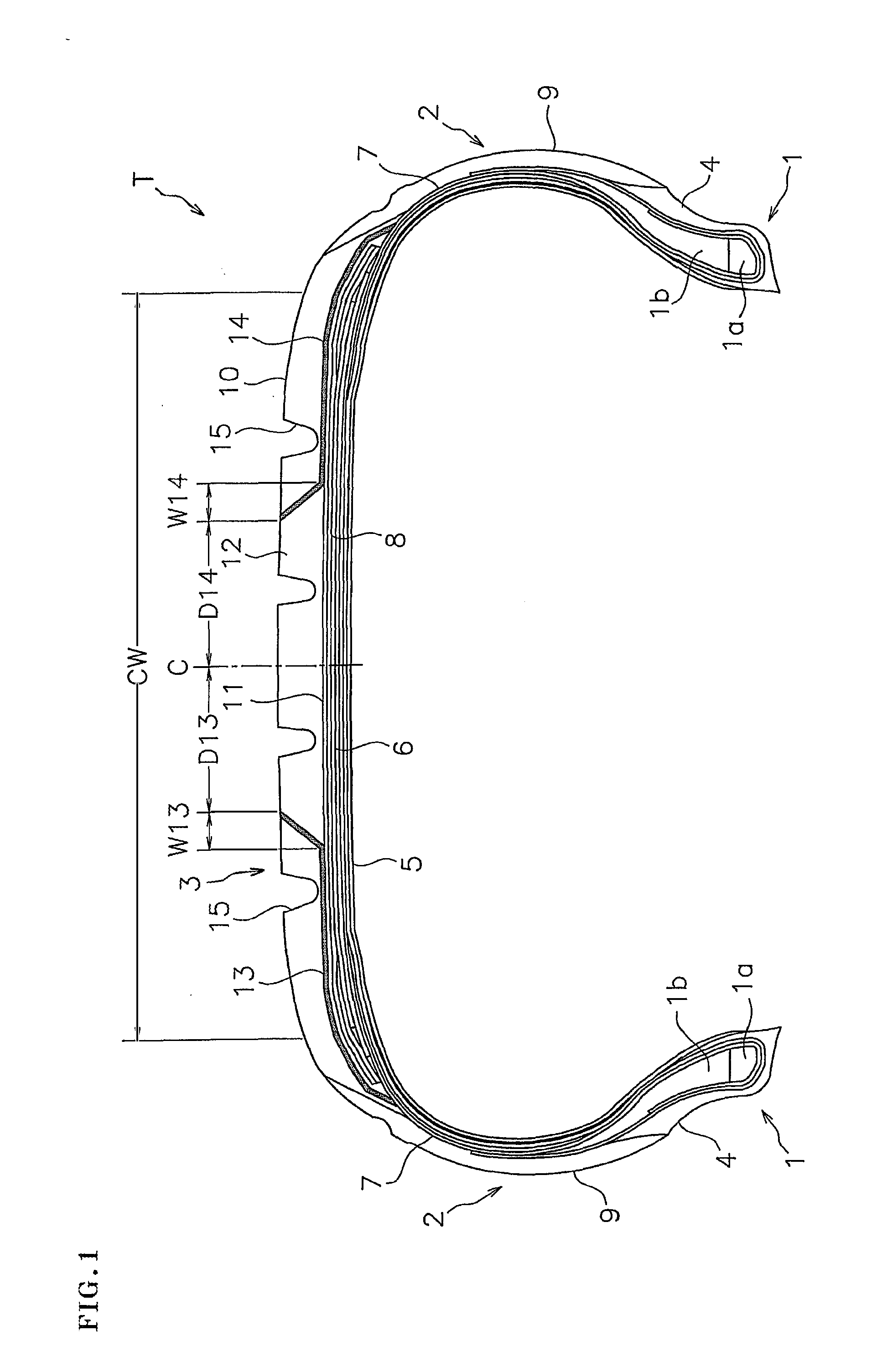

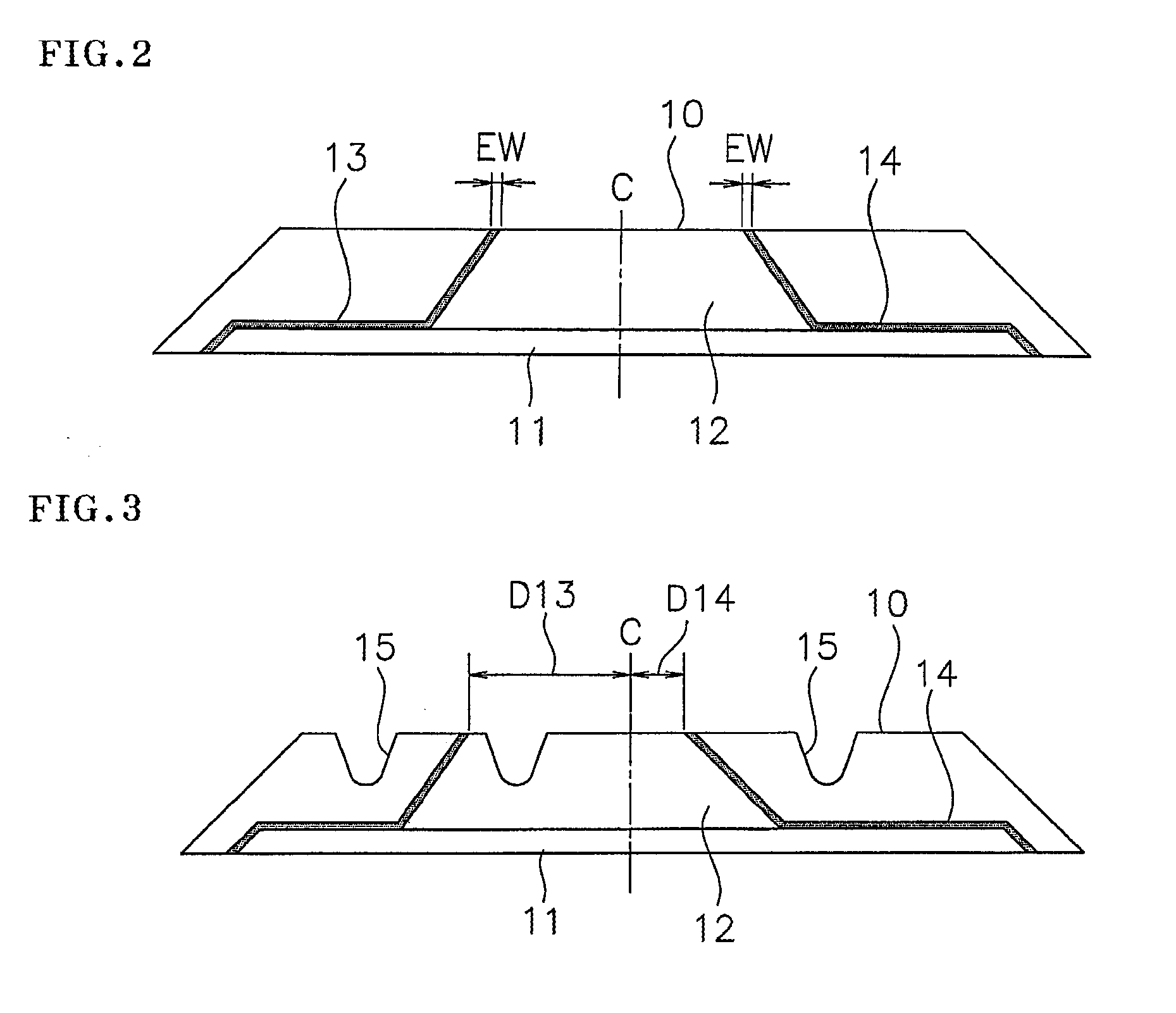

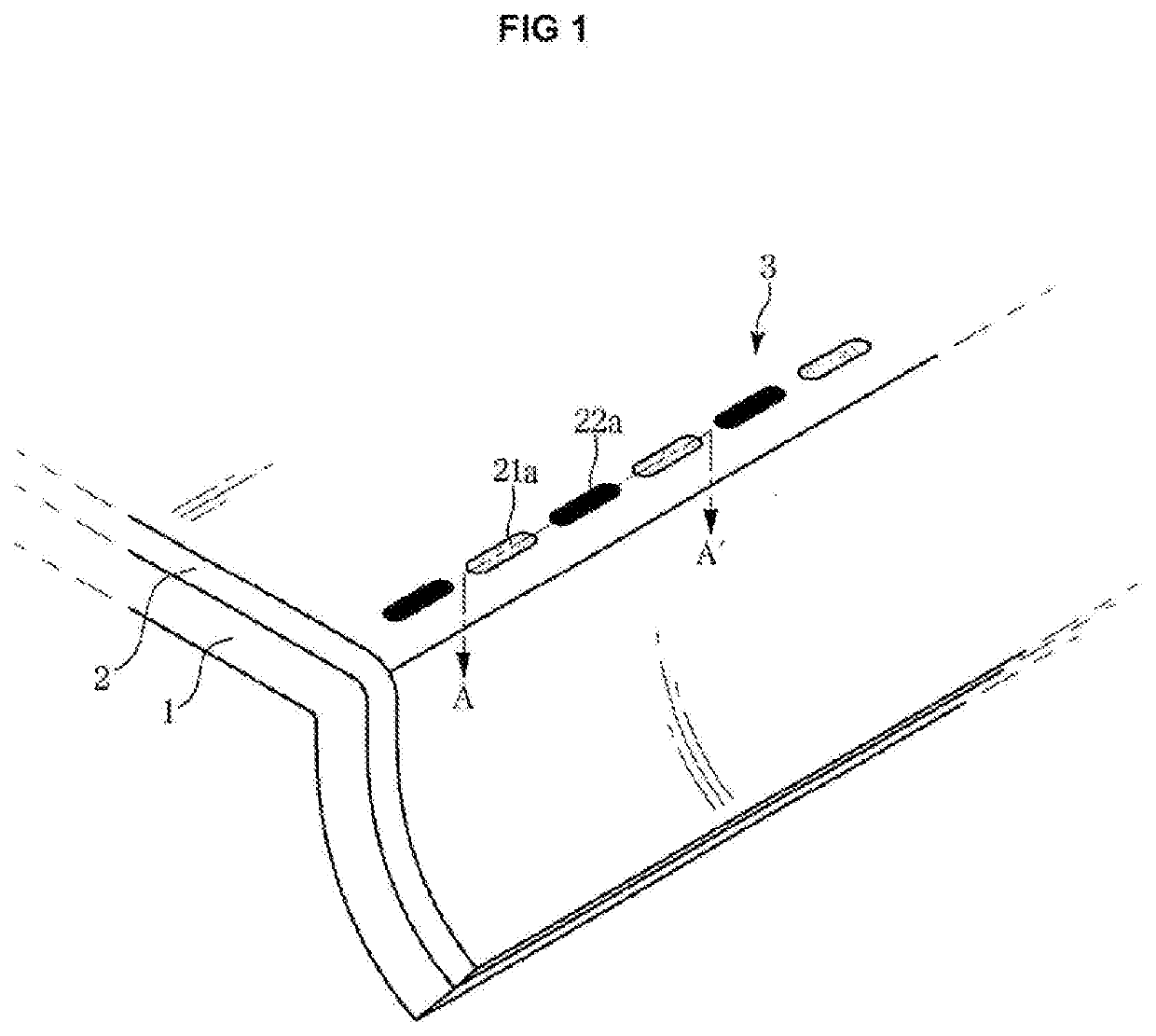

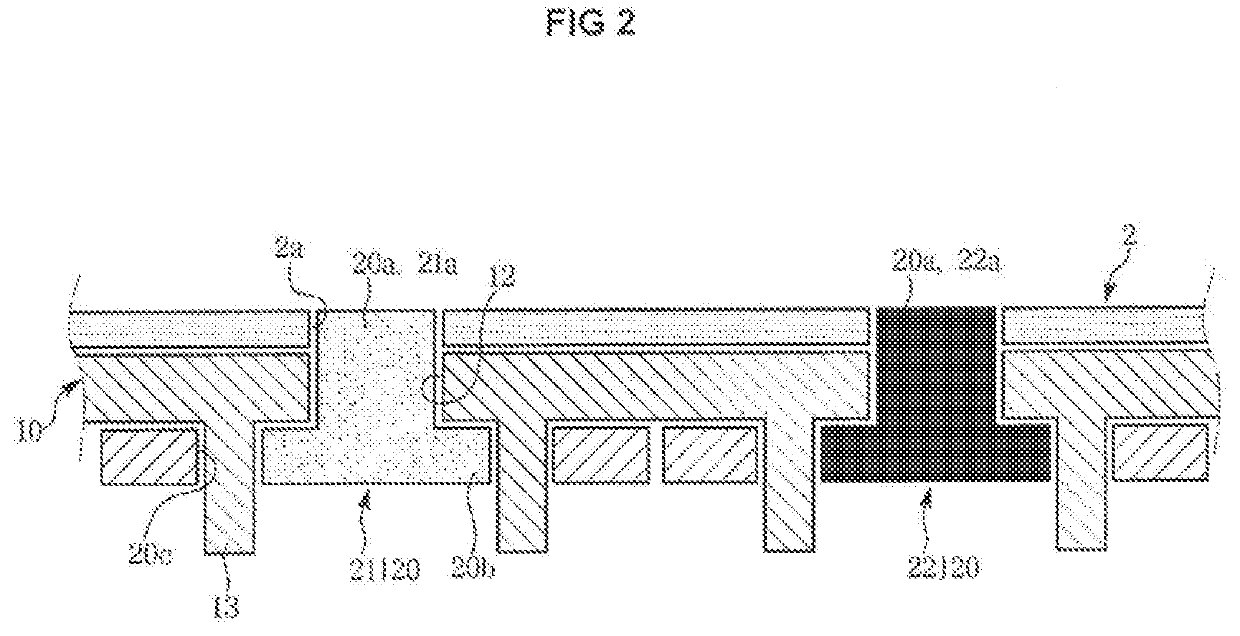

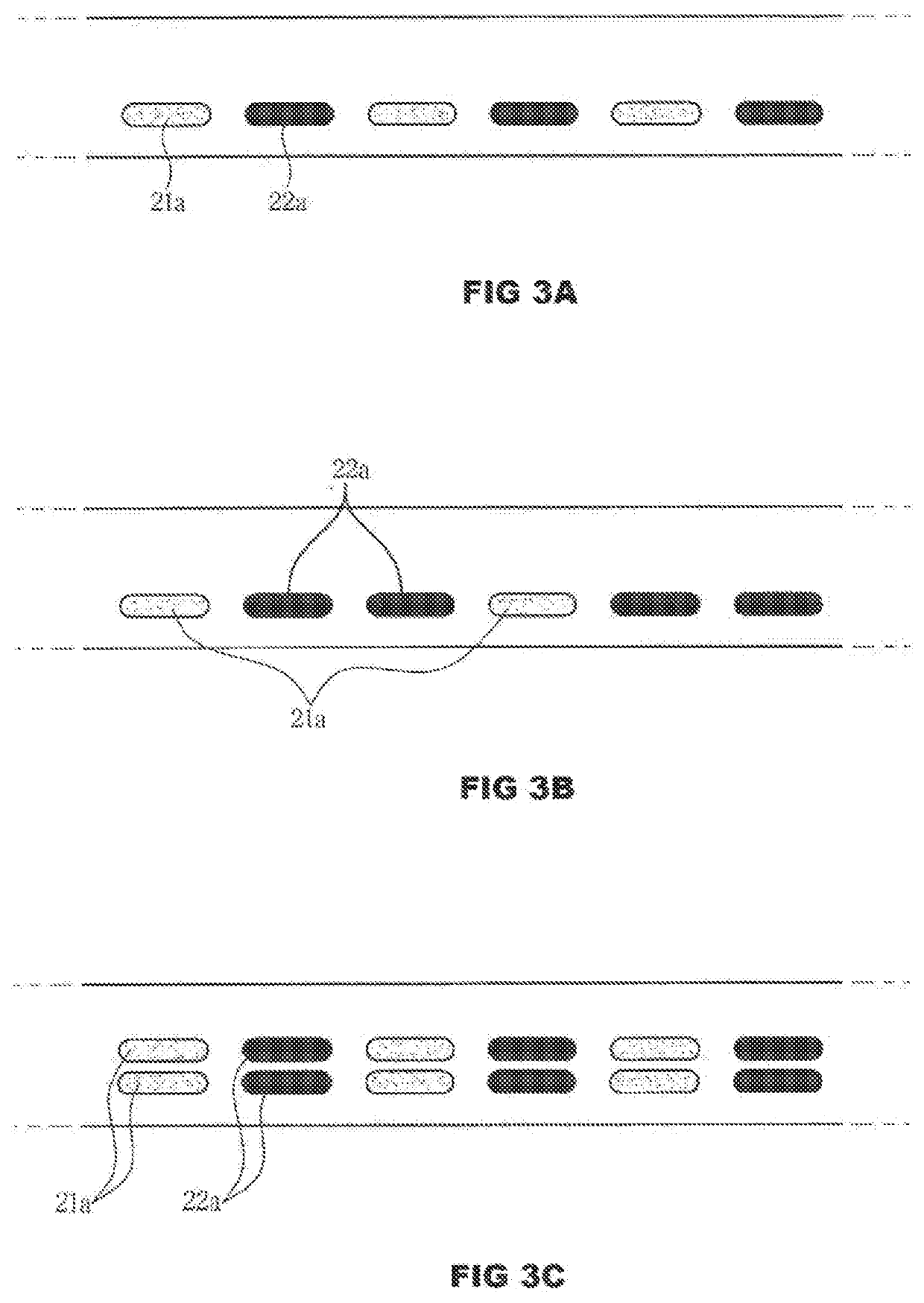

Pneumatic tire

ActiveUS20160280016A1Curb productivity declineUniformity deterioratesTyresPneumatic tyre reinforcementsGround contactTread

A pneumatic tire has a tread rubber made of a nonconductive rubber. The tread rubber is provided with a first and second conductive portions made of a conductive rubber. The first conductive portion extends radially inwardly from a ground-contacting surface, extends to one side in tire width direction, and reaches a carcass layer or a side wall rubber. An exposed position of the first conductive portion is separated from a tire equator at a distance is equal to or more than 10% of a ground-contacting width. The second conductive portion extends radially inwardly from the ground-contacting surface, extends to another side in tire width direction, and reaches the carcass layer or the side wall rubber. An exposed position of the second conductive portion is separated from the tire equator at a distance is equal to or more than 10% of the ground-contacting width.

Owner:TOYO TIRE & RUBBER CO LTD

Image forming apparatus

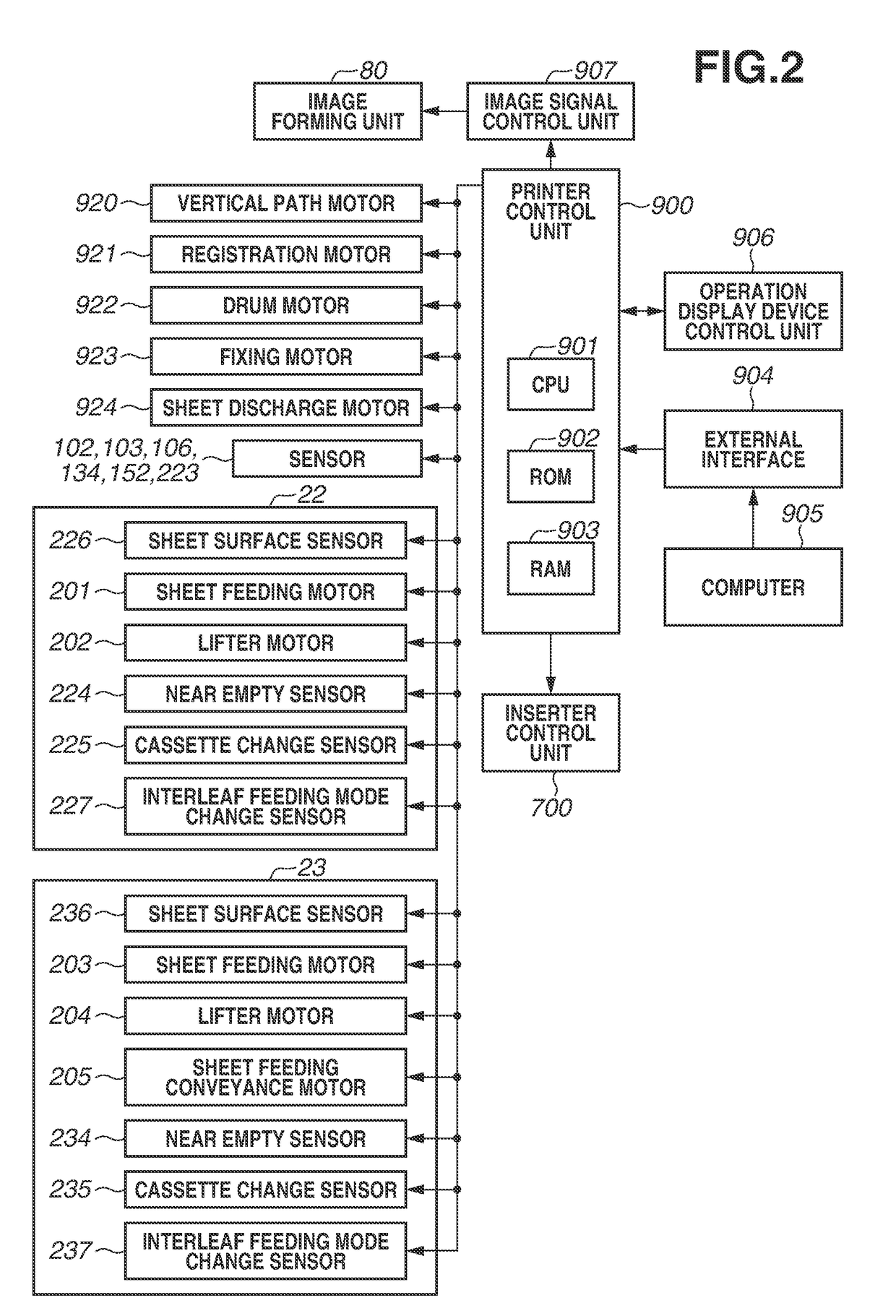

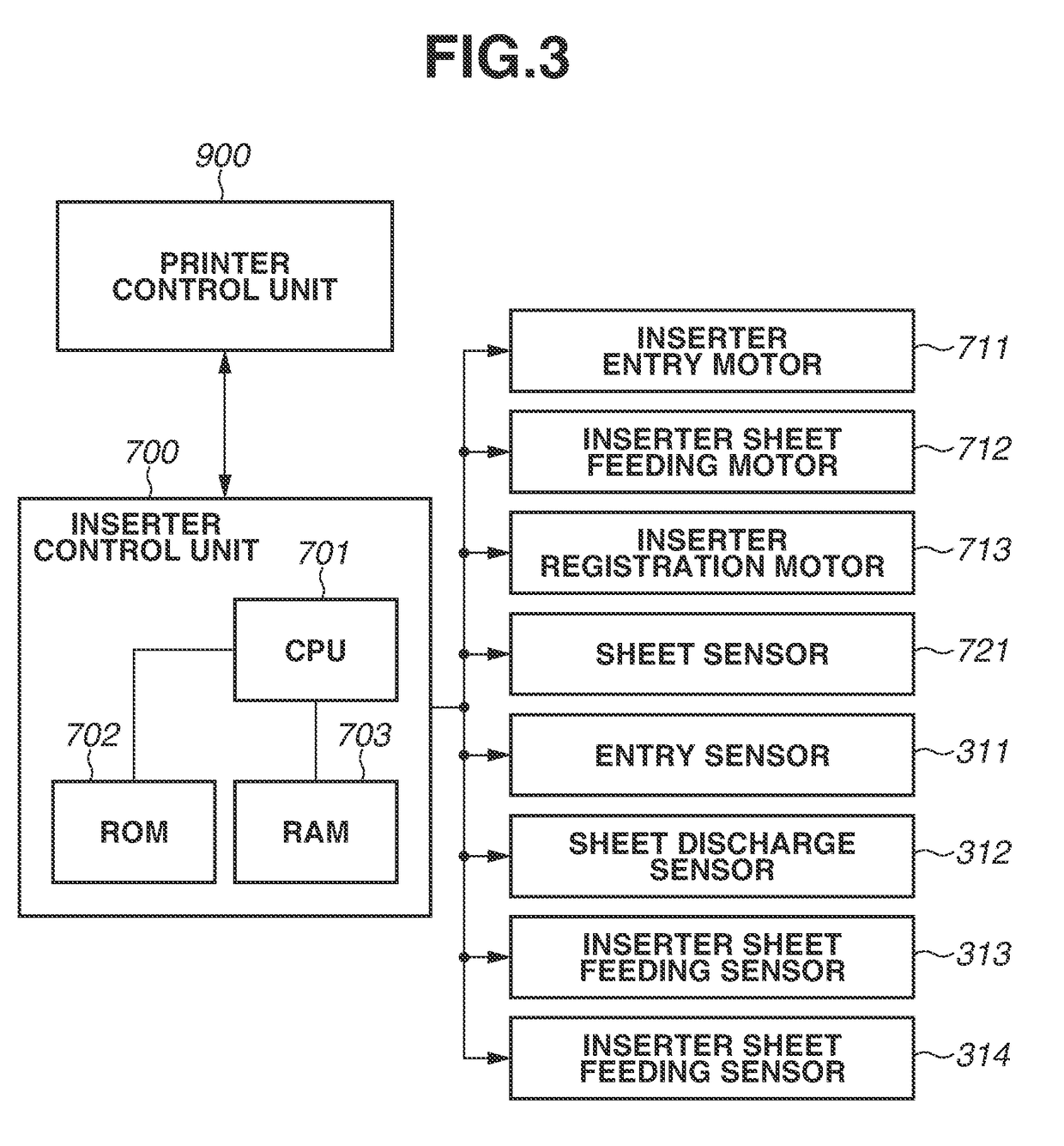

ActiveUS20180348687A1Increase productivityCurb productivity declineElectrographic process apparatusPictoral communicationImage formationComputer science

An image forming apparatus configured to change an interleaf control mode from a not confirmed sheet-feeding mode to a sheet-presence confirmed sheet-feeding mode when a remaining amount of recording sheets is less than a first threshold, wherein the image forming apparatus has a first mode of changing a feeding origin of a recording sheet, according to detection of absence of a recording sheet in a storage unit by a sheet presence / absence detection unit during execution of an image forming job, and a second mode of changing a feeding origin of a recording sheet, according to detection of a recording-sheet remaining amount of the storage unit less than a second threshold during execution of an image forming job, and wherein the second threshold is larger than the first threshold for changing an interleaf control mode.

Owner:CANON KK

Substrate processing apparatus, substrate processing system, and substrate processing method

InactiveUS20160240401A1Reduce entryCurb productivity declineSemiconductor/solid-state device manufacturingSpray nozzlesNozzleEngineering

A top plate when located at a first position is held by an opposing-member holder, and the top plate when located at a second position is held by a substrate holder and rotated along with the substrate holder. In a substrate processing apparatus, a first processing liquid nozzle located at a supply position inside a to-be-held part of the top plate supplies a first processing liquid through an opposing-member opening to a substrate and is moved from the supply position to its retracted position, and a second processing liquid nozzle is moved from its retracted position to the supply position and supplies a second processing liquid through the opposing-member opening to the substrate. This configuration suppresses or prevents mixture of multiple types of processing liquids, as compared with the case where multiple types of processing liquids are sequentially supplied from a single processing liquid nozzle.

Owner:DAINIPPON SCREEN MTG CO LTD

Pneumatic tire and manufacturing method of the same

ActiveUS20130068358A1Efficiently accurately provideAvoid rangeTyresPneumatic tyre reinforcementsGround contactEngineering

A pneumatic tire has a tread rubber made of a nonconductive rubber. The tread rubber is provided with a first and second conductive portions made of a conductive rubber. The first conductive portion extends radially inwardly from a ground-contacting surface, extends to one side in tire width direction, and reaches a carcass layer or a side wall rubber. An exposed position of the first conductive portion is separated from a tire equator at a distance is equal to or more than 10% of a ground-contacting width. The second conductive portion extends radially inwardly from the ground-contacting surface, extends to another side in tire width direction, and reaches the carcass layer or the side wall rubber. An exposed position of the second conductive portion is separated from the tire equator at a distance is equal to or more than 10% of the ground-contacting width.

Owner:TOYO TIRE & RUBBER CO LTD

Printing control apparatus, printing control method, and program

InactiveUS8433215B2Curb productivity declineSuppress decrease in job productivityElectrographic process apparatusEngineeringComputer engineering

A printing control apparatus that causes printing by a printing unit having a fixing unit that fixes a recording agent on a sheet, the printing control apparatus including: a printing control unit configured to cause the printing unit to stop printing of a currently printing job, and print another job in a state that printing of the job has been stopped; and a determining unit configured to determine whether or not to permit execution of the other job in a state that the currently printing job has been stopped by the printing control unit, based on a fixing unit temperature necessary for printing of the currently printing job and a fixing unit temperature necessary for execution of the other job.

Owner:CANON KK

Image forming apparatus

InactiveUS20060127140A1Suppress decrease in productivityCurb productivity declineElectrographic process apparatusEngineeringElectrical and Electronics engineering

Owner:CANON KK

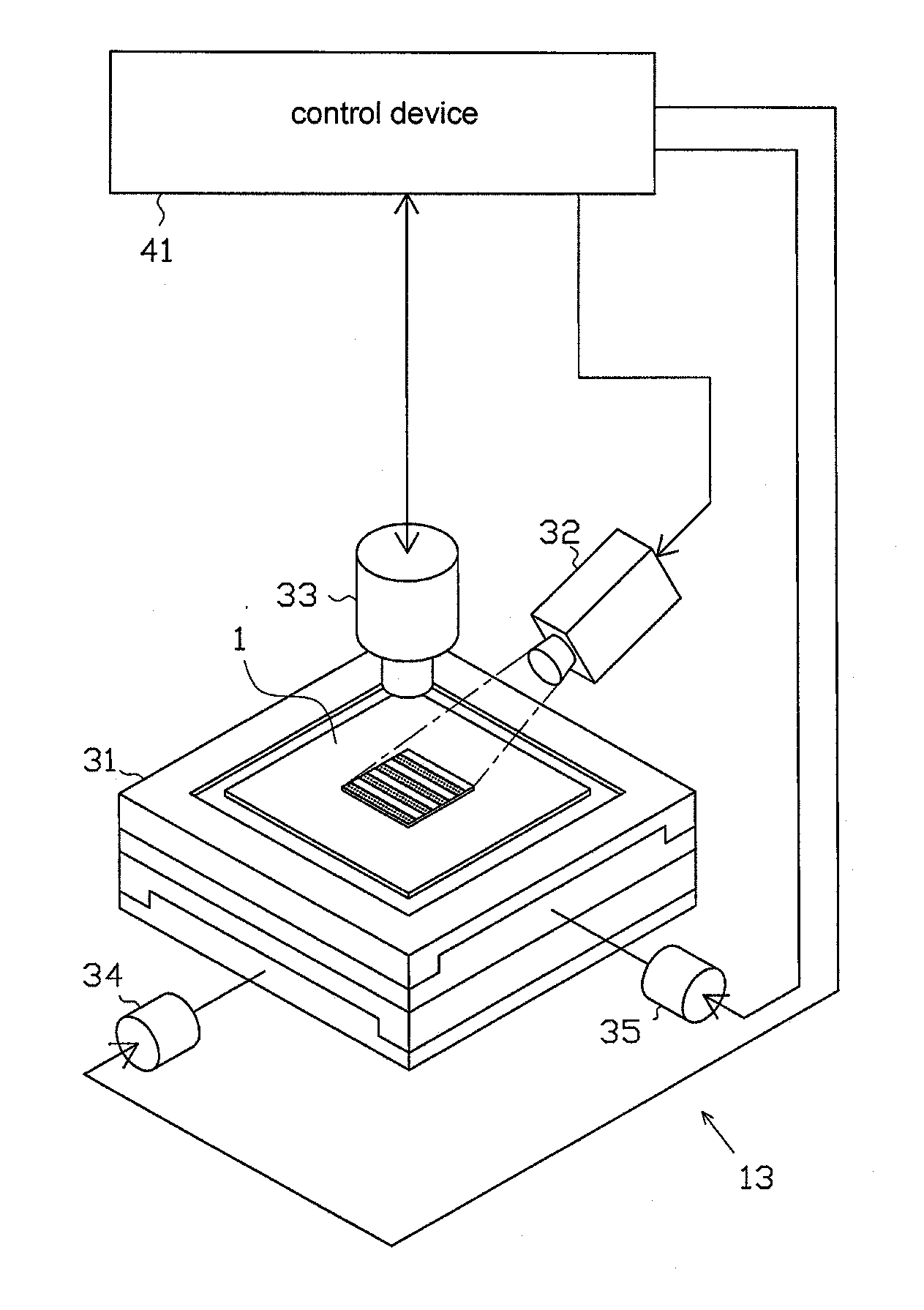

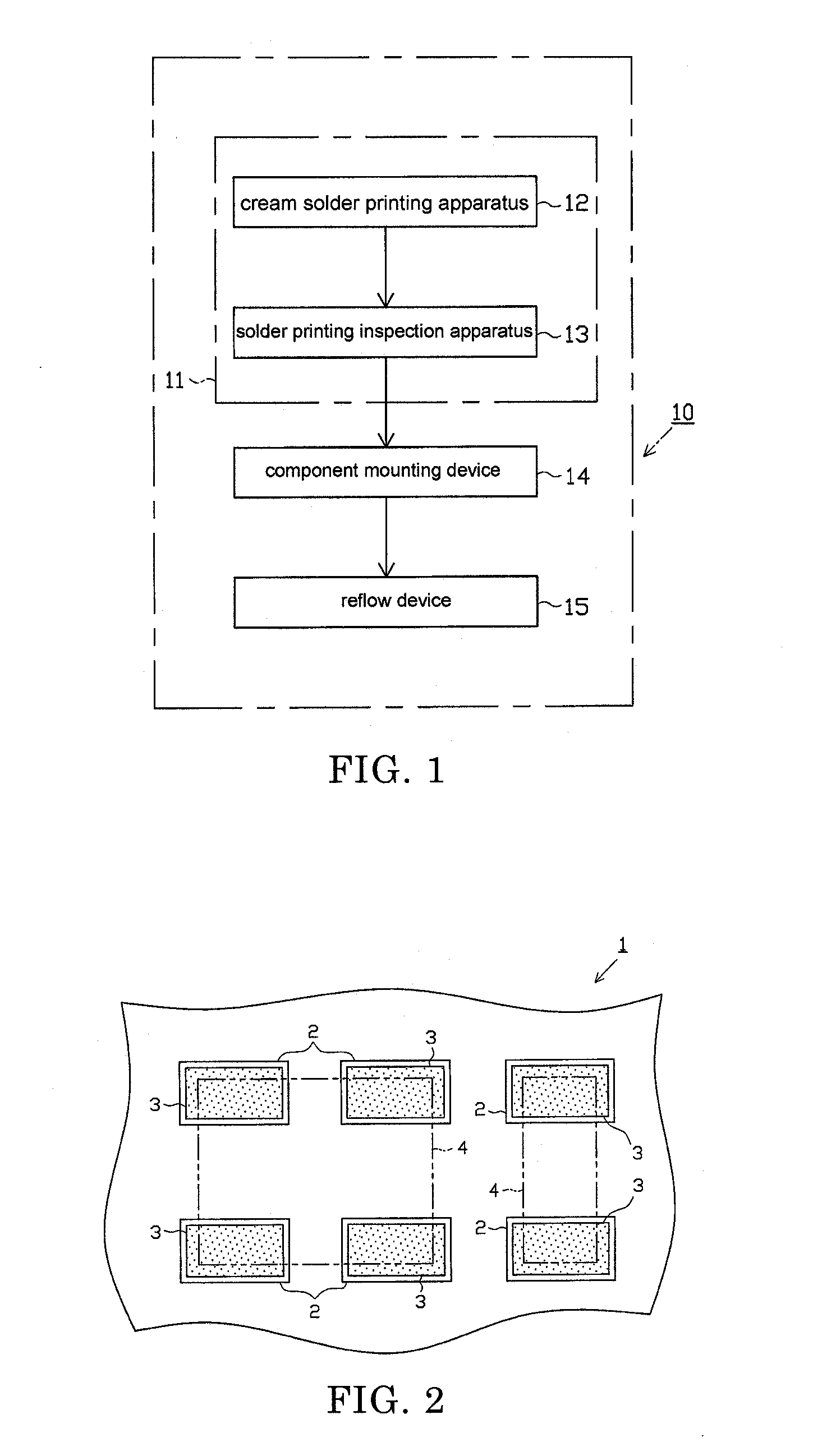

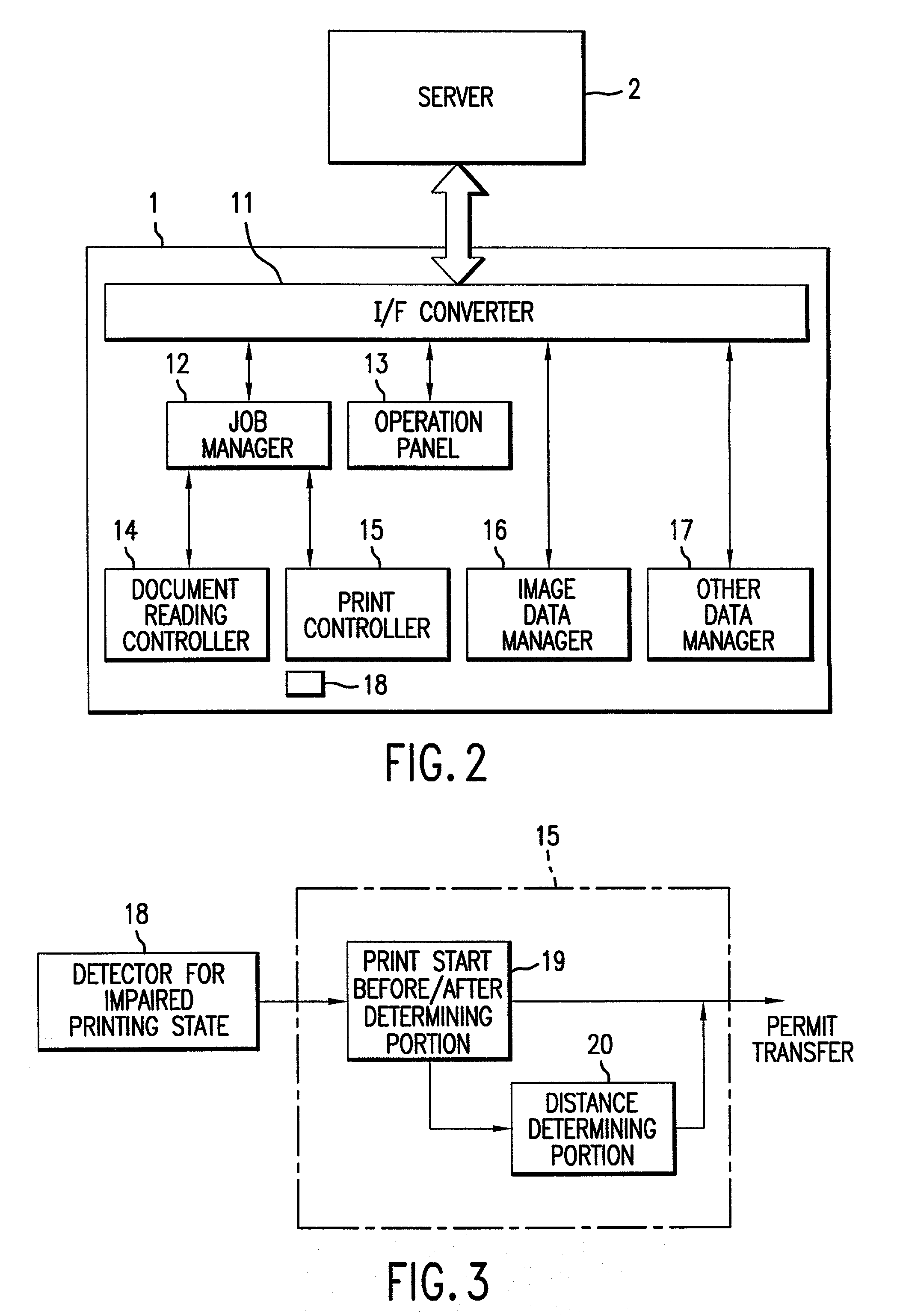

Solder printing inspection apparatus and solder printing system

ActiveUS20110216186A1Increase productivityCurb productivity declineMaterial analysis by optical meansCharacter and pattern recognitionLand basedEngineering

A solder printing inspection apparatus for inspection of solder printed on a circuit board has a multiplicity of lands for mounting of electronic components. The apparatus includes an irradiation unit for irradiating a light on the circuit board, an imaging unit for imaging the circuit board irradiated by the light, a solder bridge detection unit for detecting a solder bridge connecting two of the lands based on an image data imaged by the imaging unit, a distance calculation unit for calculating a bridge distance as distance between two lands contacting the solder bridge or solder bridging regions or solder detection frames corresponding to the two lands contacting the solder bridge, and a distance determination unit for determination of whether or not the bridge distance is within a permissible range.

Owner:CKD

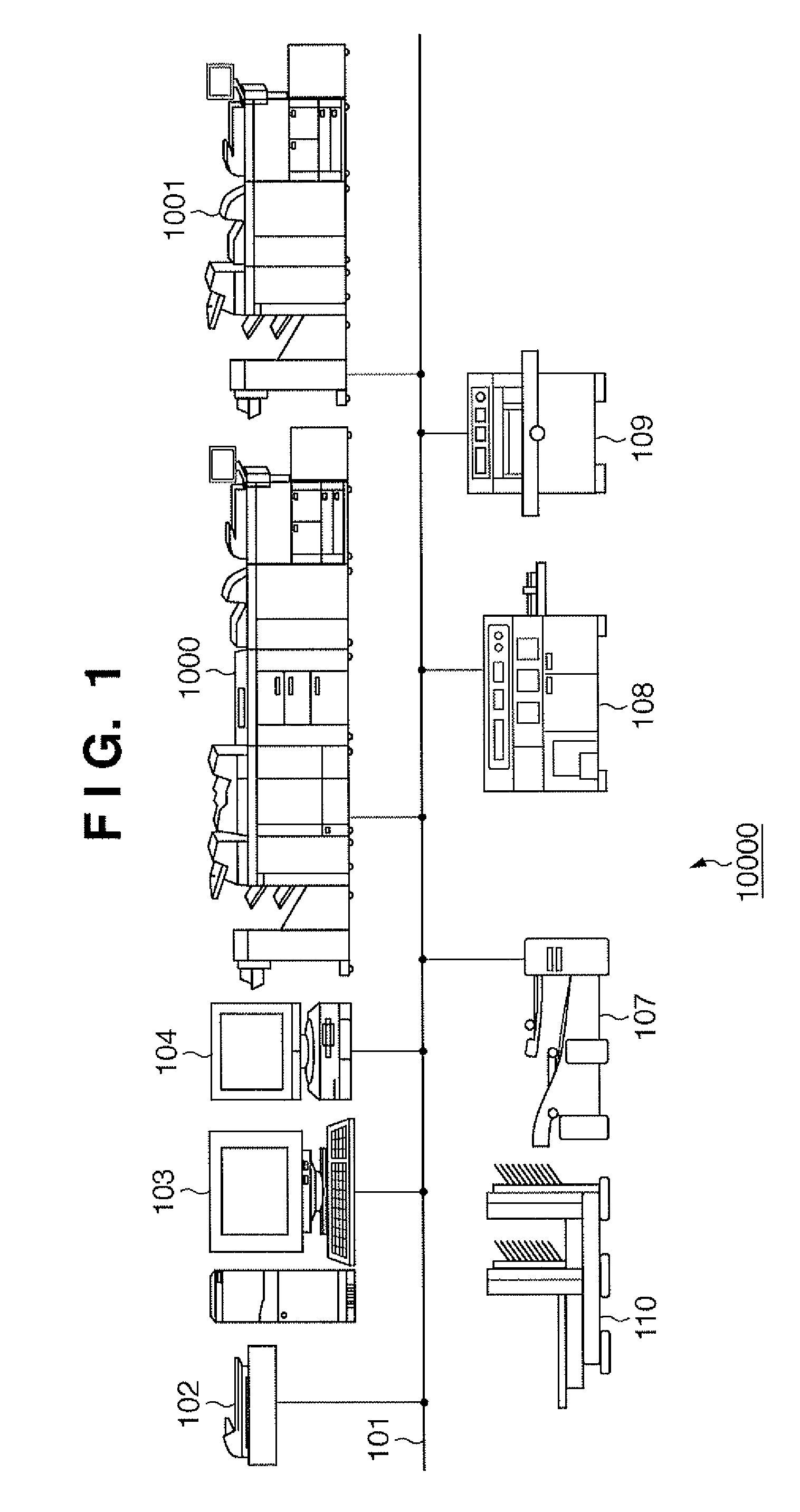

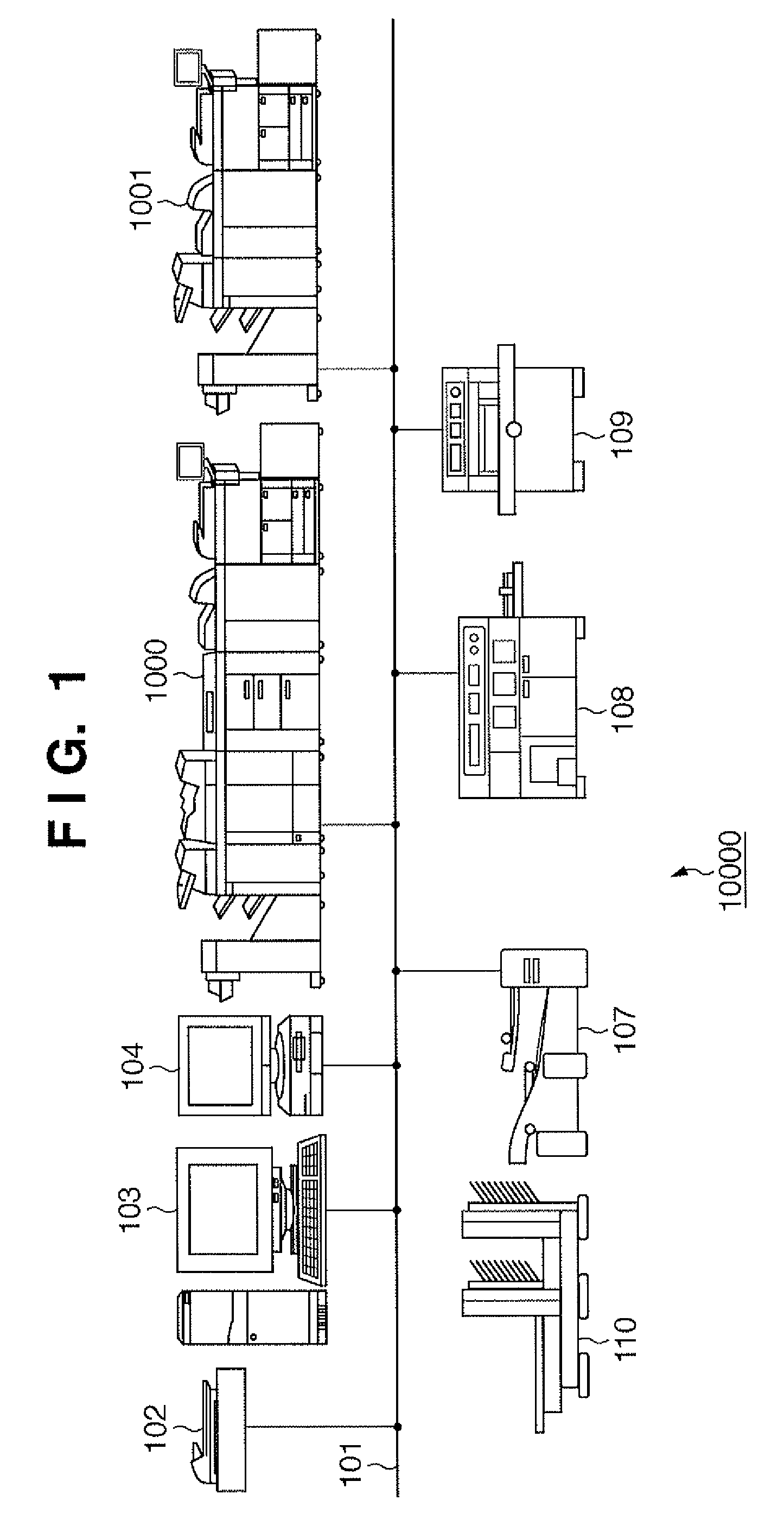

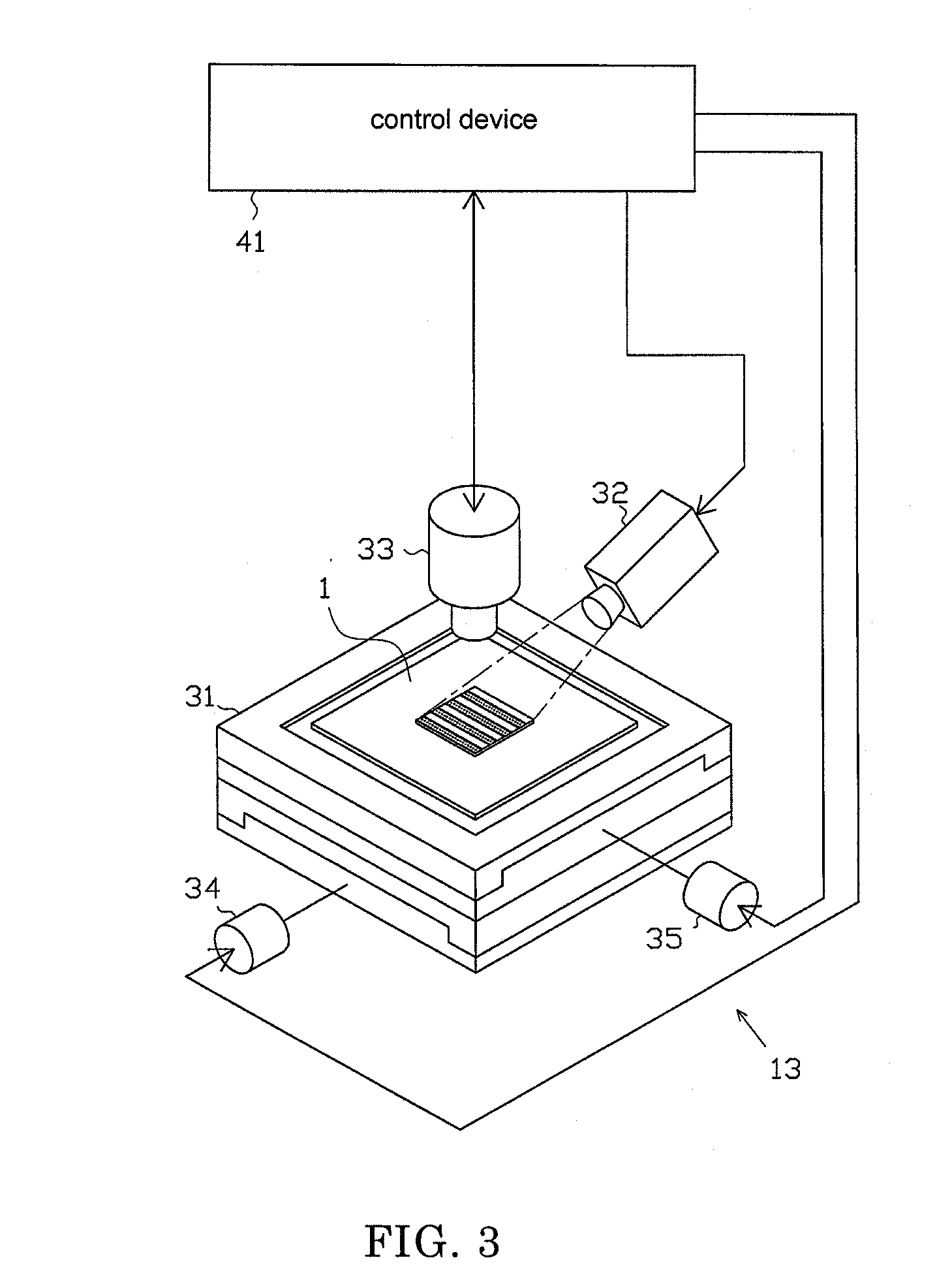

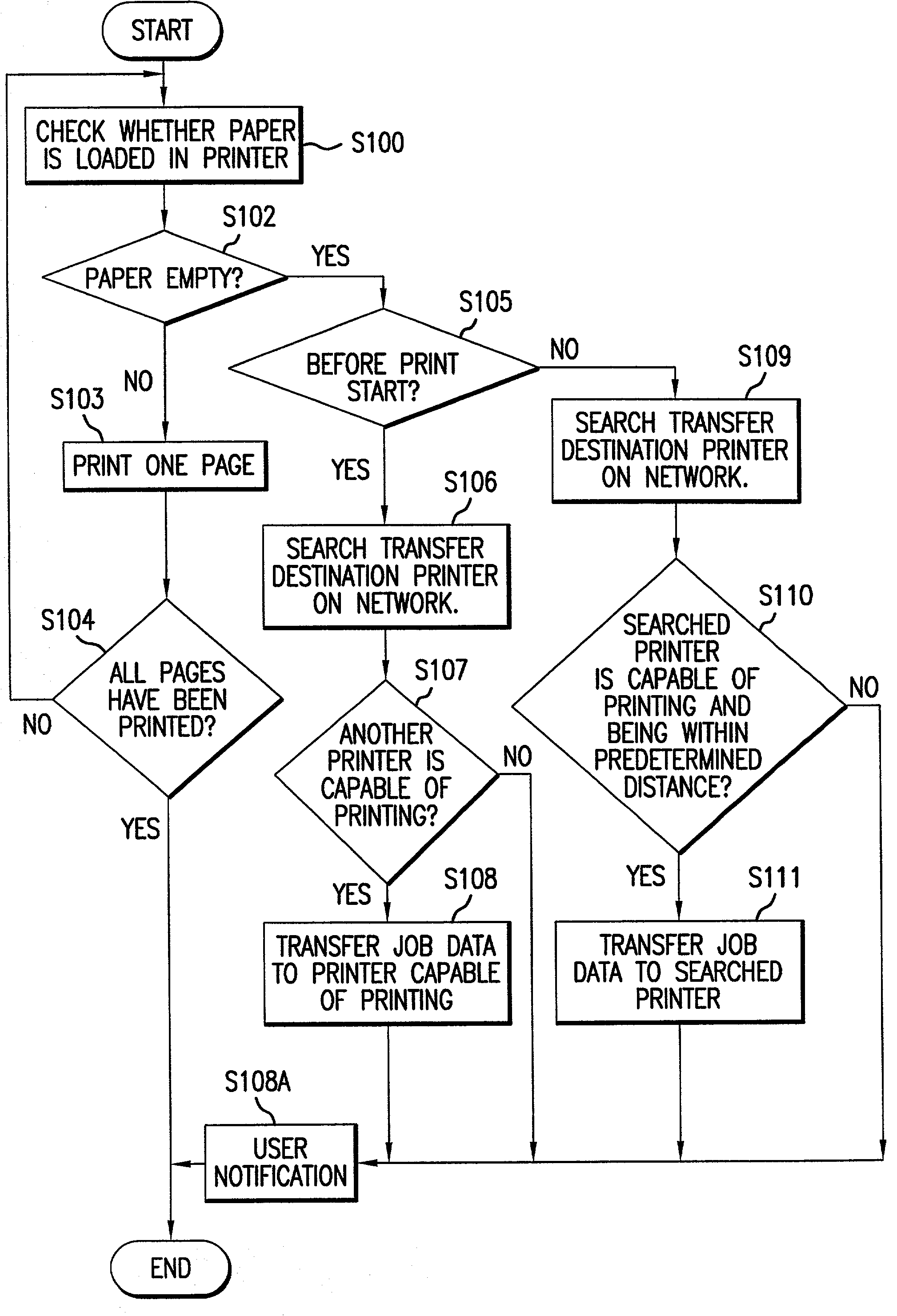

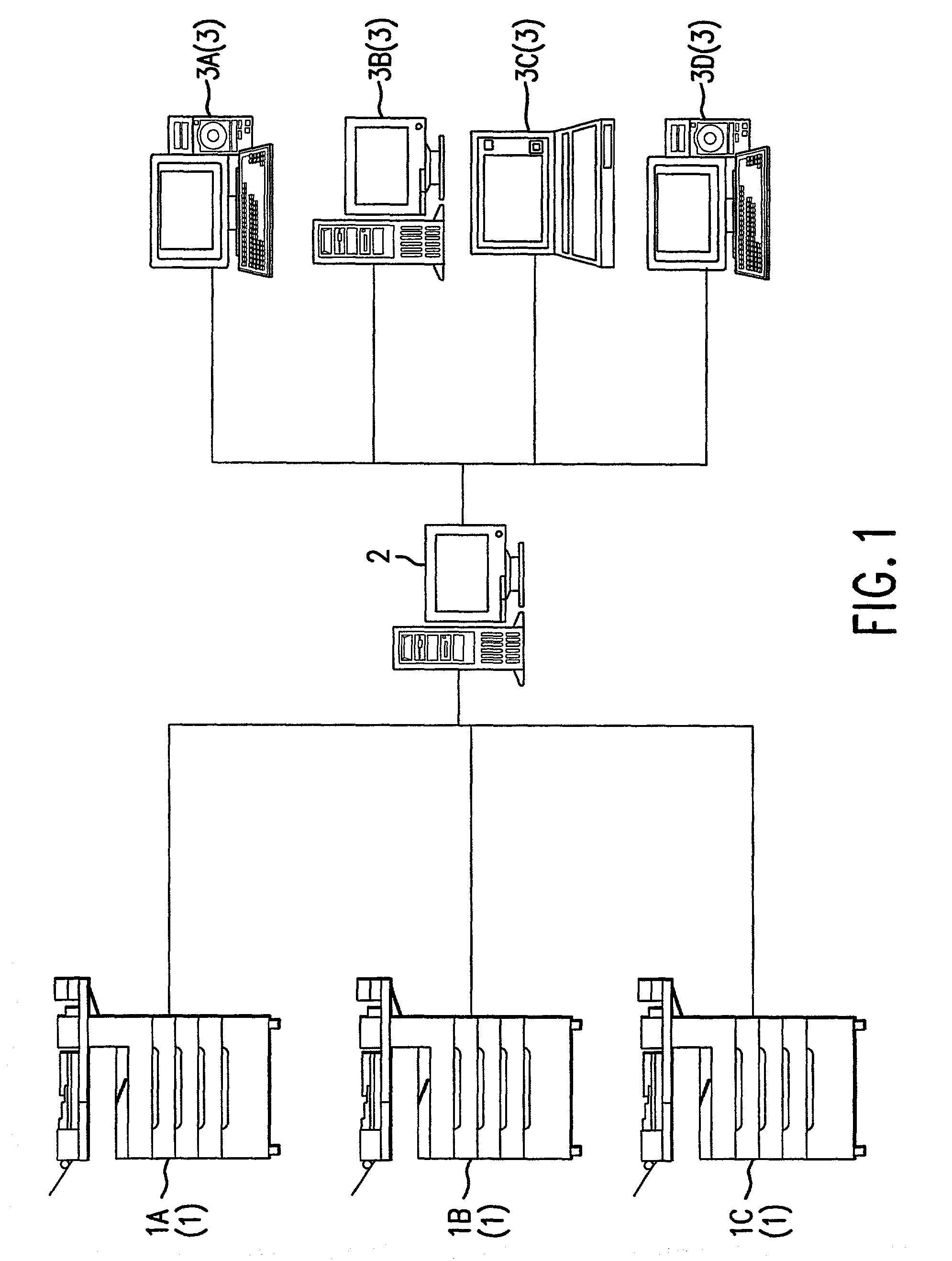

Image forming system and image forming apparatus for transferring job data when an impaired image forming state is detected

ActiveUS7110131B2Decrease productivityHinder taskElectrographic process apparatusVisual presentationProduction rateImage formation

An image forming system and image forming apparatus capable of suppressing reduced productivity and avoiding the troublesome task of sorting output materials even when image formation becomes impossible. The system and apparatus include a transfer controller that permits job data transfer to another image forming apparatus if image formation of the job data has not started when an impaired image forming state is detected in an image forming apparatus, and that prohibits job data transfer to another image forming apparatus if image formation of job data has already started. In this way, the image formation process can be executed without processing congestion by having another image forming apparatus perform the job data image formation. Moreover, the task of sorting the output material is unnecessary because the job data is not dispersed between the transfer origin and the transfer destination.

Owner:MINOLTA CO LTD

Image forming apparatus and control method therefor

InactiveUS7495683B2Curb productivity declineEnhance the imageRecording apparatusStereotype printingProduction rateImage formation

Owner:CANON KK

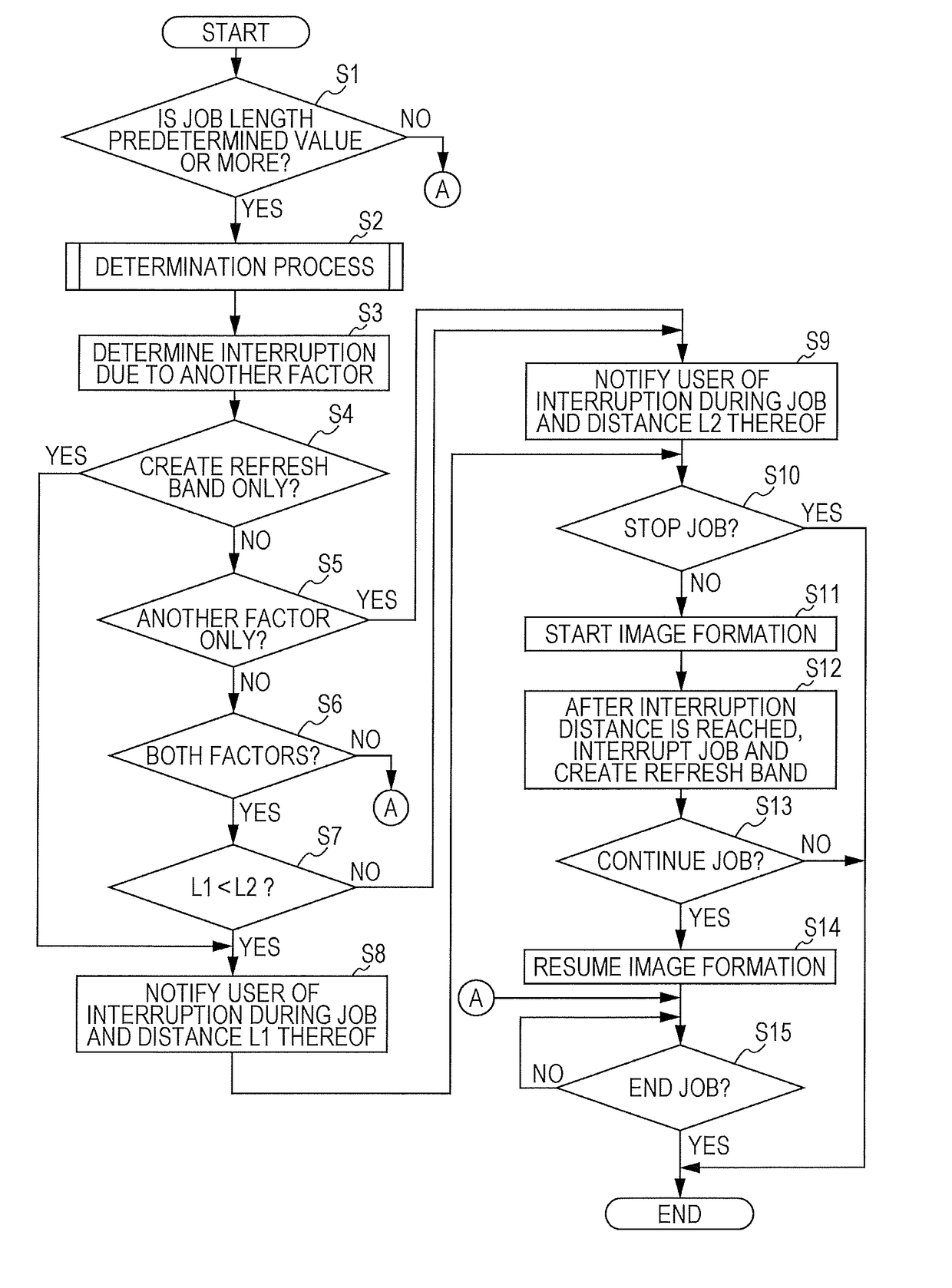

Image forming device and program

ActiveUS20170139361A1Suppress generationDecrease productivityElectrographic process apparatusPattern recognitionImage formation

An image forming device includes: an image forming unit configured to form a plurality of images on continuous paper based on a job; an image pattern creation unit configured to interrupt execution of the job and create an image pattern for consuming toner; a determination unit configured to determine necessity of creating the image pattern based on coverages of the images included in the job; and a calculation unit configured to, when the determination unit determines that it is necessary to create the image pattern, calculate a conveyance distance or a conveyance time of the continuous paper until creation of the image pattern, as interruption timing.

Owner:KONICA MINOLTA INC

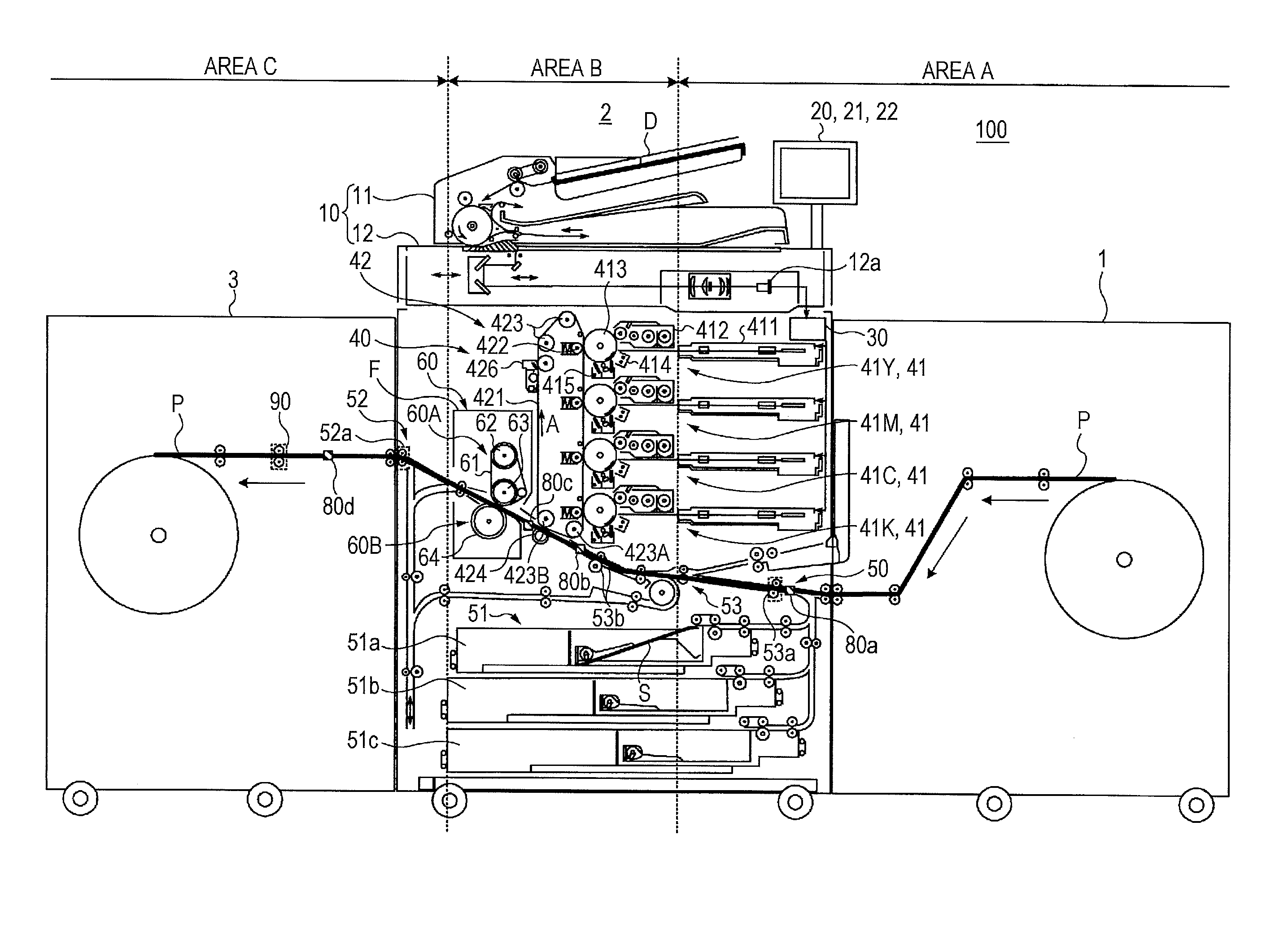

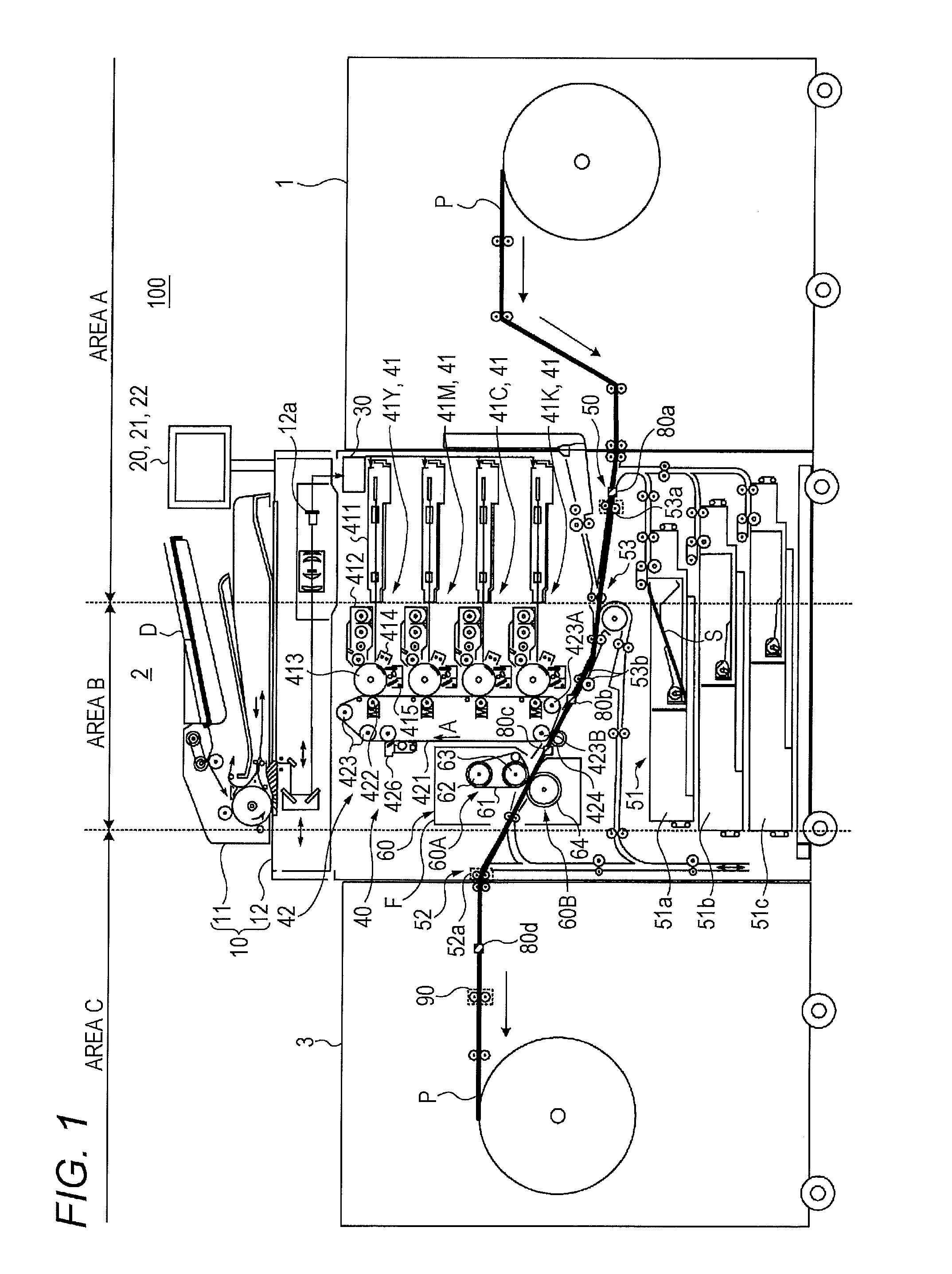

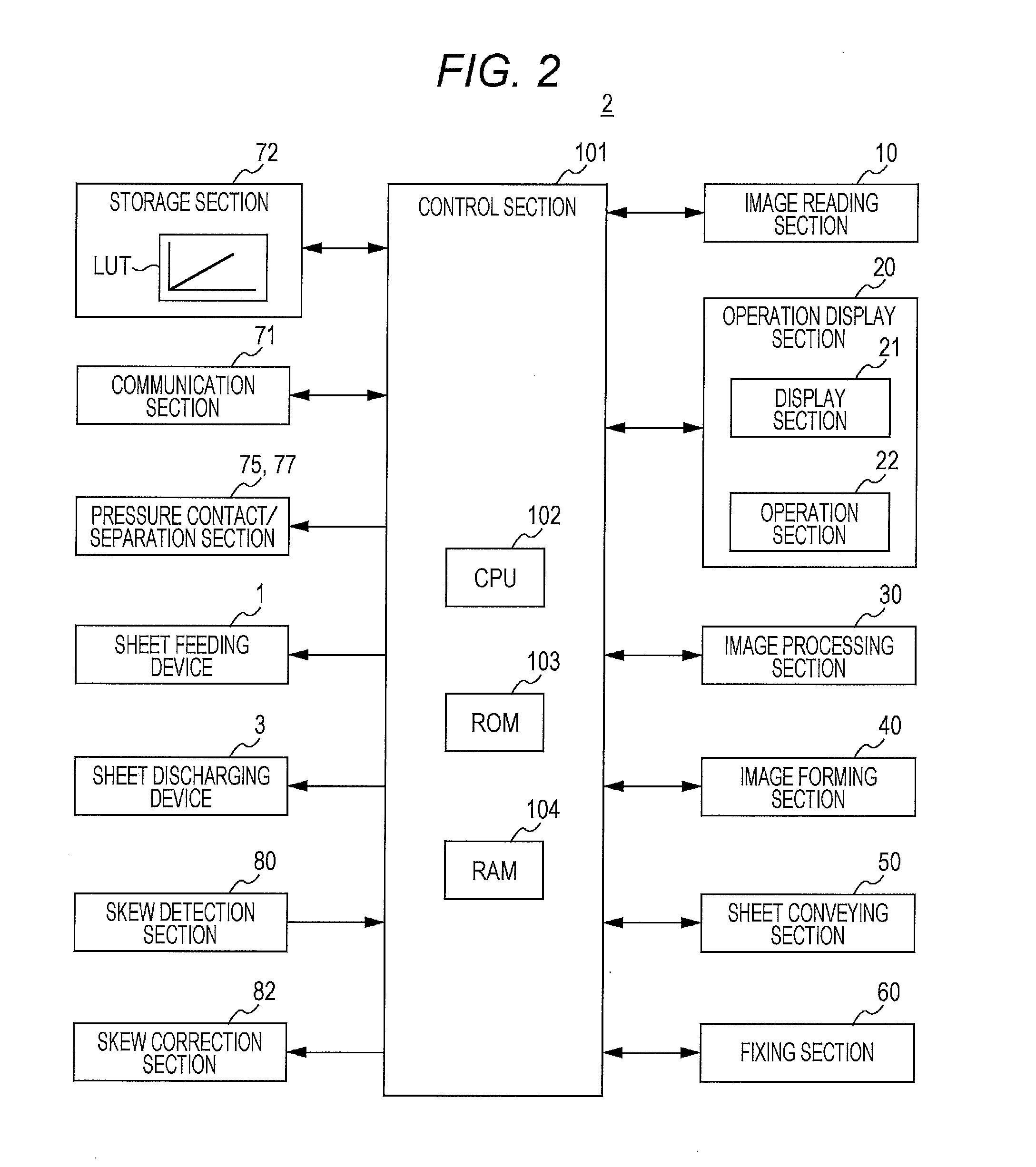

Image forming system, image forming apparatus, and skew correction method

ActiveUS20160236889A1Suppress deterioration of productivityCurb productivity declineElectrographic process apparatusWebs handlingImage formationEngineering

An image forming system includes: a sheet conveying section configured to convey a long sheet; an image forming / fixing section configured to execute an image forming / fixing operation to form and fix a toner image on the long sheet to be conveyed by the sheet conveying section; a skew detection section configured to detect a skew of the long sheet to be conveyed by the sheet conveying section; a skew correction section configured to execute a skew correction operation to correct the skew of the long sheet; and a control section configured to perform control to execute the skew correction operation when the skew has been detected in a first area where the skew correction operation does not affect the image forming / fixing operation, and perform control to execute the skew correction operation when the skew has been detected in a second area where the skew correction operation affects the image forming / fixing operation.

Owner:KONICA MINOLTA INC

Vehicle interior material having stitch line and method of implementing stitch line on vehicle interior material

InactiveUS20200391673A1Increase productivityCurb productivity declineSynthetic resin layered productsSuperstructure subunitsStructural engineeringMechanical engineering

Disclosed are a vehicle interior material having a stitch line and a method of implementing the stitch line on the vehicle interior material. The vehicle interior material includes a base material including a plurality of protrusions on a surface thereof, and a skin configured to cover the surface of the base material and including a plurality of holes into which the protrusions are fitted to be exposed to the outside in order to form a plurality of imitation stitches, wherein the plurality of imitation stitches is arranged in a row to form a stitch line, and the base material includes a main body and a coupling member coupled to the main body and including at least one of the protrusions.

Owner:DAWON ENG

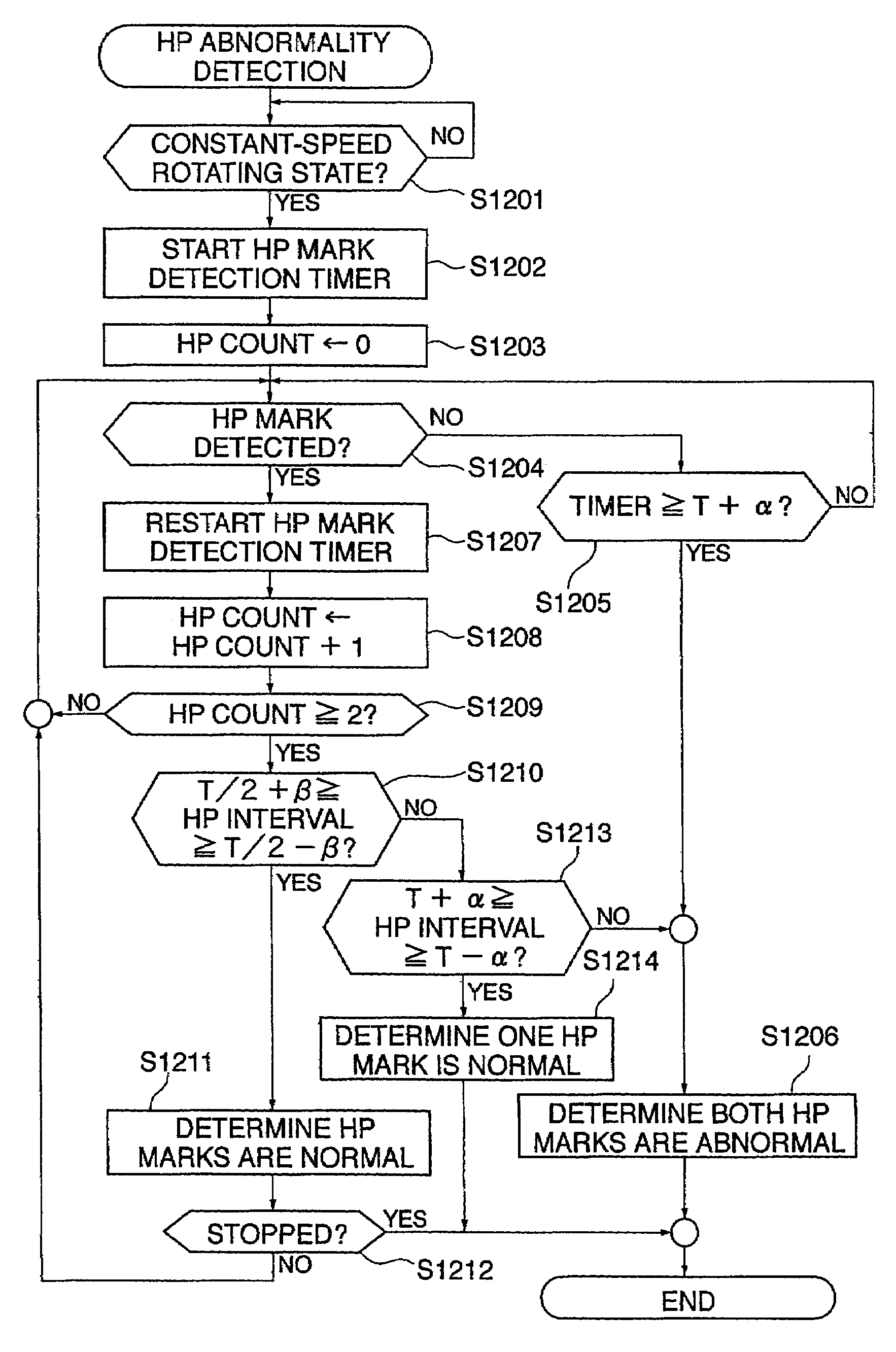

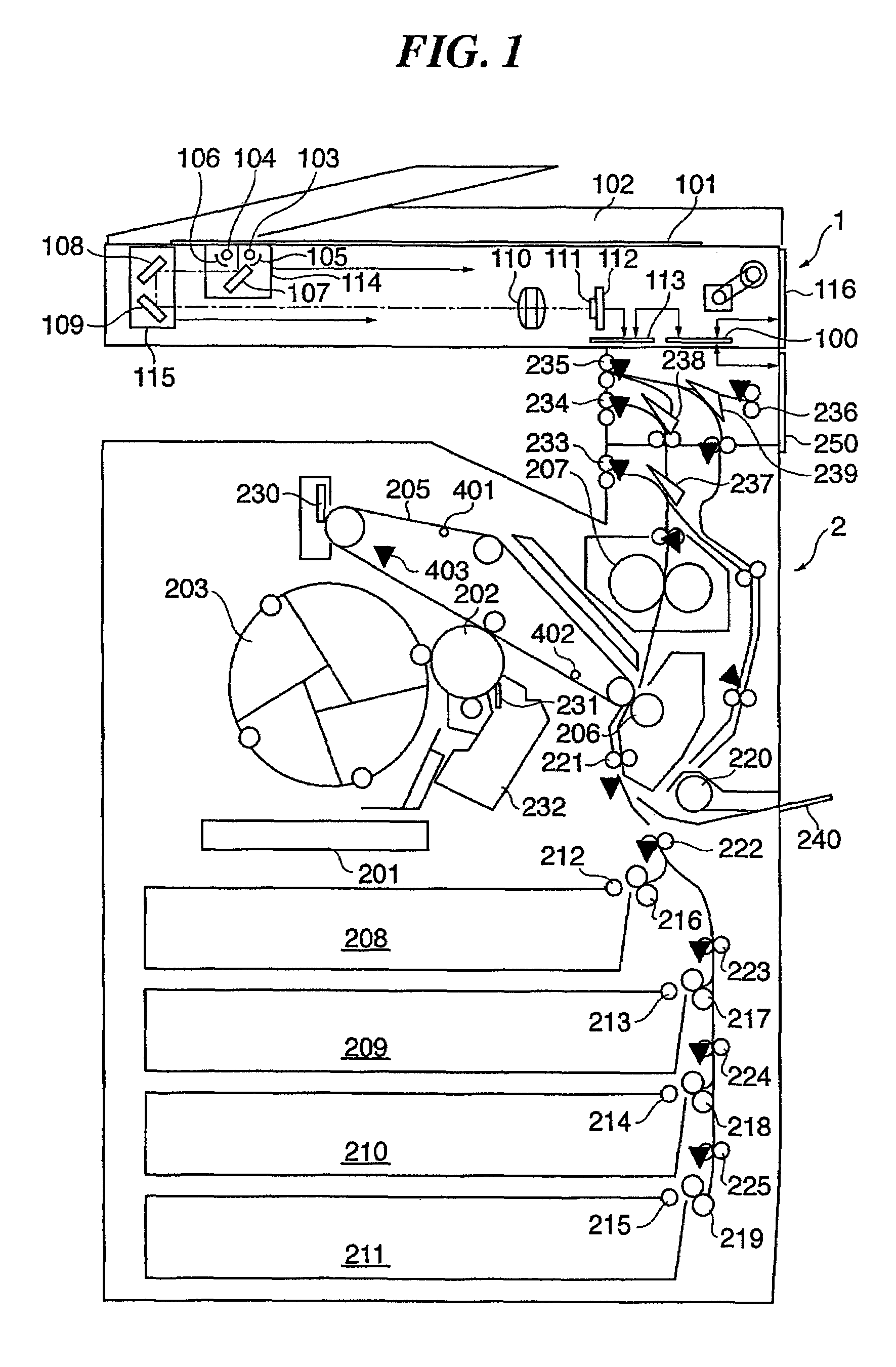

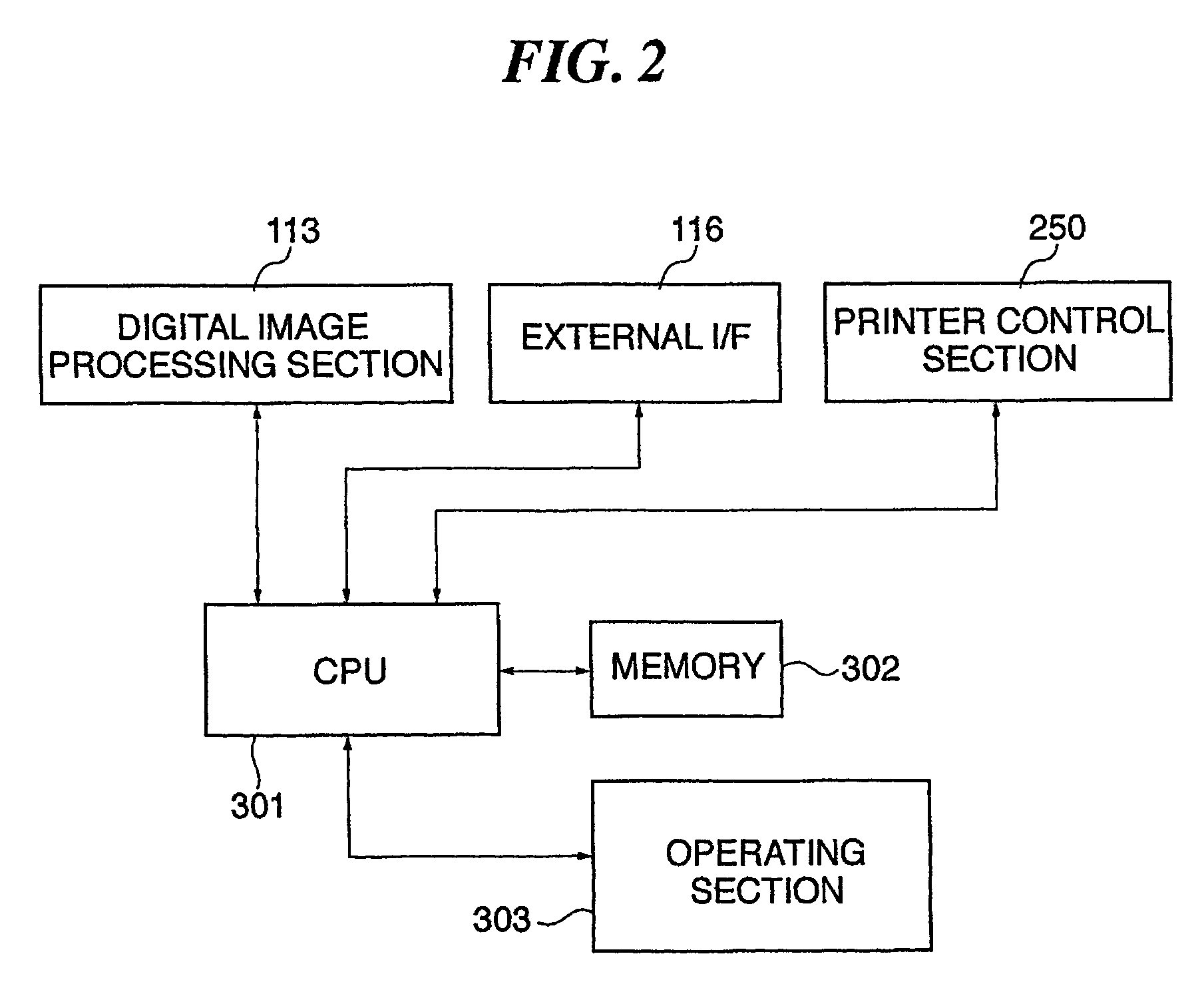

Image forming apparatus and control method therefor

InactiveUS20070144362A1Easy to optimizeDecrease productivityRecording apparatusStereotype printingProduction rateImage formation

An image forming apparatus which is capable of forming an excellent image while suppressing reduction in productivity to a minimum even when an abnormality occurs in detection of an HP mark on an intermediate transfer member. When there occurs abnormality in detection of any of HP marks, an alternate signal is generated in place of a signal associated with a mark the detection of which is determined to be abnormal, and image formation is carried out with reference to the time of normal HP mark detection and the alternate signal.

Owner:CANON KK

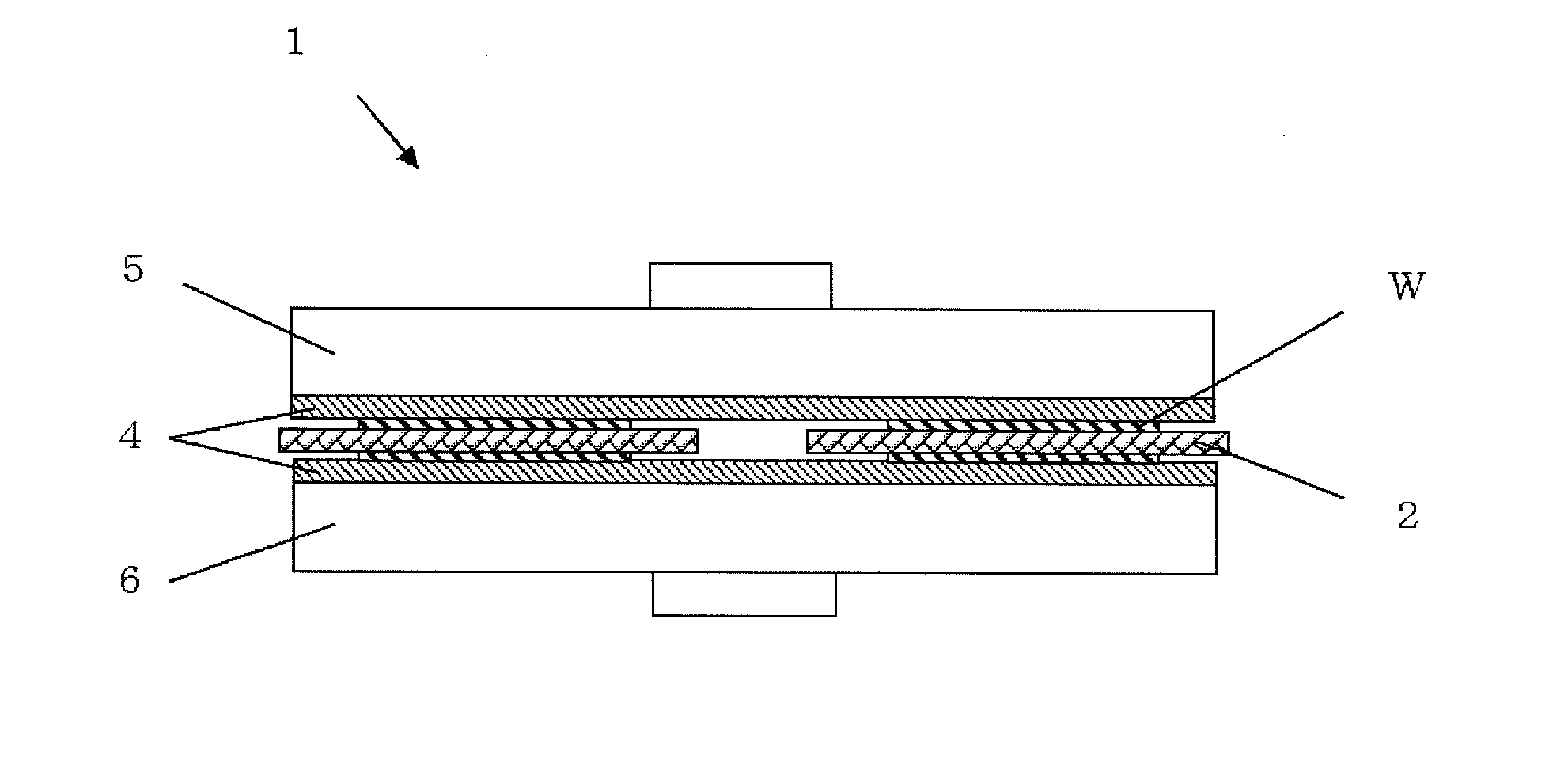

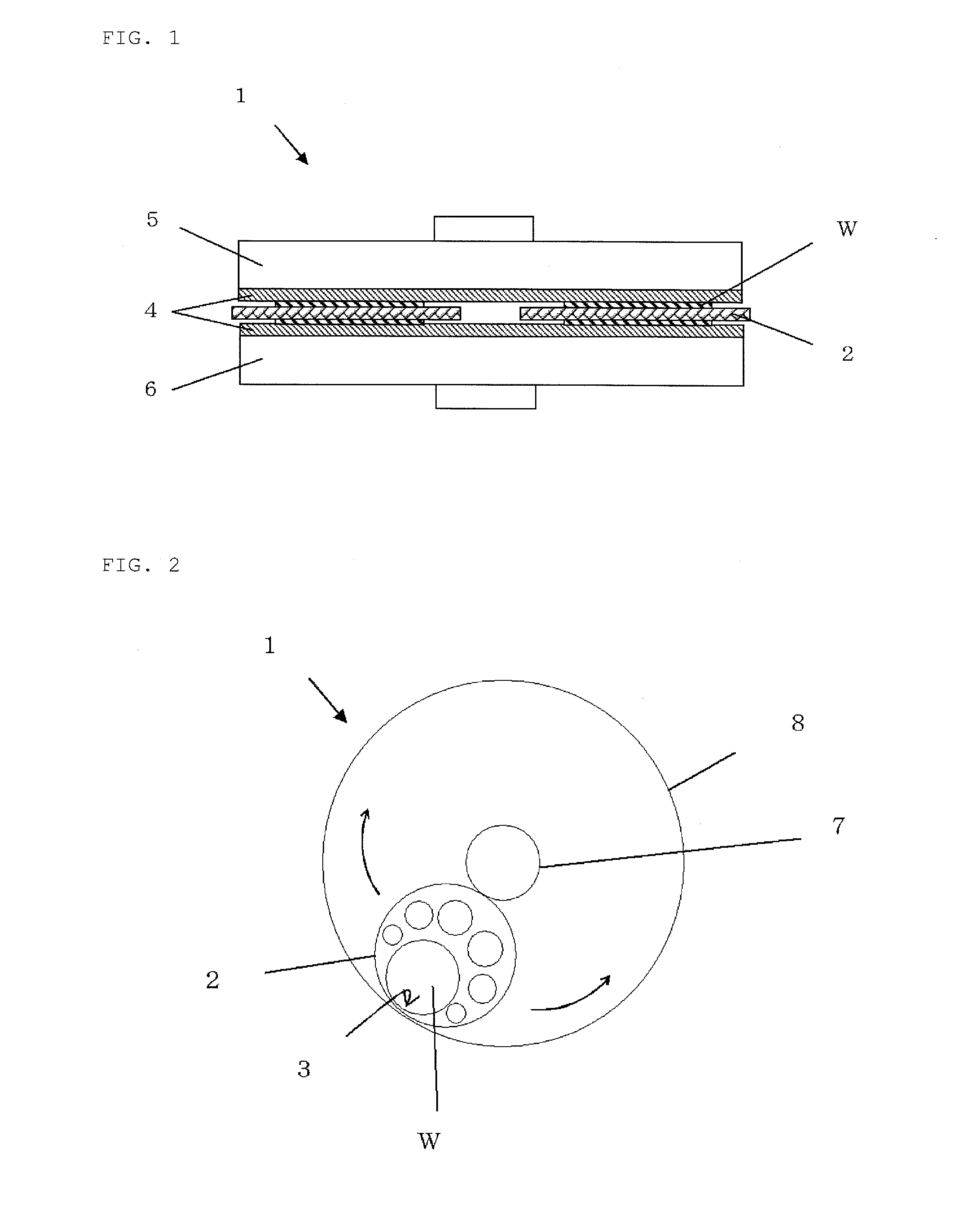

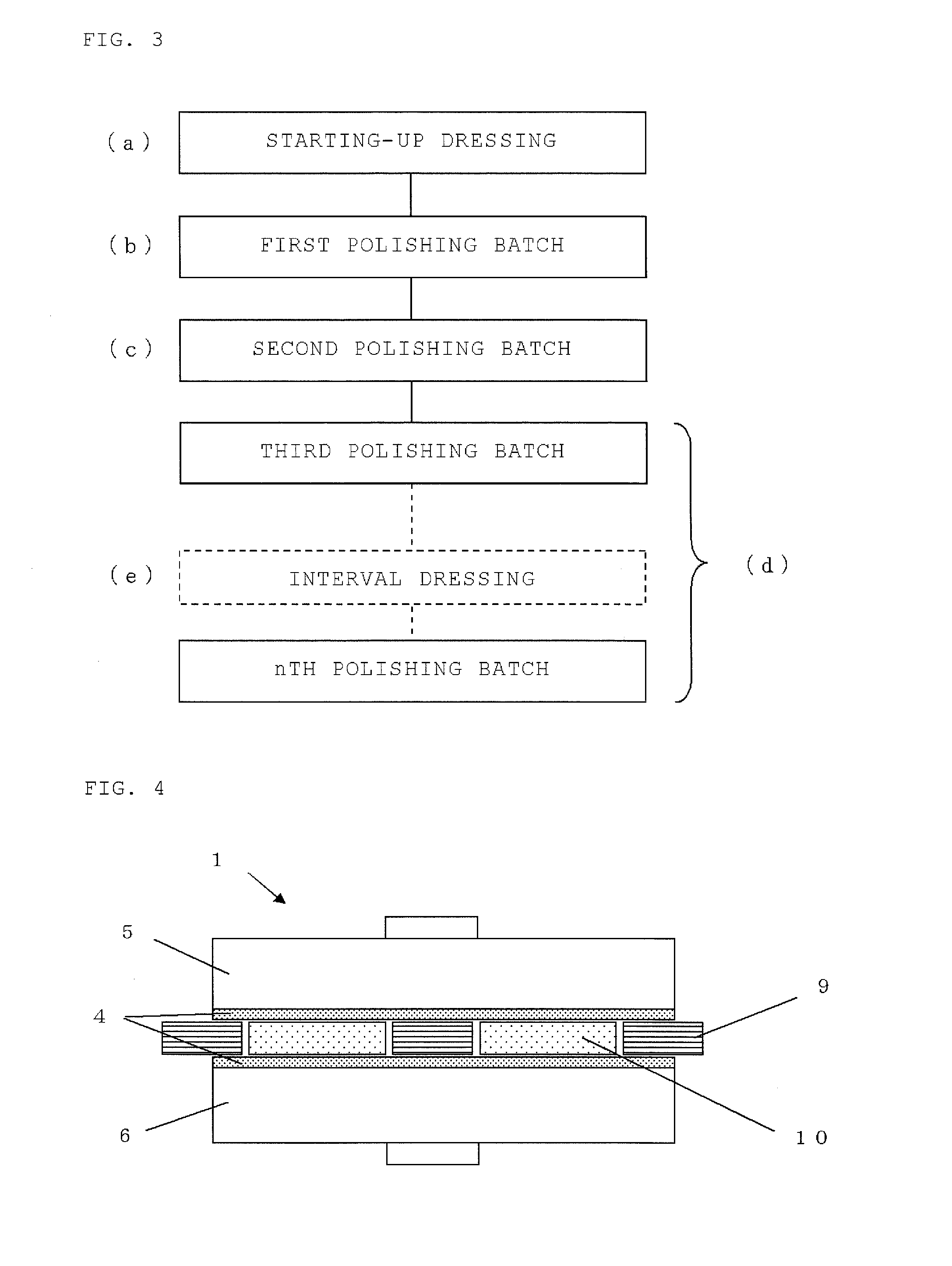

Method of double-side polishing wafer

ActiveUS20150147942A1Process stabilityIncrease productivitySemiconductor/solid-state device manufacturingLapping machinesProduction rateEngineering

The present invention provides method of double-side polishing a wafer, including: simultaneously polishing both surfaces of the wafer by holding the wafer in a holding hole of a carrier, interposing the held wafer between upper and lower turn tables to which polishing pads are attached, rotating the carrier about an axis of the carrier and revolving the carrier; and repeating the polishing in a batch manner, wherein a direction in which the carrier is revolved is reversed every polishing batch while repeating the polishing in a batch manner. The method enables wafers with high flatness to be stably obtained while inhibiting reduction in productivity due to dressing.

Owner:SHIN-ETSU HANDOTAI CO LTD

Image forming apparatus

InactiveUS7343125B2Curb productivity declineElectrographic process apparatusImage formationEngineering

Owner:CANON KK

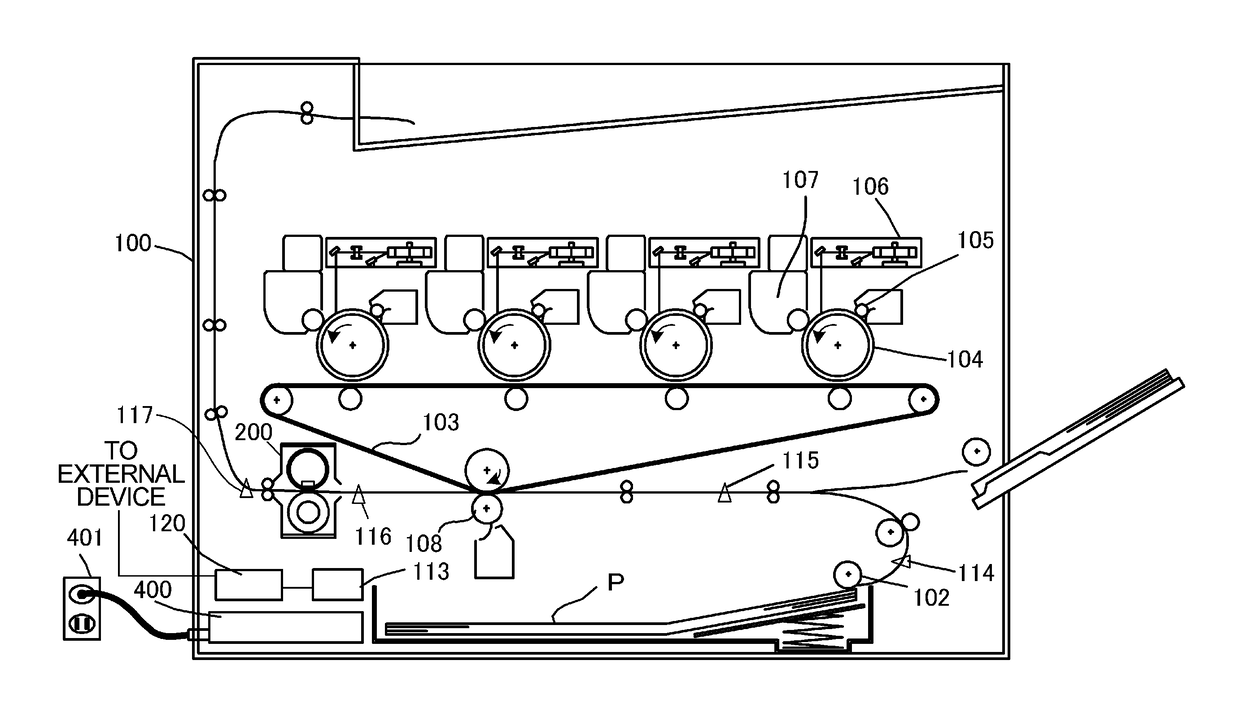

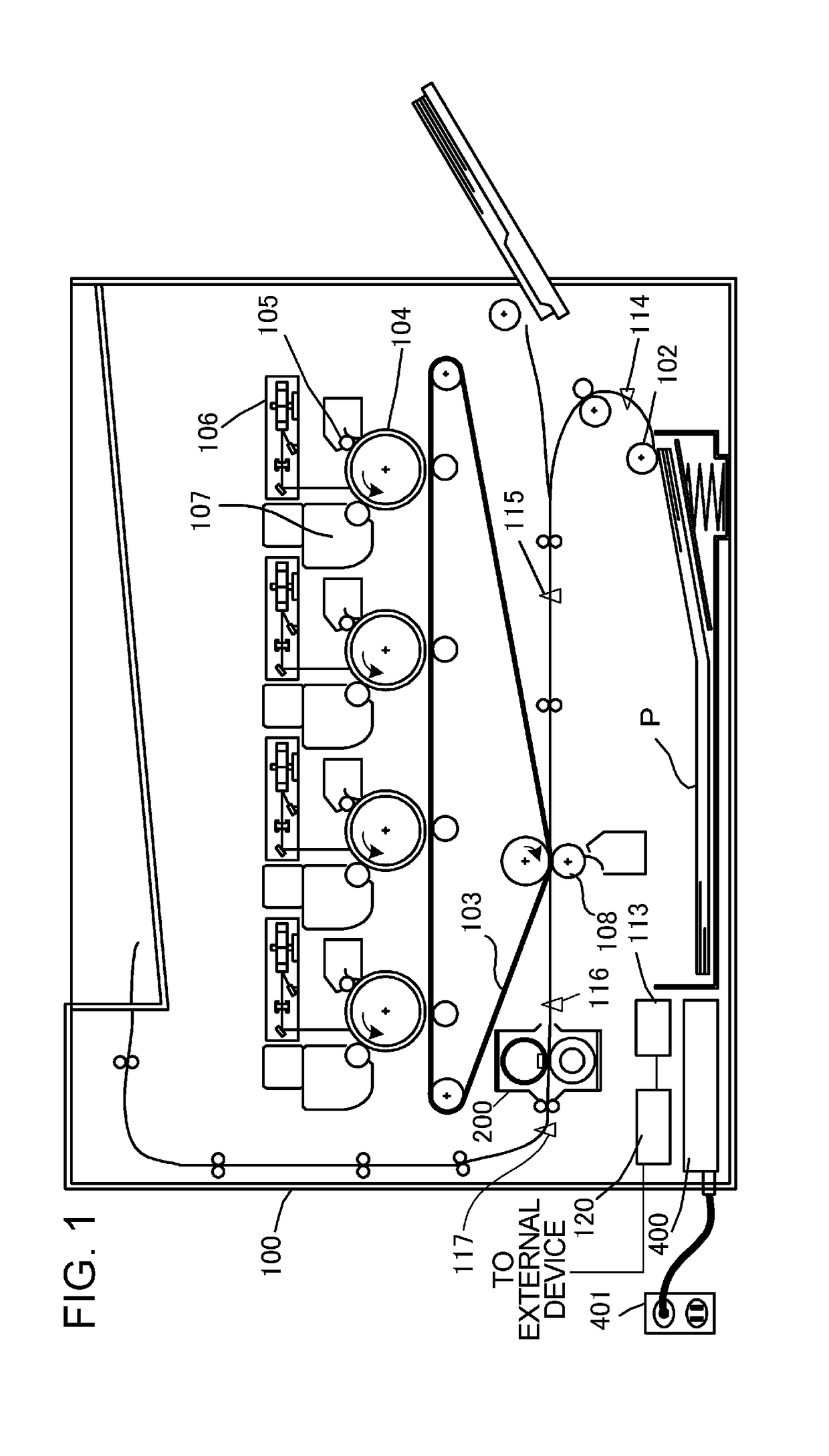

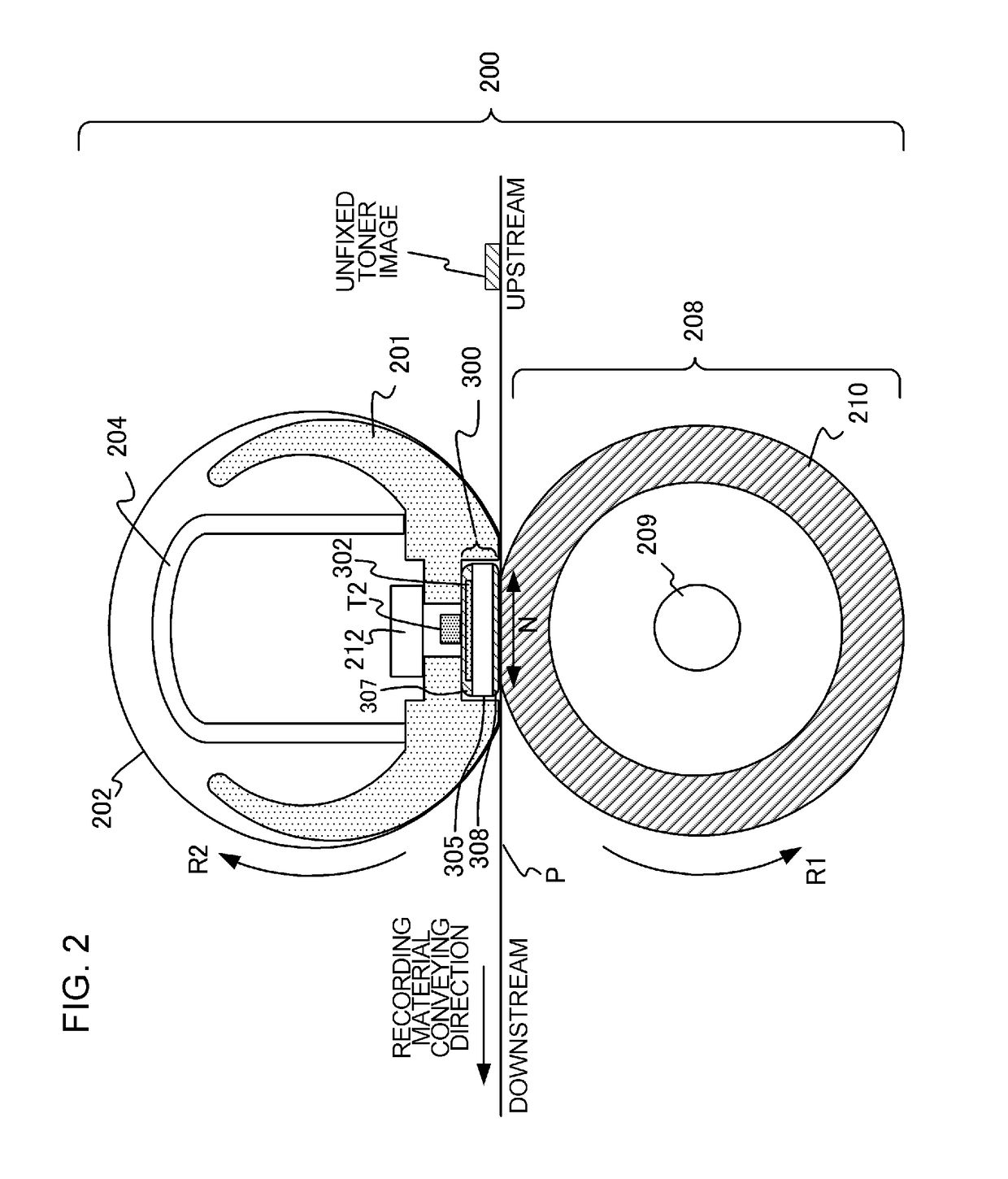

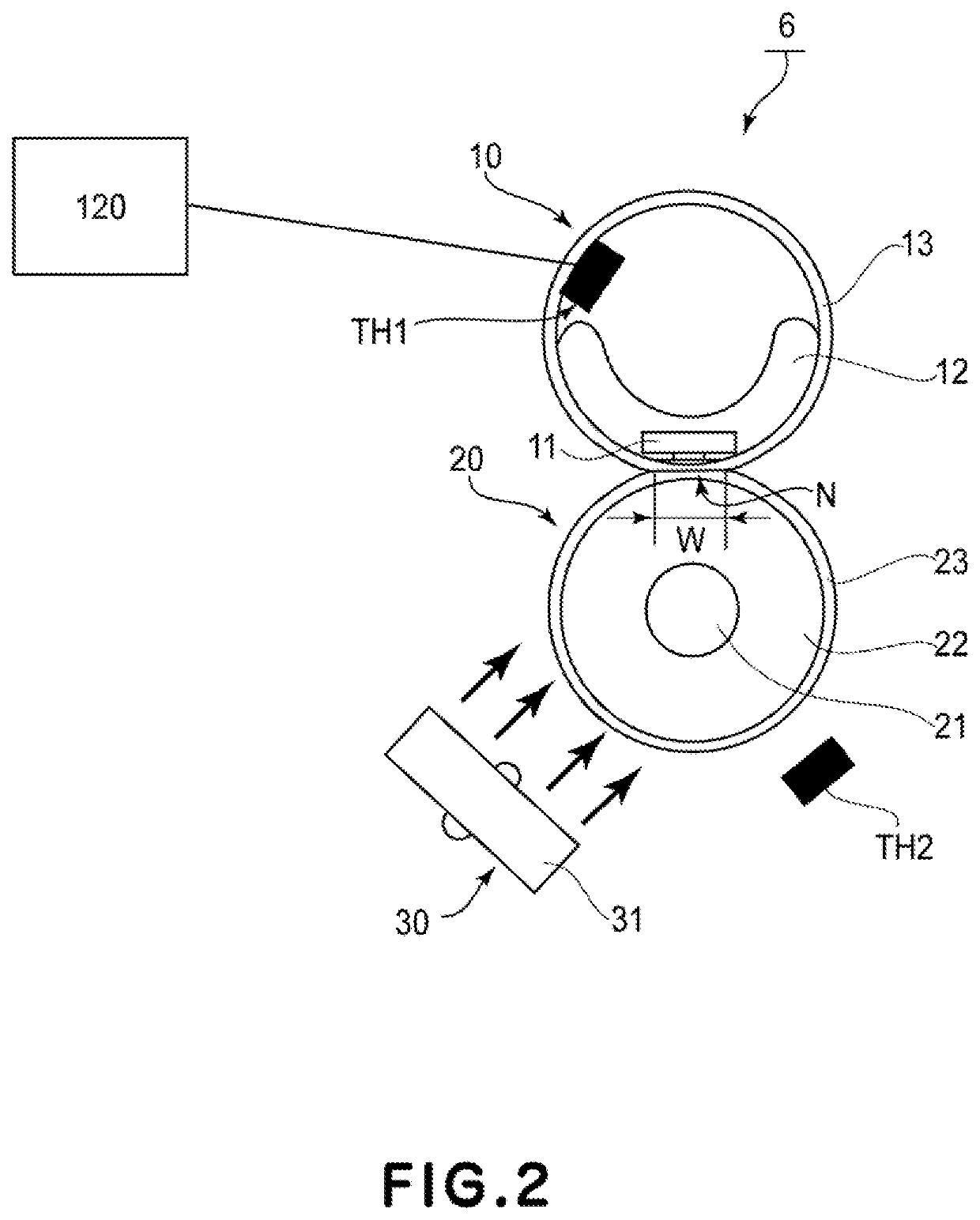

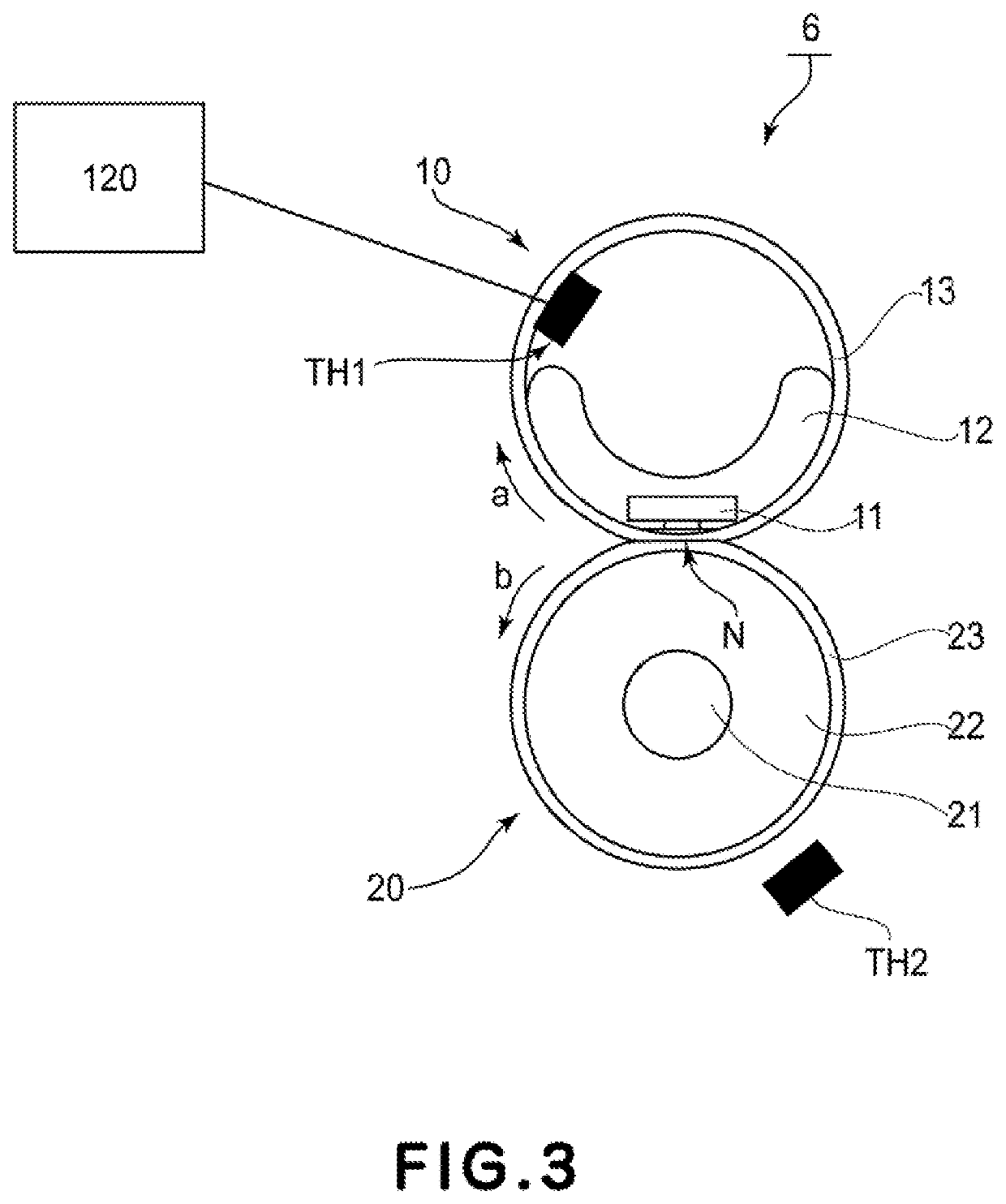

Image heating apparatus

ActiveUS10627751B2Curb productivity declineElectrographic process apparatusImage formationEngineering

Owner:CANON KK

Recording medium transport device in image recording apparatus

InactiveUS7900920B2Curb productivity declineReduce throughputTypewritersOther printing apparatusImage recordingEngineering

An image recording apparatus includes a plurality of linear motor mechanisms for transporting a plurality of tables in a first transport section including at least an area in which an image is recorded on recording media, and an endless transport mechanism for transporting the plurality of tables in at least a second transport section contiguous with the first transport section and capable of transporting the plurality of tables in the first transport section. The image recording apparatus further includes an unused linear motor mechanism determination part for determining an unused linear motor mechanism. When the unused linear motor mechanism is determined, the endless transport mechanism is used as an alternative to transport at least one of the tables which is to be transported in the first transport section but which is able to be transported by none of the plurality of linear motor mechanisms. If a malfunctioning linear motor mechanism is present because of a breakage, an operation anomaly and the like, the image recording apparatus achieves the image recording while maintaining the accuracy of the recorded image although the throughput thereof decreases.

Owner:DAINIPPON SCREEN MTG CO LTD

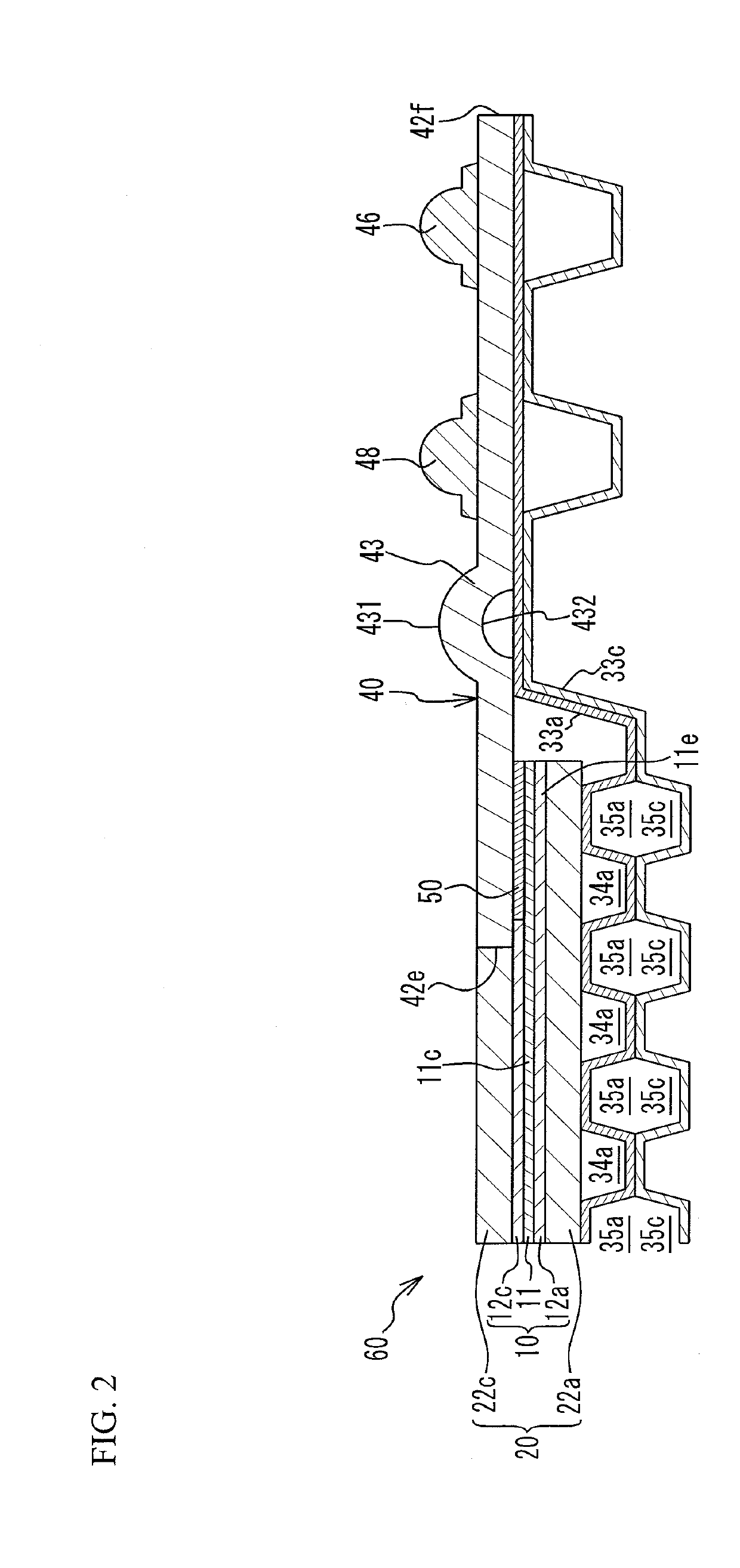

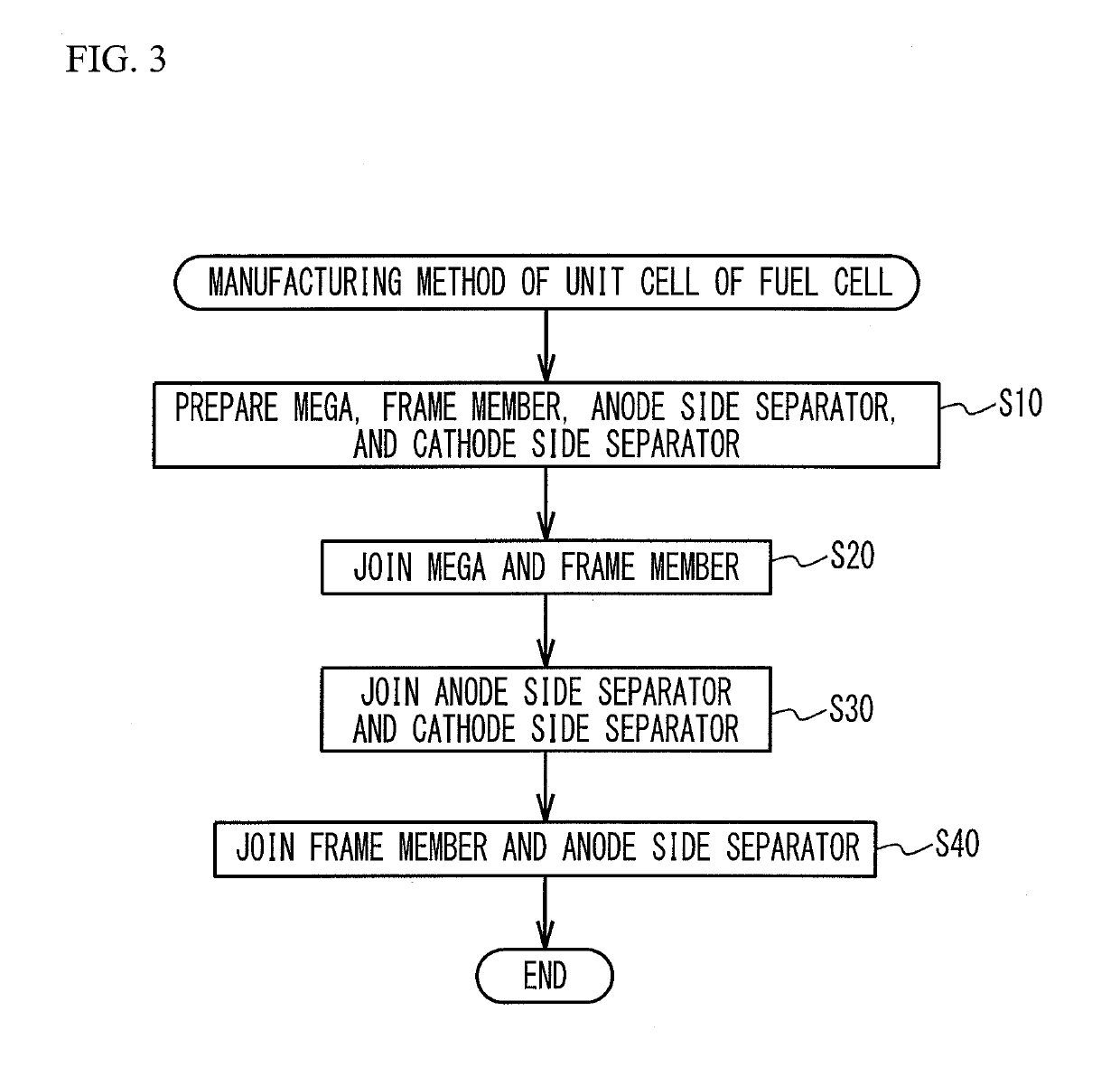

Manufacturing method of unit cell of fuel cell

ActiveUS20190109341A1Decrease productivityEasy to transformCell electrodesFinal product manufactureFuel cellsEngineering

A manufacturing method of a unit cell of a fuel cell, includes: preparing a membrane-electrode-gas diffusion layer assembly; preparing a frame member; bringing an inner peripheral edge of the frame member into contact with a first gas diffusion layer by pushing a convex surface and by deforming a curved portion, in a state where a surface of the frame member is in contact with a peripheral region through an adhesive bond; and joining the frame member and the membrane-electrode-gas diffusion layer assembly with the adhesive bond, in a state where the inner peripheral edge of the frame member is in contact with the first gas diffusion layer.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com