Substrate processing apparatus, substrate processing system, and substrate processing method

a substrate and processing system technology, applied in the direction of cleaning process and apparatus, chemistry apparatus and processes, cleaning liquids, etc., can solve the problem of reducing the extent of the upper limit of the oxygen concentration in the space between the lid member, and affecting the efficiency of cleaning liquids. , to achieve the effect of suppressing the reduction of productivity and reducing the entry of outside air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

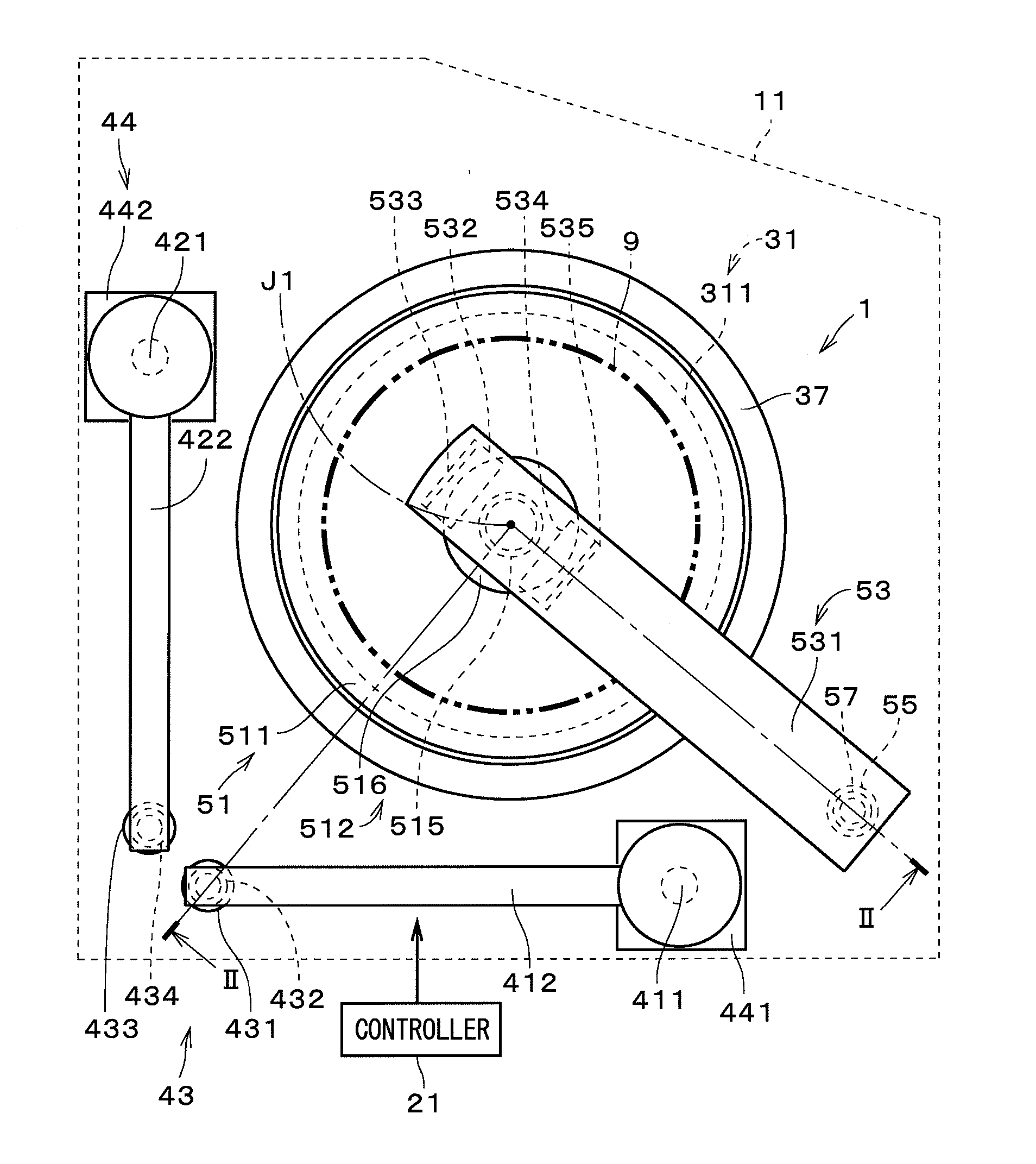

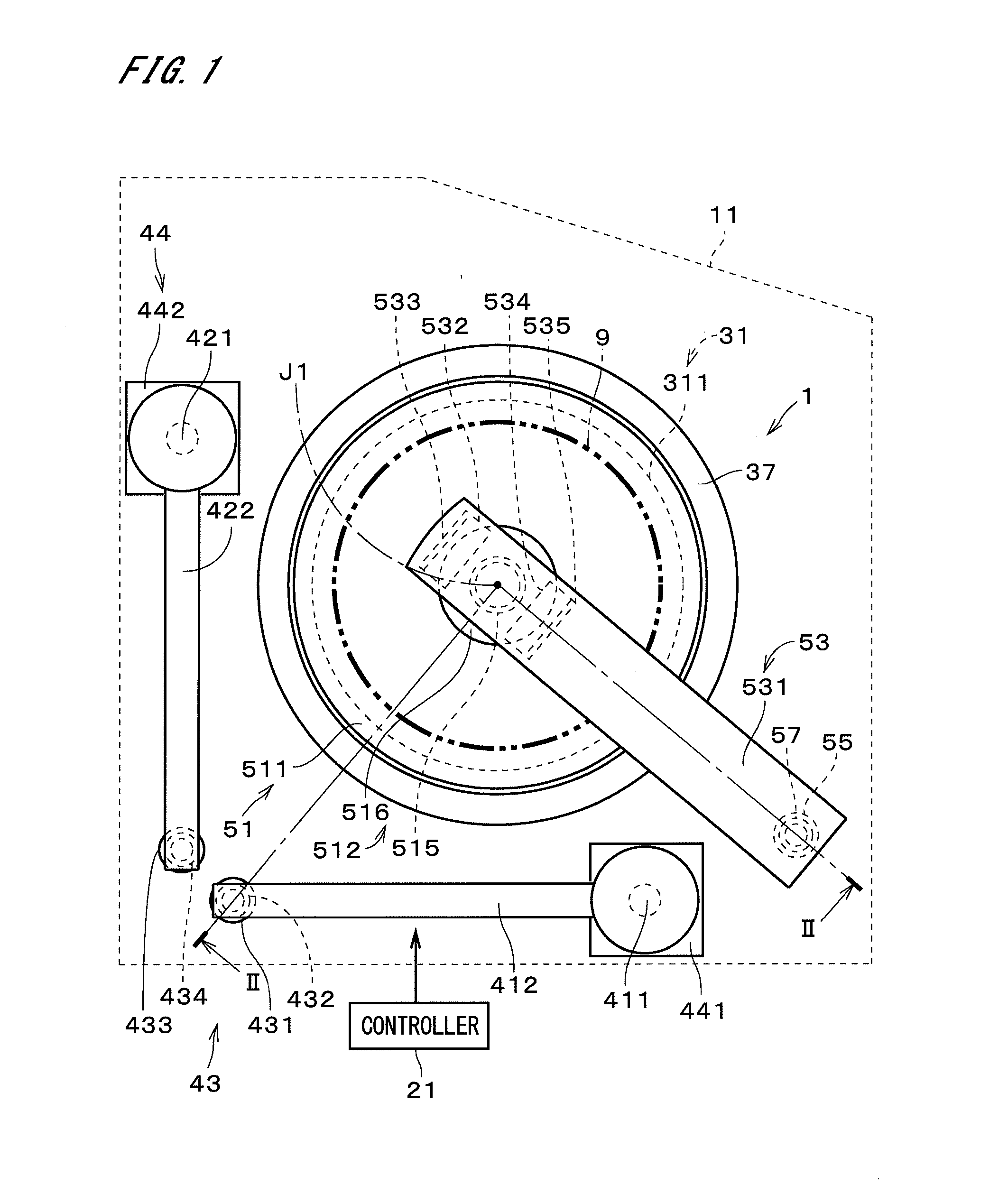

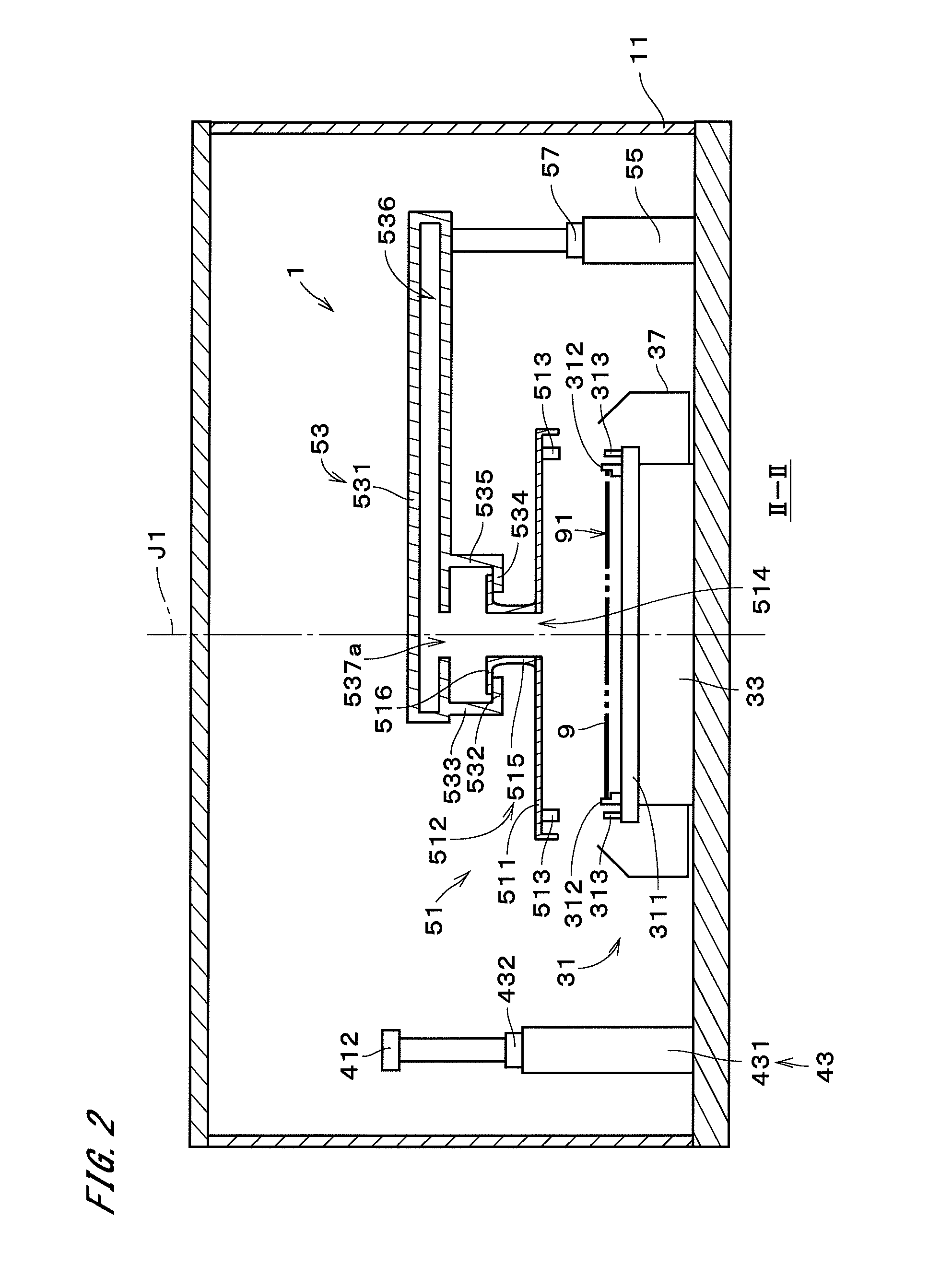

[0067]FIG. 1 is a plan view of a substrate processing apparatus 1 according to the present invention. FIG. 2 is a cross-sectional view of the substrate processing apparatus 1 taken along II-II in FIG. 1. The substrate processing apparatus 1 is a sheet-fed apparatus for processing semiconductor substrates 9 (hereinafter, simply referred to as “substrates 9”) one at a time. The substrate processing apparatus 1 is housed in a housing 11, which is an apparatus housing chamber. In FIG. 1, the housing 11 is indicated by a broken line.

[0068]The substrate processing apparatus 1 includes a controller 21, a substrate holder 31, a substrate rotation mechanism 33, a cup part 37, a first processing liquid nozzle 411, a second processing liquid nozzle 421, a nozzle moving mechanism 43, a nozzle cleaning part 44, a top plate 51, an opposing-member holder 53, an opposing-member elevating mechanism 55, and an opposing-member-holder moving mechanism 57. The controller 21 controls constituent elements...

second embodiment

[0142]FIG. 13 is a plan view of a substrate processing apparatus 1a according to the present invention. The substrate processing apparatus 1a includes, instead of the opposing-member holder 53, an opposing-member holder 53a that differs in the orientations of the first flange supporter 532 and the second flange supporter 534 from the opposing-member holder 53 illustrated in FIGS. 1 and 2. The opposing-member holder 53a also includes a supporter moving mechanism 530. The other configuration of the substrate processing apparatus 1a is similar to the configuration of the substrate processing apparatus 1 illustrated in FIG. 1, and constituent elements that correspond to those of the substrate processing apparatus 1 are given the same reference numerals in the following description.

[0143]As illustrated in FIG. 13, the first flange supporter 532, the first connector 533, the second flange supporter 534, and the second connector 535 of the opposing-member holder 53a are mounted on the end ...

third embodiment

[0151]FIG. 15 is a plan view of a substrate processing apparatus 1b according to the present invention. FIG. 16 is a cross-sectional view of the substrate processing apparatus 1b taken along XVI-XVI in FIG. 15. An opposing-member holder 53b of the substrate processing apparatus 1b includes a flange supporter 538 and a connector 539, instead of the first flange supporter 532, the first connector 533, the second flange supporter 534, and the second connector 535 of the substrate processing apparatus 1. The substrate processing apparatus 1b also includes a first processing liquid nozzle 411a and a second processing liquid nozzle 421a that have different configurations from the configurations of the first processing liquid nozzle 411 and the second processing liquid nozzle 421. In the substrate processing apparatus 1b, the opposing-member-holder moving mechanism 57 illustrated in FIG. 1 is omitted, and the first processing liquid nozzle 411a and the second processing liquid nozzle 421a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com