Patents

Literature

45results about How to "Large shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

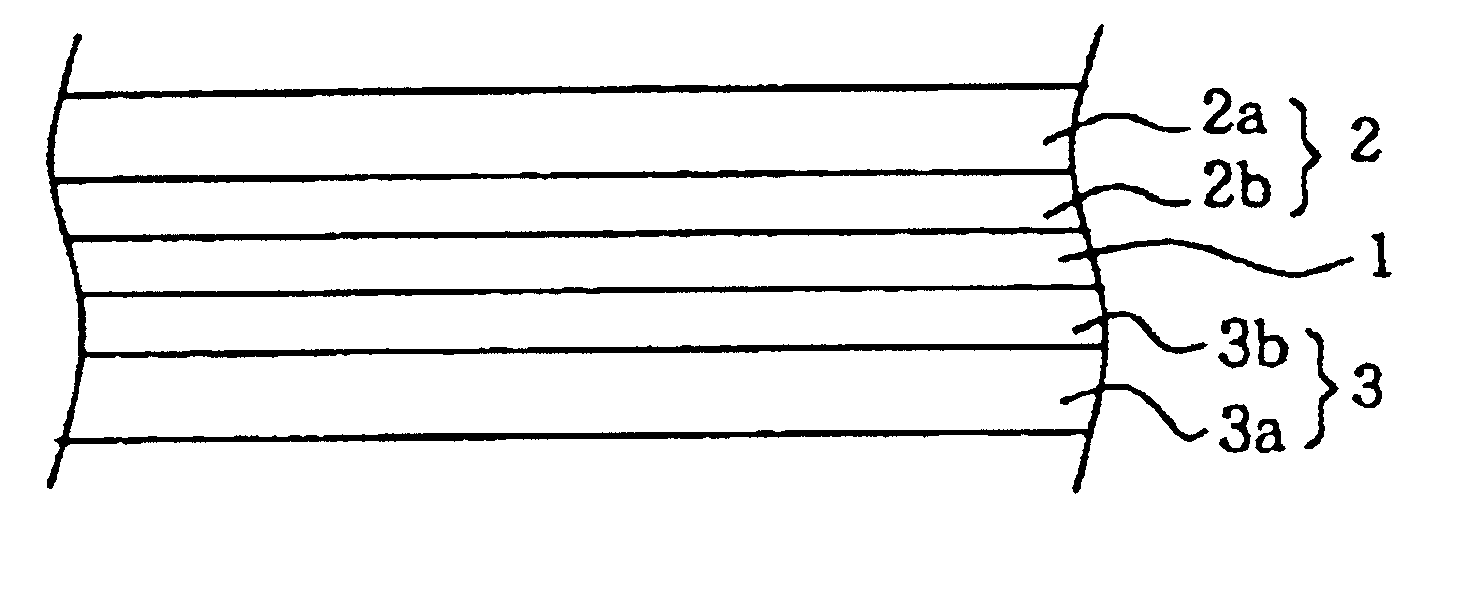

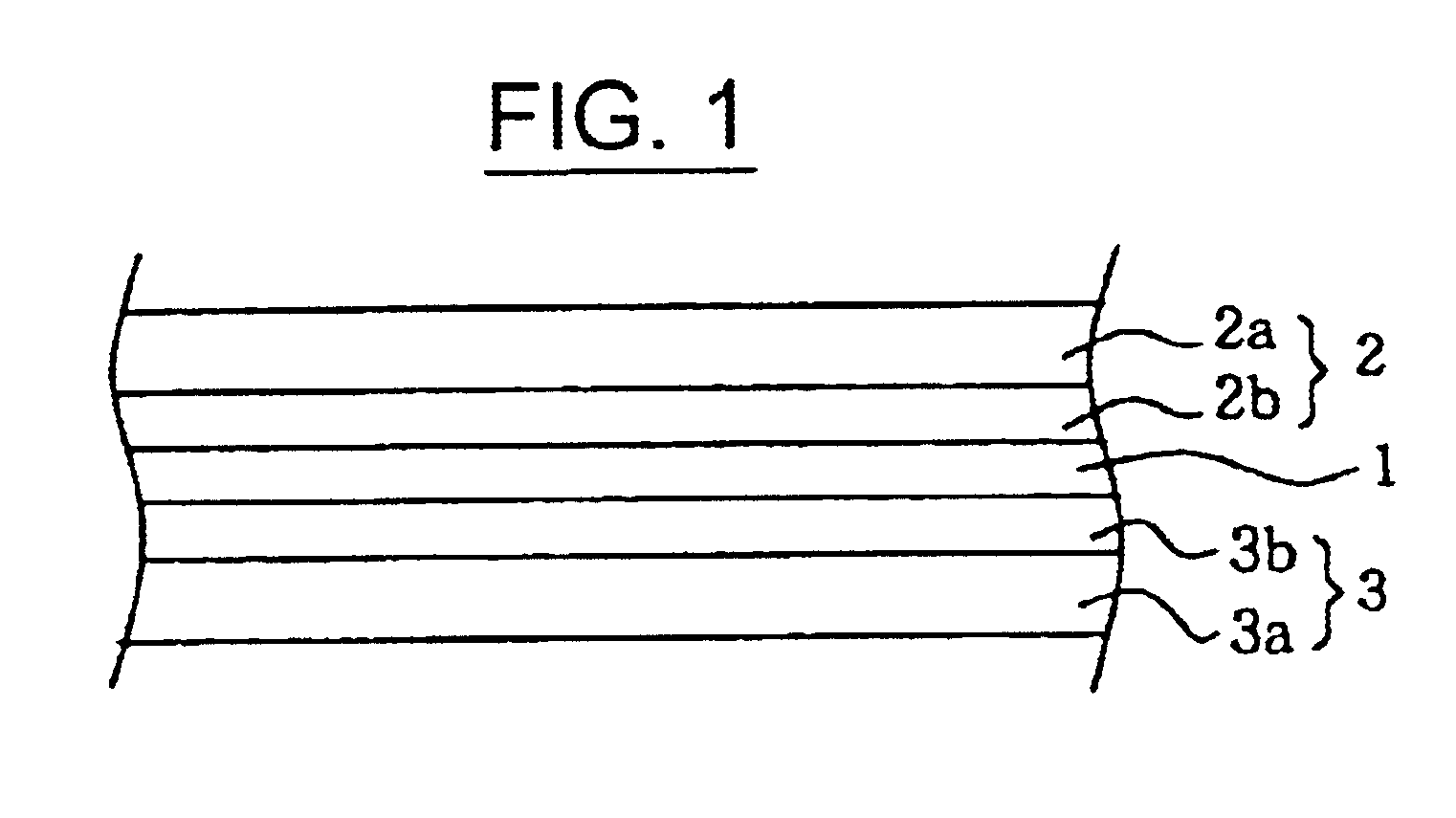

Electroacoustic transducer and diaphragm

InactiveUS20080053745A1Large shapeImprove appearance qualityHeadphones for stereophonic communicationEarpiece/earphone attachmentsEngineeringTransducer

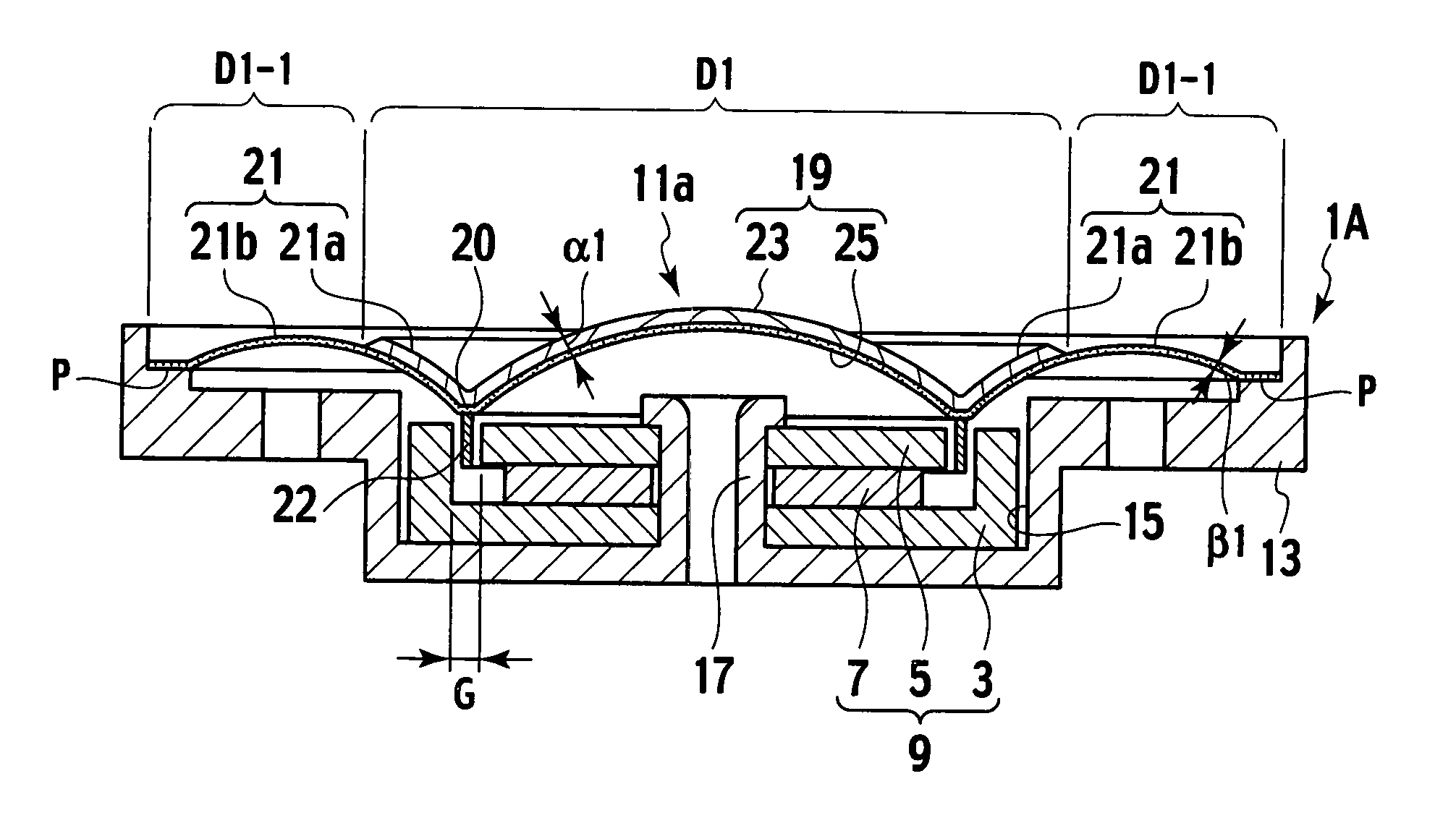

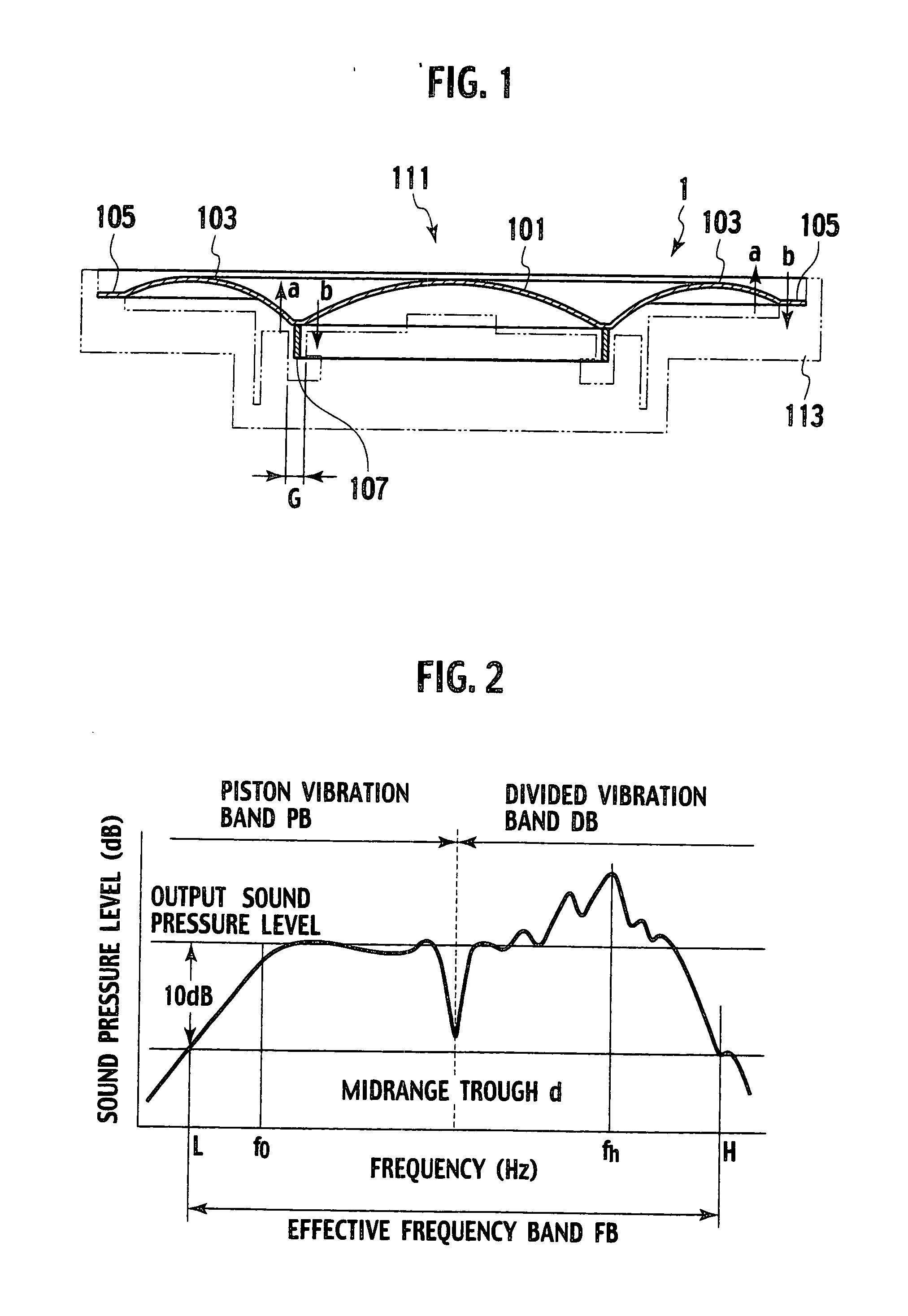

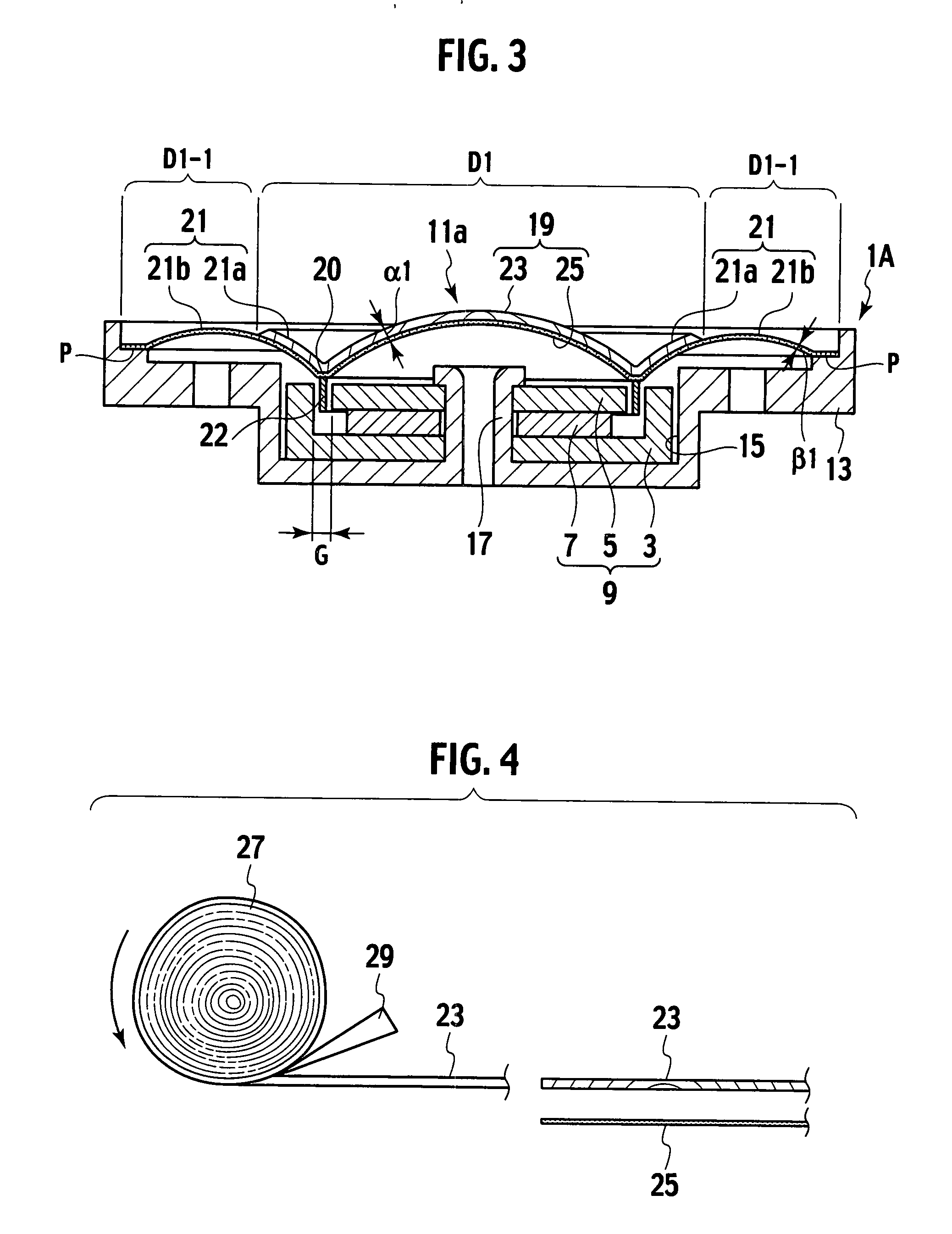

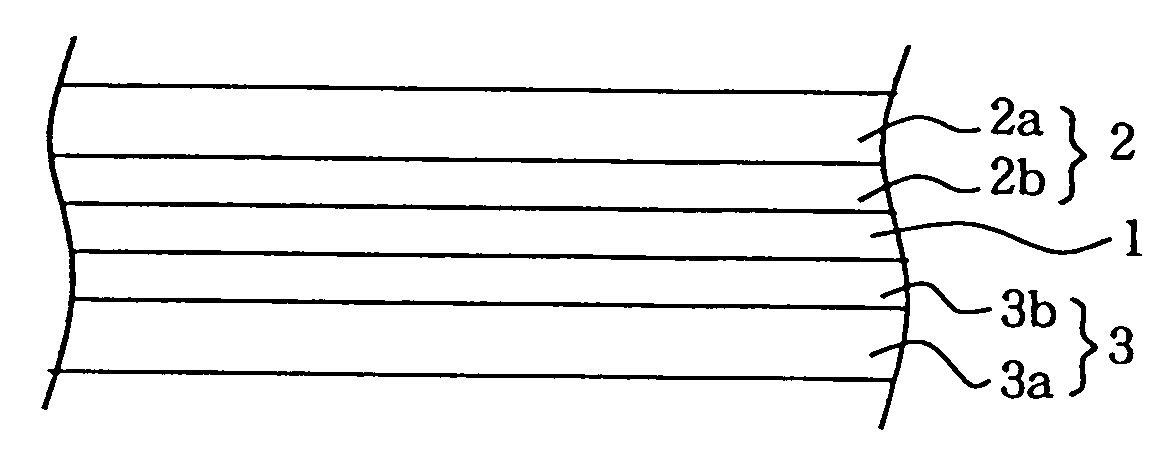

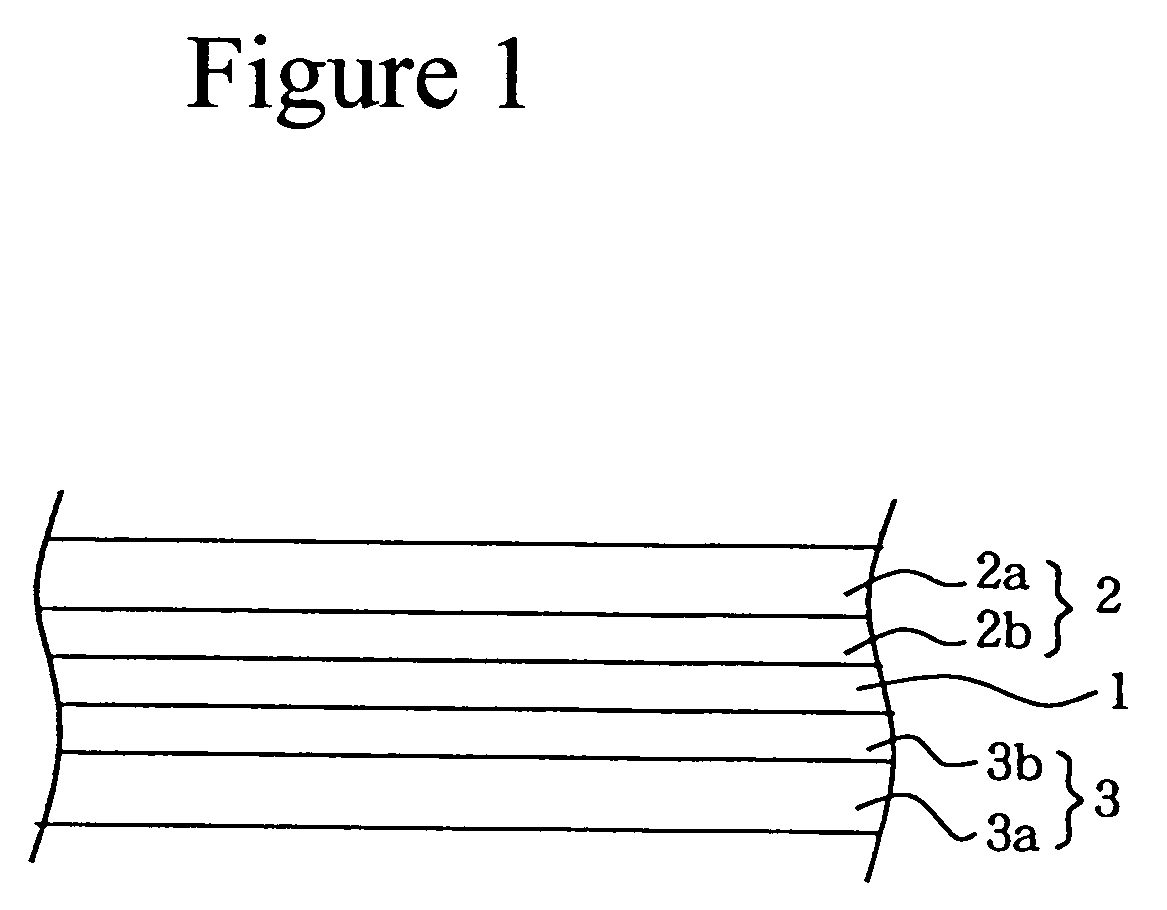

An electroacoustic transducer includes a magnetic circuit; a frame enclosing the magnetic circuit; and a diaphragm including a center vibrating portion and an outer circumferential vibrating portion, the diaphragm comprising: a first plate thickness area including an entirety of the center vibrating portion, having a double-layer structure of a wood sheet and a reinforcement sheet; and a second plate thickness area including the edge portion of the outer circumferential vibrating portion, having a plate thickness thinner than a thickness of the first plate thickness area, and having a single-layer structure of the reinforcement sheet.

Owner:VICTOR CO OF JAPAN LTD

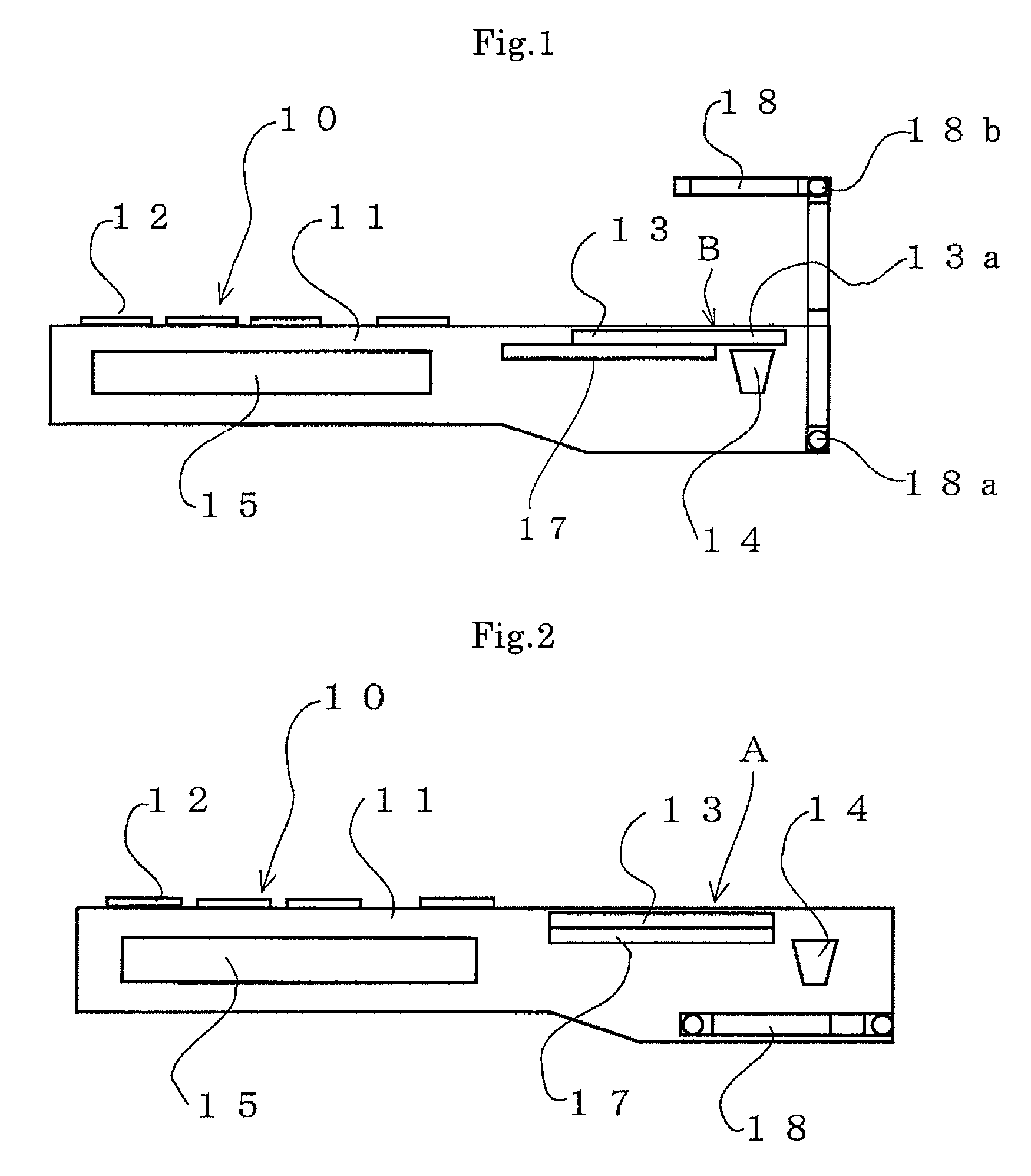

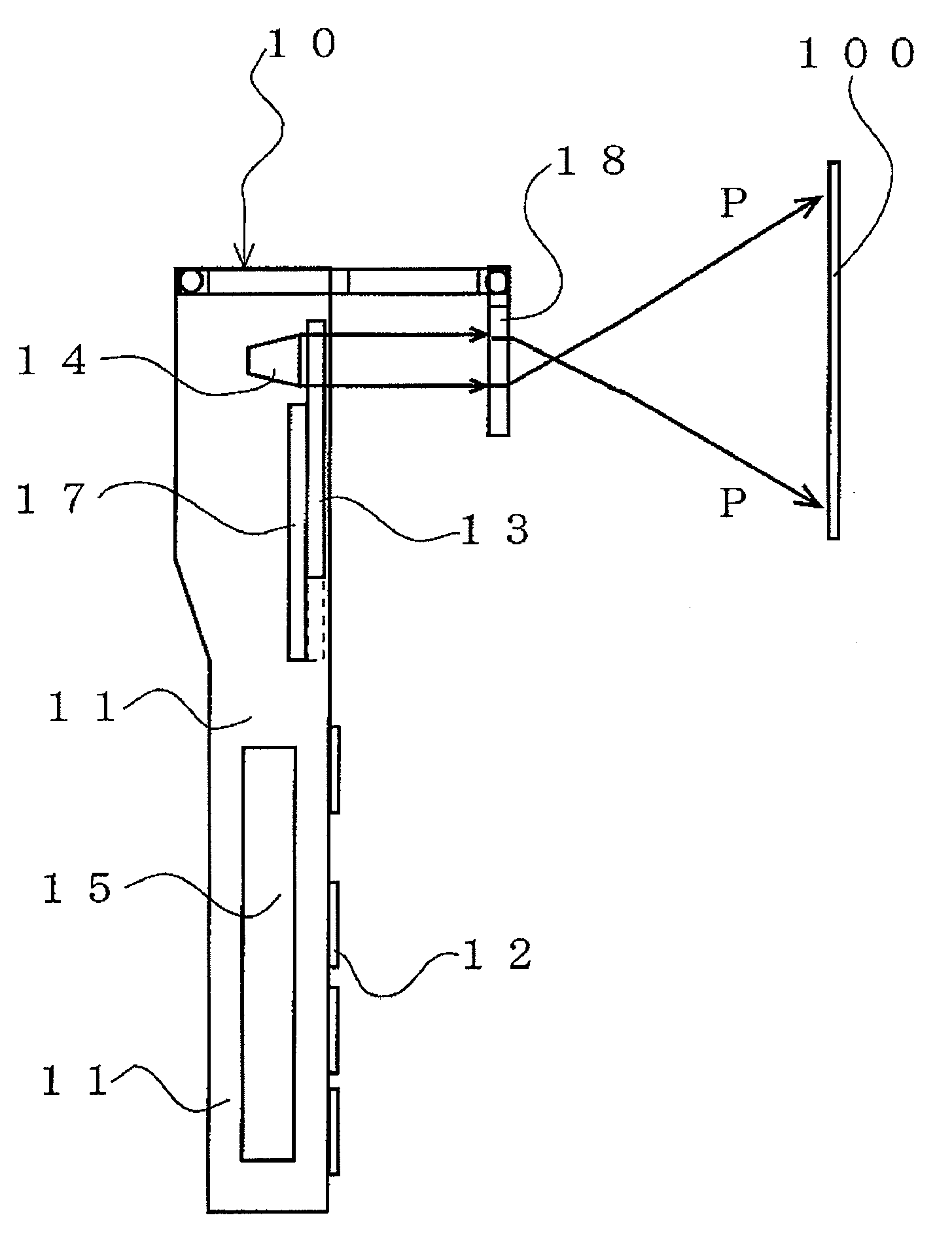

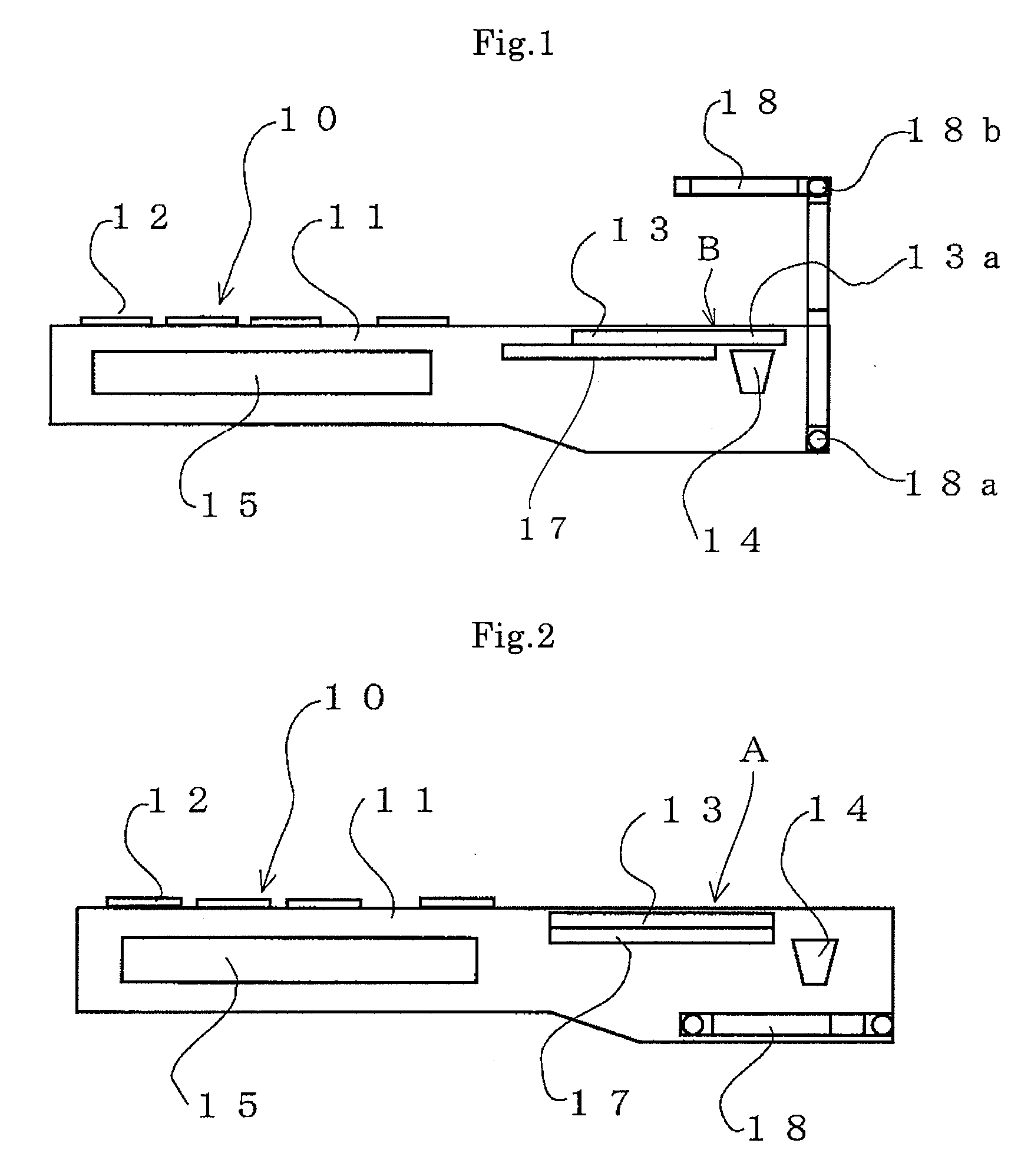

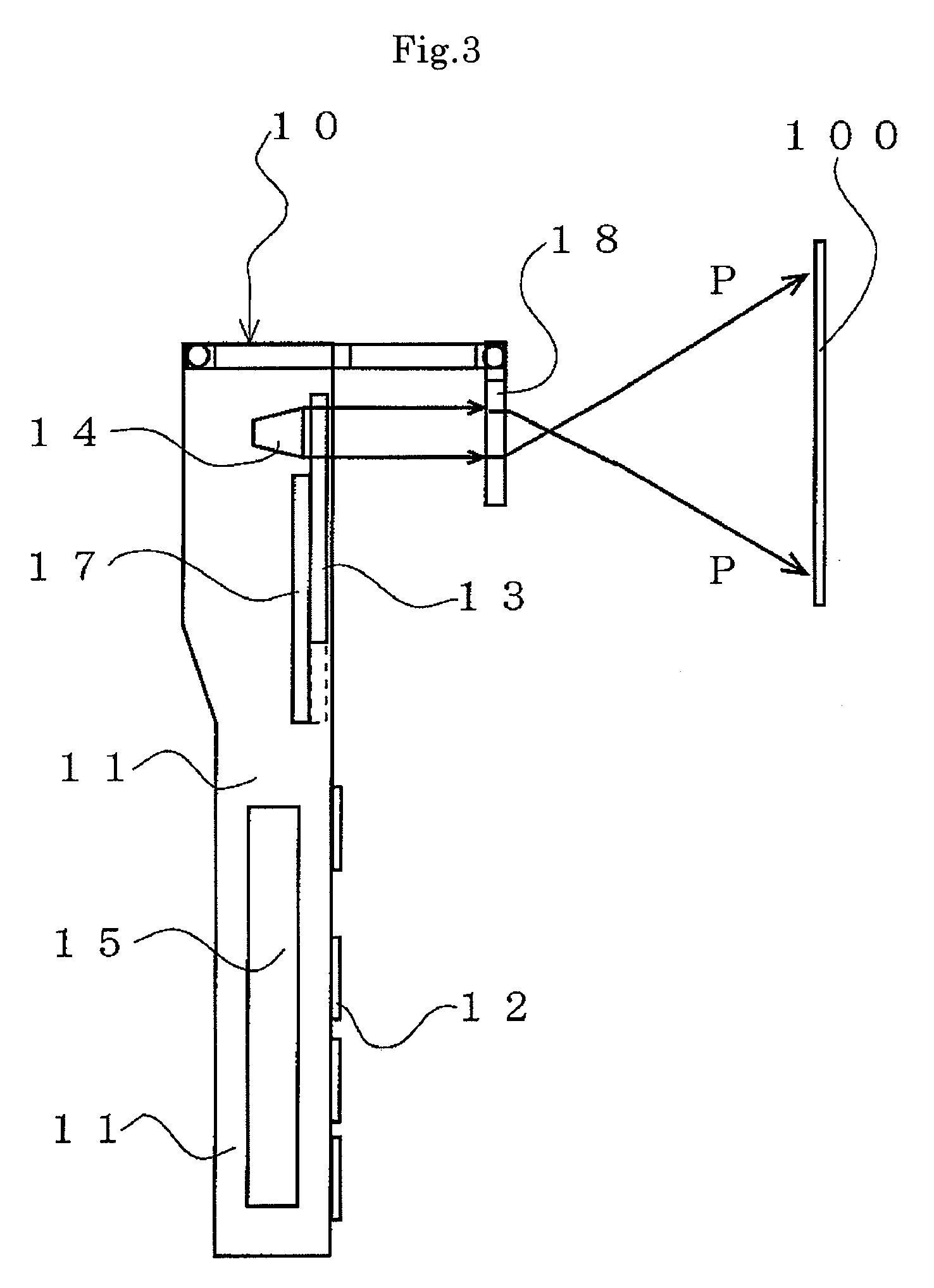

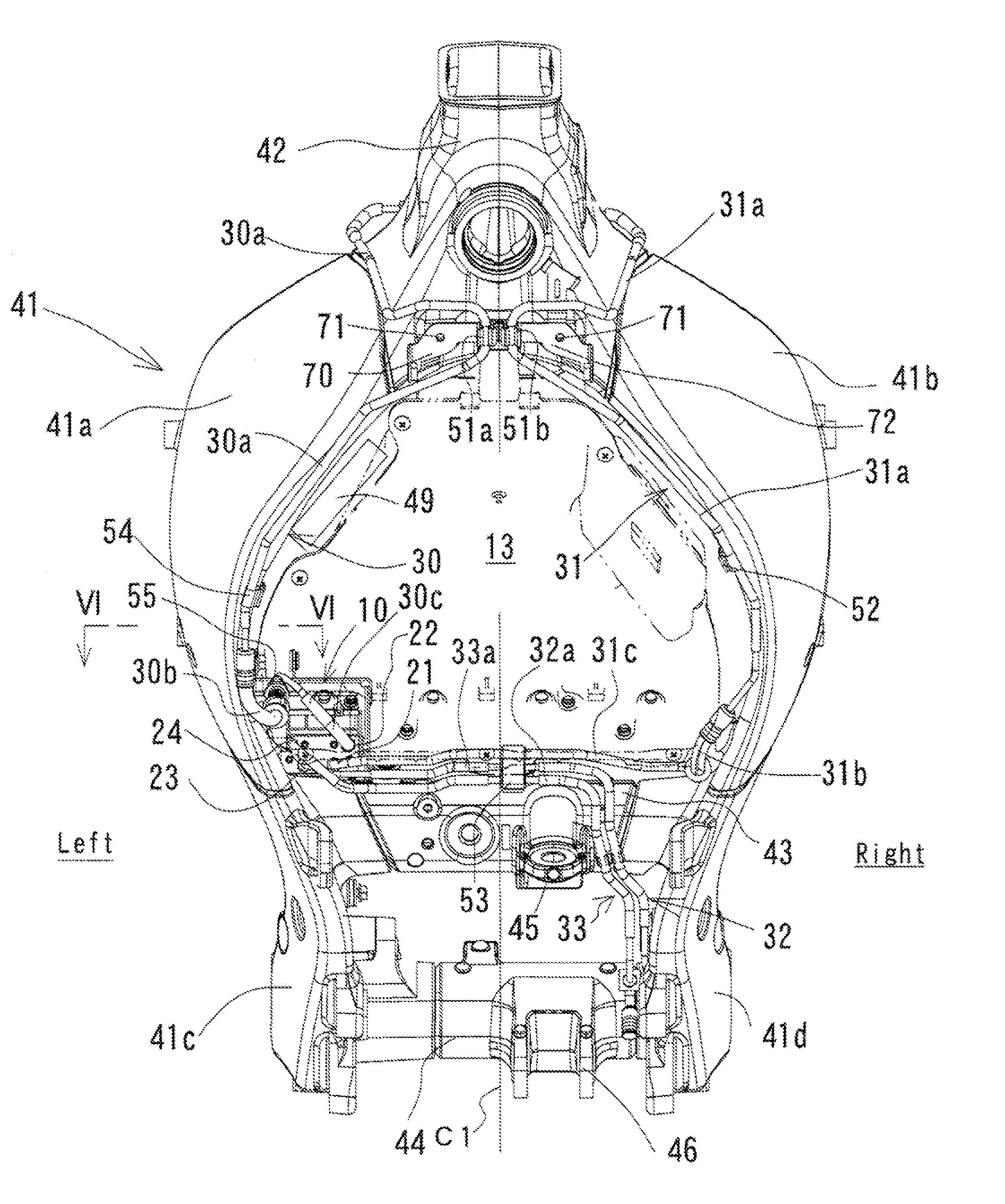

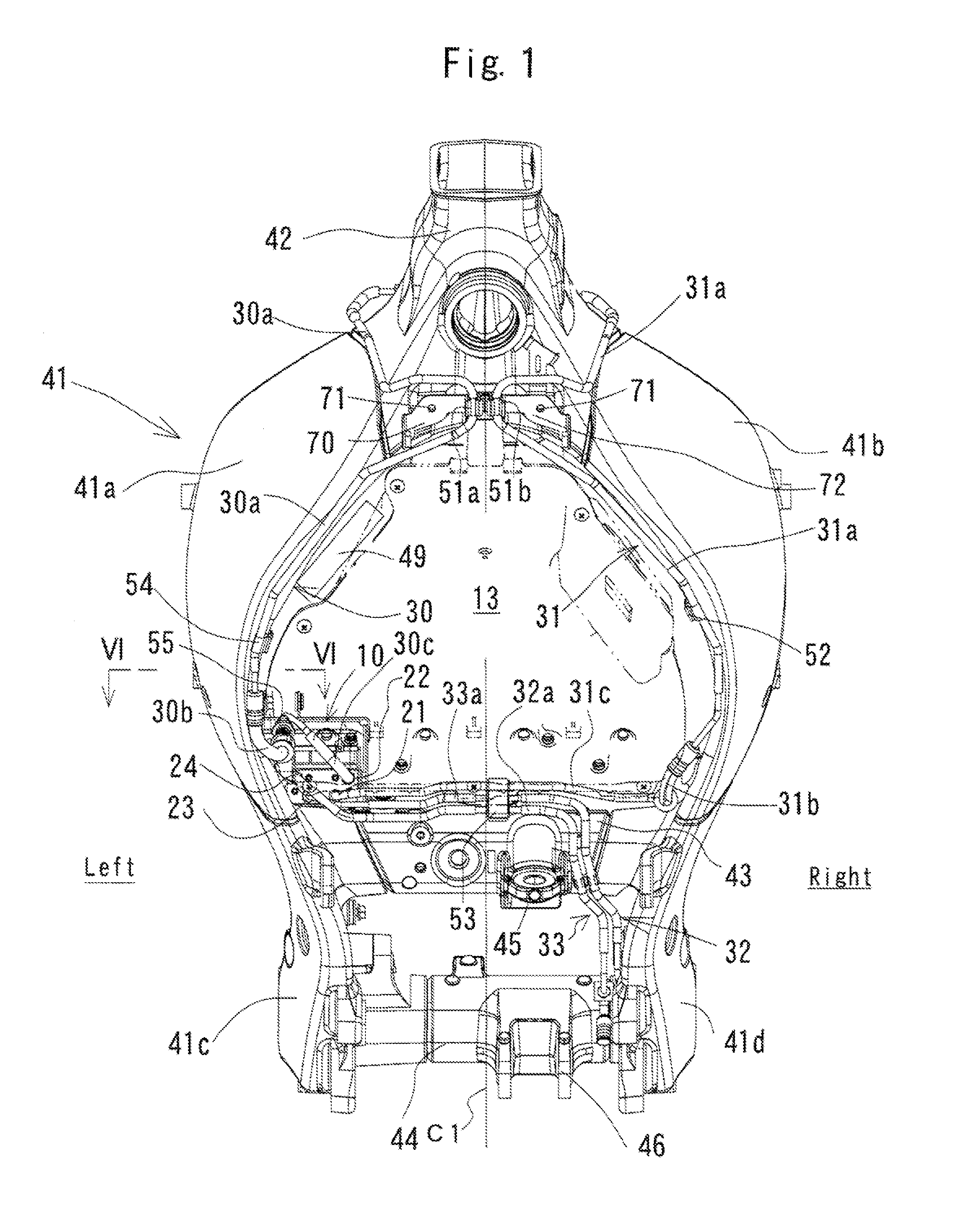

Mobile phone with an image projection device

InactiveUS7874683B2Impairing portabilityWithout impairing portabilityTelevision system detailsPrintersProjection lensComputer science

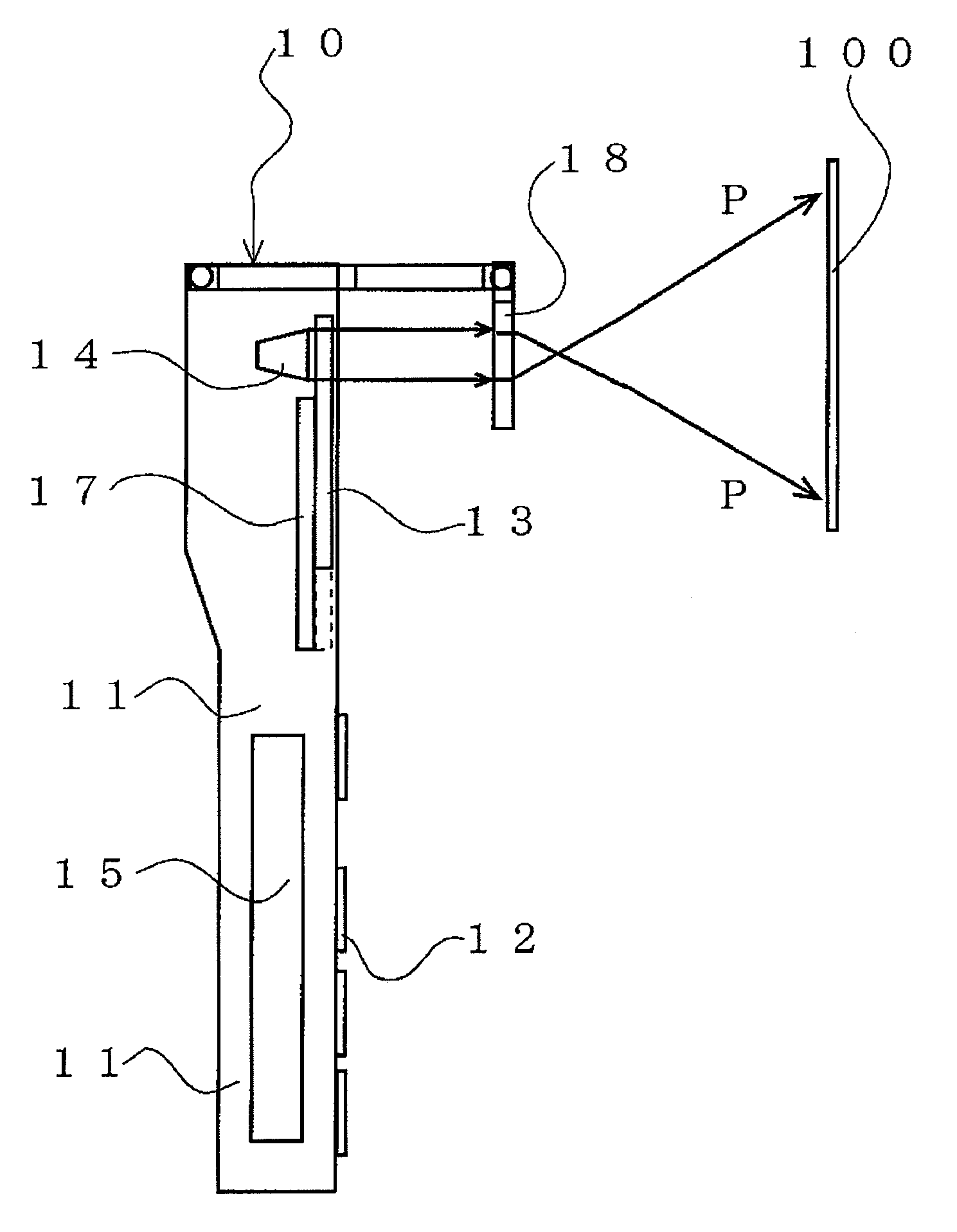

A mobile phone includes an information display device and an image projection device. The information display device has a transmissive liquid crystal panel (13) for information display that has a specific region (13a) in a part thereof. The information display device further has a backlight unit (17) that illuminates the transmissive liquid crystal panel. The image projection device has a light source (14) that illuminates the specific region (13a), and a projection lens (18) that directs light from the light source (14) received through the specific region toward a screen.

Owner:CITIZEN ELECTRONICS CO LTD

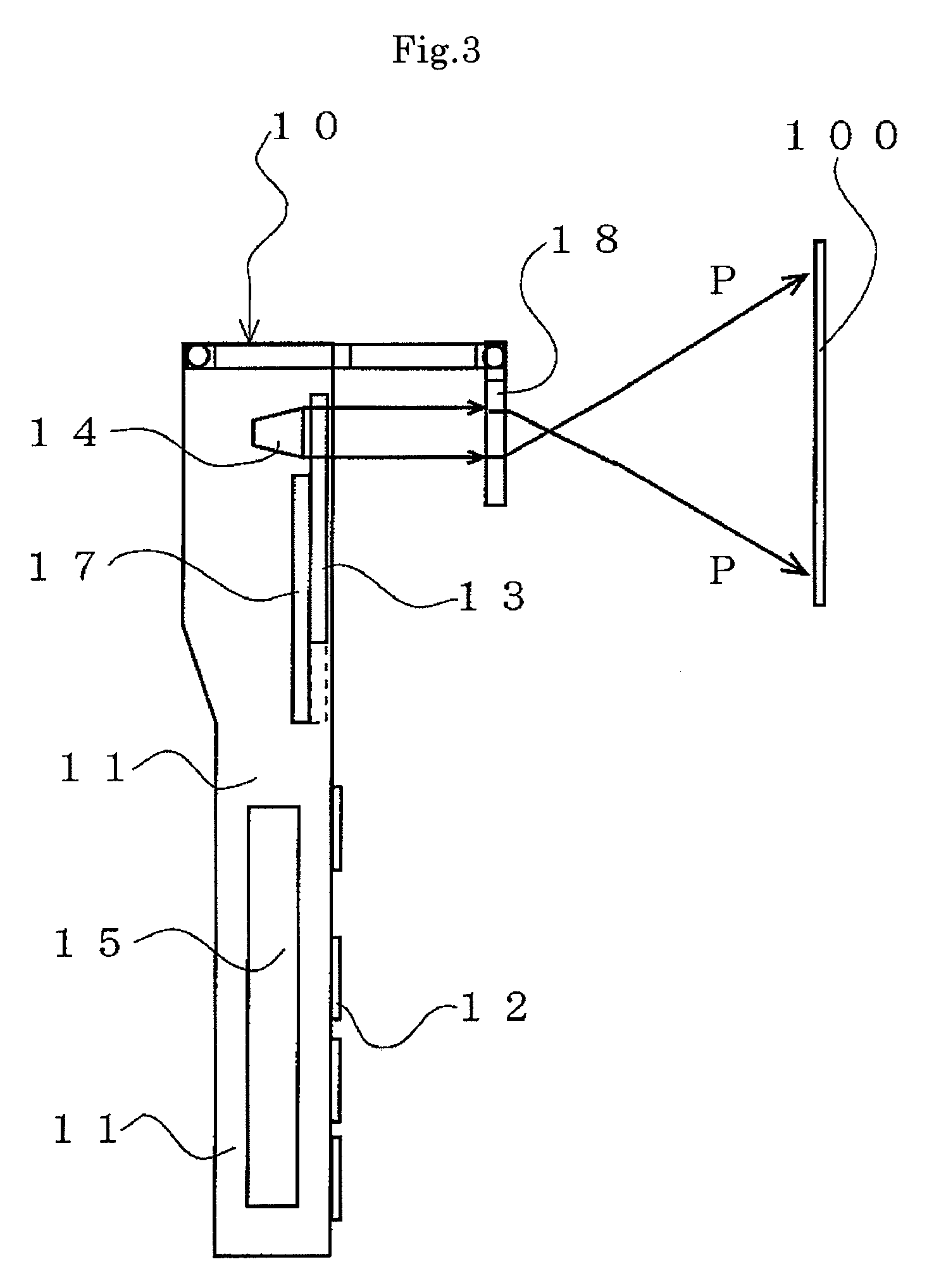

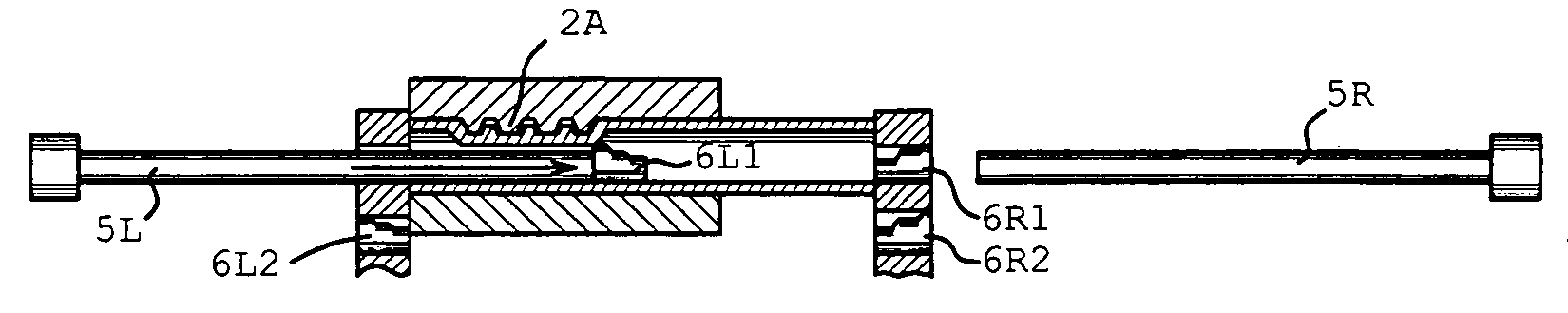

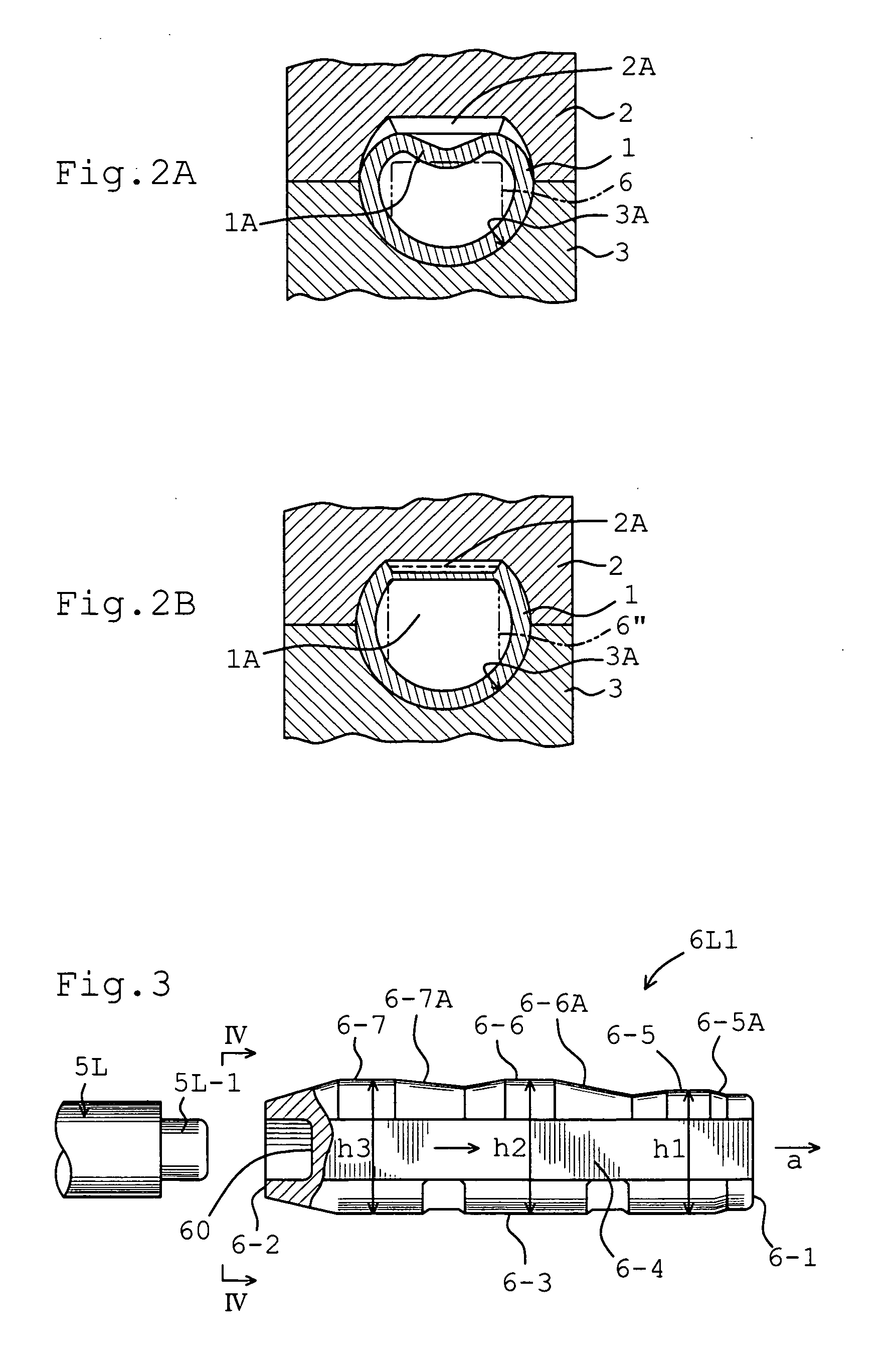

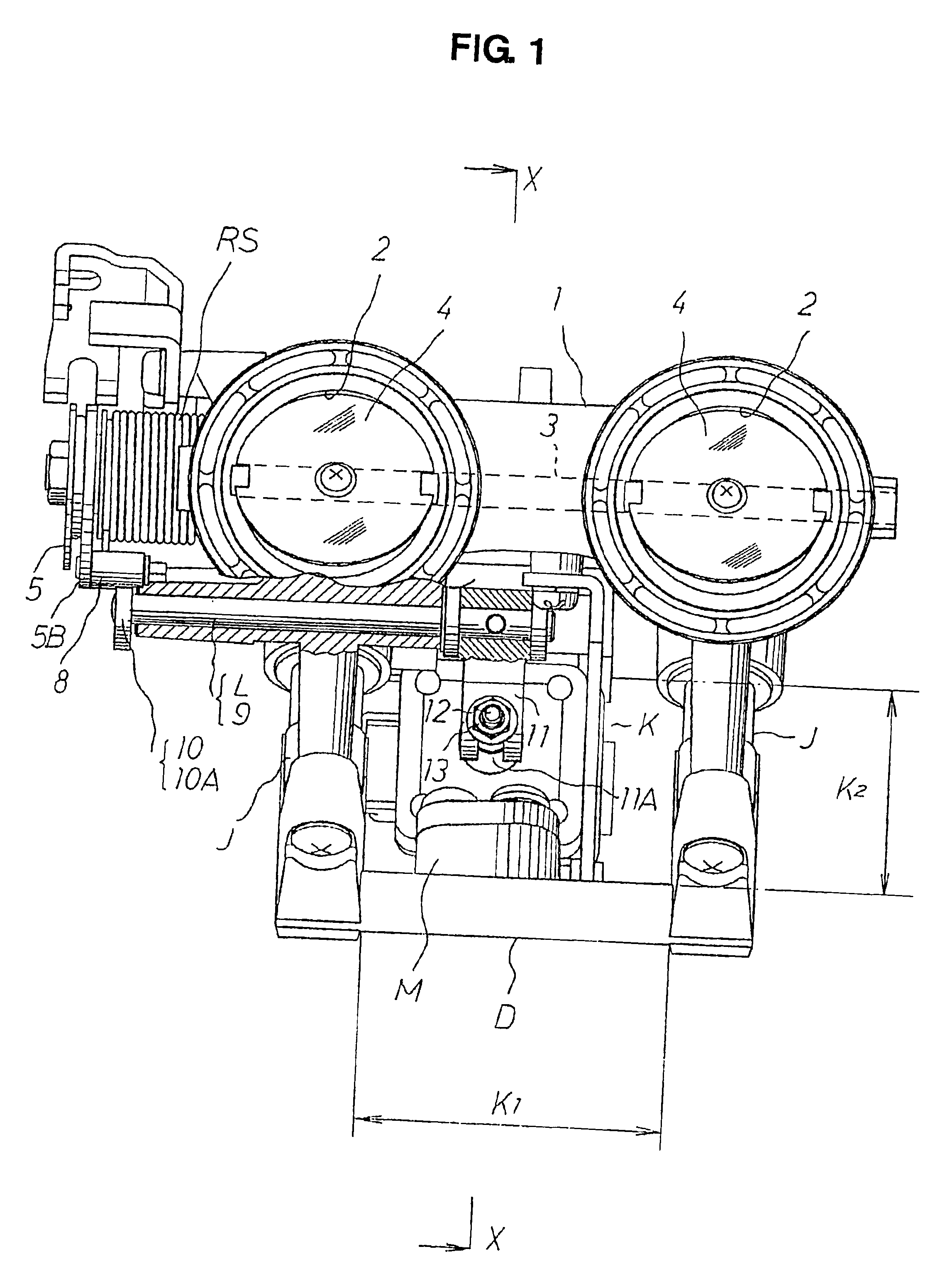

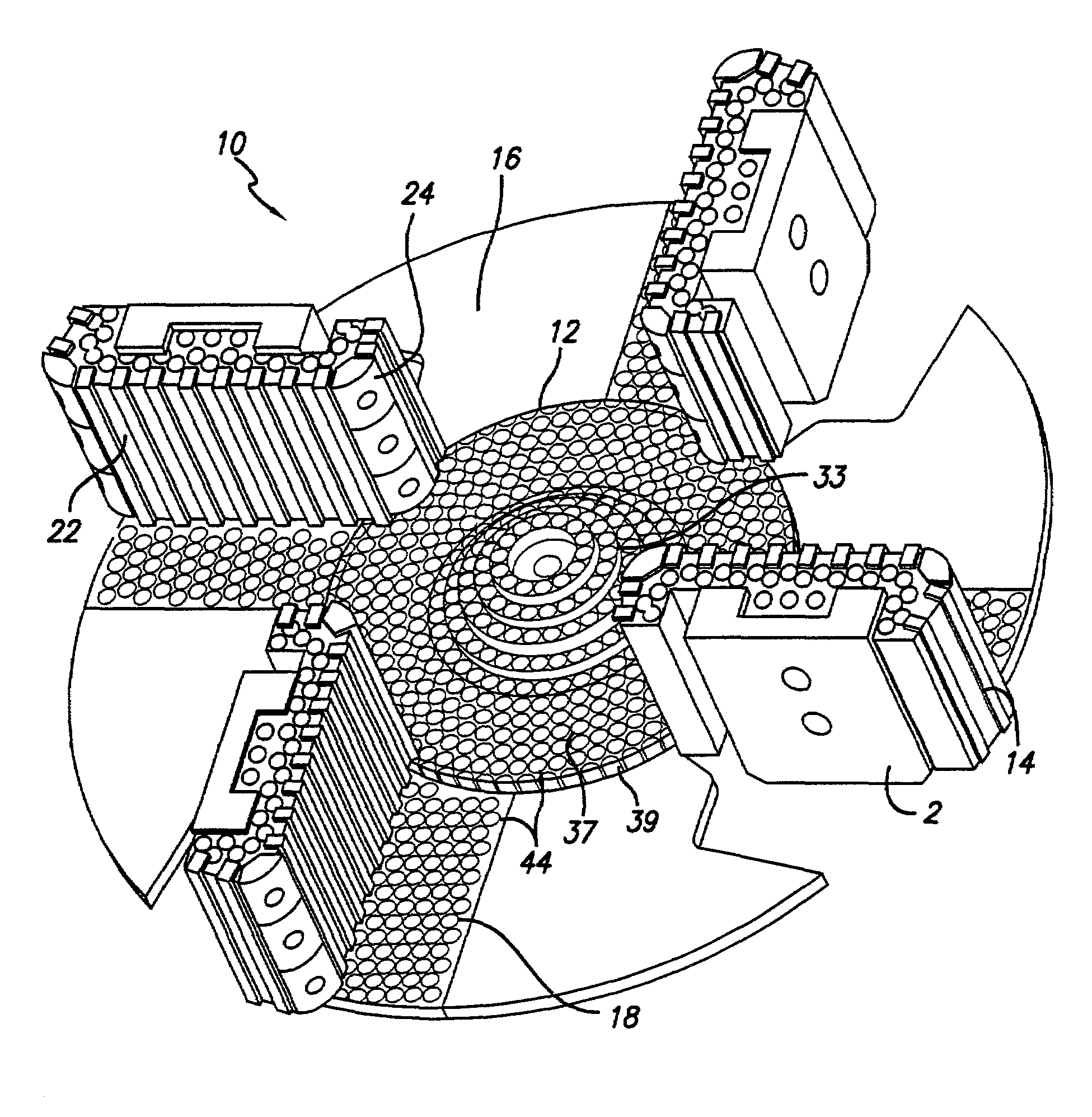

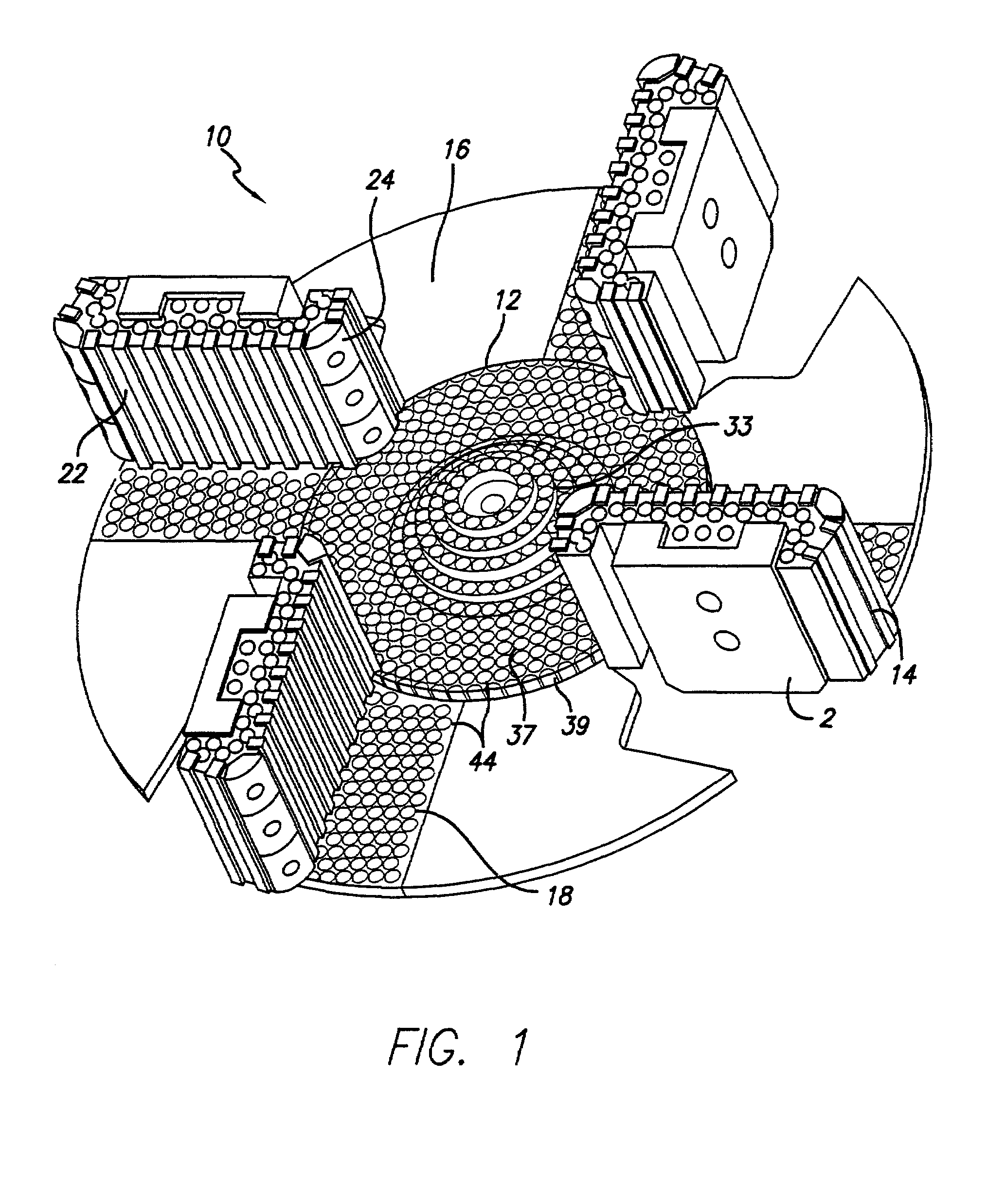

Method and apparatus for producing hollow rack bar and mandrel used for rack bar production

InactiveUS20060016238A1Low costLow running costNutsMetal-working apparatusEngineeringMechanical engineering

A system for forging a rack bar from a blank pipe. A blank pipe 1 is held between dies 2 and 3. Stockers 7L and 7R are arranged on respective sides of the die set. In the stockers 7L and 7R, left-handed shuttles 6L1, 6L2, 6L3, . . . 6Ln and right-handed shuttles 6R1, 6R2, 6R3 . . . 6Rn are stored. First, a left-handed presser rod 5L inserts the shuttles 6L1 to the blank pipe from the left-handed stocker 7L. Then, a right-handed presser rod 5R inserts the shuttles 6R1 to the blank pipe from the right-handed stocker 7R, causing the shuttles 6L1 to be entrained and returned to the left-handed stocker 7L. Vertical shift movement is alternately executed between the left-handed and right-handed stockers 7L and 7R, so that a shuttle of step-likely increased working height is selected for executing a working process.

Owner:MATSUOKA MINAKO +2

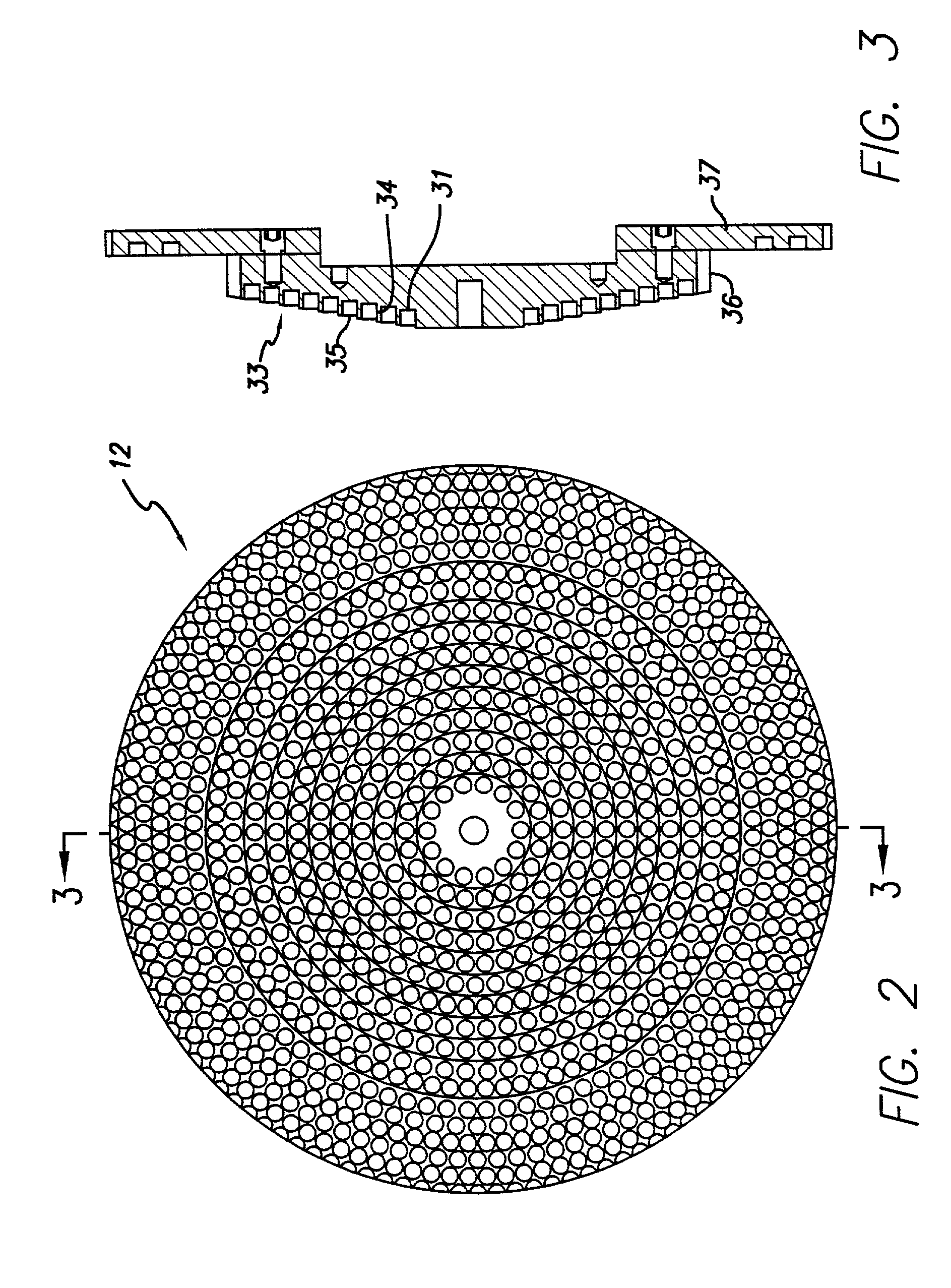

Sandwich core material

InactiveUS20130171381A1Reduce weightSpacePropellersFinal product manufactureTurbine bladeMechanical engineering

A sandwich core material for a sandwich laminate is disclosed. The sandwich core material includes a number of flexible core material elements having a longitudinal structure. A flexible core material for a sandwich core material, a sandwich laminate and a wind turbine blade including such a sandwich core material are provided. In addition, the present a method of manufacturing such a sandwich core material is provided.

Owner:SIEMENS AG

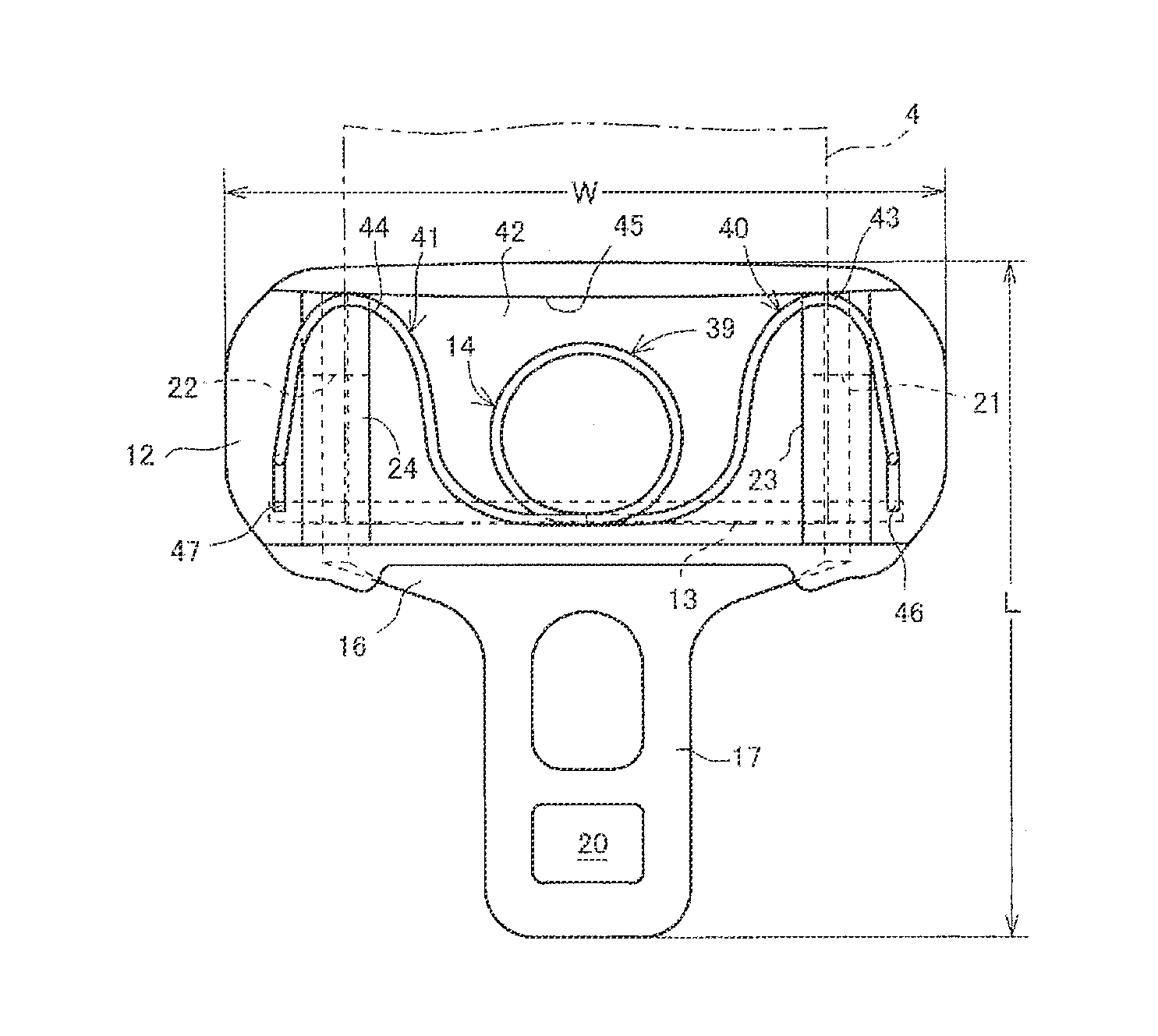

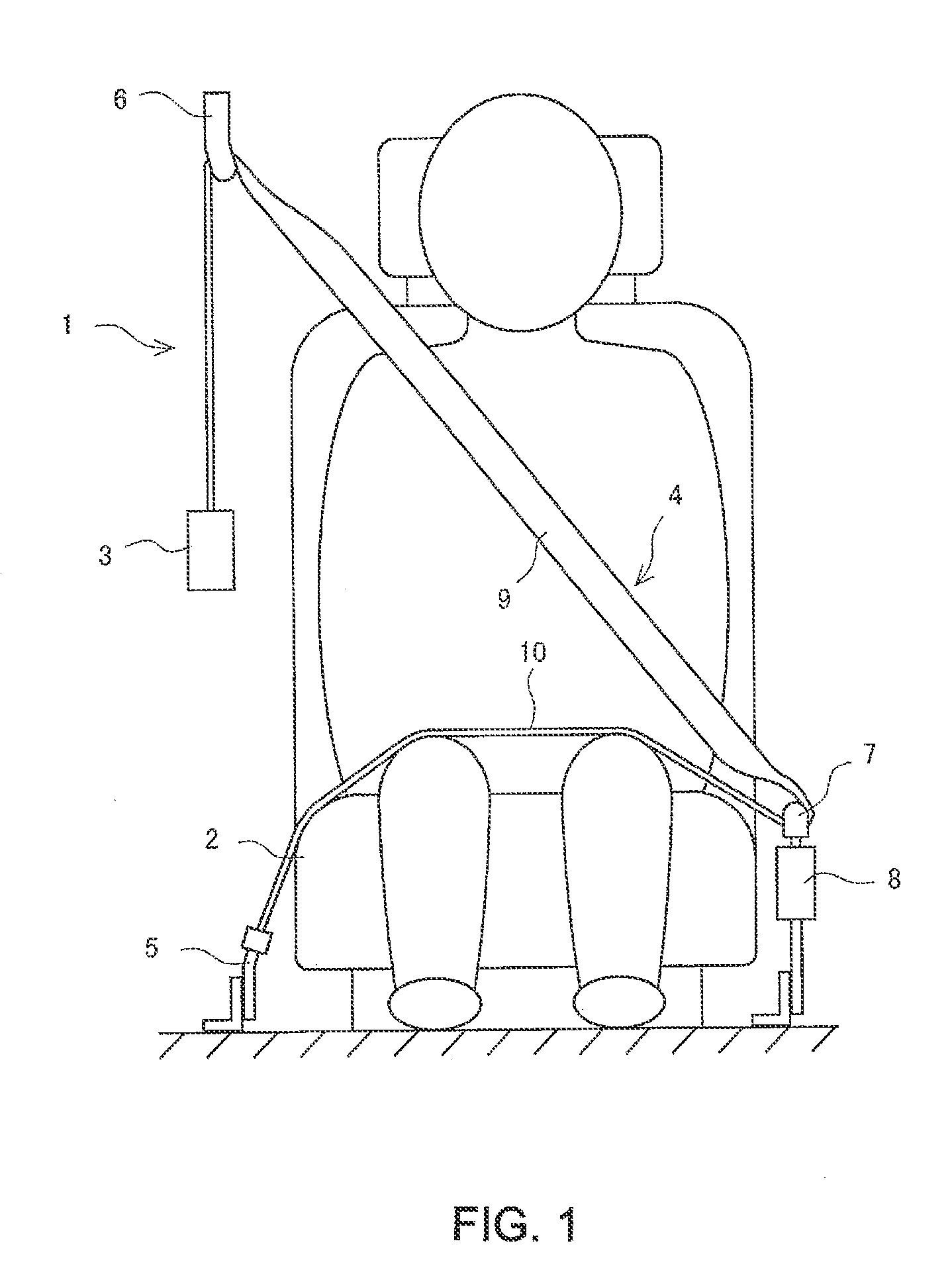

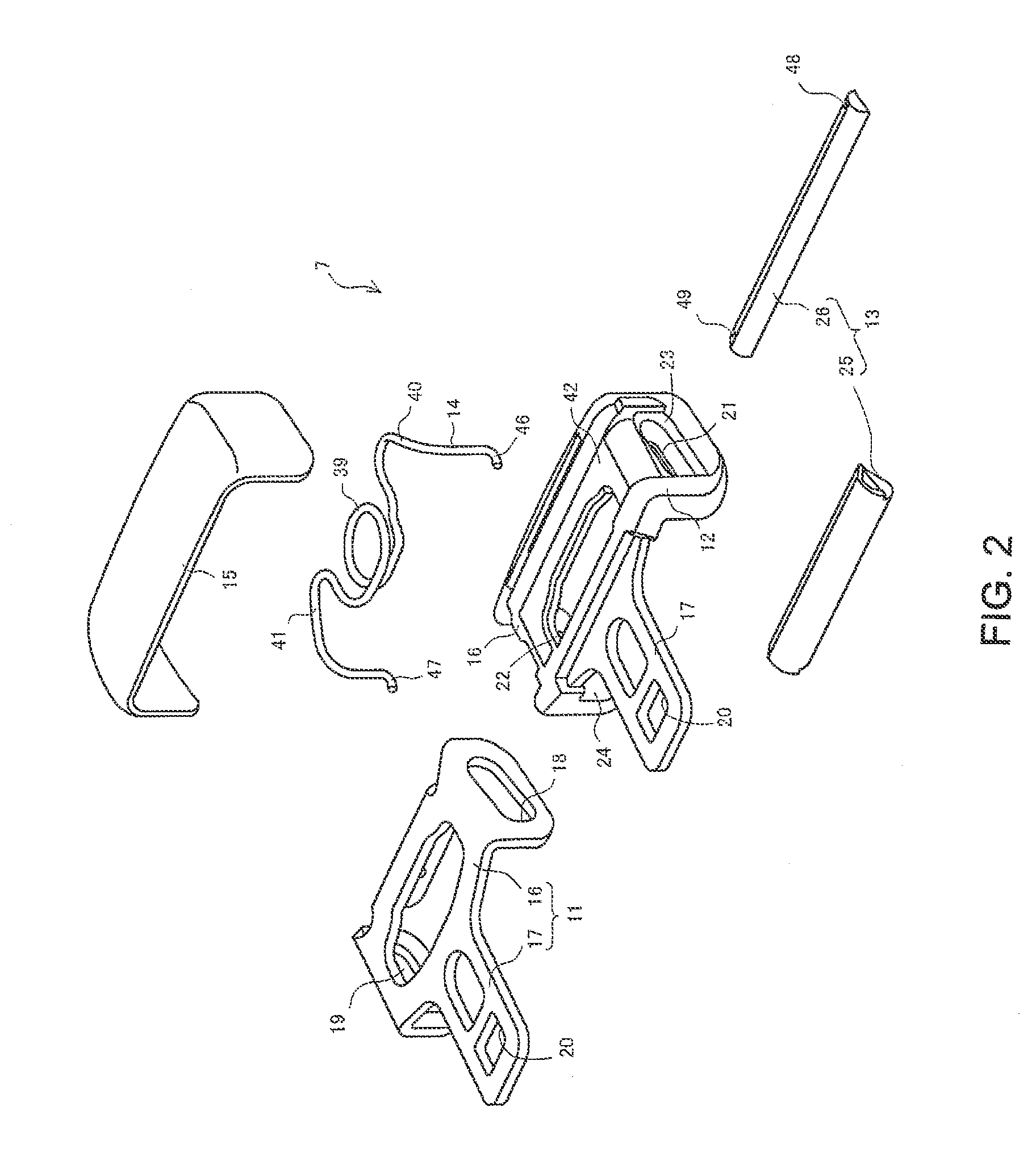

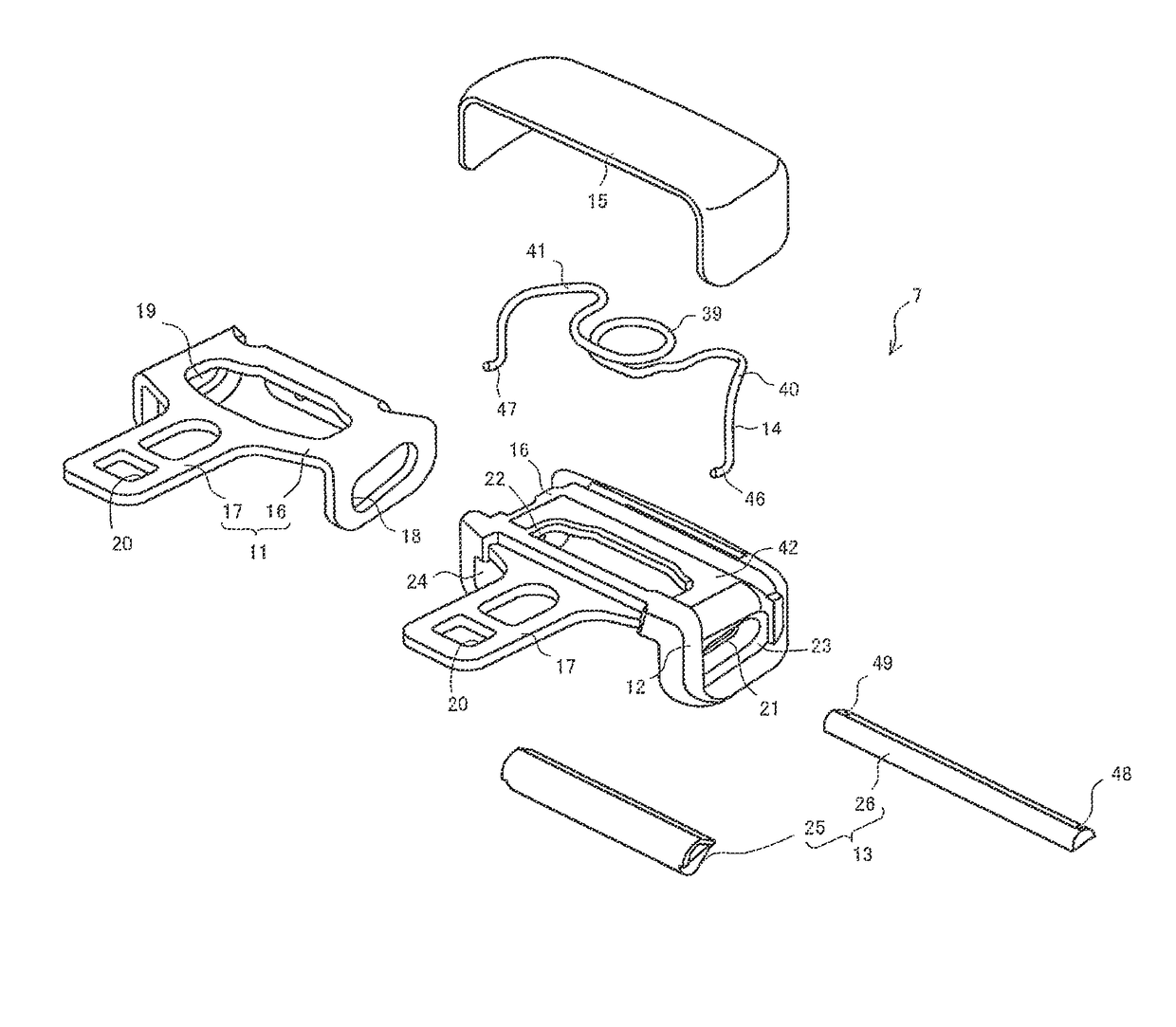

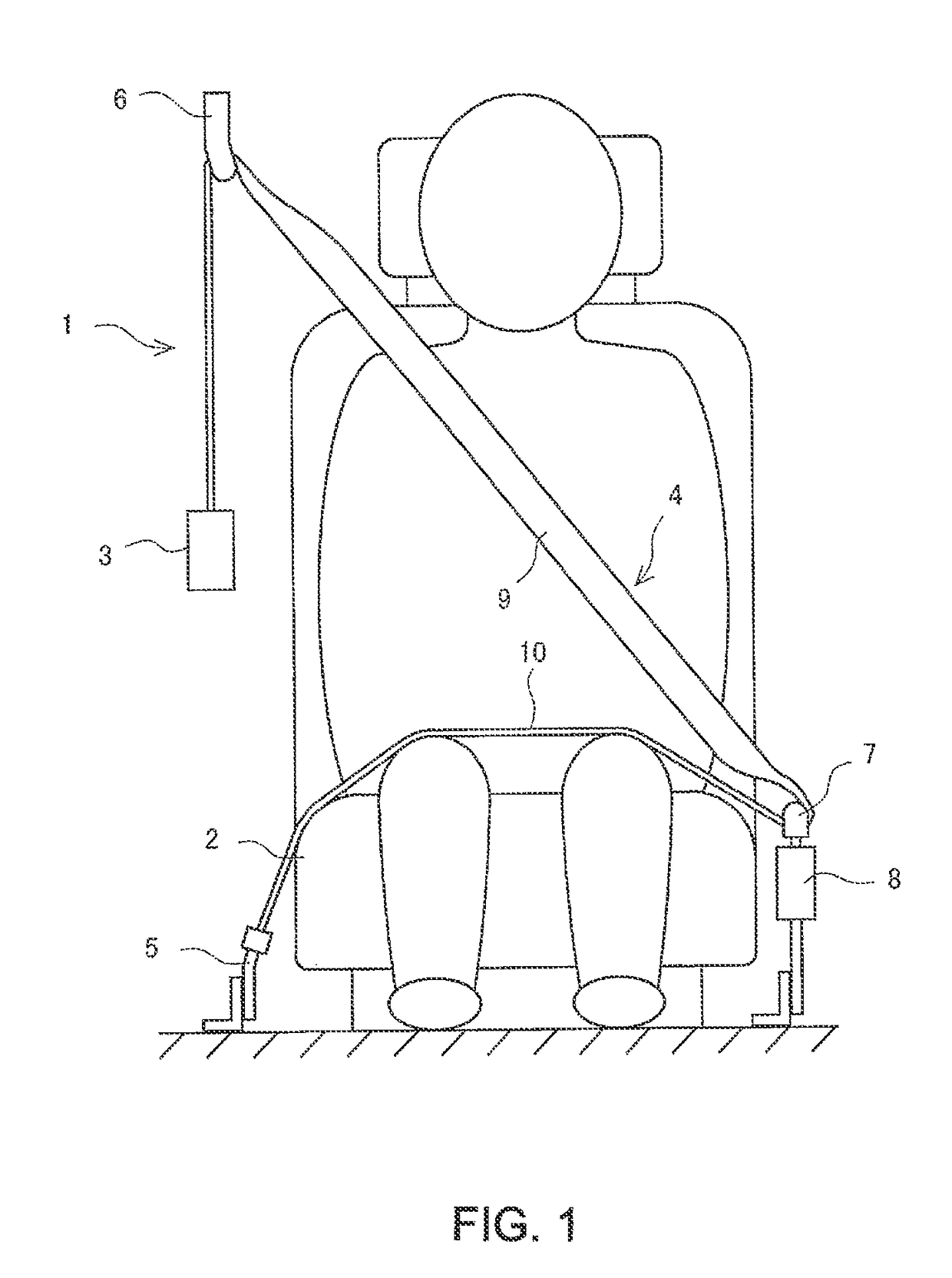

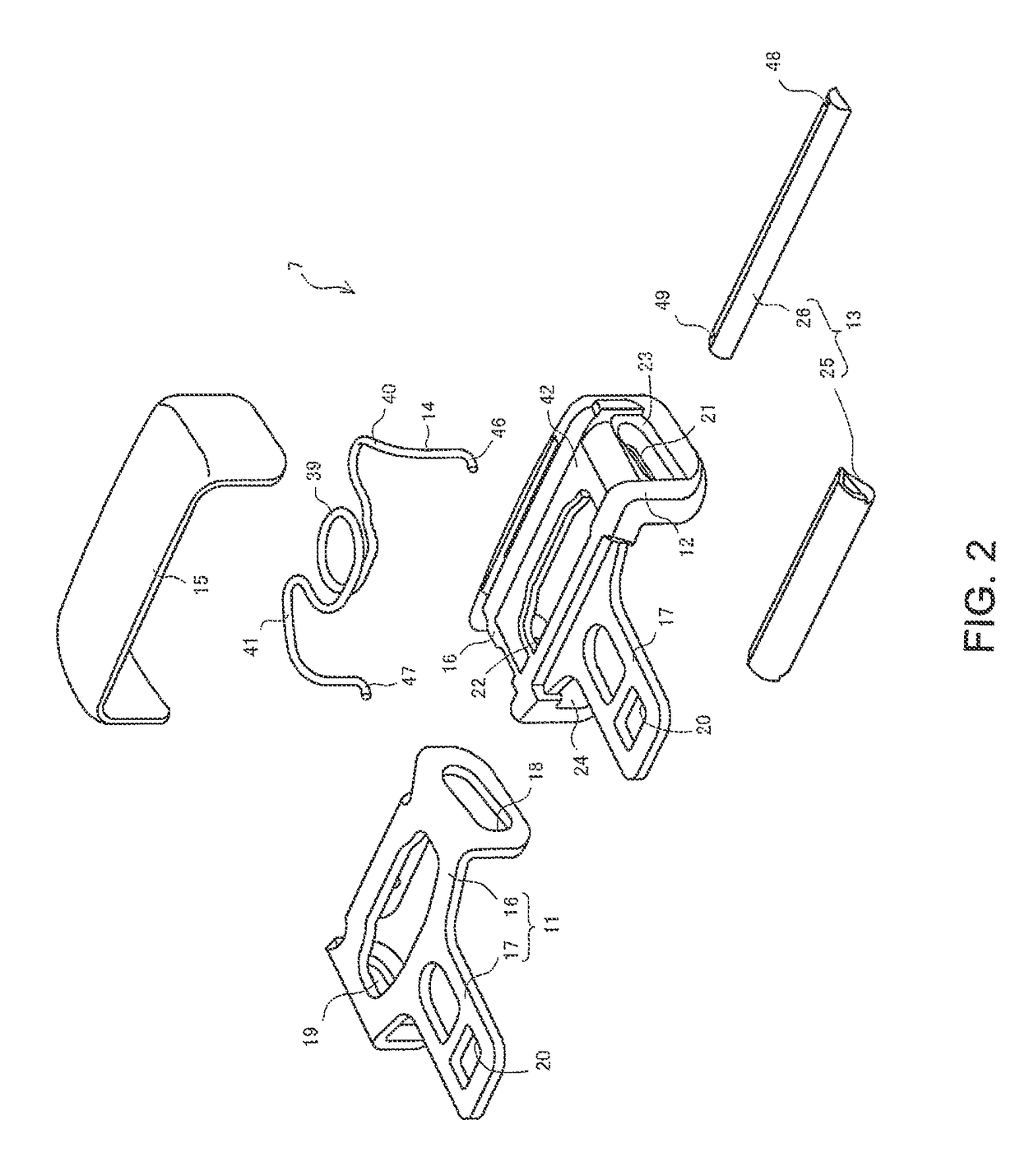

Tongue and seat belt device using same

[Object] To enable a tongue to be more compact in size even when a seat-belt locking member is disposed and to achieve satisfactory mountability.[Solution] A tongue 7 includes a resin mold portion 12 having seat belt lock guide holes 21 and 22. The resin mold portion 12 is provided with a seat belt lock 13 such that it is movable between an unlocking position where it does not lock a seat belt 4 and a locking position where it locks the seat belt 4 while being guided by the seat belt lock guide holes 21 and 22, and the seat belt lock 13 is set in the unlocking position under normal conditions and is set in the locking position in emergency. The seat belt lock 13 is continuously urged toward the unlocking position by a torsion spring 14. In emergency, the seat belt lock 13 is set in the locking position by a pressing force from the seat belt 4 against the urging force of the torsion spring 14.

Owner:JOYSON SAFETY SYST JAPAN GK

Technology for fabricating big vessel shaped Ru porcelain bottle

The invention relates to a technology for fabricating big vessel shaped Ru porcelain bottle, which comprises the following steps of: taking the following constituents in percentage by weight as blank materials: 15-20% of kaolin, 4-10% of camwood knot, 25-40% of hargil, 15-25% of chinastone, 4-10% of quartz and 15-20% of potassium feldspar; grinding the blank materials, adding water for wet grinding, and regulating water content of the slurry to 35-45%; making the slurry into blank bodies of bottle opening part, middle part and bottom part respectively, bonding by mud, wiping the blanks and burning into bisques; grinding glaze material, and adding water for wetly grinding into the slurry; wiping the bisques, and placing in the glaze material slurry for glaze immersion; and placing the bisques in a kiln, burning in oxidation atmosphere, increasing temperature of the kiln to 1050 degrees centigrade, burning in reducing atmosphere, insulating for 1h at 1050 degrees centigrade, increasing temperature to 1250 degrees centigrade, insulating for half an hour, stopping burning and cooling to finish fabrication of the big vessel shaped Ru porcelain bottle. In the technical scheme, the constituents are firmly combined, the fabrication method can improve strength of the Ru porcelain to prevent cracks, and the fabricated Ru porcelain has thin body, big vessel shape and high strength.

Owner:韩琴

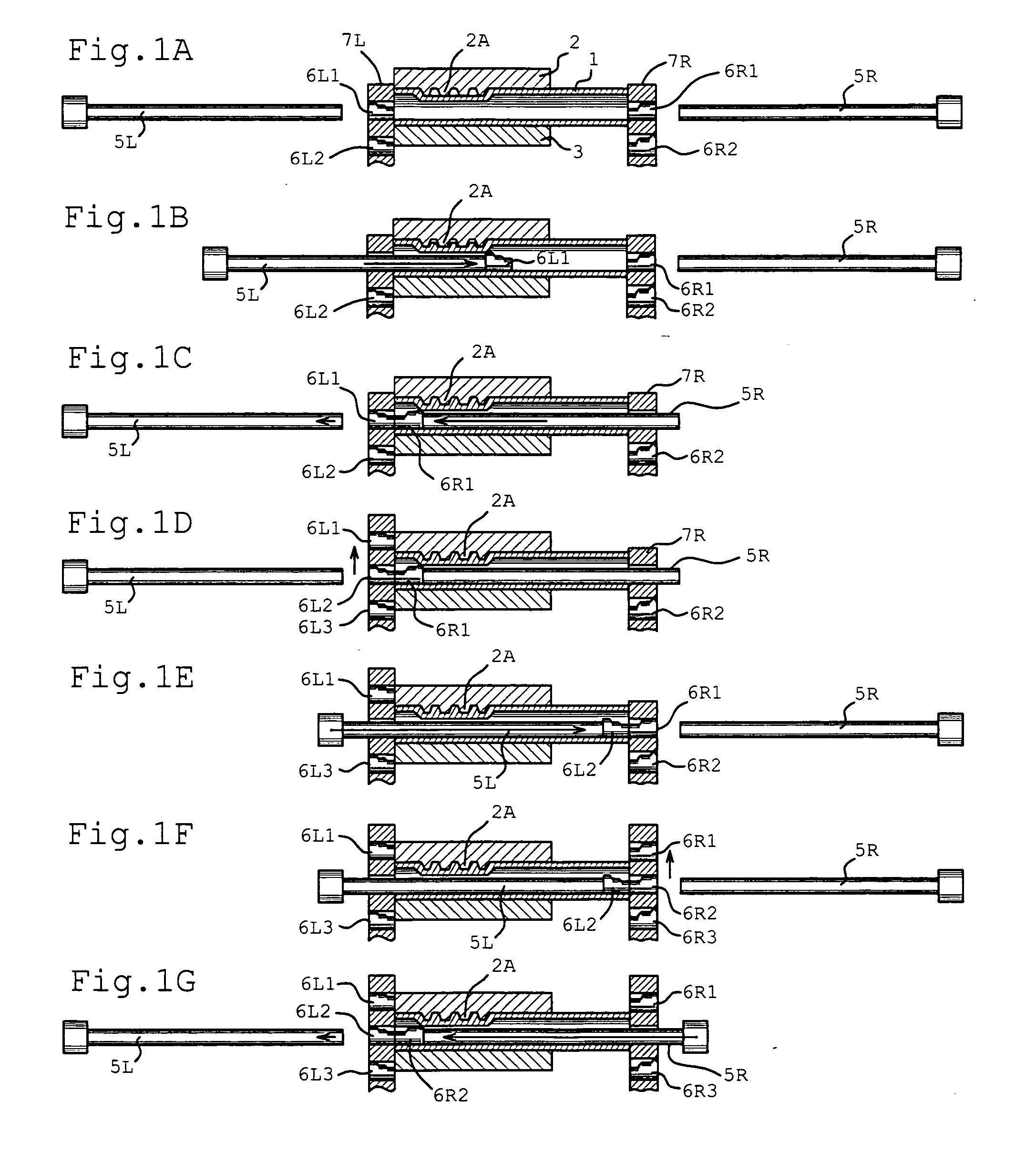

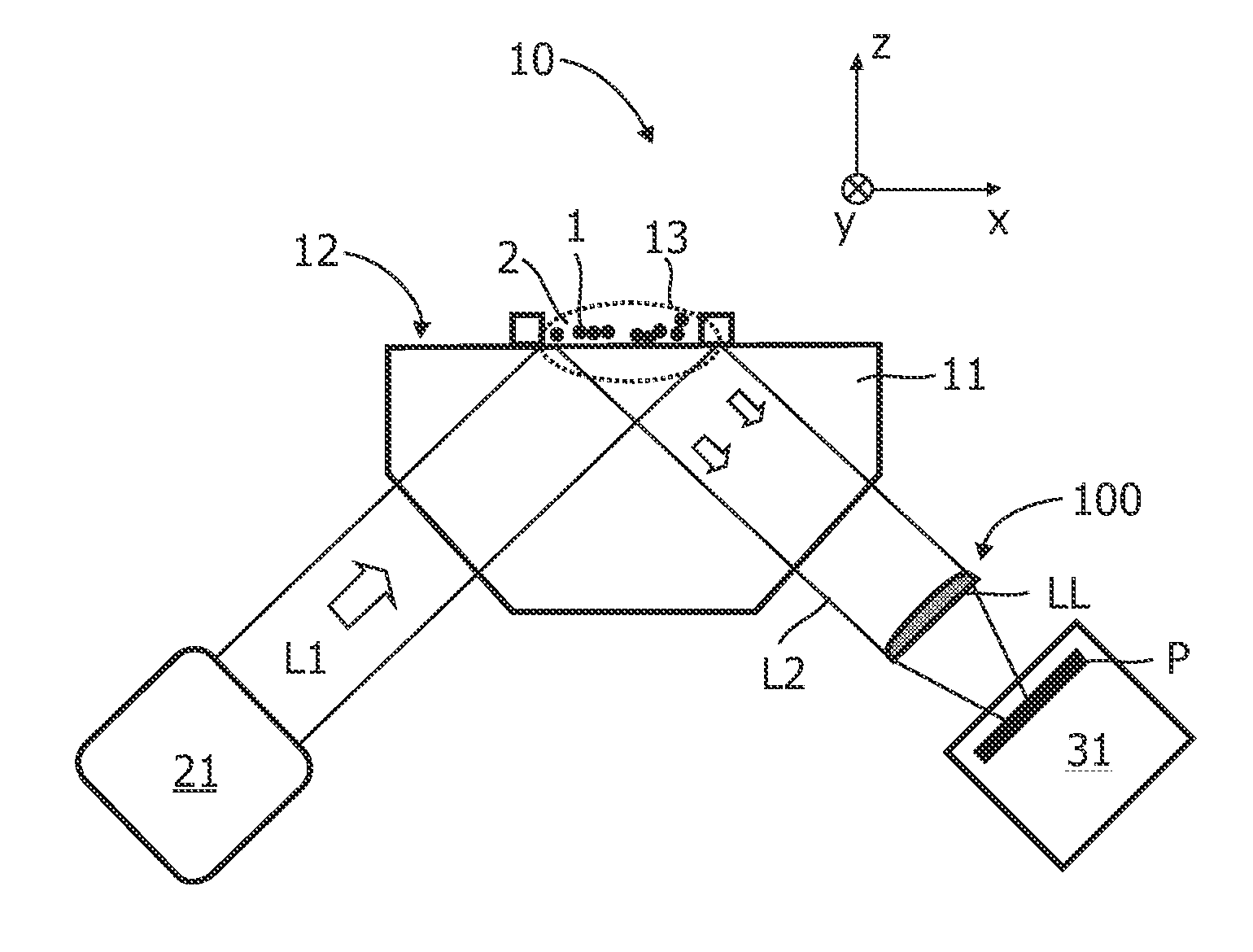

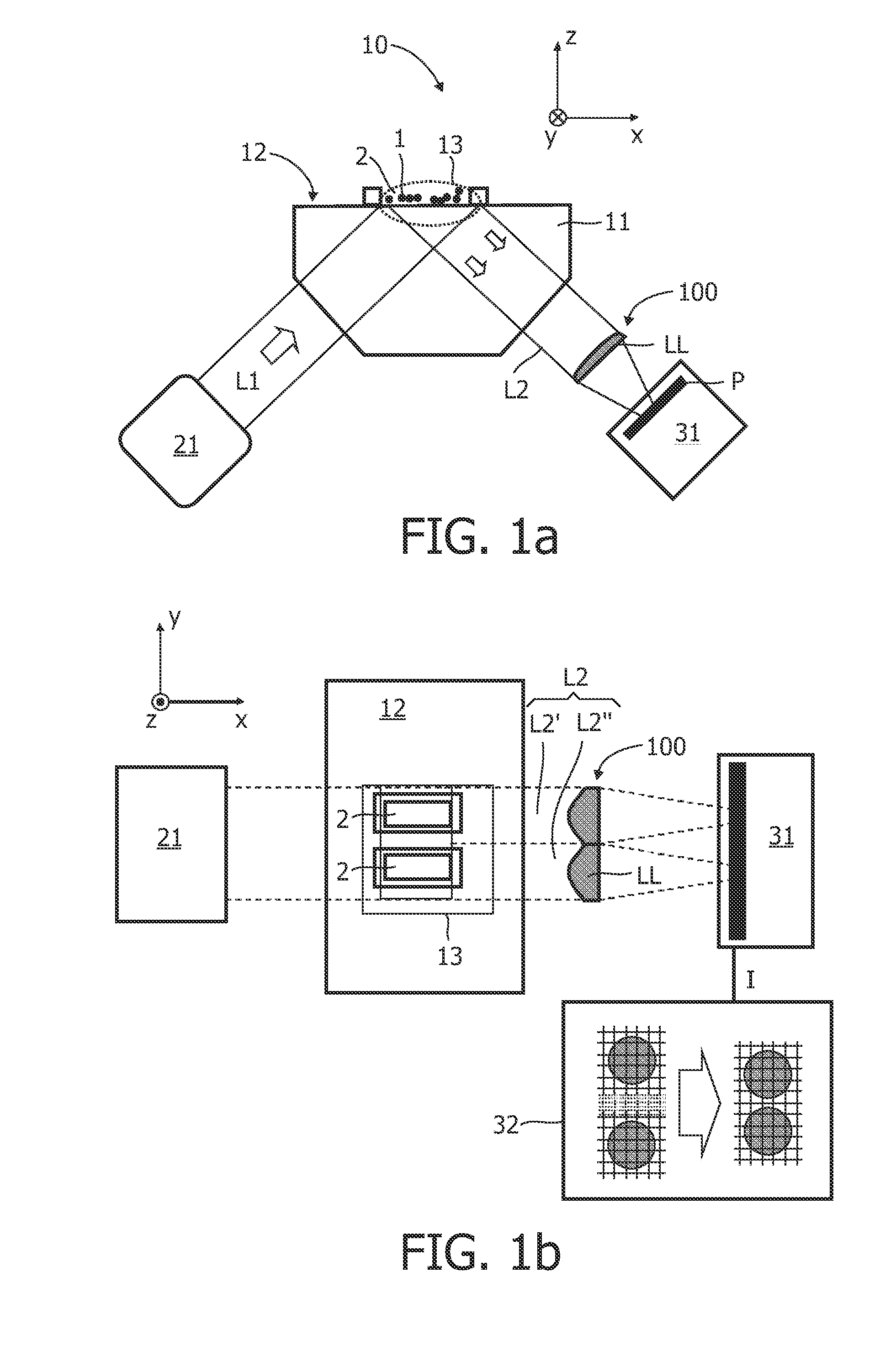

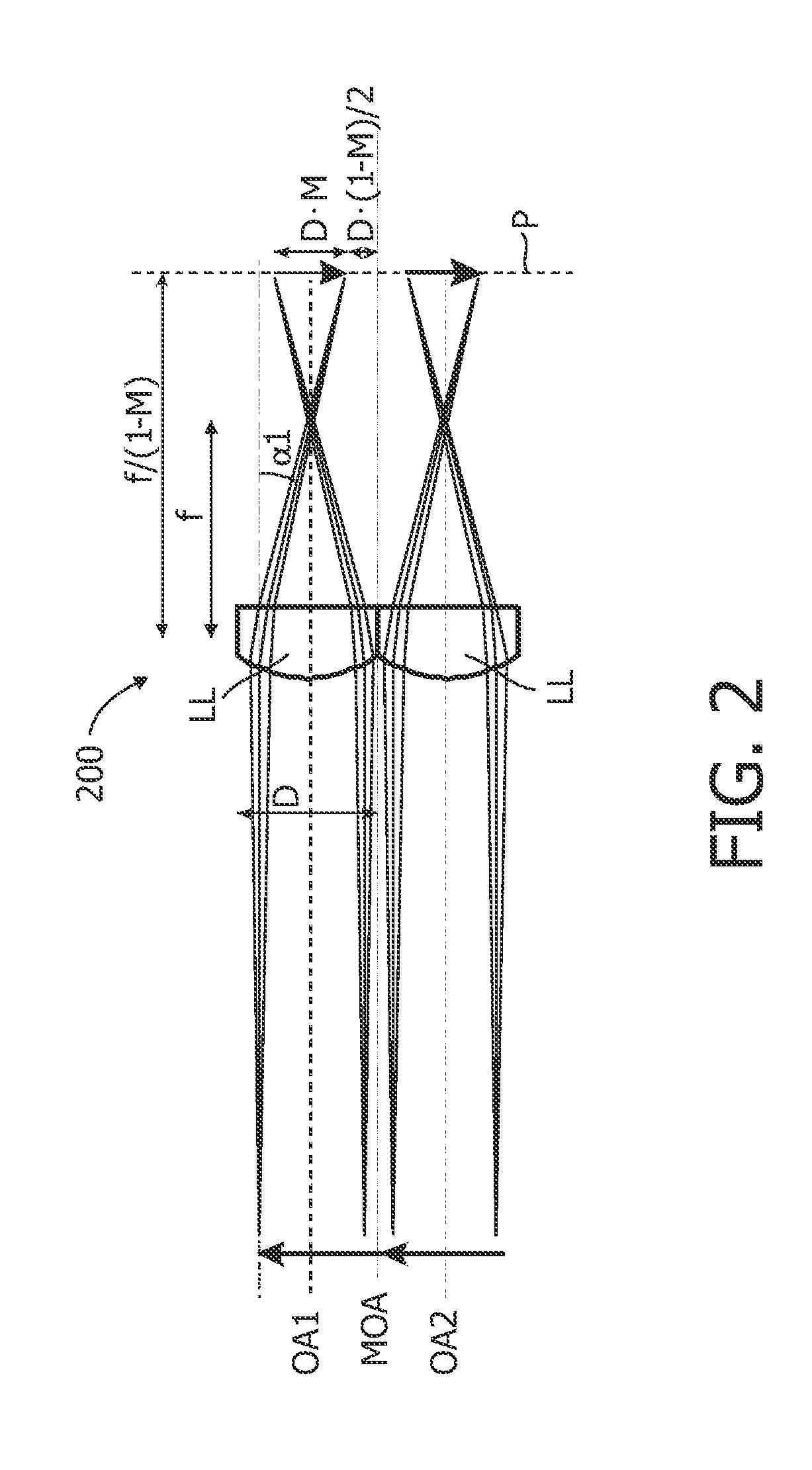

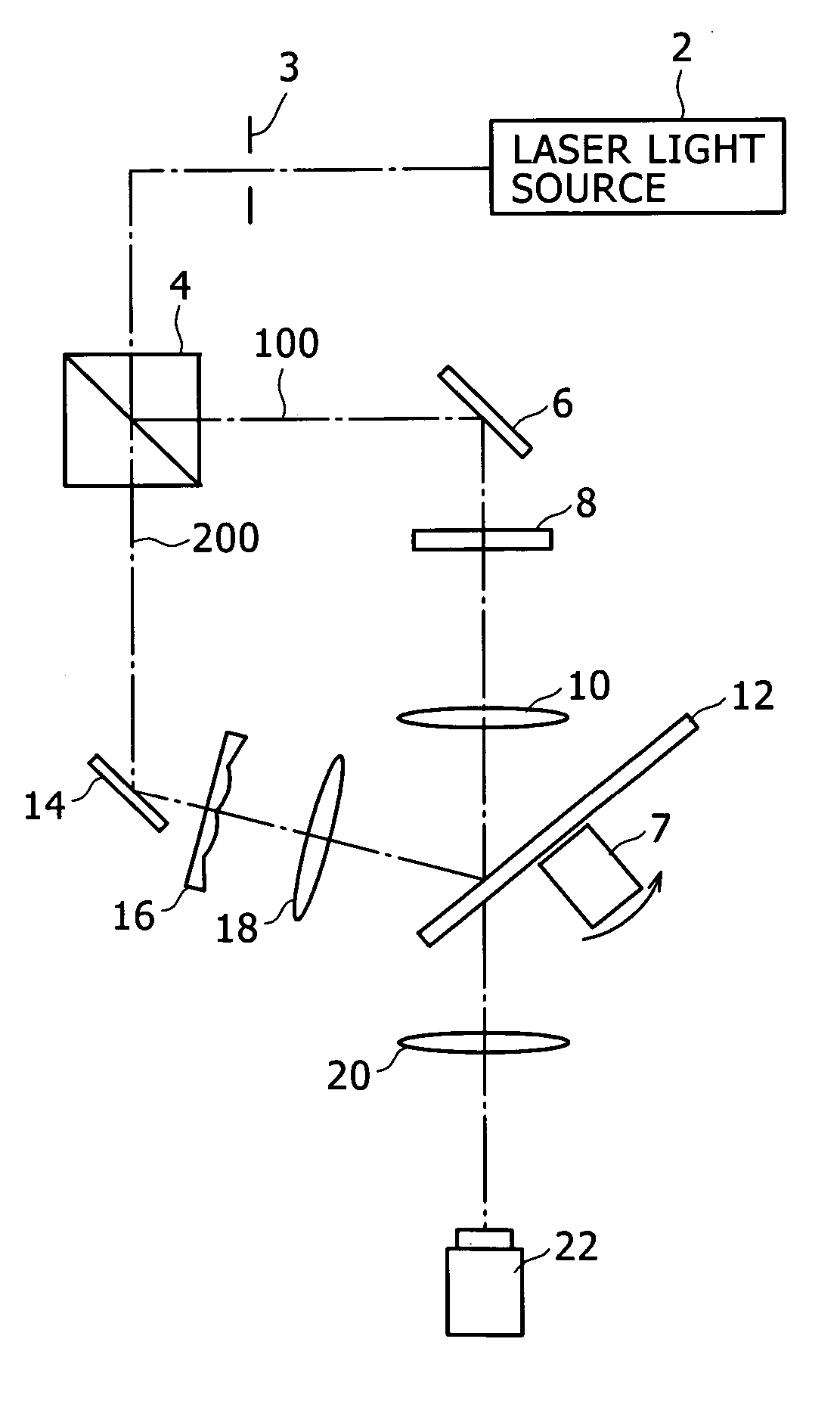

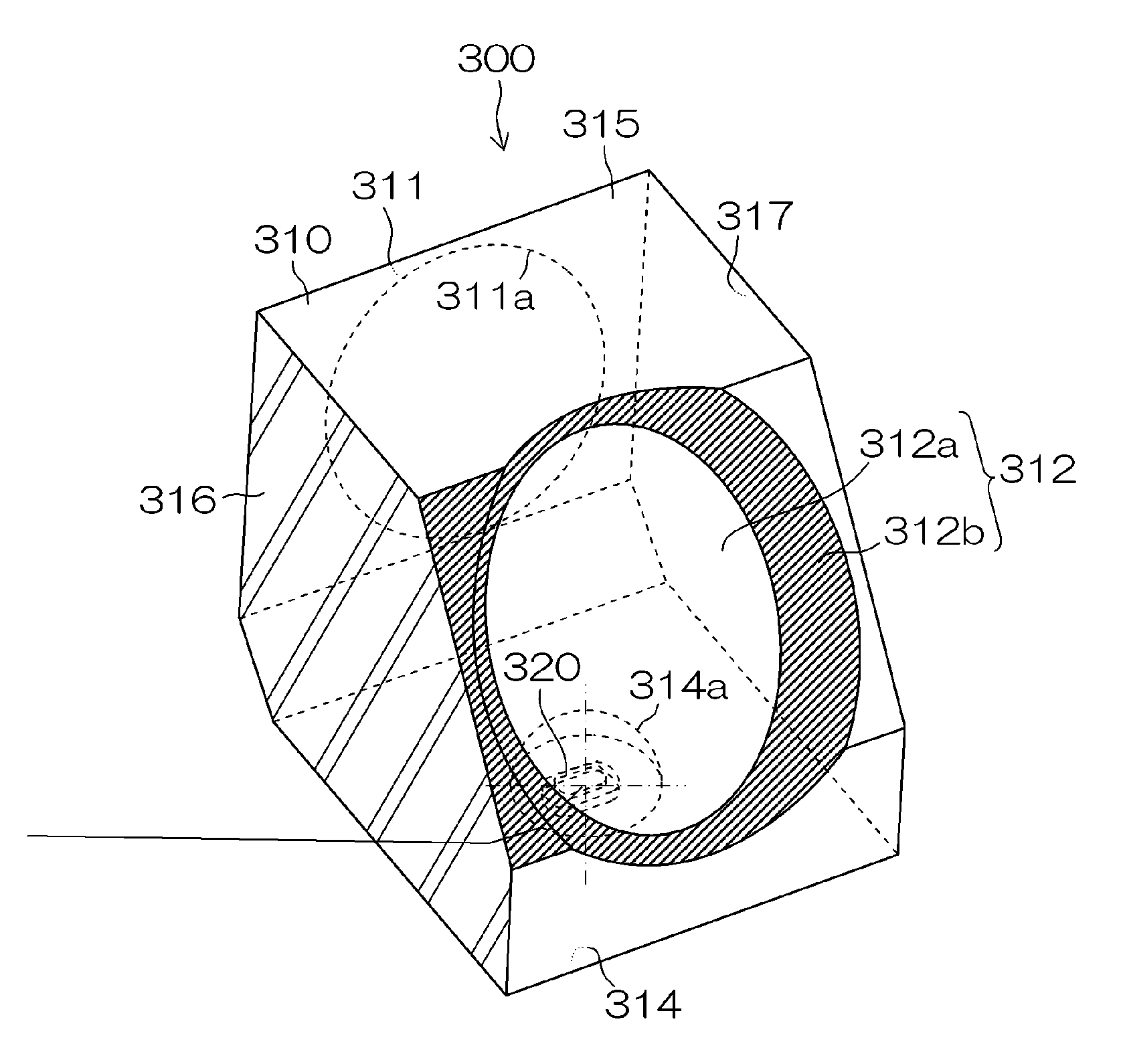

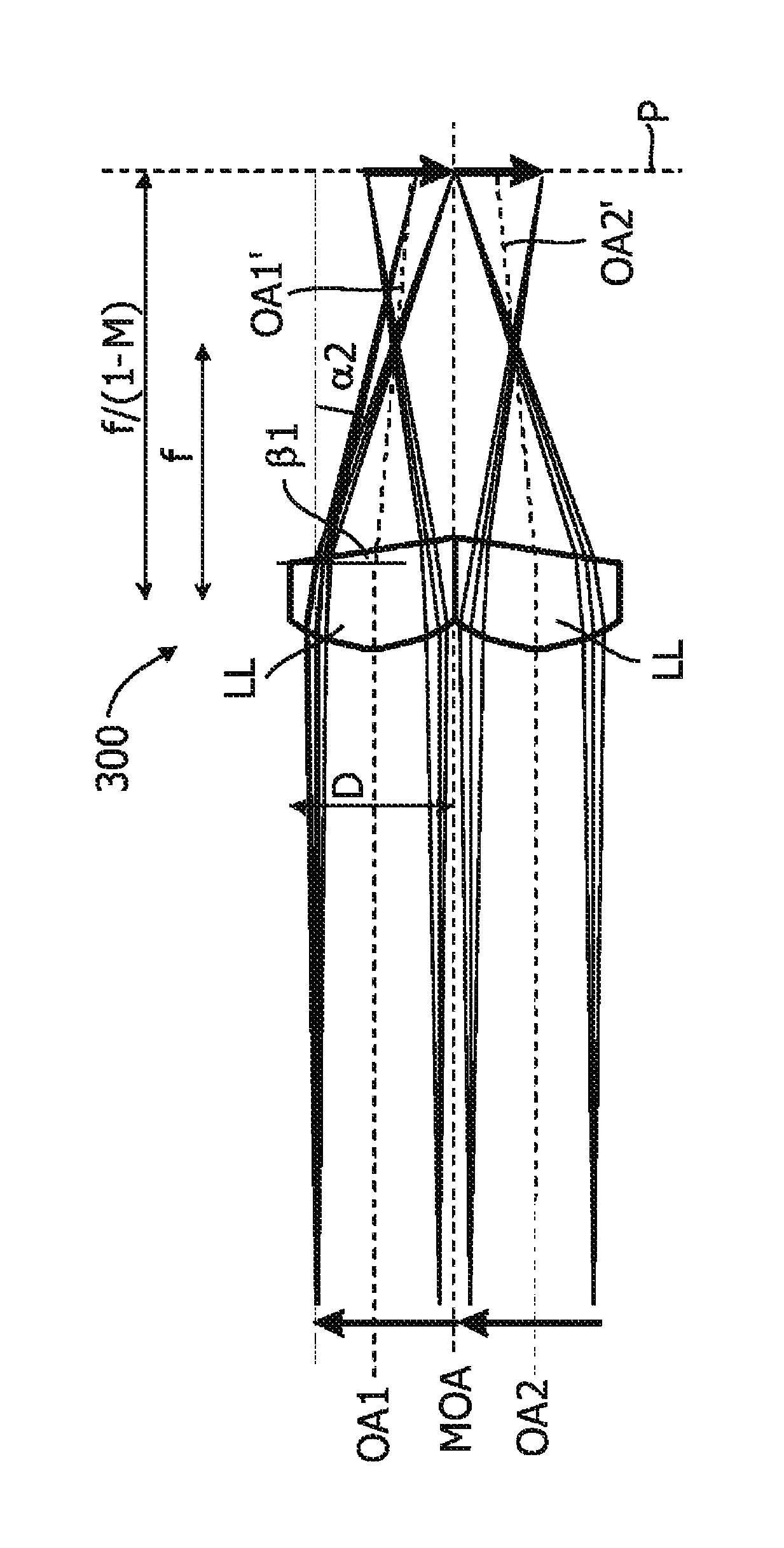

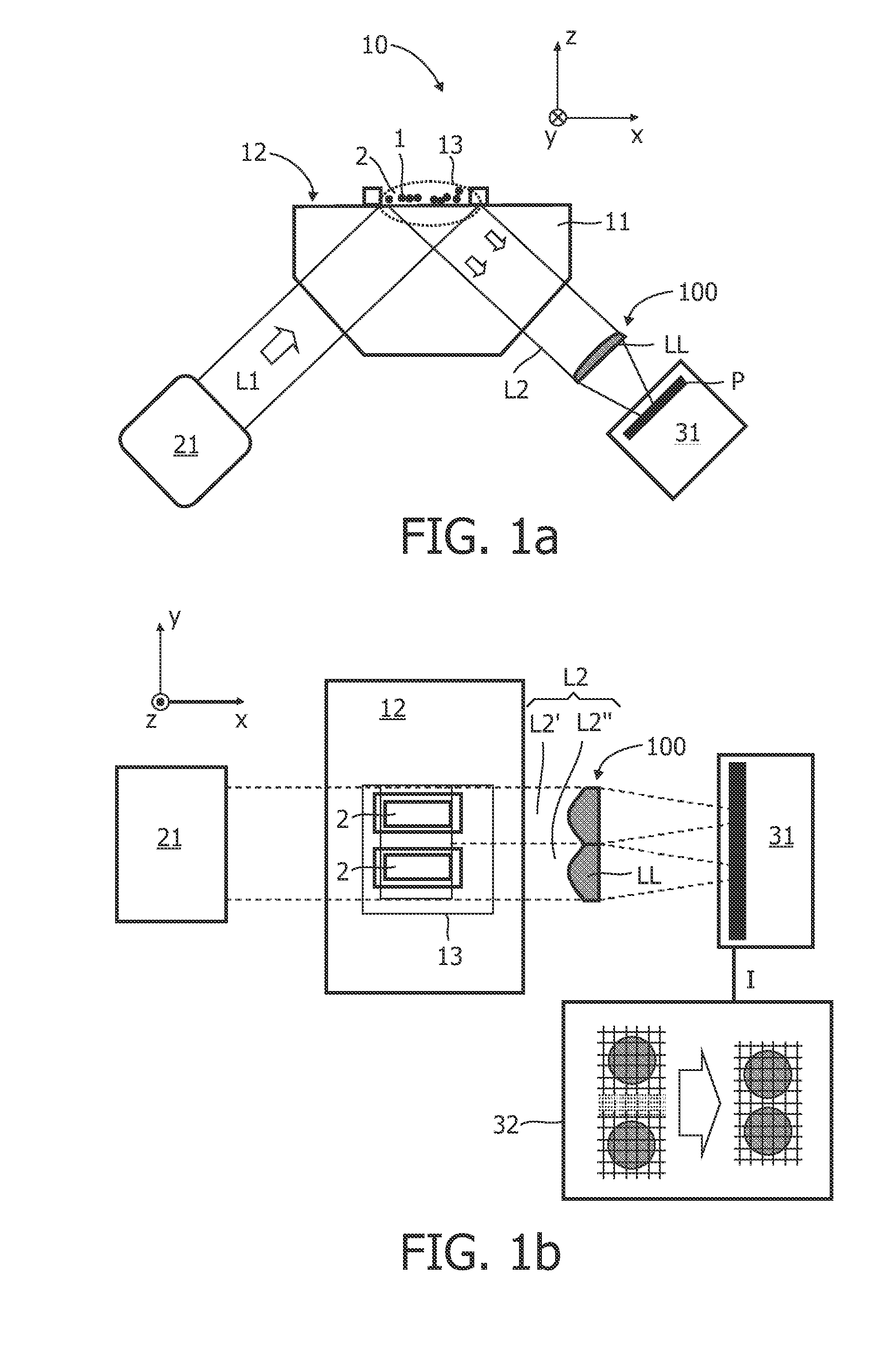

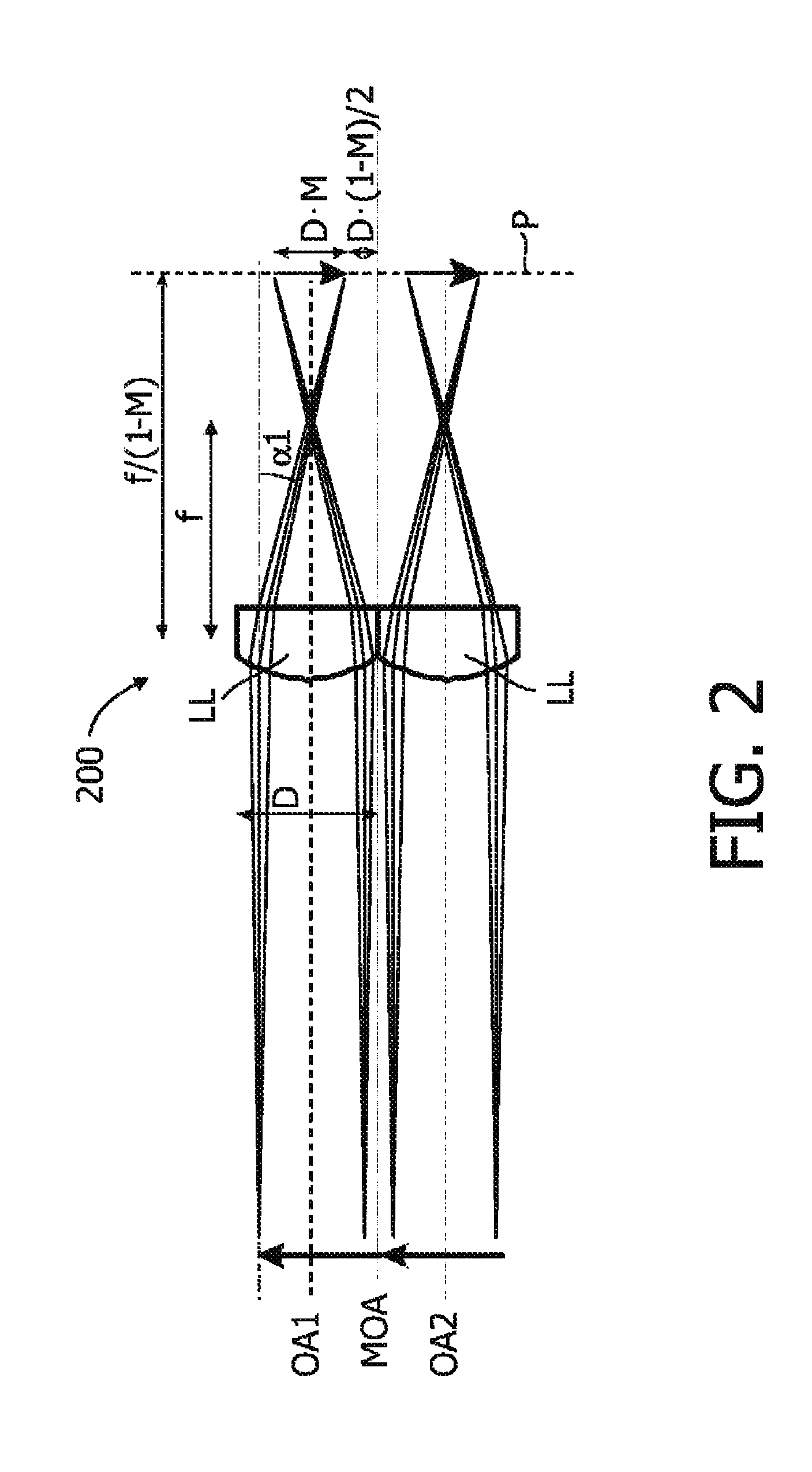

Optical biosensor with focusing optics

ActiveUS20120147377A1Avoid optical distortionImprove accuracyScattering properties measurementsMountingsTotal internal reflectionOptical axis

The invention relates to focusing optics (100) for a biosensor (10) which allow with simple means to accurately image an extended investigation region (13) onto a detector plane (P). To this end, the focusing optics (100) comprises at least two focusing lenslets (LL) that are arranged adjacent to each other such that they image an incident parallel light beam (L2) that is directed along a main optical axis (MOA) onto a common plane (P). The output light beam (L2) that is received by the focusing optics (100) may preferably originate from total internal reflection of a parallel input light beam (L1) at the investigation region (13) of a transparent carrier.

Owner:SIEMENS HEALTHINEERS NEDERLAND BV

Mobile Phone

InactiveUS20080079916A1High driving electric powerBrighter and sharper projected imageTelevision system detailsPrintersProjection lensComputer science

A mobile phone includes an information display device and an image projection device. The information display device has a transmissive liquid crystal panel (13) for information display that has a specific region (13a) in a part thereof. The information display device further has a backlight unit (17) that illuminates the transmissive liquid crystal panel. The image projection device has a light source (14) that illuminates the specific region (13a), and a projection lens (18) that directs light from the light source (14) received through the specific region toward a screen.

Owner:CITIZEN ELECTRONICS CO LTD

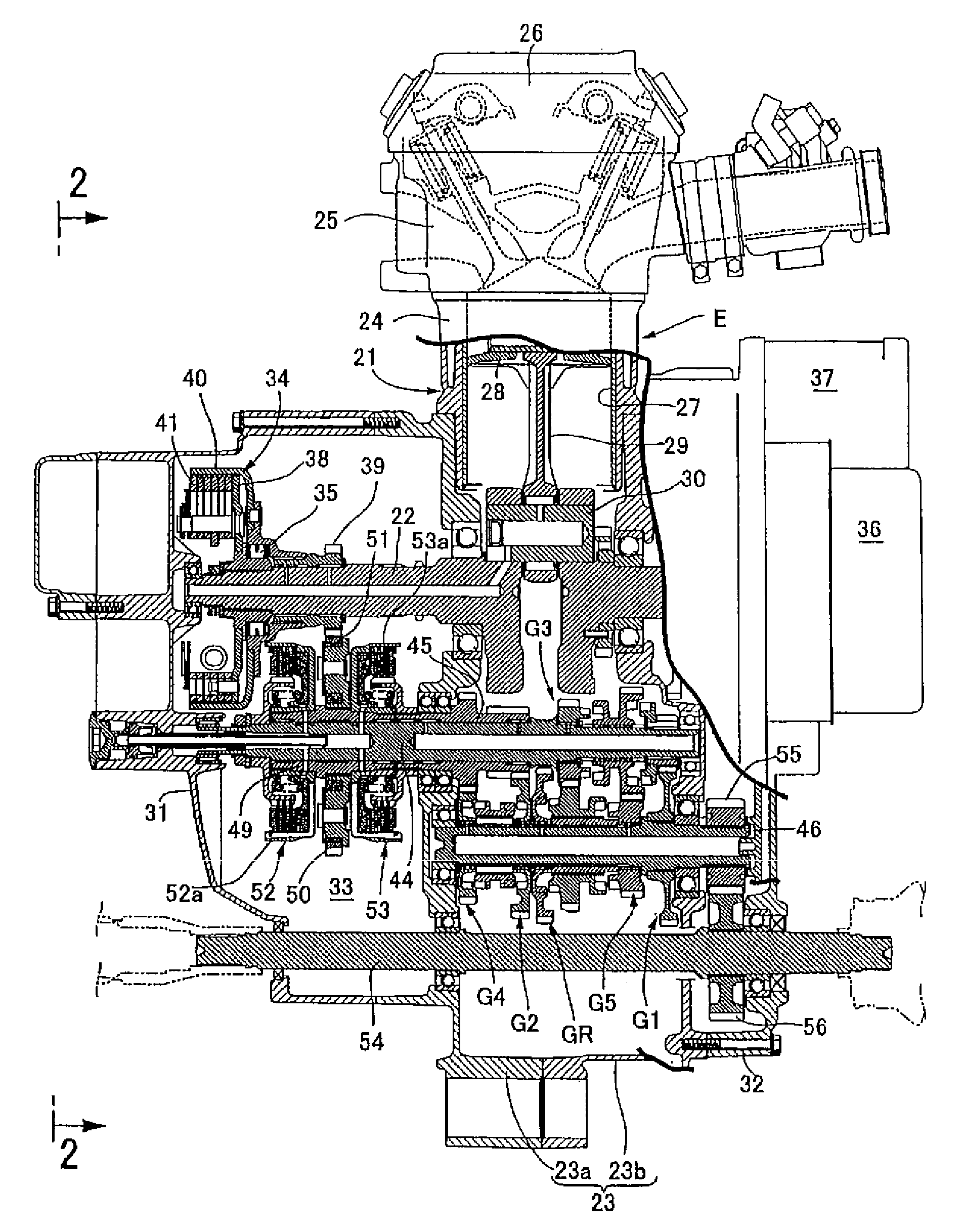

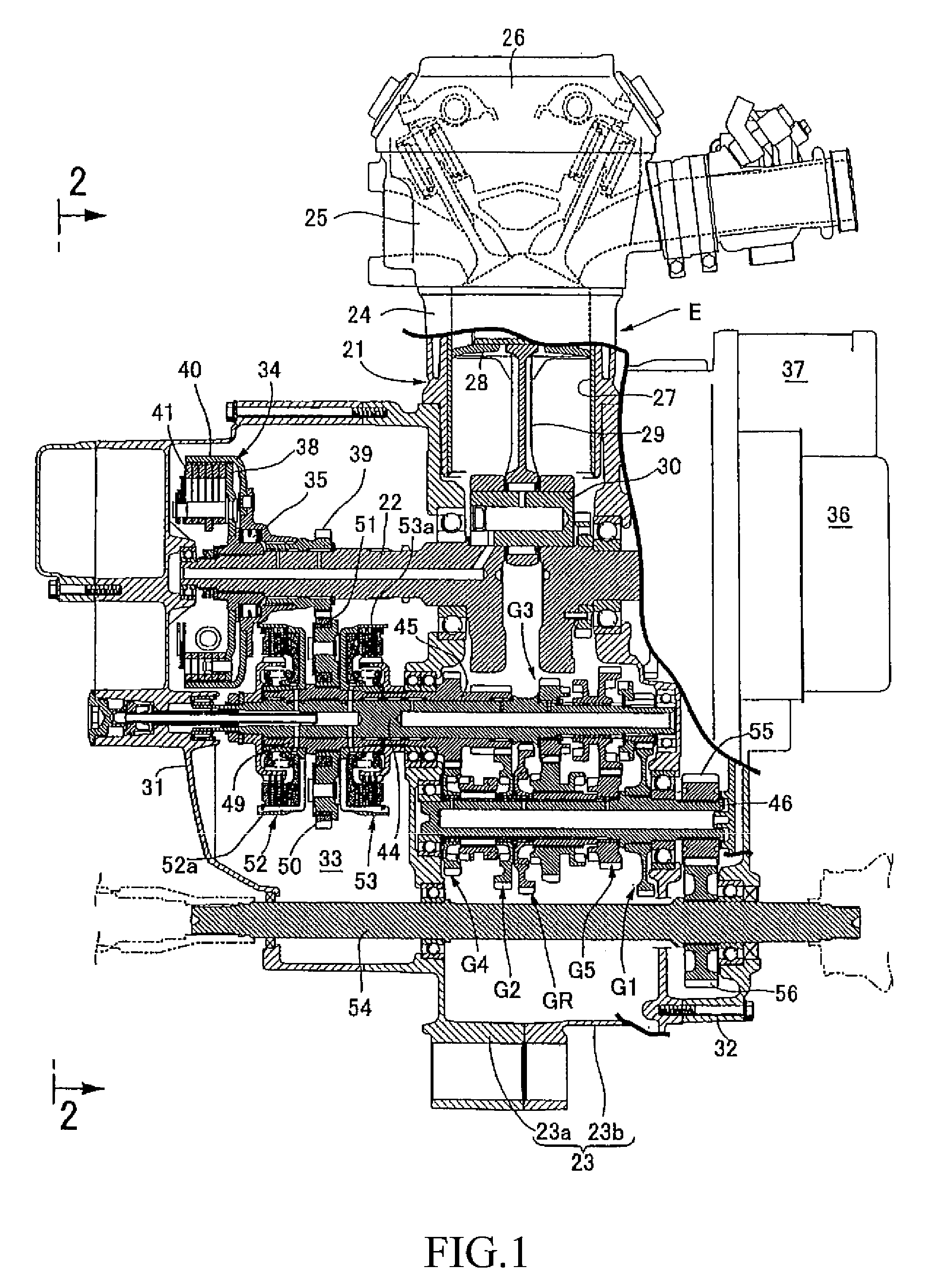

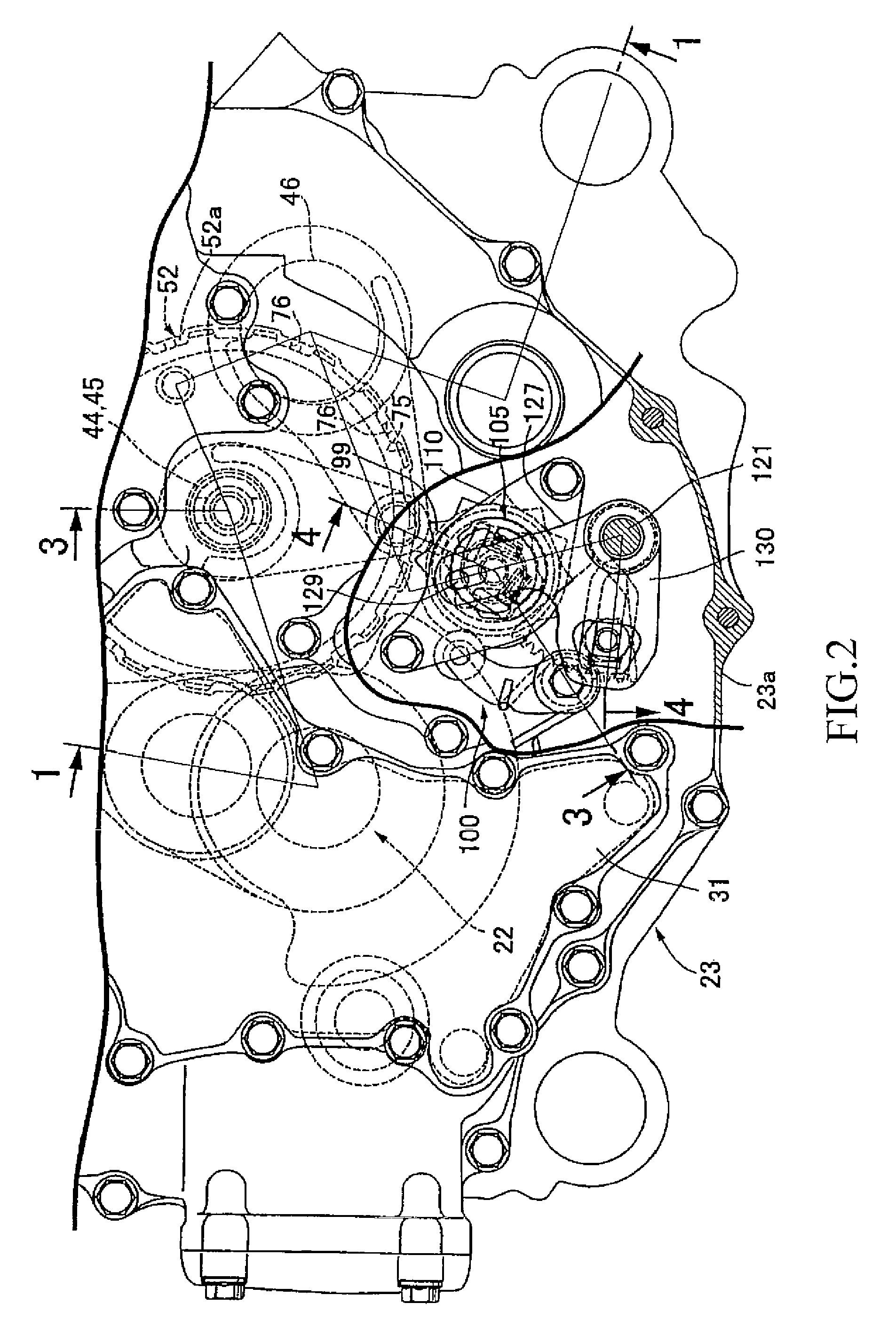

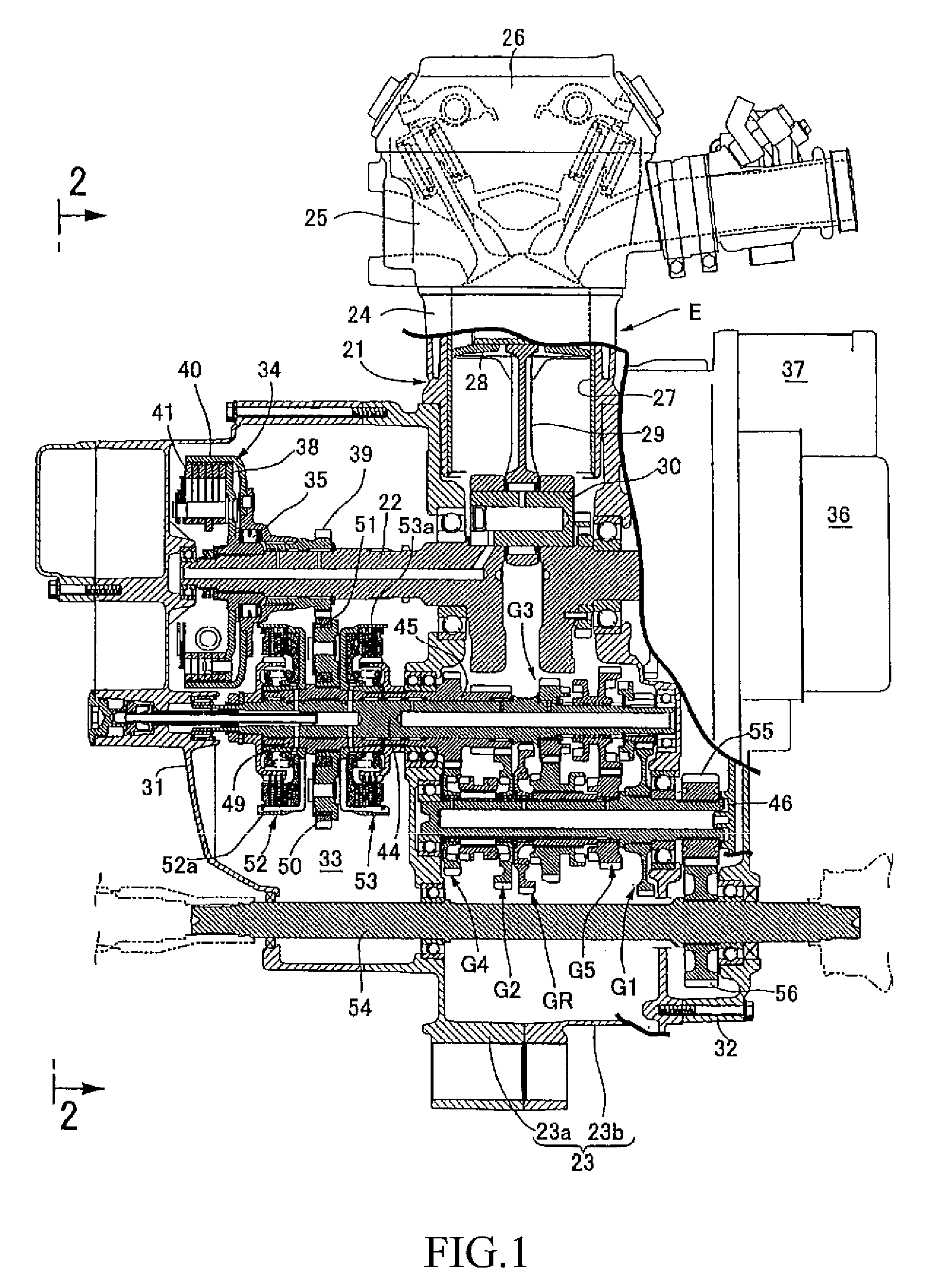

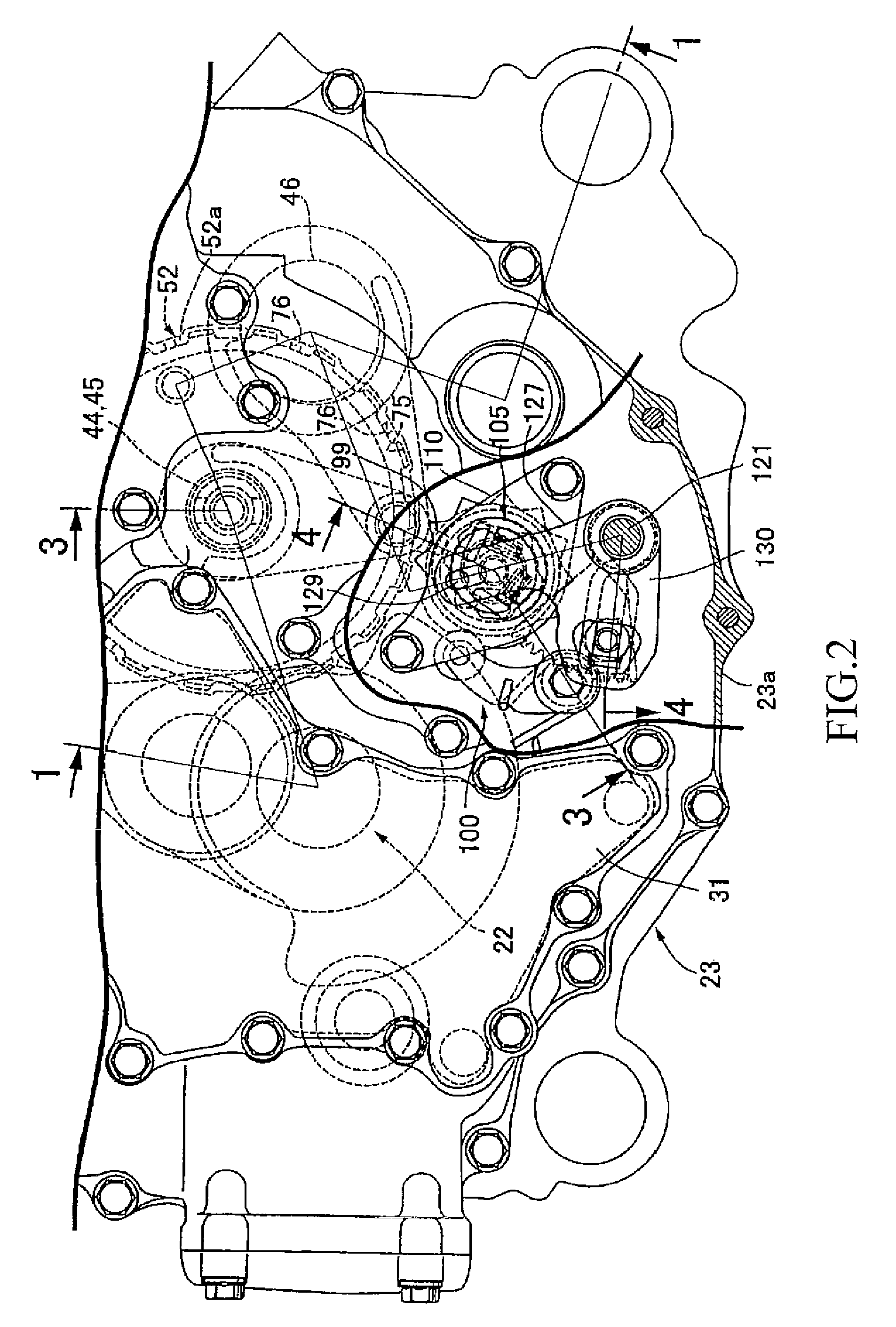

Vehicle transmission

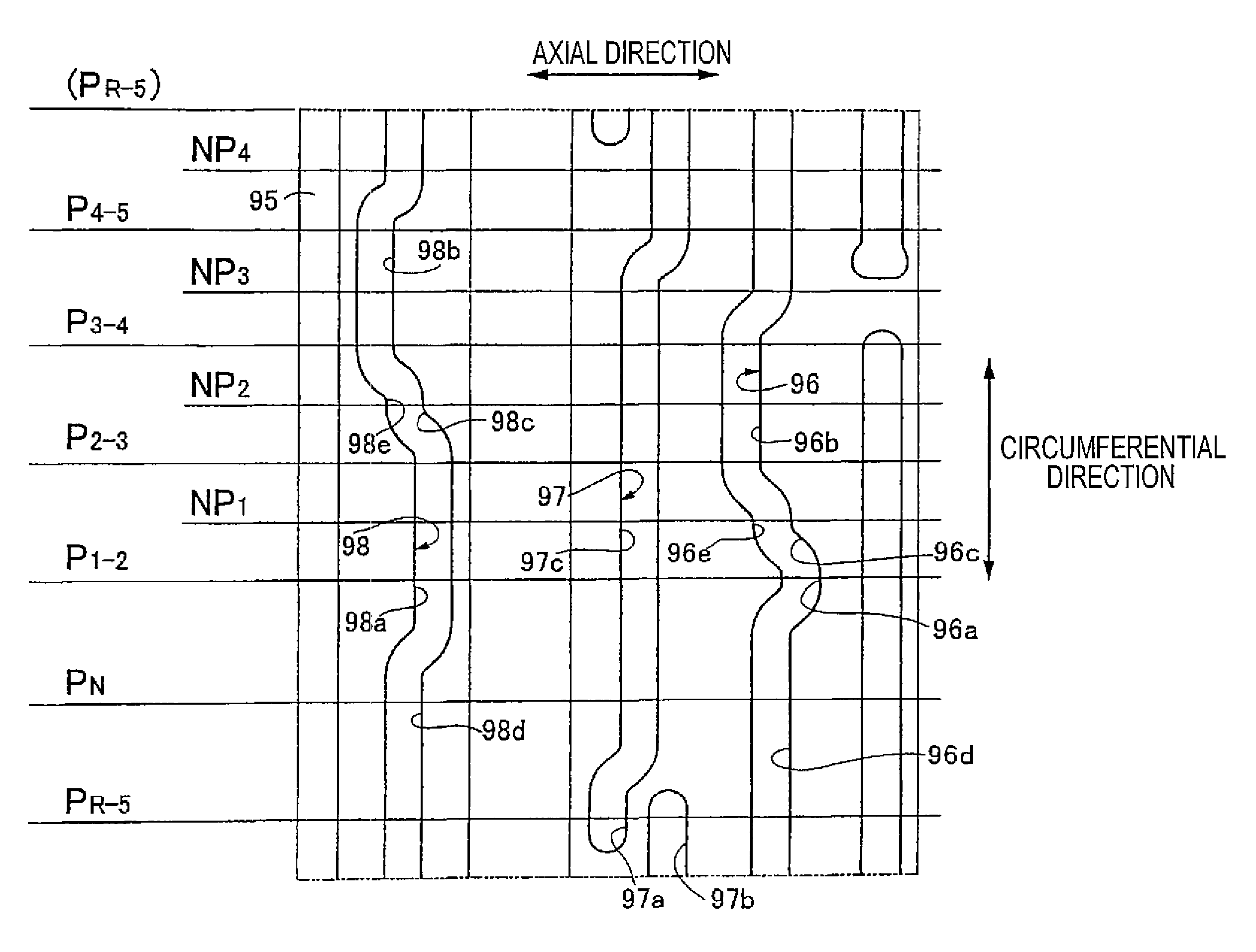

ActiveUS20080236316A1Reduce the overall diameterEliminate significant changeGearing controlEngineeringGear train

An outer circumference of a shift drum of a vehicle transmission is provided with at least one particular lead groove among multiple lead grooves which continuously extends beyond one circle of the shift drum. Two ends of the particular lead groove are arranged so as to be out of alignment with each other in the axial direction of the shift drum. A common shift position adapted to establish gear trains with two shift stages different from each other is set at one position corresponding to the two ends of the particular lead groove along the circumferential direction of the shift drum. The resulting configuration prevents an increase in the diameter of a shift drum and eliminates the significant change of the shape of a lead groove, even as the number of shift positions set on the shift drum is increased.

Owner:HONDA MOTOR CO LTD

Apparatus For Recovery Metal

InactiveUS20080142374A1Facilitate recovery and recyclingLarge shapeCellsPhotography auxillary processesMetalMaterials science

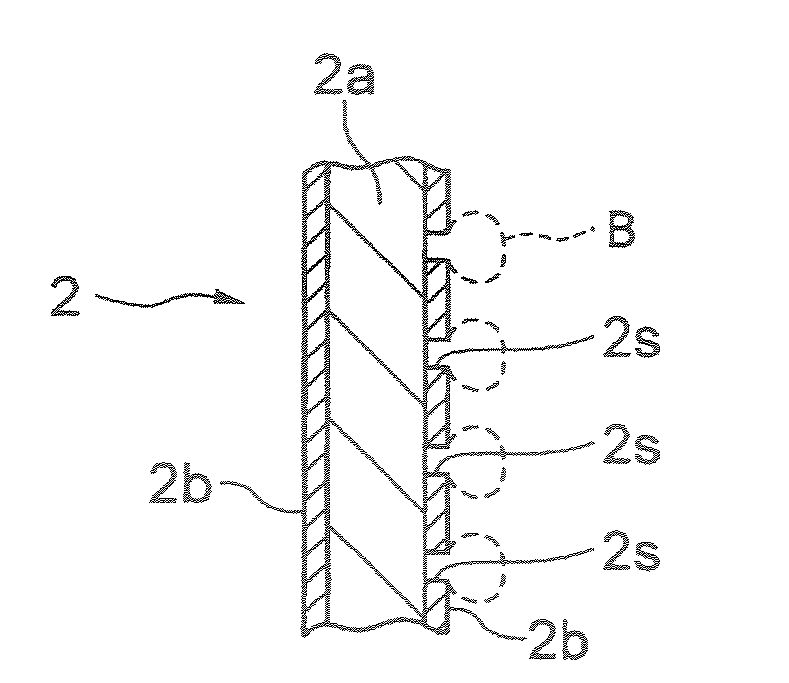

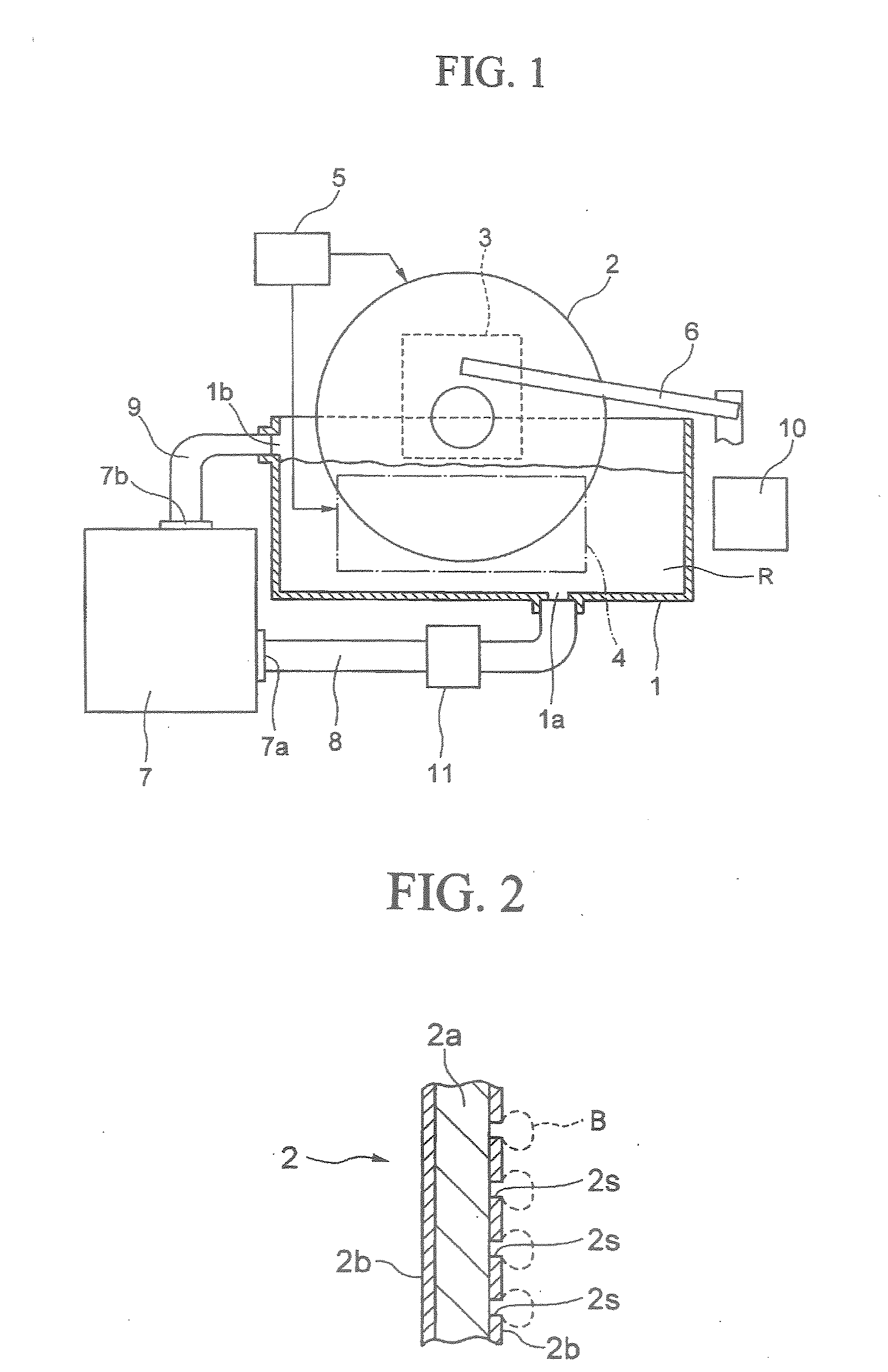

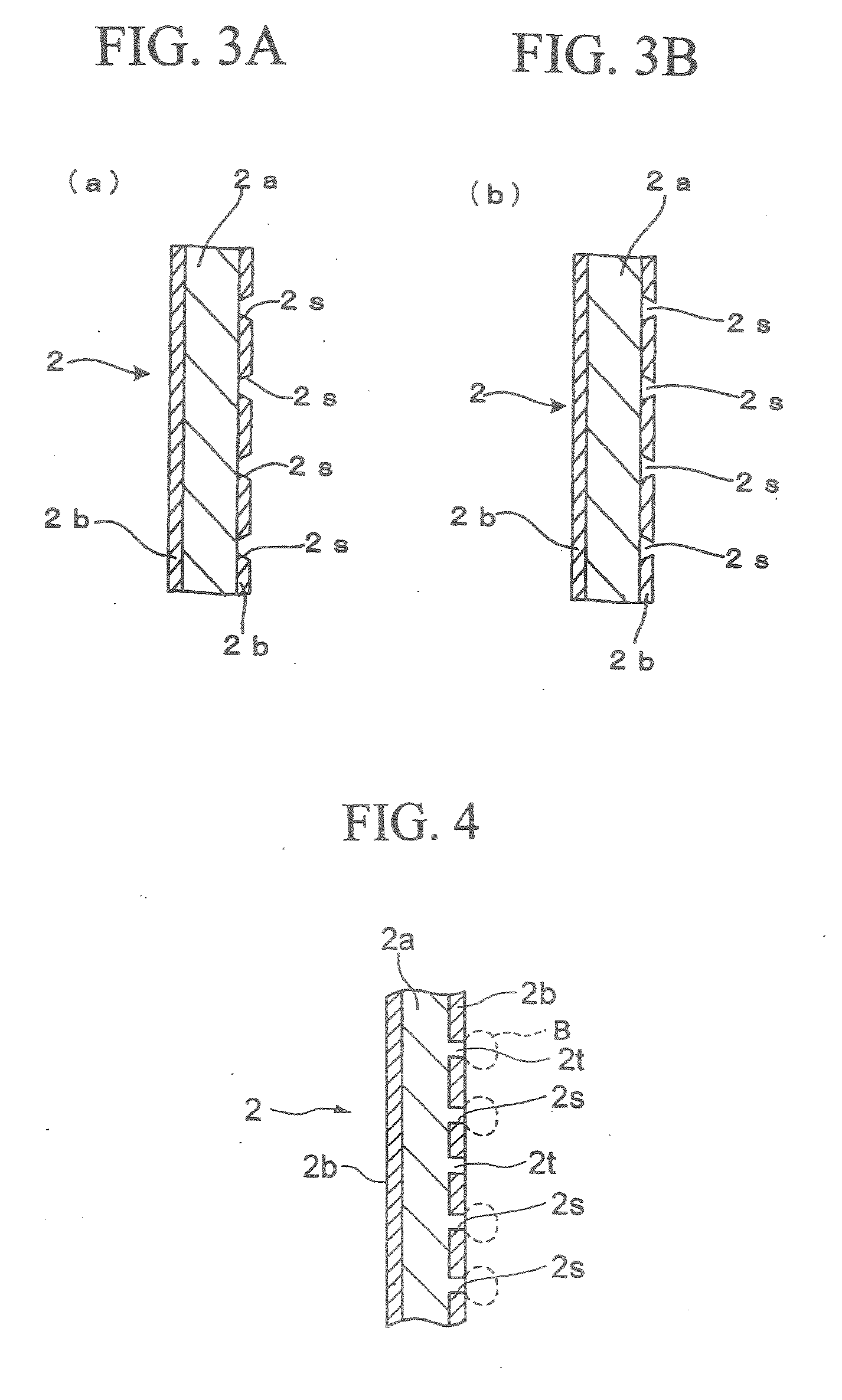

An apparatus for recovering a metal, which comprises a metal-recovering board (2) having an electrodeposition surface (2a, 2t) for the attachment of a metal component (R) precipitated from a solution and an insulating material (2b) formed around a pattern of the electrodeposition surface (2a, 2t). The metal-recovering board (2) is immersed in a metal-containing solution in an electrolytic treatment vessel (1), and thereby the metal in the solution is selectively precipitated on the electrodeposition surface (2a, 2t) and is converted to a bulk. The resultant metal bulk is scraped together for recovery with a blade (6) in a form as it is. The above apparatus for recovering a metal can be suitably used for recovering a metal in a solution in a state allowing easy reuse with good efficiency.

Owner:FURUKAWA ELECTRIC CO LTD

Vehicle transmission

ActiveUS8042419B2Increase the diameterEliminate significant changeGearing controlEngineeringGear train

Owner:HONDA MOTOR CO LTD

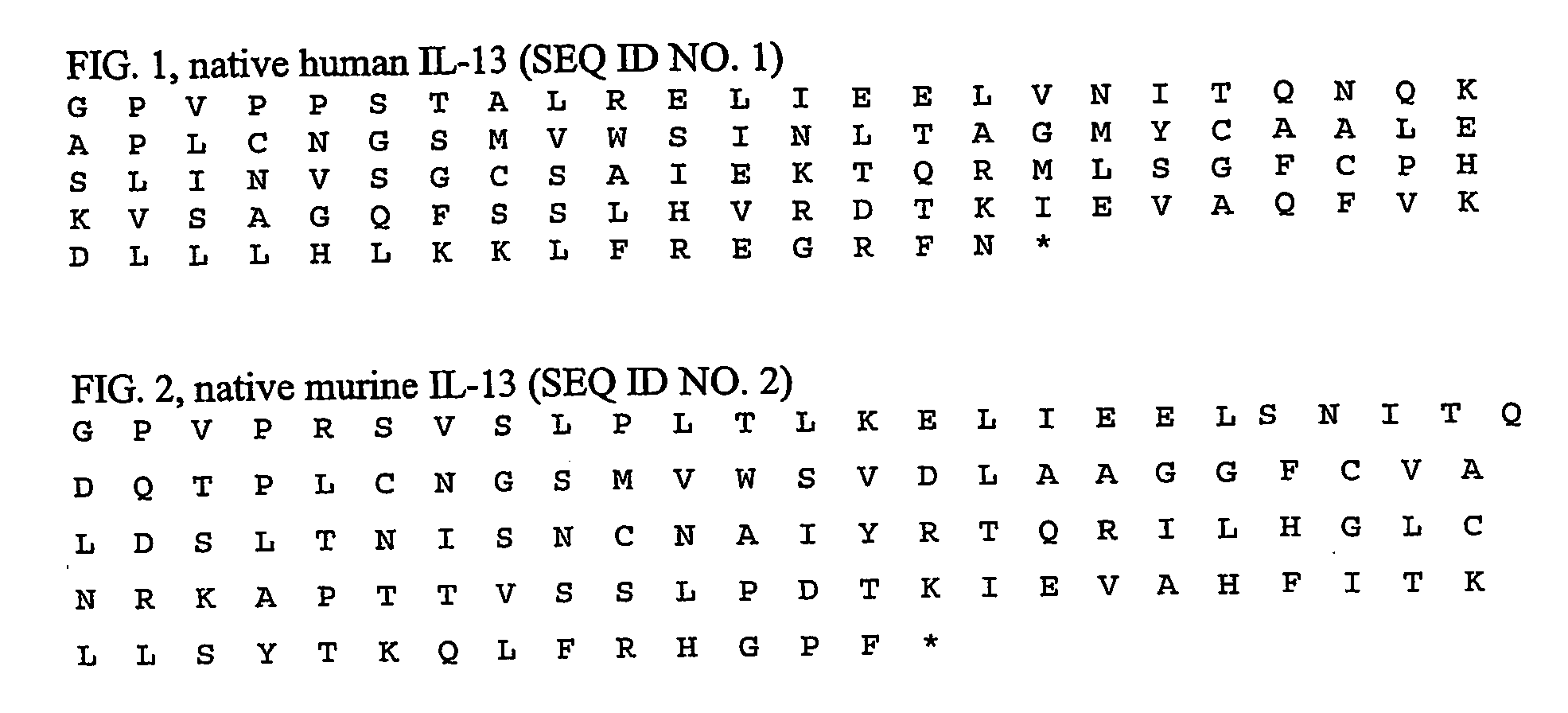

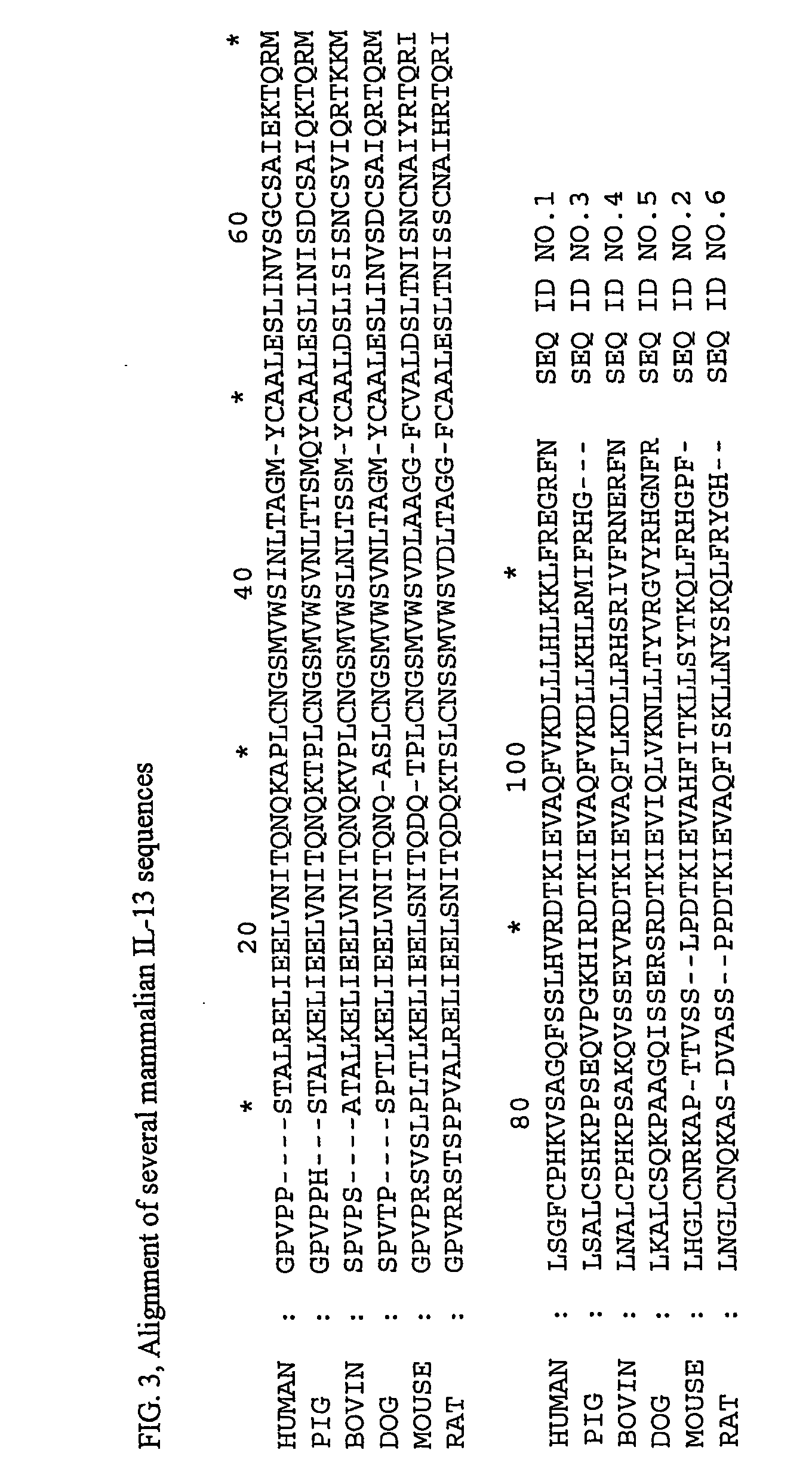

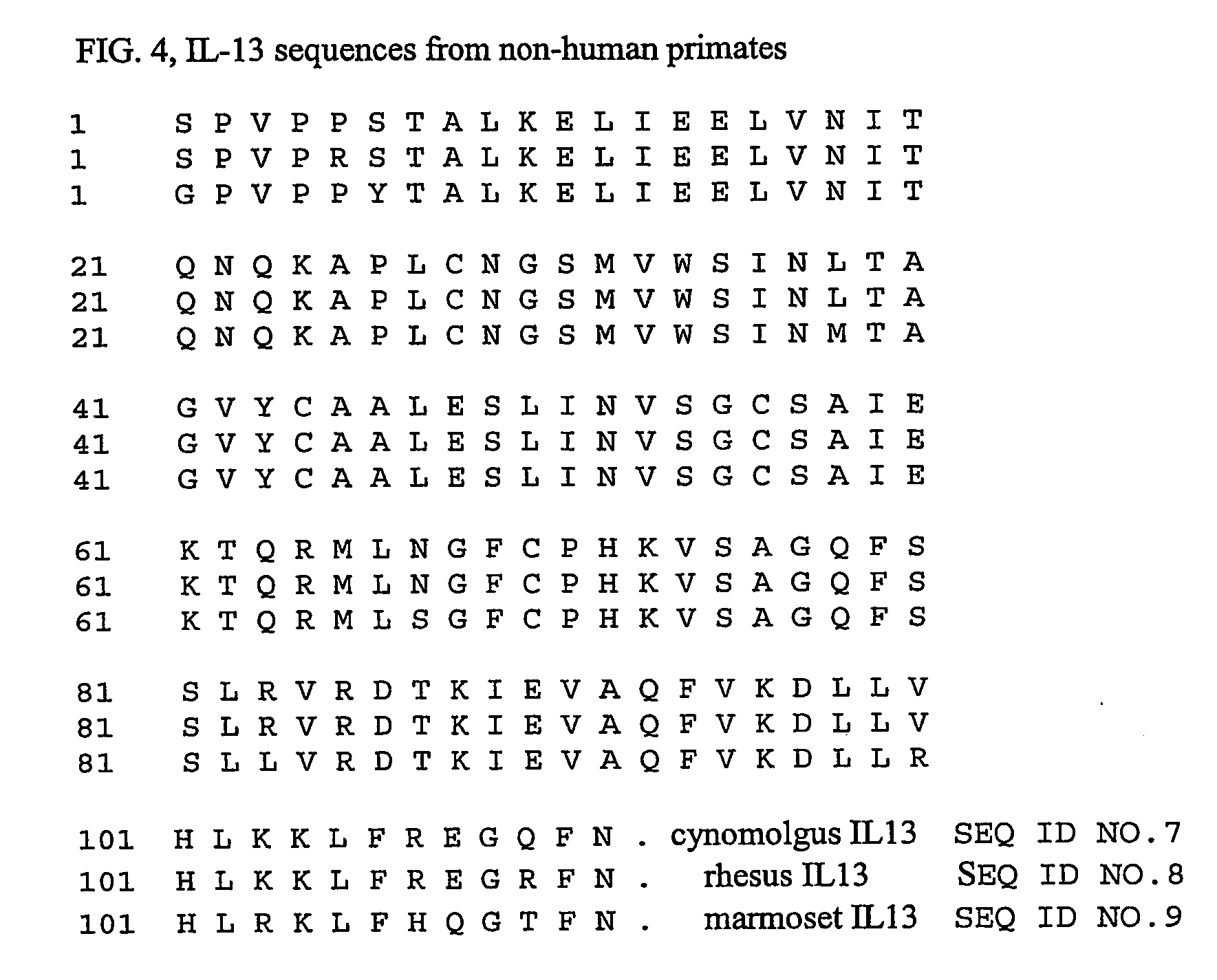

Immunogenic composition comprising an il-13 element and t cell epitopes, and its therapeutic use

InactiveUS20060147417A1Improve assessmentEnhanced antibodyBacterial antigen ingredientsPeptide/protein ingredientsVaccinationContact allergy

Owner:GLAXO GROUP LTD

Polymer electrolyte containing a vinylidene fluoride copolymer and a nonaqueous electrolytic solution, and nonaqueous battery containing the polymer electrolyte

InactiveUS6824927B1High strengthRetention stabilityElectrolytic capacitorsConductive materialPolymer electrolytesPolymer science

A nonaqueous battery, such as a lithium ion battery, is formed from a polymer electrolyte comprising: a vinylidene fluoride copolymer comprises 80 to 97 wt. % of vinylidene fluoride monomer units and 3 to 20 wt. % of units of at least one monomer copolymerizable with the vinylidene fluoride monomer and has an inherent viscosity of 1.5 to 10 dl / g. The polymer electrolyte stably retains the nonaqueous electrolytic solution in a large amount and has excellent strength in this state.

Owner:KUREHA KAGAKU KOGYO KK

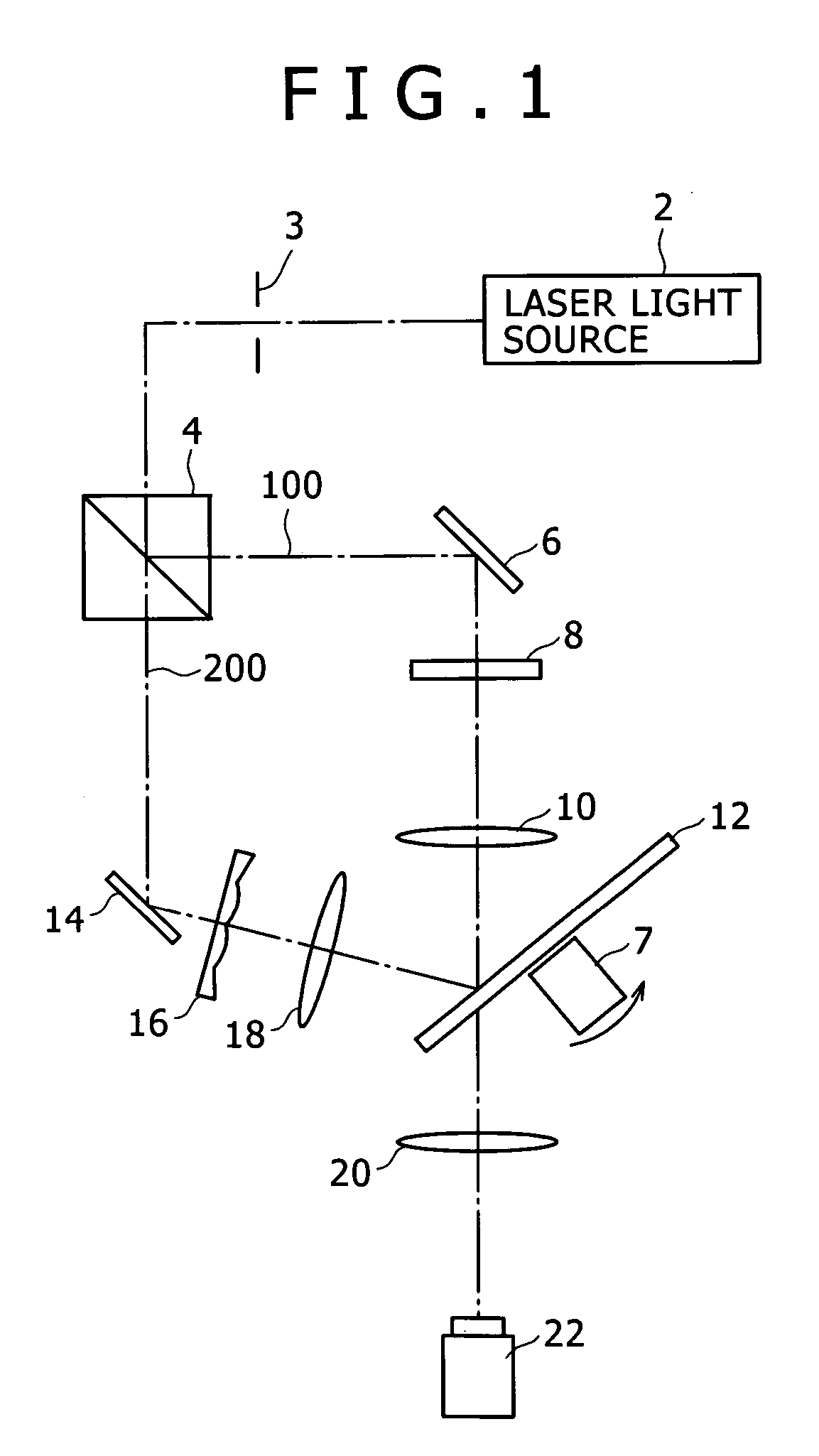

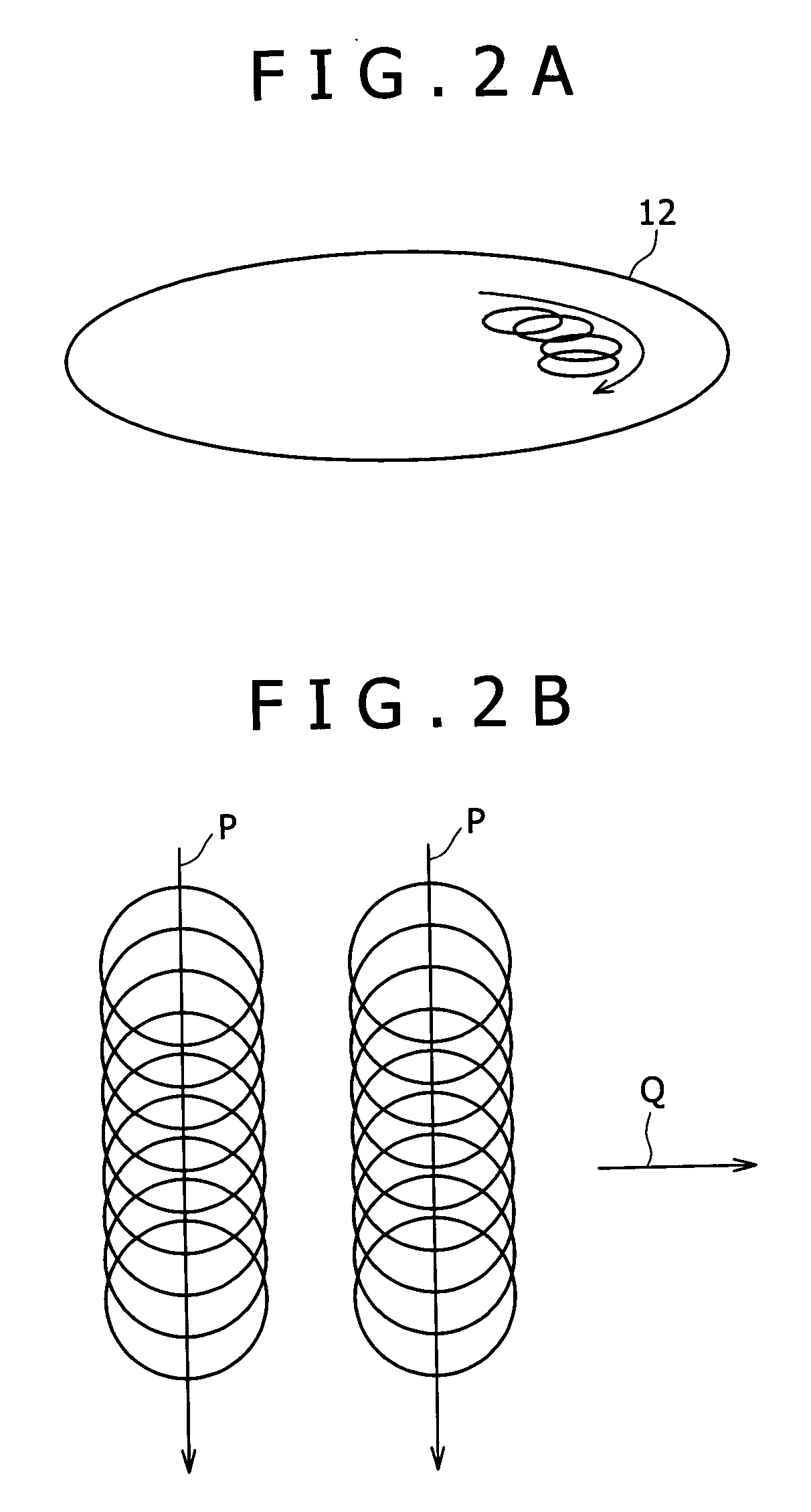

Hologram apparatus and hologram recording method

InactiveUS20060013104A1Improve toleranceStably and easily performedRecord information storageOptical beam guiding meansIncreased toleranceLight beam

The present invention provides a hologram apparatus for recording an interference fringe of a signal beam and a reference beam having a speckle pattern in a recording area of a hologram recording material. The hologram apparatus includes a speckle pattern generating unit for generating the speckle pattern so that the speckle pattern is different in form in the track direction and the cross-track direction of the recording area. With this configuration, it is possible to perform recording under an increased tolerance in the cross-track direction while securing the shift selectivity necessary in the track direction, and, hence, to easily and stably perform the tracking servo at the time of reproduction.

Owner:SONY CORP

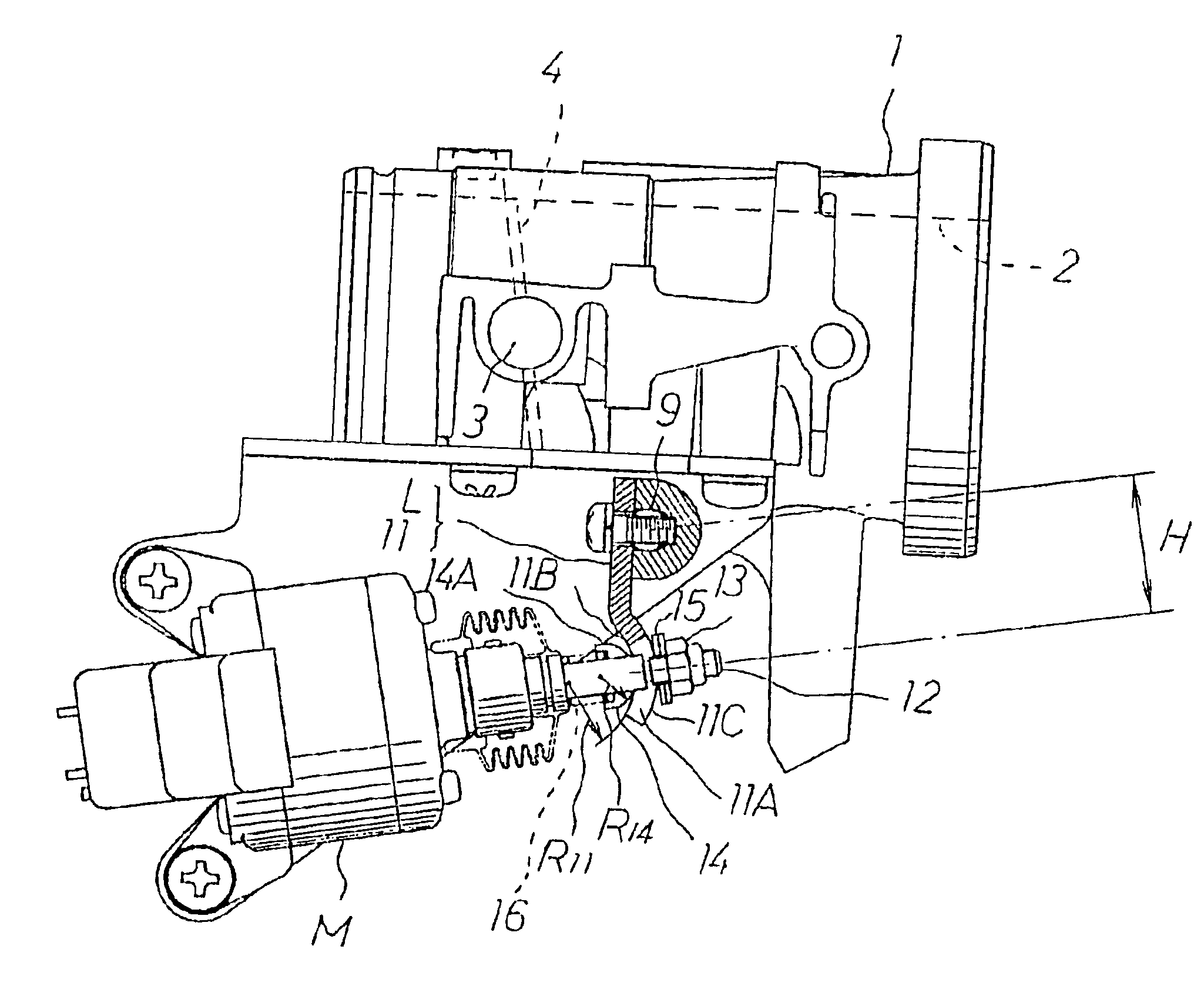

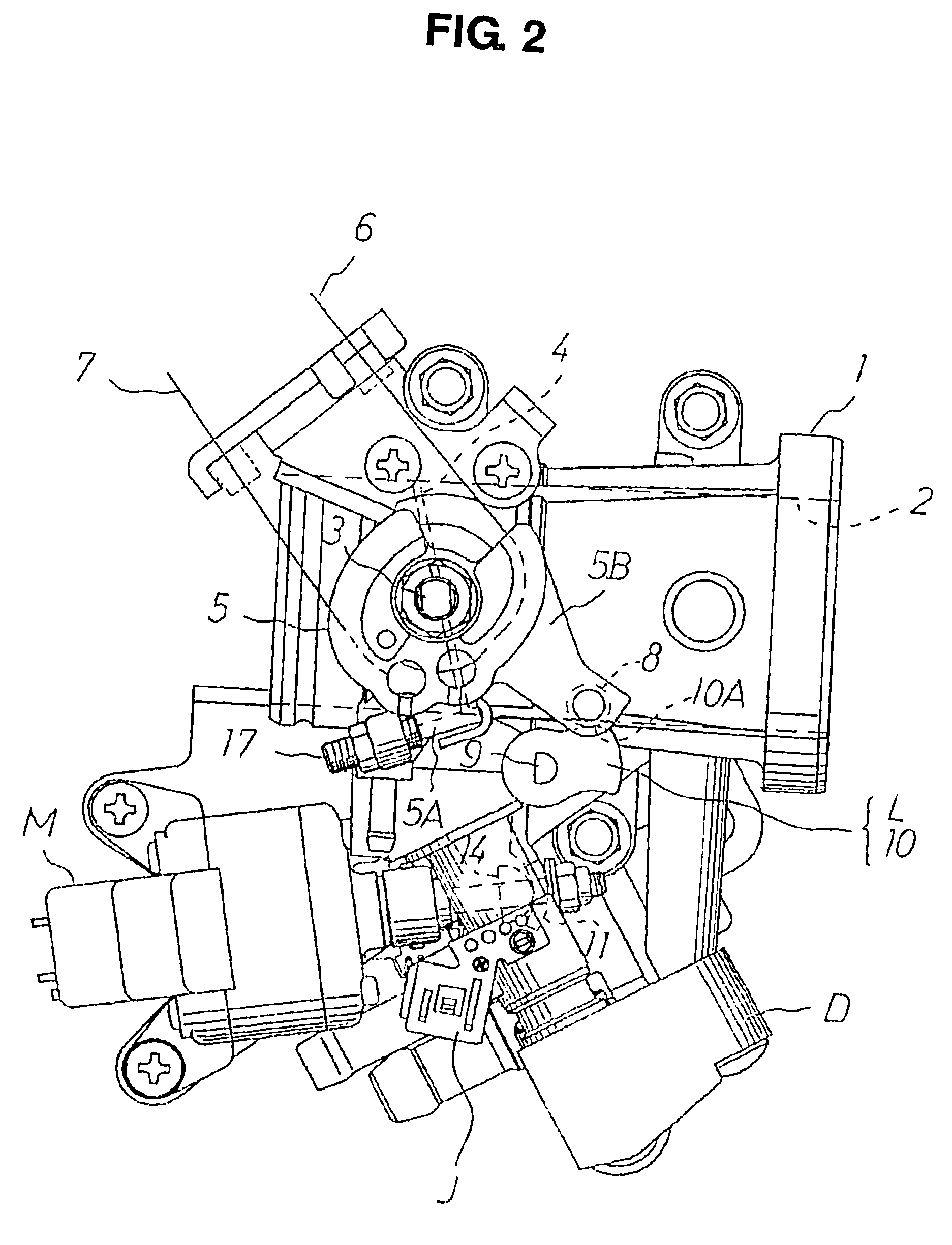

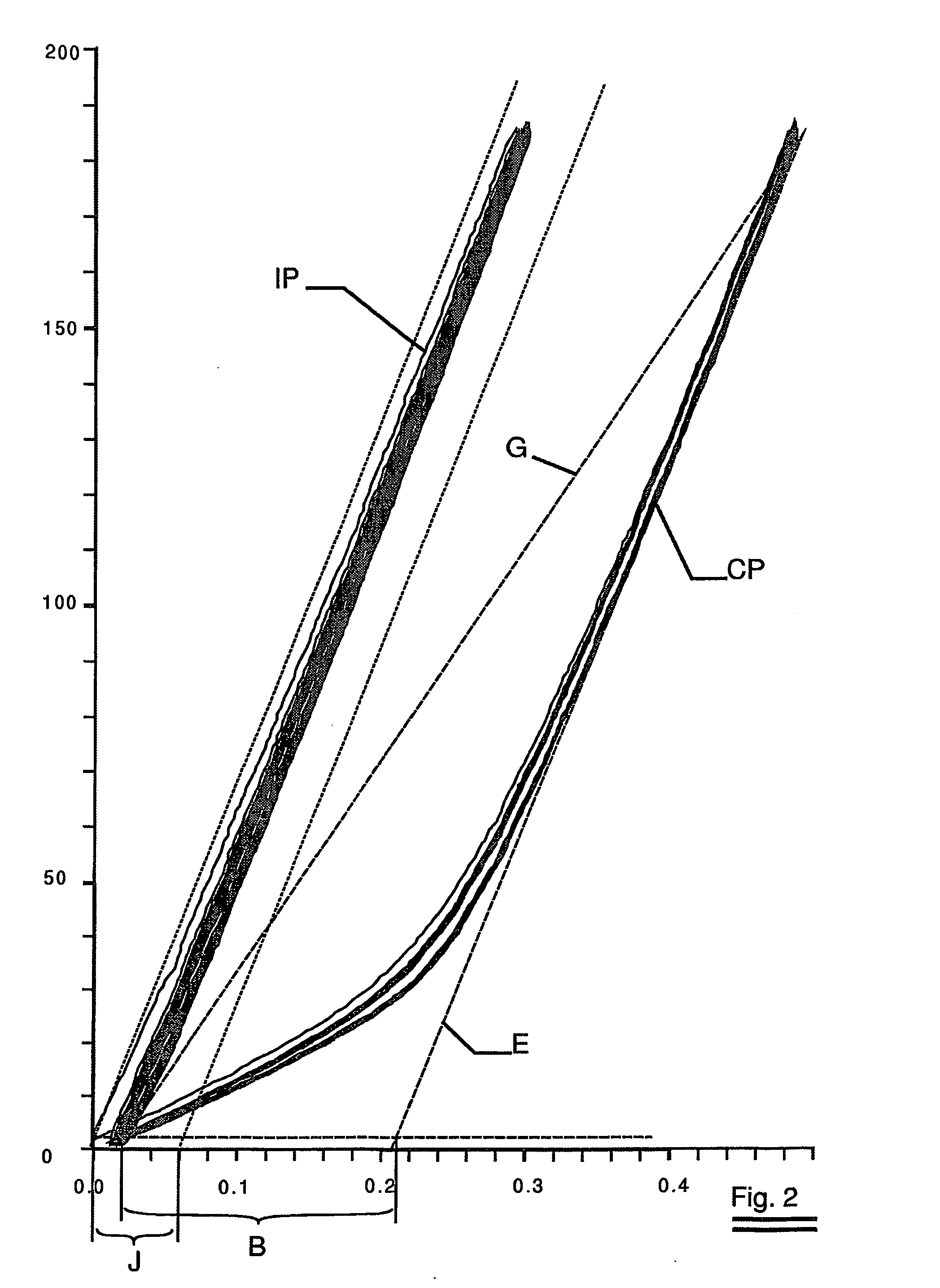

Idle speed control apparatus in throttle body

InactiveUS6868828B2Increased freedom of choiceHigh resolutionElectrical controlIdling devicesLinear motionIdle speed control

An idle speed control apparatus which improves freedom of selection in an opening degree characteristic of a throttle valve is structured such that an intake passage of a throttle body is opened and closed by a throttle valve, a cam lever is attached to one end of a rotatably supported link shaft, a link lever is attached to another end of the link shaft, a slider of a stepping motor is connected to the link lever, a cam portion of the cam lever is connected to a roller of the throttle valve lever, linear motion of the slider is transmitted to the link shaft via the link lever to rotationally displace the link shaft, rotation of the cam lever is transmitted to the throttle valve lever, and the throttle valve opens an idling opening degree corresponding to the rotation of the stepping motor.

Owner:KEIHIN CORP

Vehicle Light

InactiveUS20100321948A1Avoid it happening againLess heatVehicle headlampsVehicle interior lightingDistribution patternOptoelectronics

Owner:STANLEY ELECTRIC CO LTD

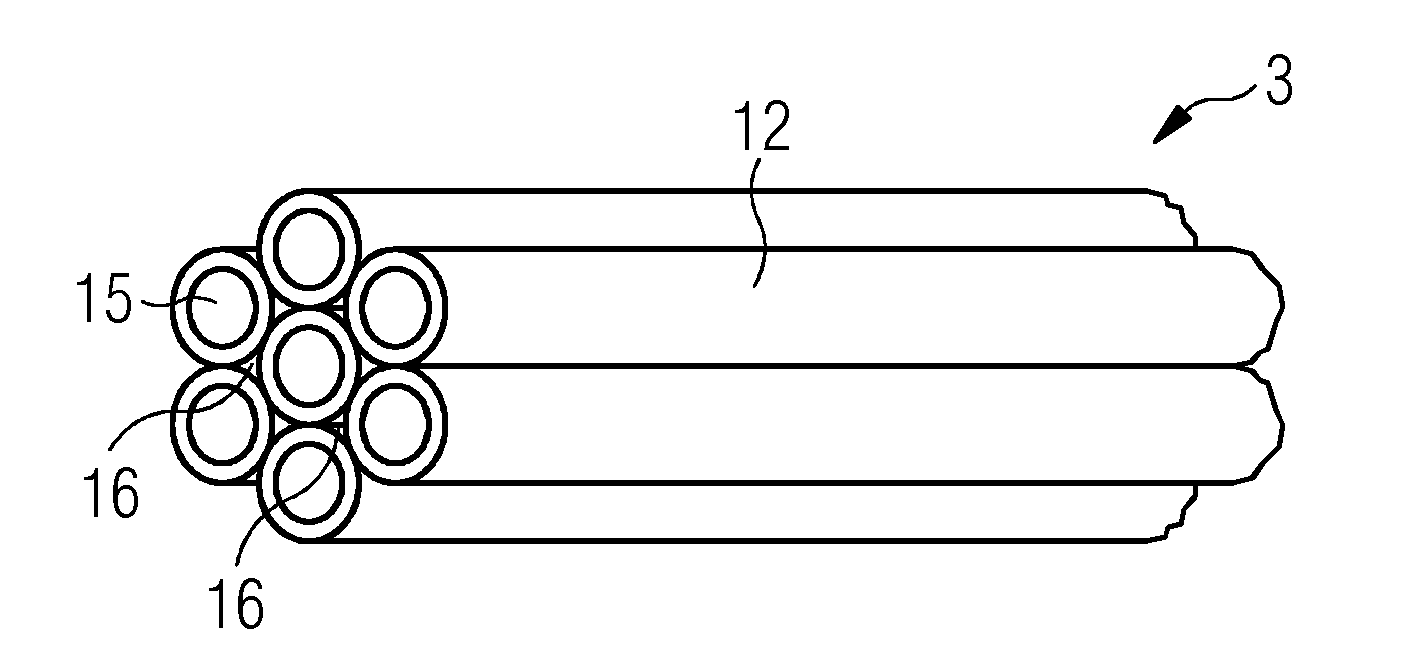

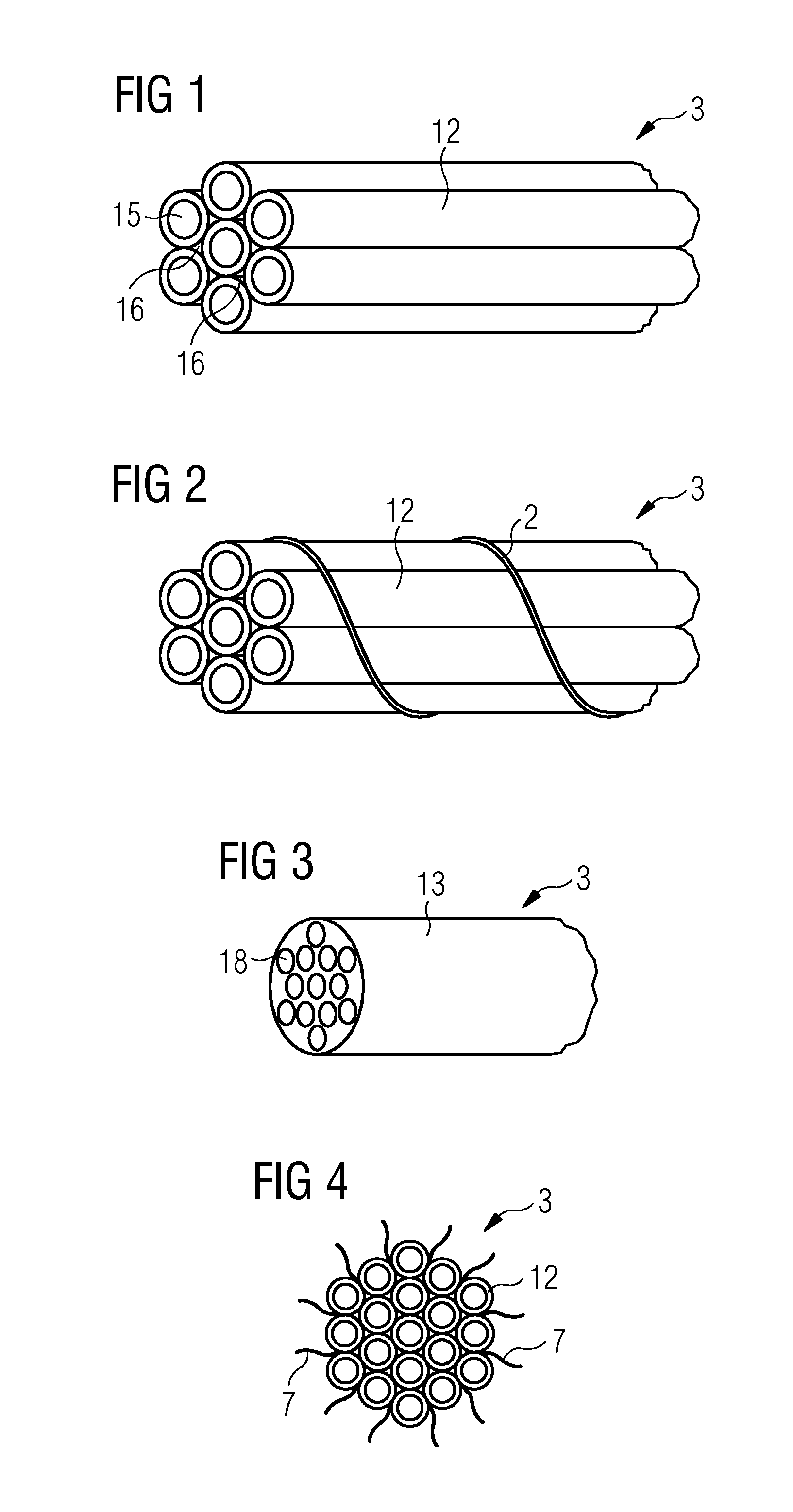

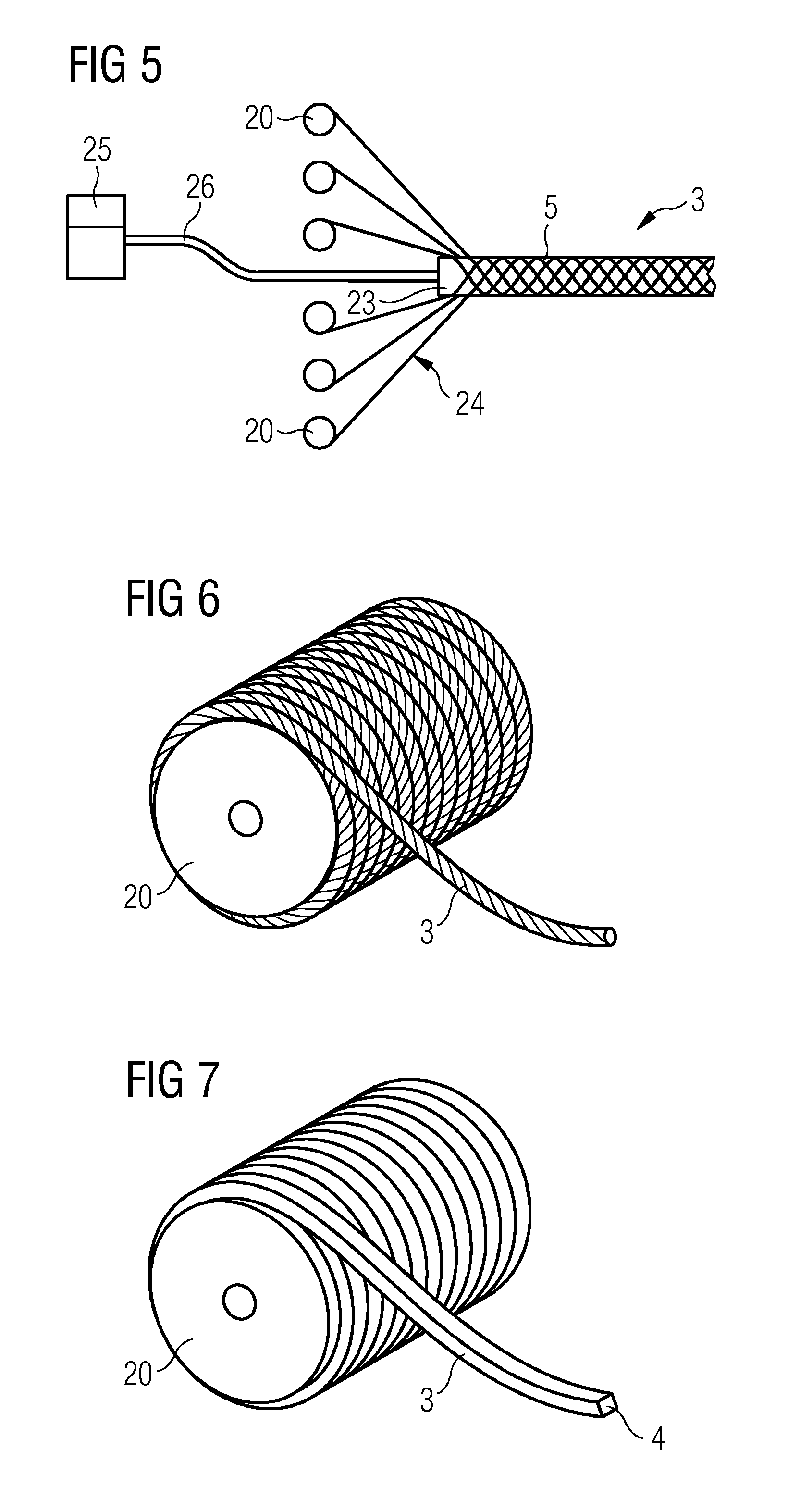

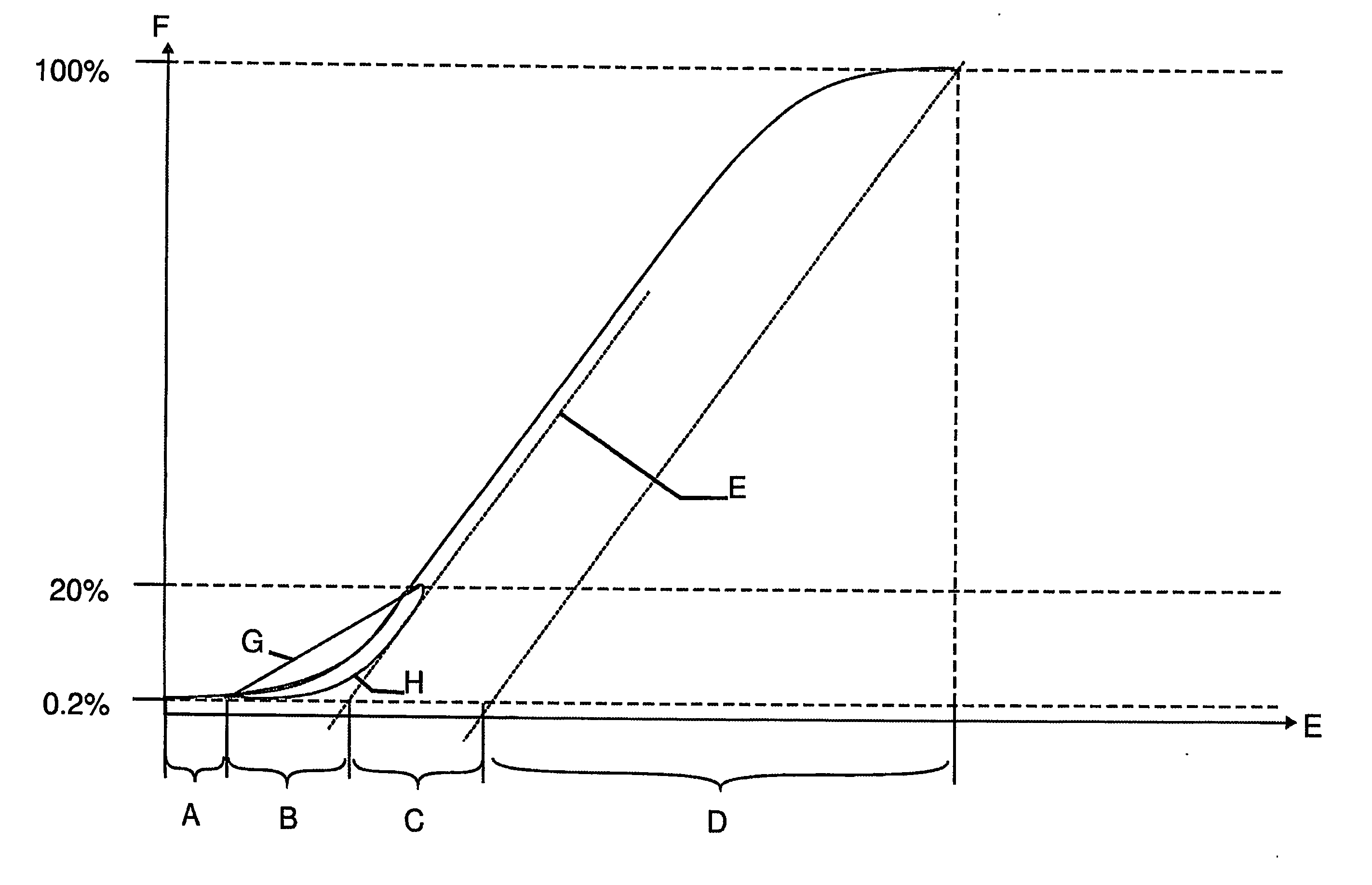

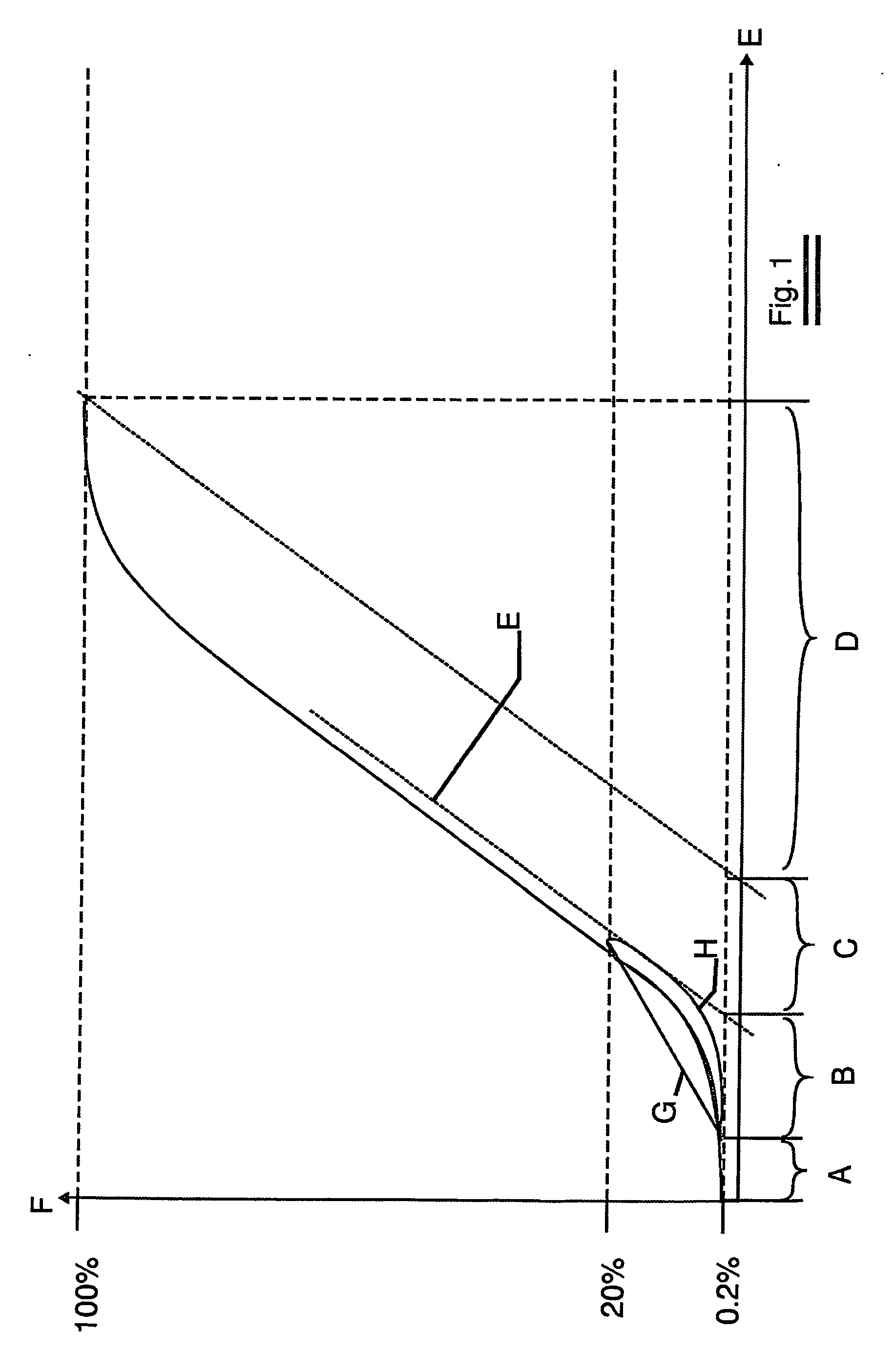

Fine steel cord with a low structural elongation

InactiveUS20070089394A1High modulusLow elongationRope making machinesDriving beltsElastomerMetallurgy

A fine steel cord for the reinforcement of synchronous belts is presented. The fine cord has a distinct load elongation curve characterized by a very low structural elongation (below 0.09% preferably below 0.06%), and a high equivaslent modulus between 0.2 and 20% of the breaking, load. The favorable results are maintained when the cords are coated with an elastomer coating. Such a fine steel cord reduces the geometrical spread on the tooth pitch of the synchronous belts during use. A method to produce such a fine steel cord is also presented.

Owner:NV BEKAERT SA

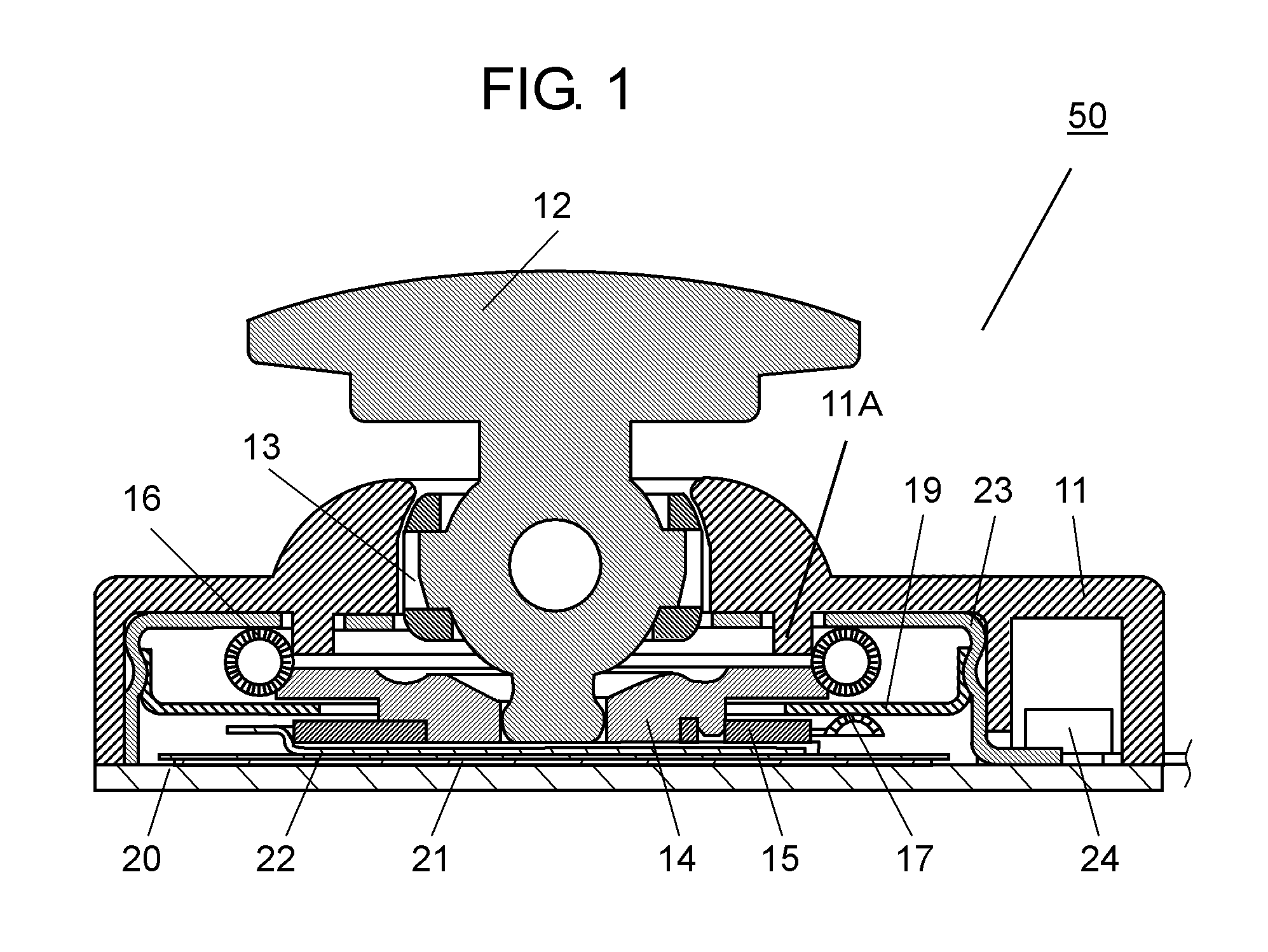

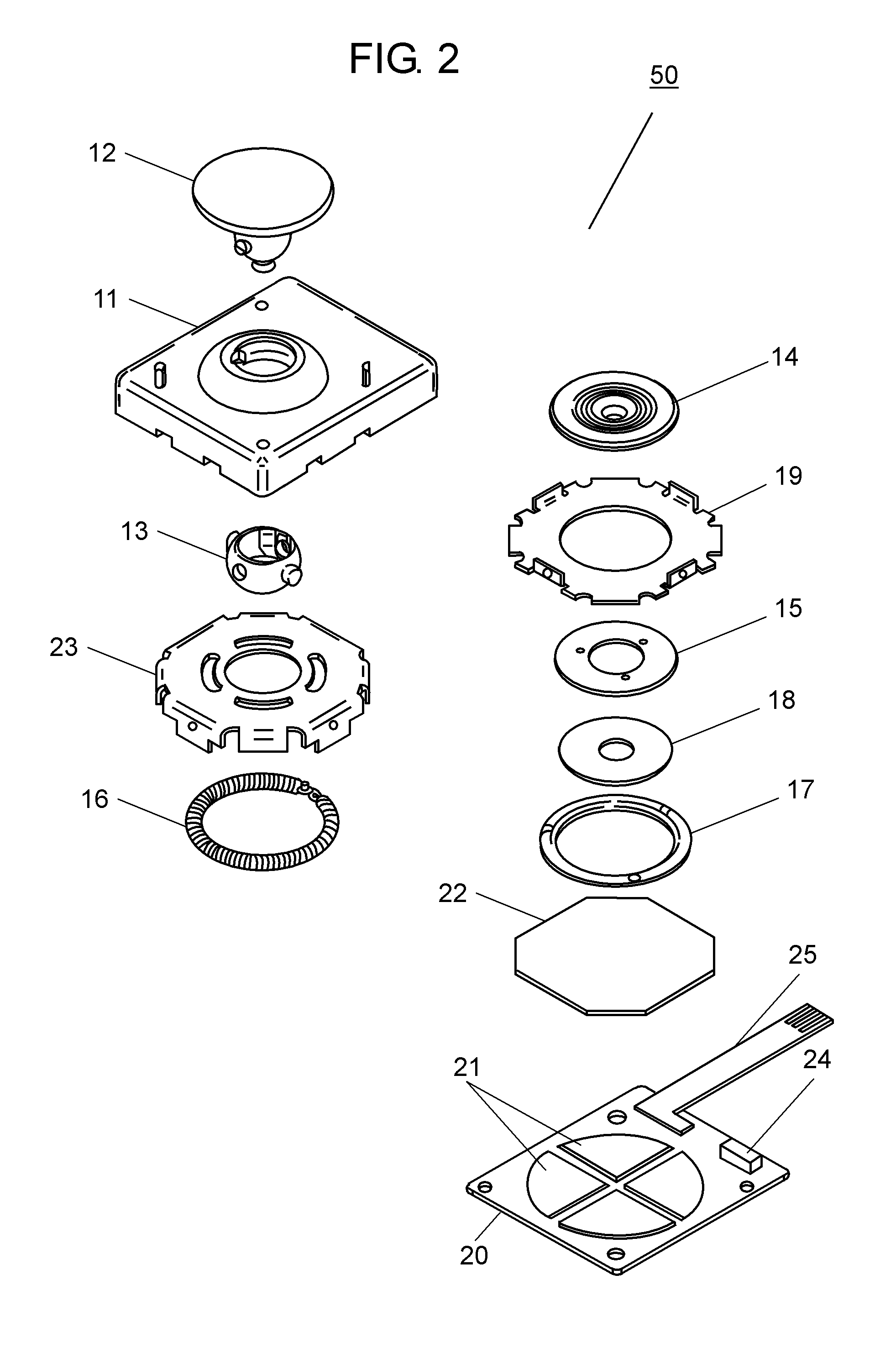

Multi-directional input device

InactiveUS20130161163A1Increase changeLarge shapeElectronic switchingElectric switchesCapacitanceEngineering

An object is to provide a multi-directional input device mainly used for operations of various electronic devices, the multi-directional input device being capable of performing various reliable operations. A movable electrode installed on a lower surface of a sliding body which is engaged with a lower end of an operation body is connected to a ground, and a plurality of fixed electrodes arranged so as to face the movable electrode with a predetermined gap is arranged at predetermined intervals. Thereby, the plurality of fixed electrodes facing the movable electrode can be formed in a large shape, so that a change in a capacitance due to operations of the operation body can be increased. As a result, not only the operating direction but also an operation amount can be precisely detected. Thus, the multi-directional input device capable of performing various reliable operations can be obtained.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Wear resistant center feed impact impeller

The present invention is particularly, but not exclusively, useful for reducing wear of component parts of impact crushers caused by earth aggregate flows during operation of impact crushers. The present invention includes a stepped central feed cone that allows for cylindrical carbide rods to be press fit therein to reduce wear. The downward steps of the stepped cone urge material fed to the stepped cone outwardly to the table. The top surface of a first rod inserted into a first bore formed in the impeller housing extends a distance beyond the bottom of a second bore on the next step up. The first rod protects the housing material forming the second bore from being washed out by material flow. In one embodiment, the impeller shoes have a geometric shape that reduces excessive normal forces and accompanying high friction of the material against the shoe. The reduction in high friction significantly reduces the wear rate.

Owner:KENNAMETAL INC

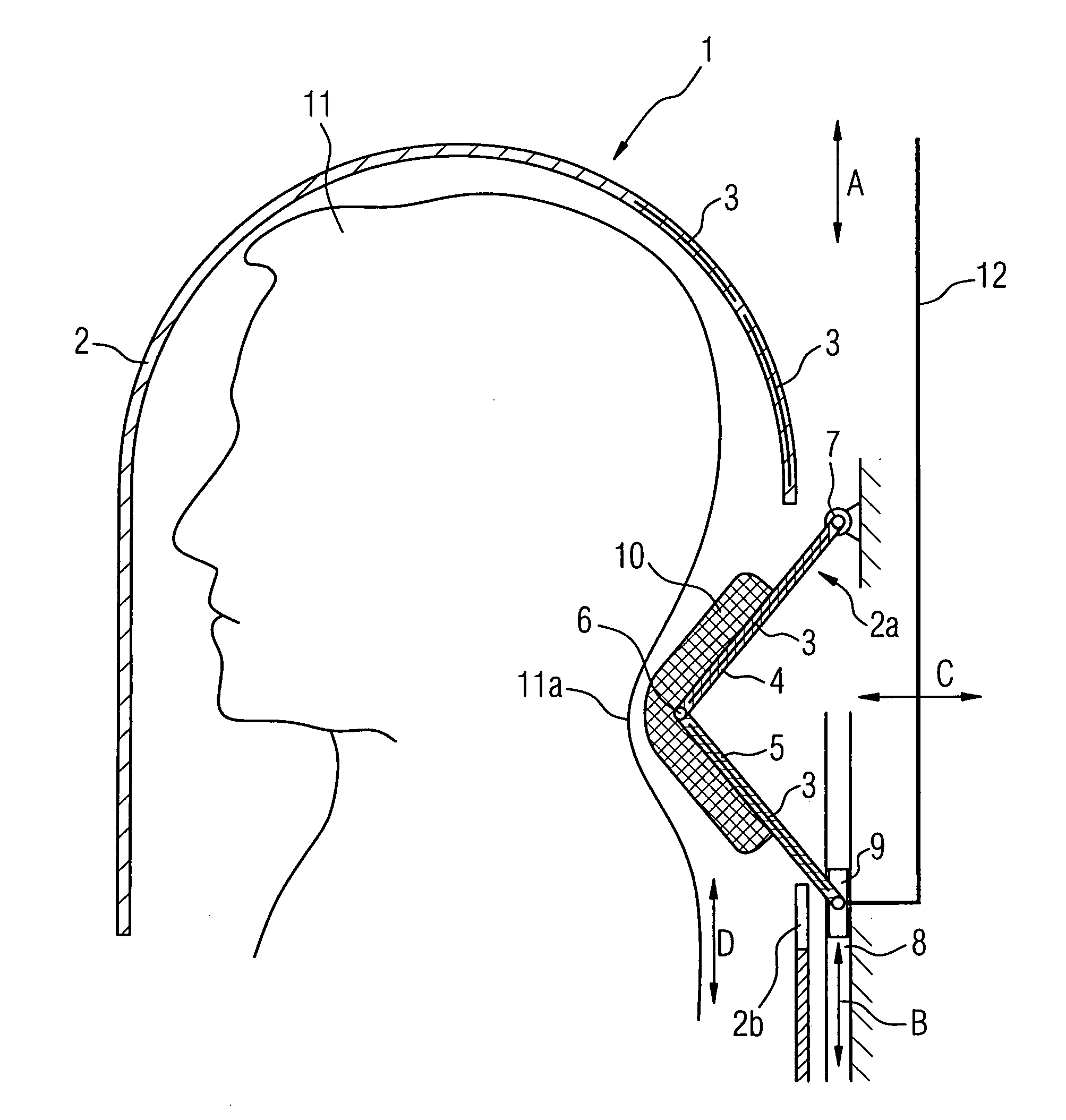

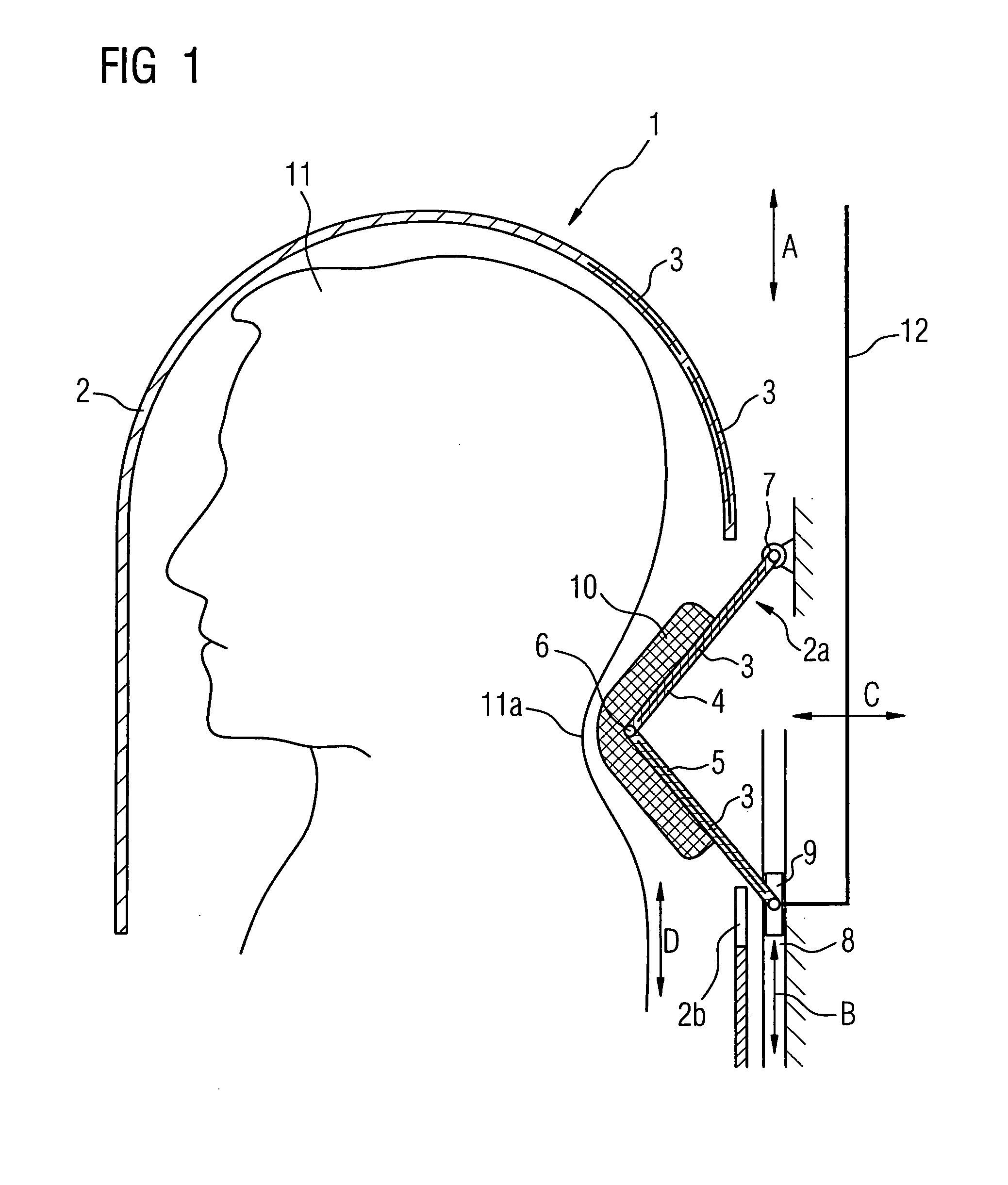

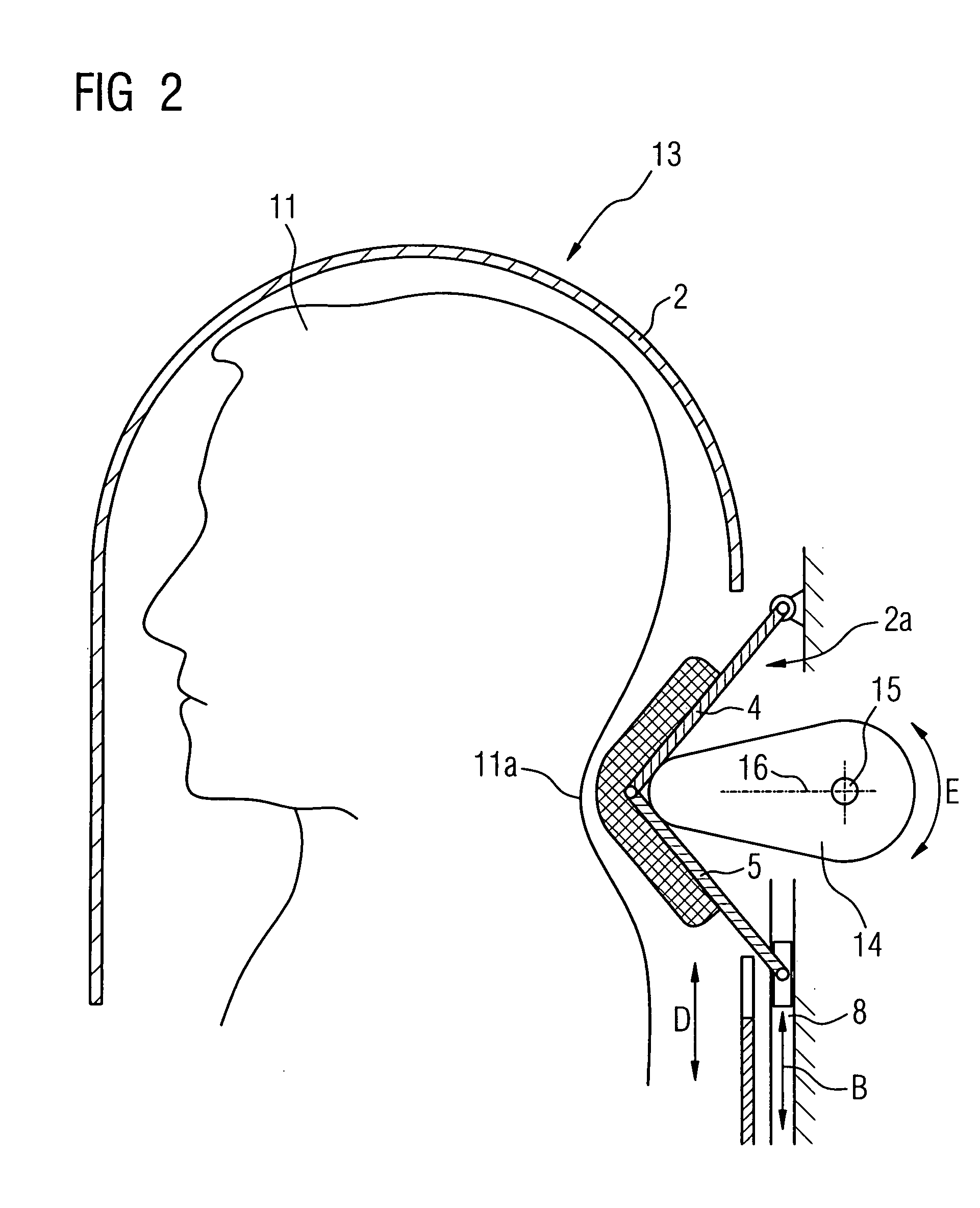

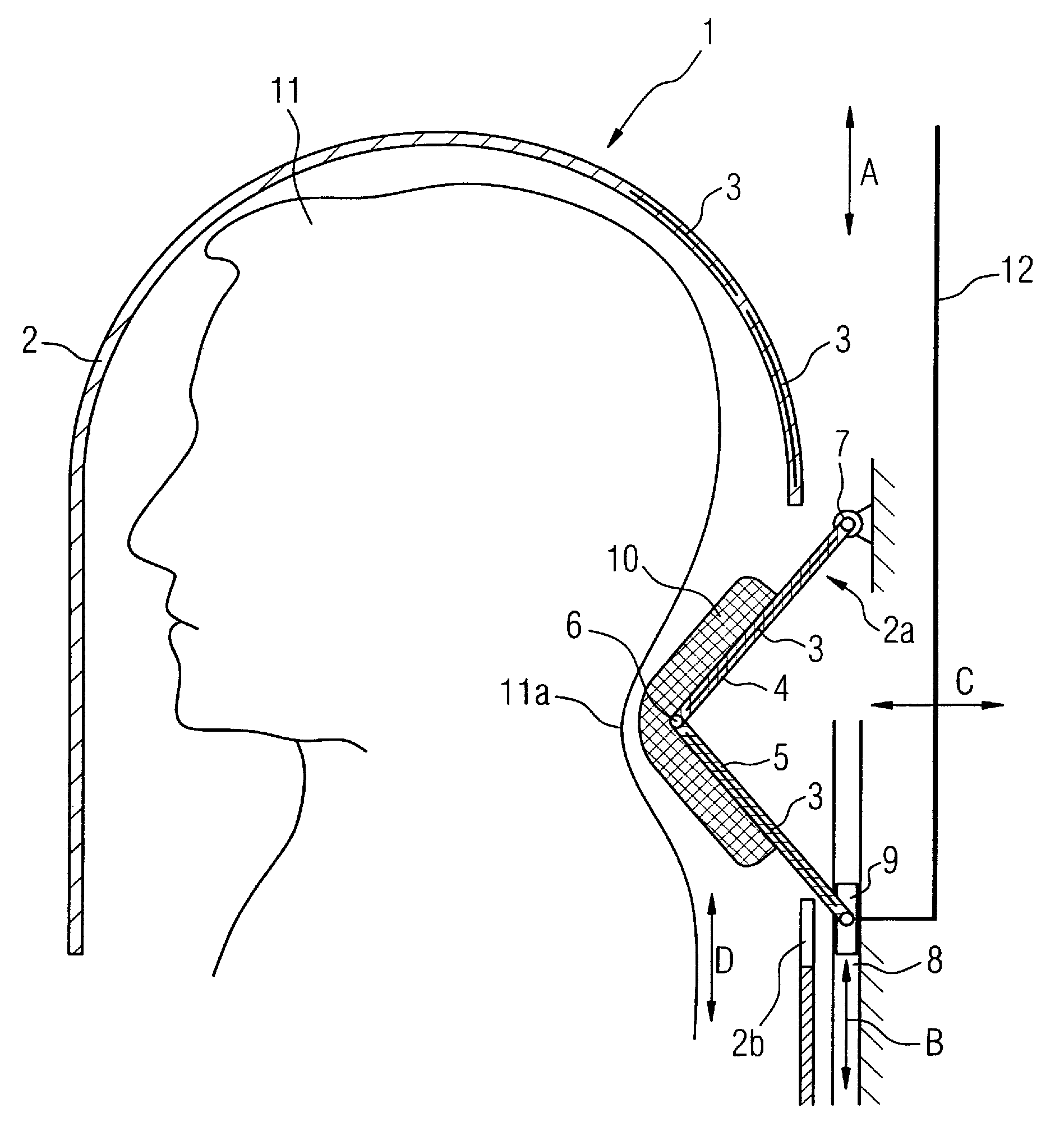

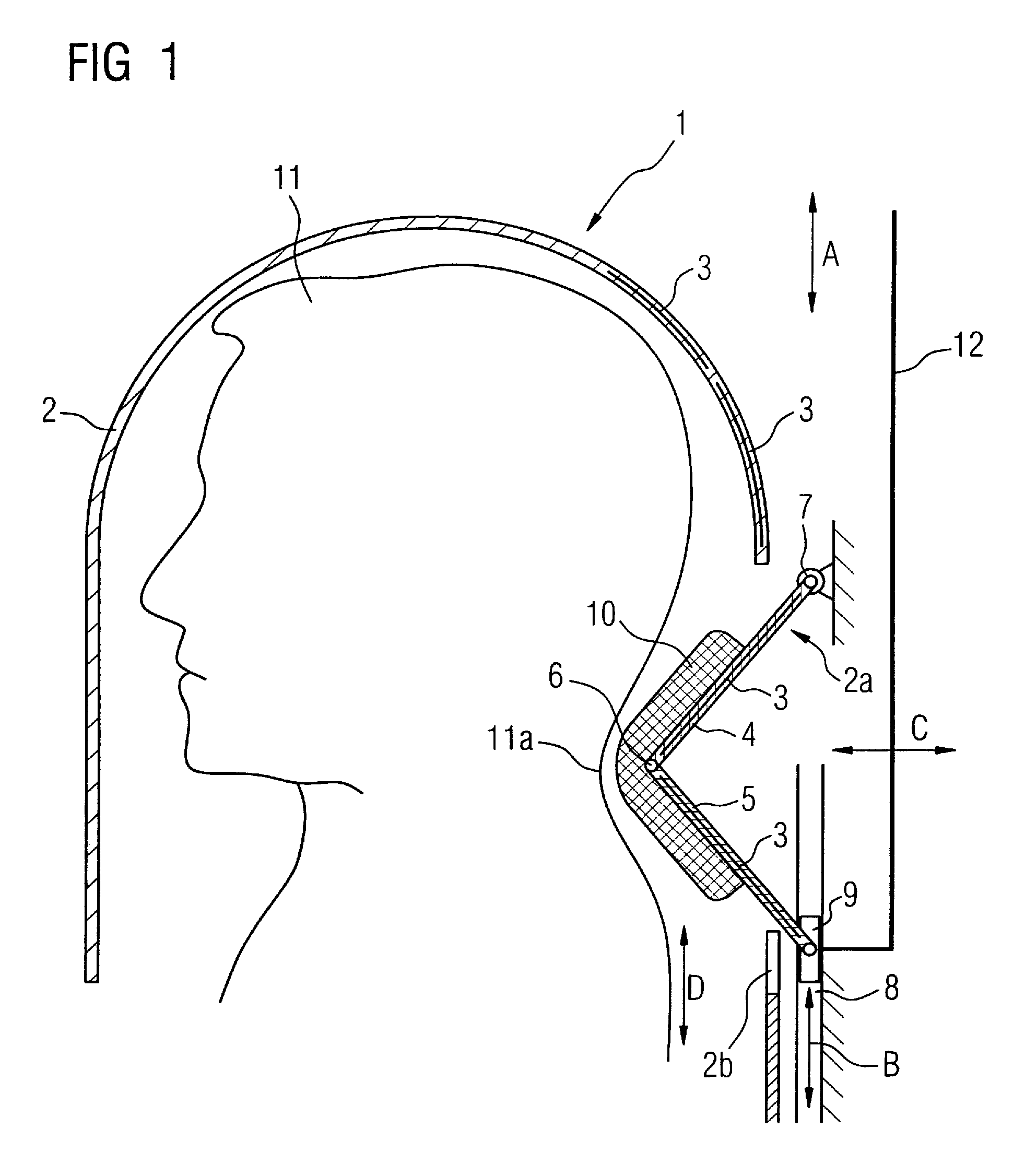

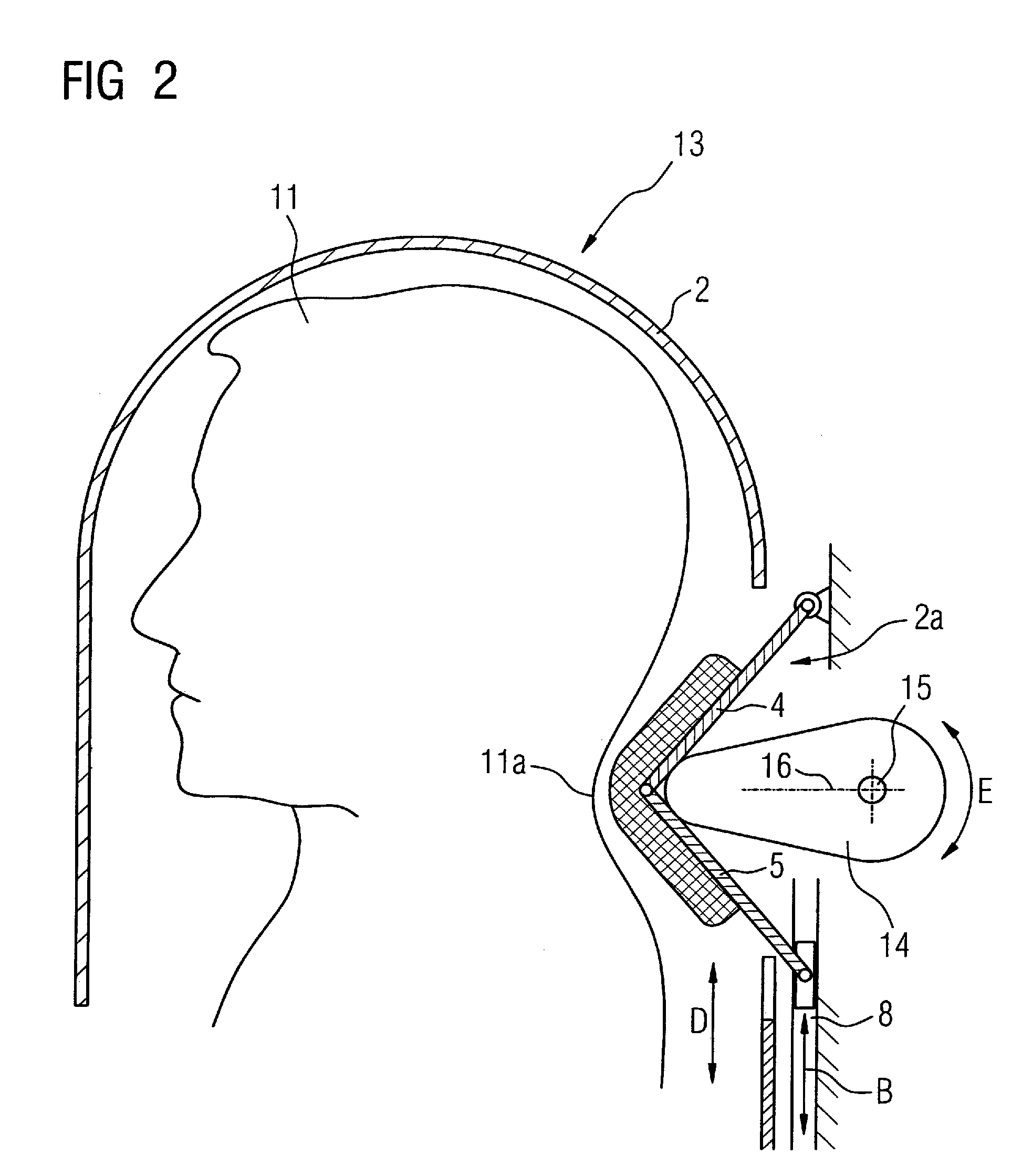

Head coil arrangement with an adjustable neck-engaging portion for use in a magnetic resonance apparatus

InactiveUS20070285093A1Improve signal-to-noise ratioLarge shapeMagnetic measurementsDiagnostic recording/measuringResonanceEngineering

Head coil arrangement for a magnetic resonance apparatus has a housing with a number of coil elements arranged in or on the housing, and the housing has at least one movable and / or moldable housing part (2a) for adjustment to different neck shapes in the region designated for the neck of a patient.

Owner:SIEMENS HEALTHCARE GMBH

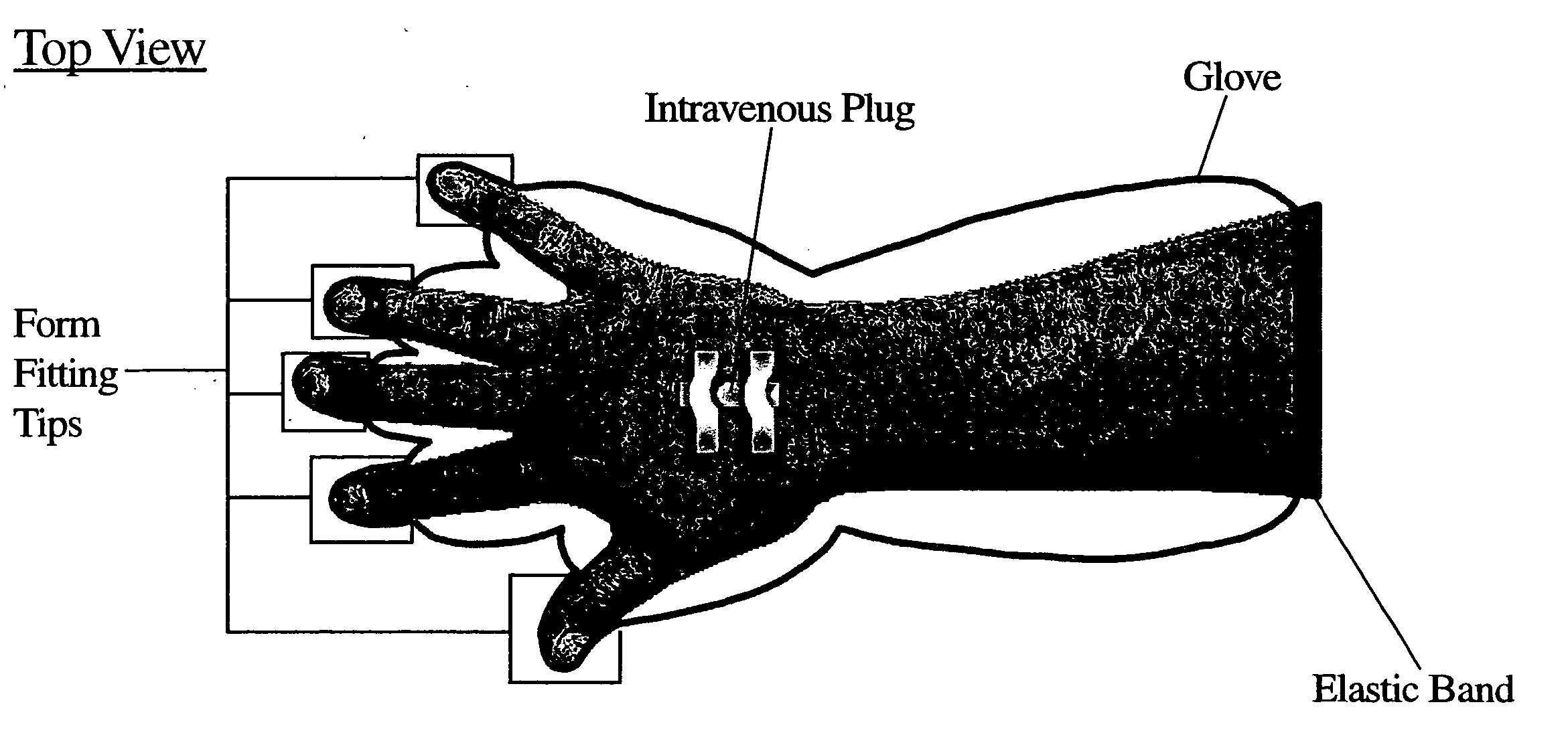

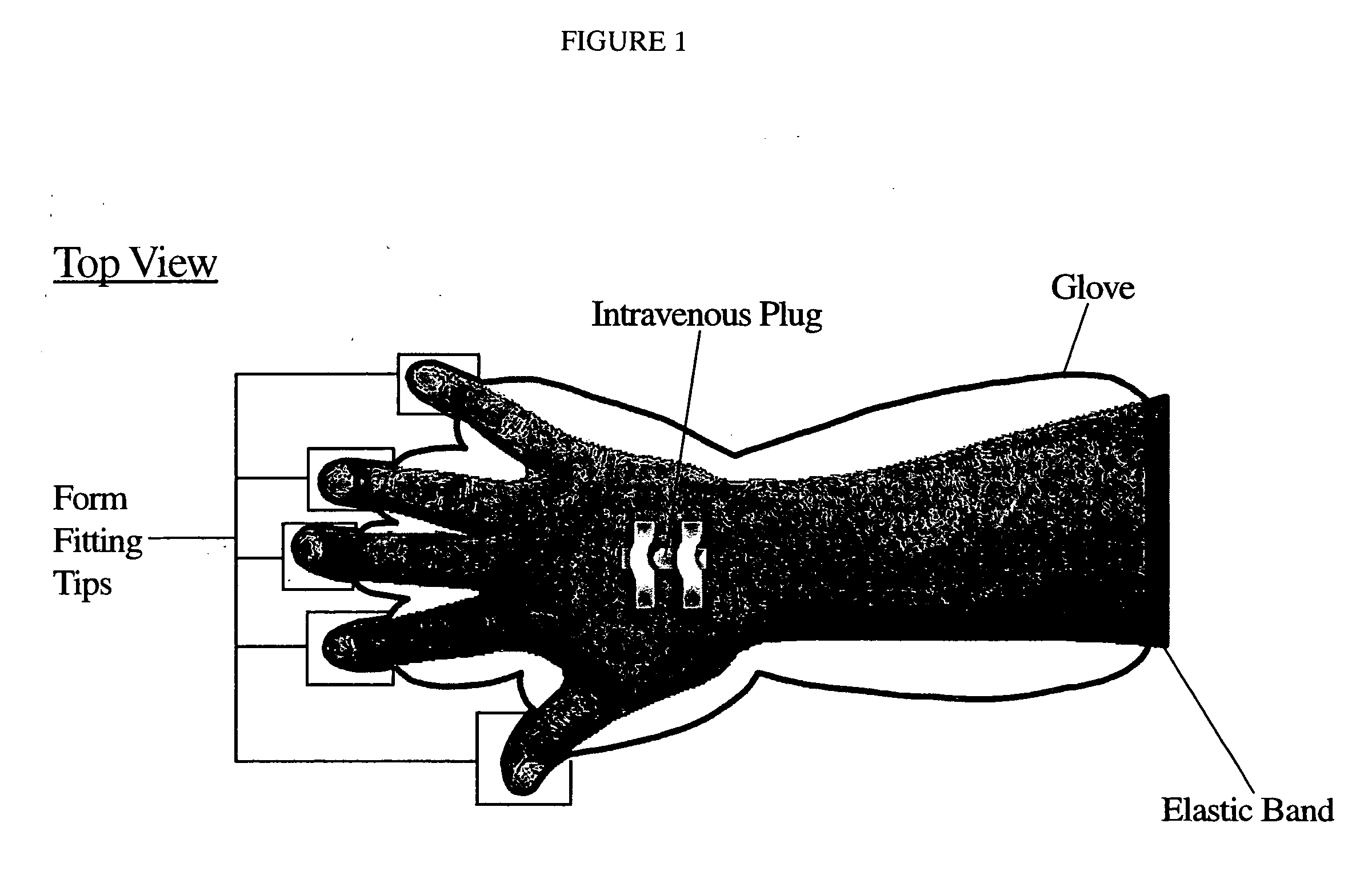

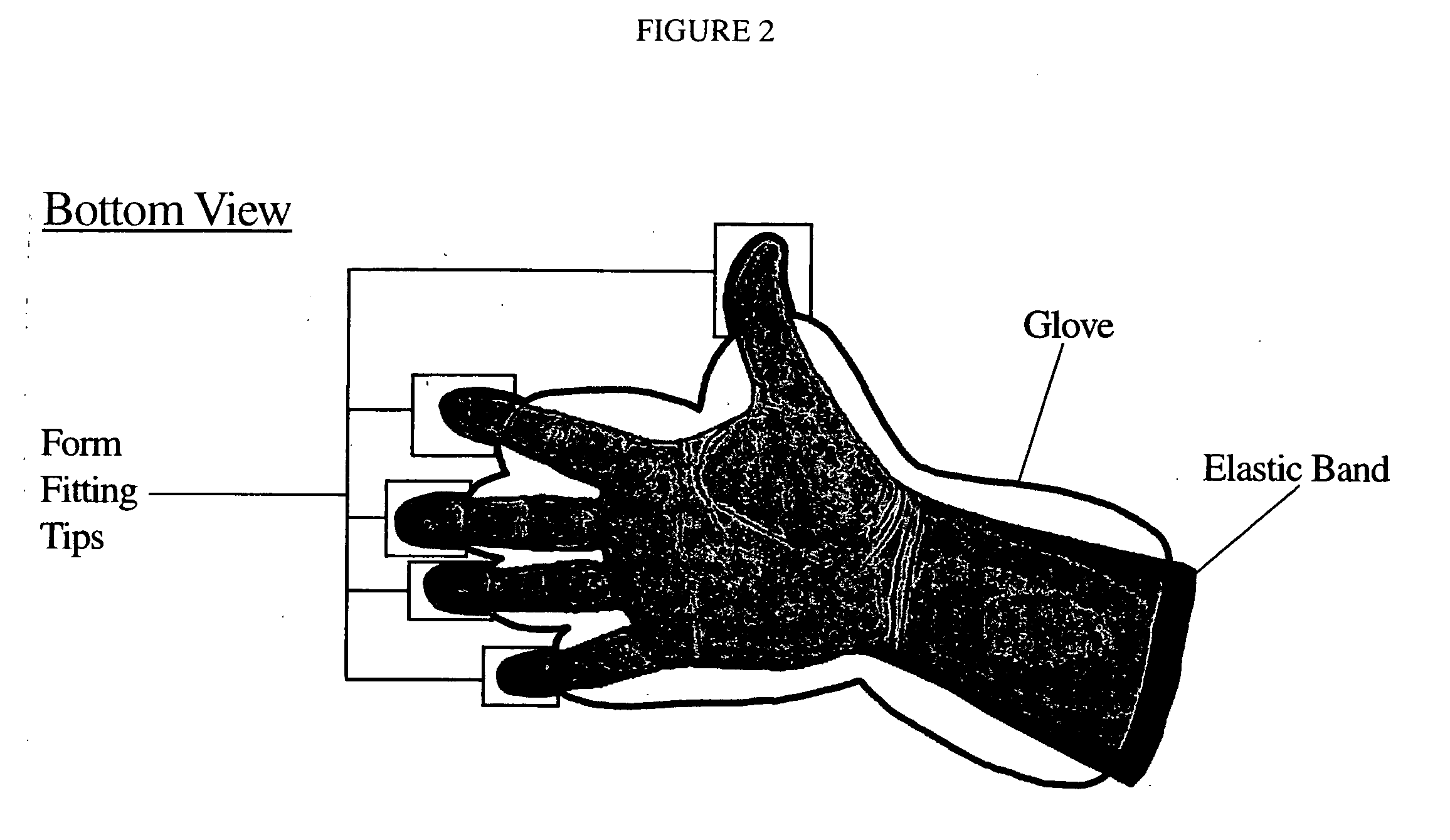

Medical utility cupped fingertip glove

The medical utility-cupped fingertip glove is designed for use in hospital, homes and facilities where medical attention is provided. The invention encases the fingers, hand and arm, providing protection from contaminants. The device protects a patient's intravenous plug (IV) without feeder tube, whether located on the hand or the arm, while showering. There may be additional uses. The invention is designed to allow maximum use of hand and fingers by form fitting tips of the four phalanges and thumb, while providing sufficient leeway in the remainder of its design to easily fit over a protected area. The glove remains in place through the use of an elastic band that secures the uppermost portion of the glove midway between the wrist and the elbow, by wrapping securely around the arm. The invention is ambidextrous and has multiple sizes, dependent upon the body size of the user.

Owner:VILLARREAL JIMMY FR

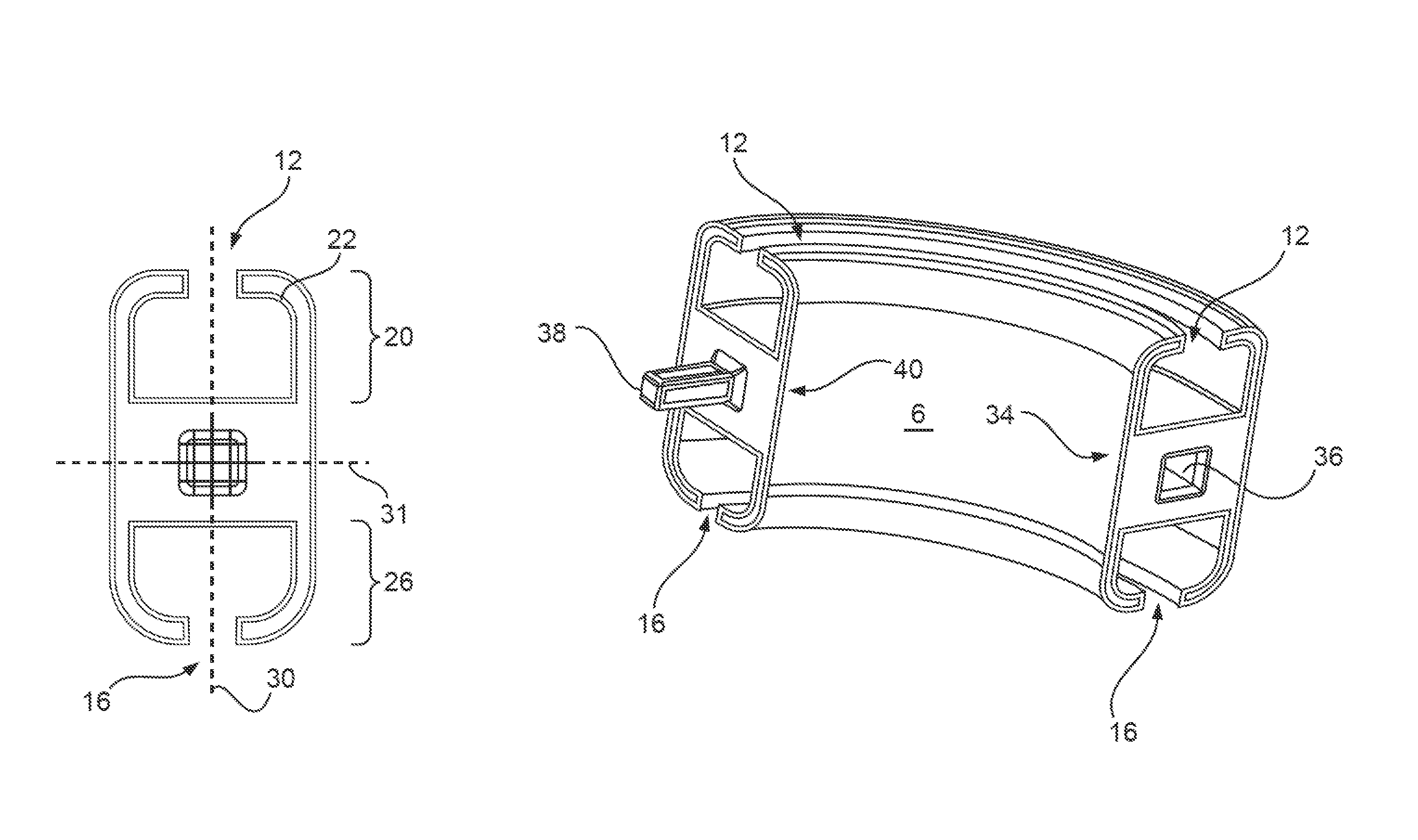

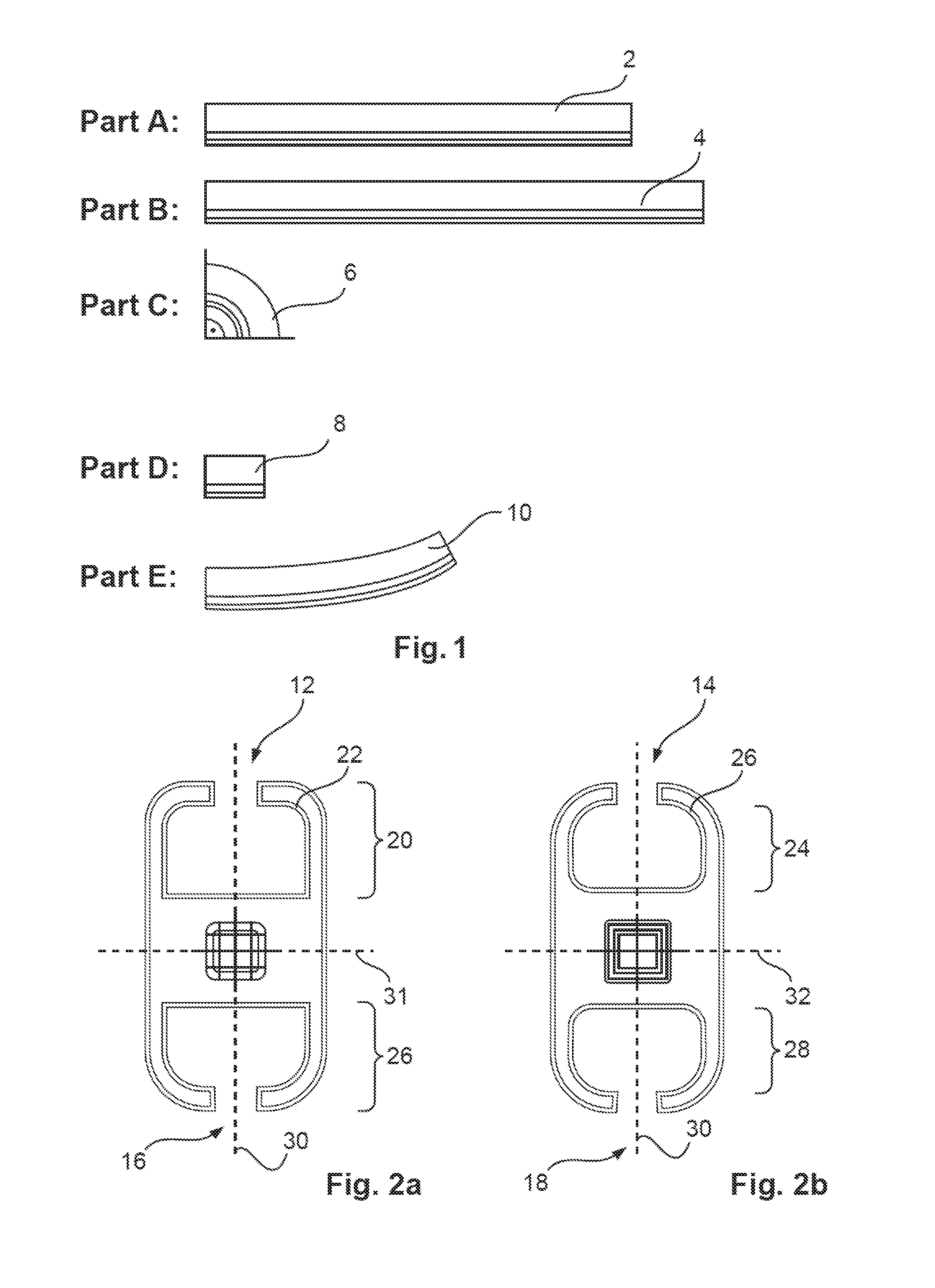

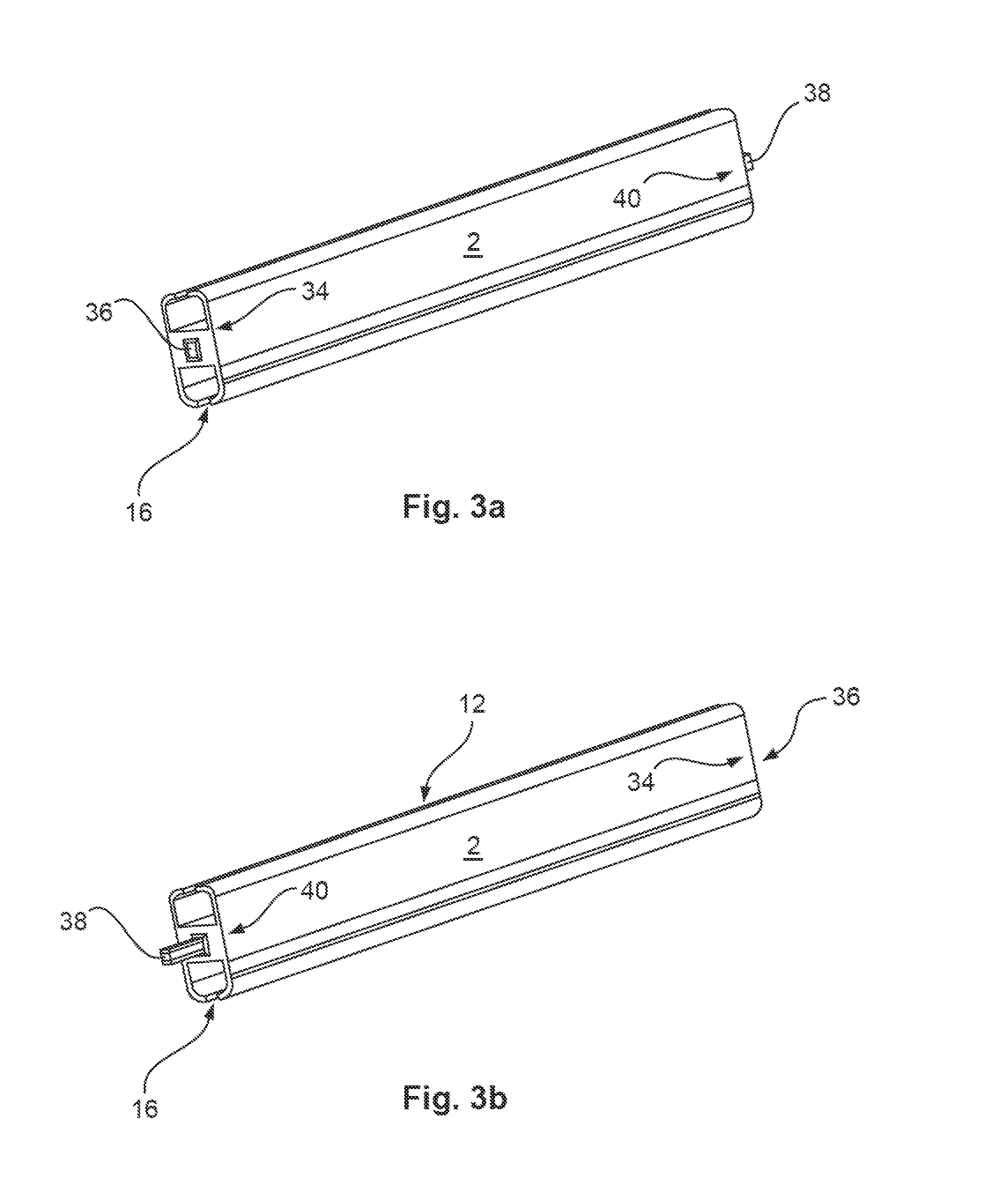

Aircraft cabin curtain rail assembly kit, aircraft cabin curtain rail and aircraft with an aircraft cabin having a curtain supported on such an aircraft cabin curtain rail

ActiveUS8756760B2Easy to provideEliminate needCurtain suspension devicesCurtain rodsNacelleEngineering

An aircraft cabin curtain rail assembly kit includes a plurality of curtain rail components with linear curtain rail sections and curved curtain rail sections with an angle of curvature in a range of 0-90°. Each curtain rail component has a first end and a second end. On the first end, a recess for receiving a fixation protrusion of another curtain rail component is arranged and, on the second end, a fixation protrusion for inserting into a recess of another curtain rail component is present. The recess and the fixation protrusion include a fastening means for fixating the recess and the fixation protrusion relative to each other. Each curtain rail component includes a holder slit for attaching the respective curtain rail component to an object and a curtain slit for guiding curtain rail guiding means in the curtain rail component.

Owner:AIRBUS OPERATIONS GMBH

Optical biosensor with focusing optics

ActiveUS8670123B2Avoid optical distortionImprove accuracyScattering properties measurementsMountingsTotal internal reflectionOptical axis

The invention relates to focusing optics (100) for a biosensor (10) which allow with simple means to accurately image an extended investigation region (13) onto a detector plane (P). To this end, the focusing optics (100) comprises at least two focusing lenslets (LL) that are arranged adjacent to each other such that they image an incident parallel light beam (L2) that is directed along a main optical axis (MOA) onto a common plane (P). The output light beam (L2) that is received by the focusing optics (100) may preferably originate from total internal reflection of a parallel input light beam (L1) at the investigation region (13) of a transparent carrier.

Owner:SIEMENS HEALTHINEERS NEDERLAND BV

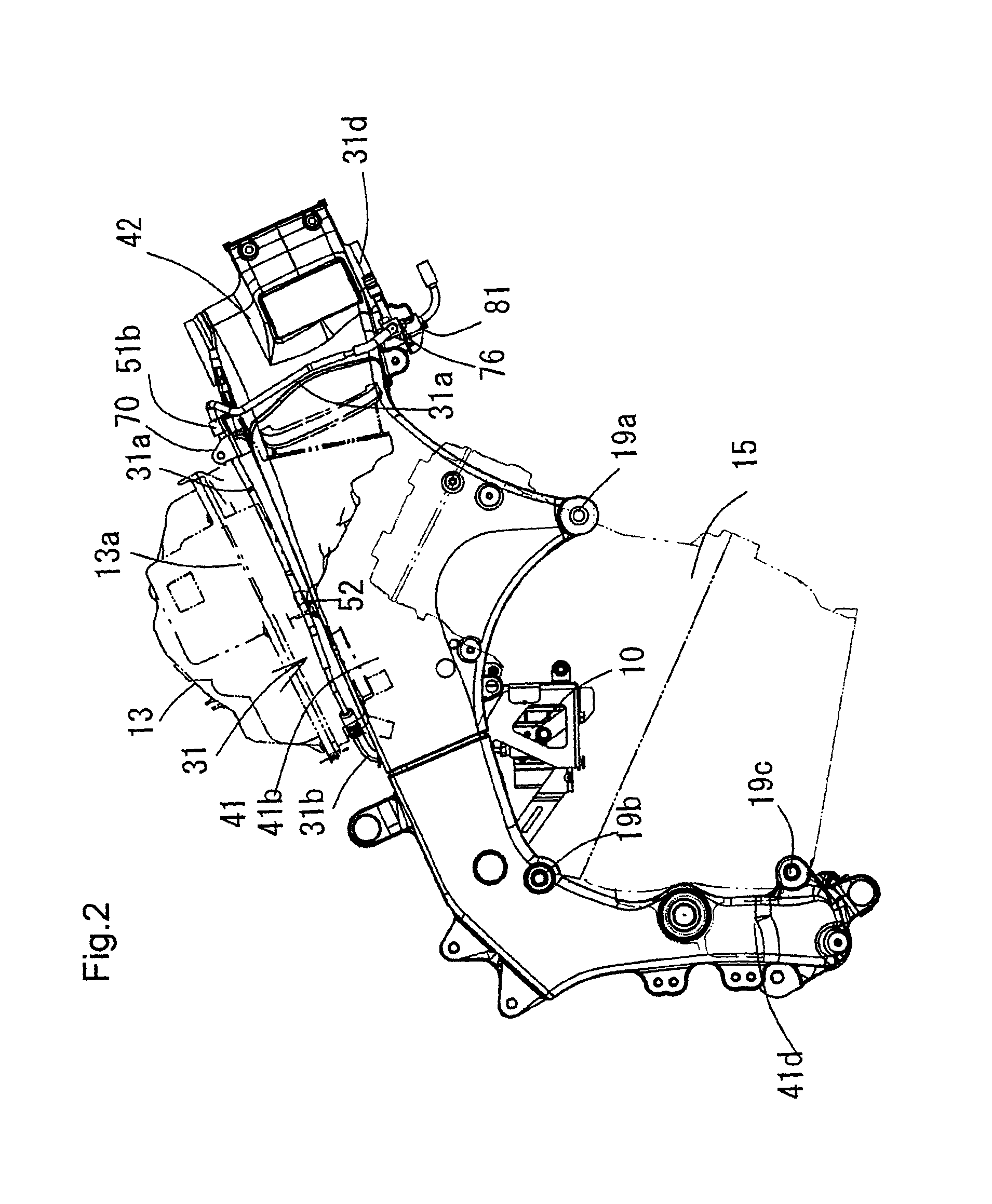

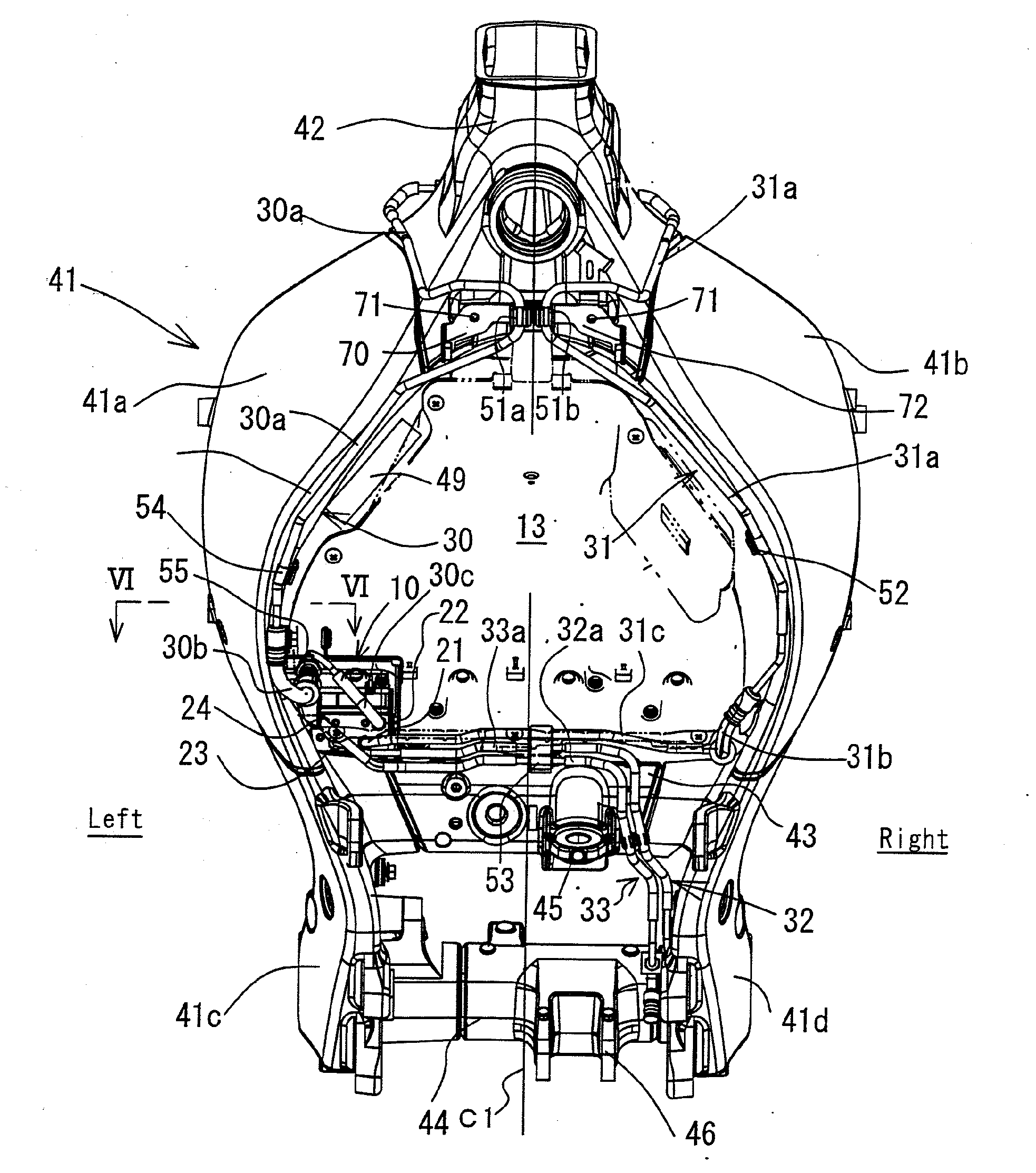

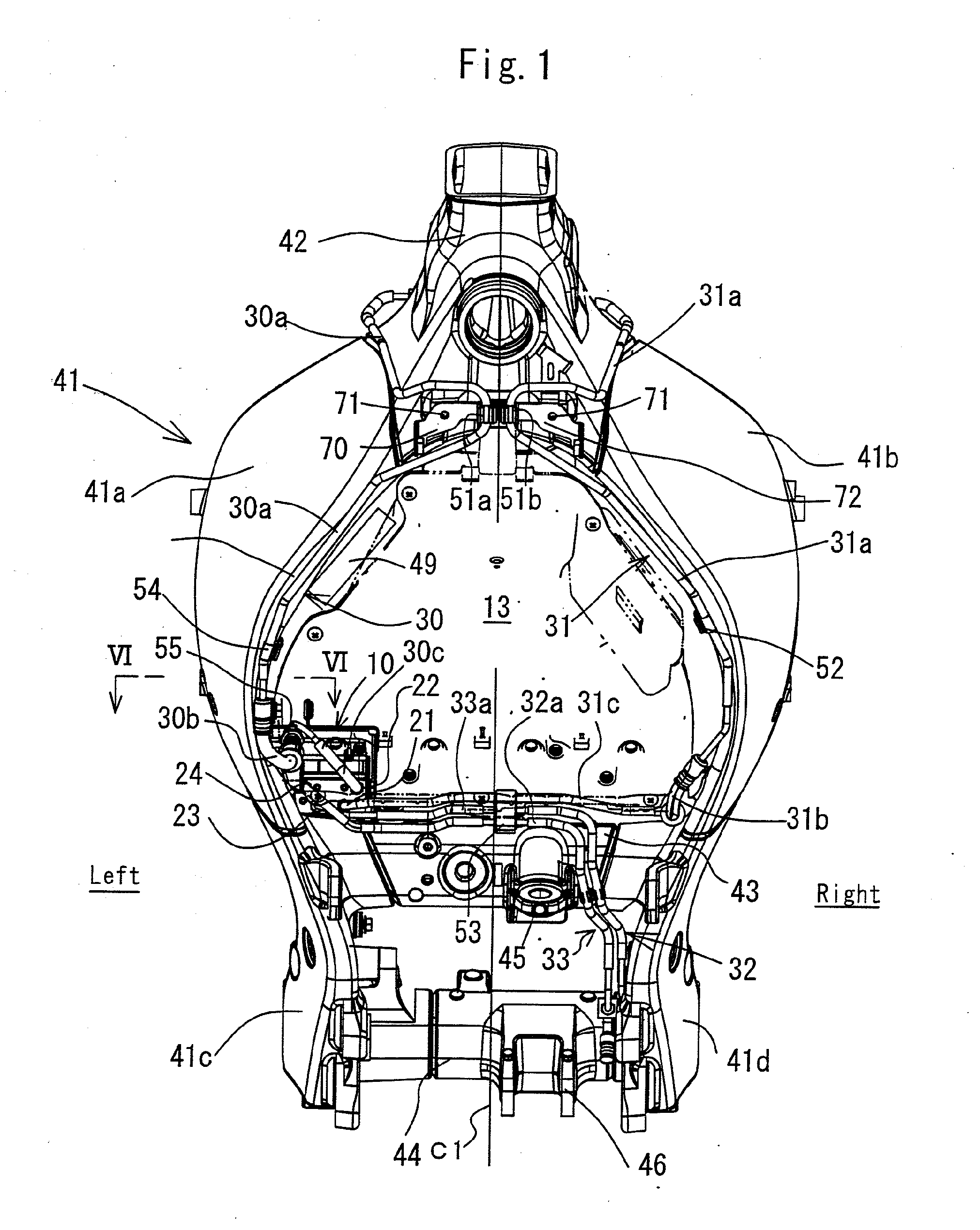

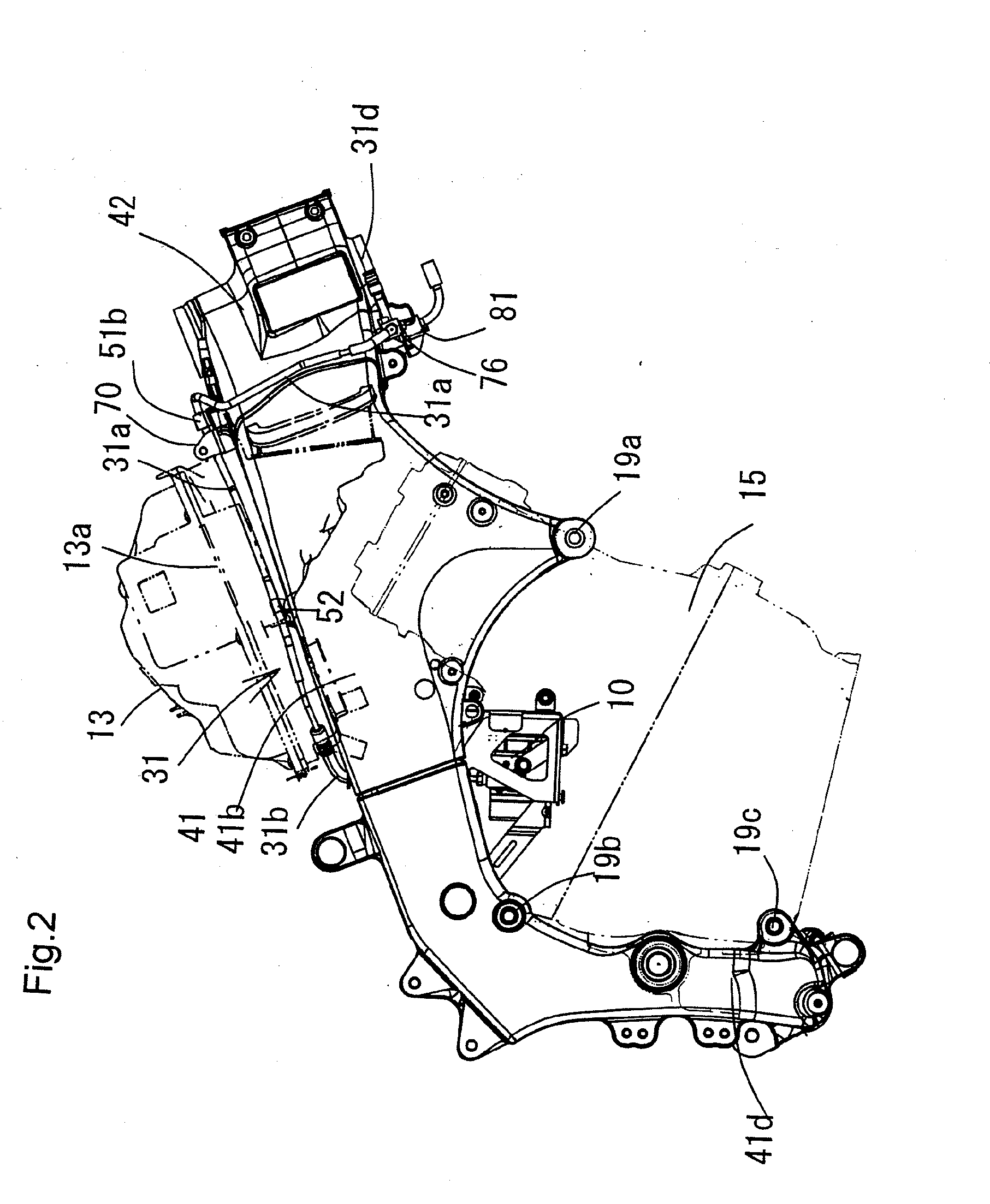

Hydraulic brake apparatus of motorcycle

ActiveUS8672422B2Easy to separateEasy maintenanceBraking action transmissionAxle suspensionsBrake fluidHydraulic pressure

Owner:KAWASAKI MOTORS LTD

Process for producing a polymer electrolyte for a nonaqueous battery

InactiveUS20040209168A1Excellent strengthLarge shapeElectrode carriers/collectorsConductive materialPolymer chemistryLithium electrode

A nonaqueous battery, such as a lithium ion battery, is formed from a polymer electrolyte comprising: a vinylidene fluoride copolymer comprises 90 to 97 wt. % of vinylidene fluoride monomer units and 3 to 10 wt. % of units of at least one monomer copolymerizable with the vinylidene fluoride monomer and has an inherent viscosity of 1.5 to 10 dl / g. The polymer electrolyte stably retains the nonaqueous electrolytic solution in a large amount and has excellent strength in this state.

Owner:KUREHA KAGAKU KOGYO KK

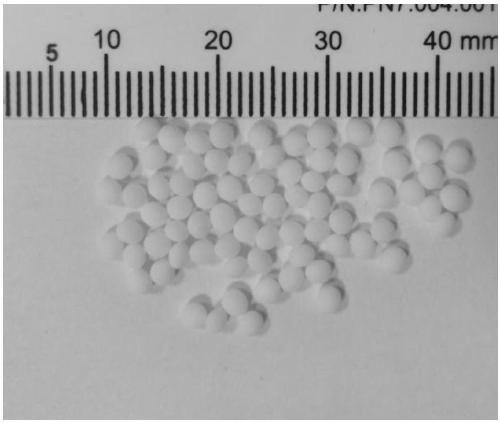

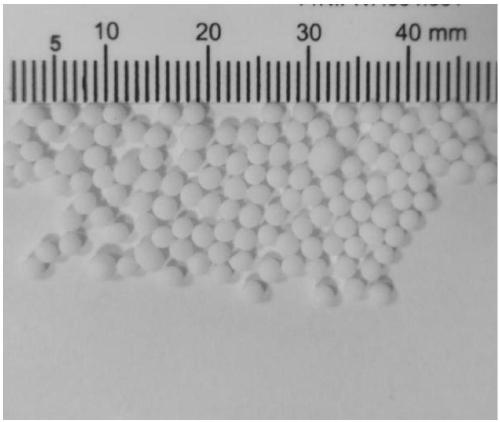

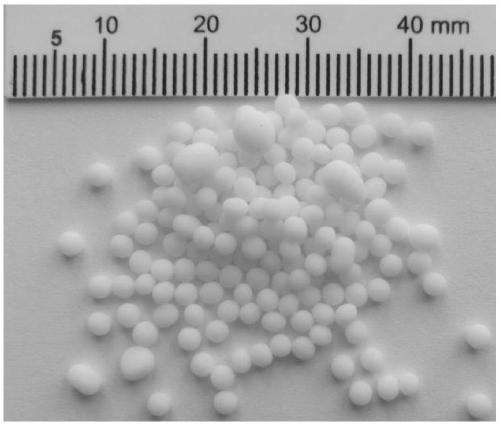

Hydroxyapatite forming method, hydroxyapatite and application of hydroxyapatite

ActiveCN111217598AImprove adsorption capacityHigh sphericityPhosphorus compoundsChlorideAqueous solution

The invention discloses a forming method of spherical hydroxyapatite, hydroxyapatite and application of the hydroxyapatite. The forming method specifically comprises the following steps: uniformly stirring and mixing a calcium chloride aqueous solution and an ammonium dihydrogen phosphate aqueous solution, filtering to obtain a hydroxyapatite precipitate, and directly dispersing the hydroxyapatiteprecipitate into deionized water without washing to obtain a turbid liquid; and mixing the hydroxyapatite turbid liquid and an alginate aqueous solution to form slurry, then adding the slurry into ametal salt solution in a dropwise manner, solidifying the hydroxyapatite into gel balls, and drying and roasting to obtain the spherical hydroxyapatite. The preparation method is simple in process, and the prepared spherical hydroxyapatite is high in sphericity degree and strength and has wide application prospects in the fields of catalysis, adsorption separation and bioengineering.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Tongue and seat belt device using same

Owner:JOYSON SAFETY SYST JAPAN GK

Head coil arrangement with an adjustable neck-engaging portion for use in a magnetic resonance apparatus

InactiveUS7518365B2Improve signal-to-noise ratioLarge shapeMagnetic measurementsDiagnostic recording/measuringResonanceEngineering

Head coil arrangement for a magnetic resonance apparatus has a housing with a number of coil elements arranged in or on the housing, and the housing has at least one movable and / or moldable housing part (2a) for adjustment to different neck shapes in the region designated for the neck of a patient.

Owner:SIEMENS HEALTHCARE GMBH

Hydraulic brake apparatus of motorcycle

ActiveUS20120032500A1Easy to separateEasy maintenanceBraking action transmissionCycle brakesBrake fluidHydraulic pressure

The present invention provides a hydraulic brake apparatus of a motorcycle, including a main frame having a pair of right and left frame members extending rearward from a head pipe, and equipment arranged in a space between the right and left frame members, the hydraulic brake apparatus further including at least one brake fluid pipe, wherein the at least one brake fluid pipe is arranged so as to extend rearward from near the head pipe along an upper surface at least one of the frame members.

Owner:KAWASAKI MOTORS LTD

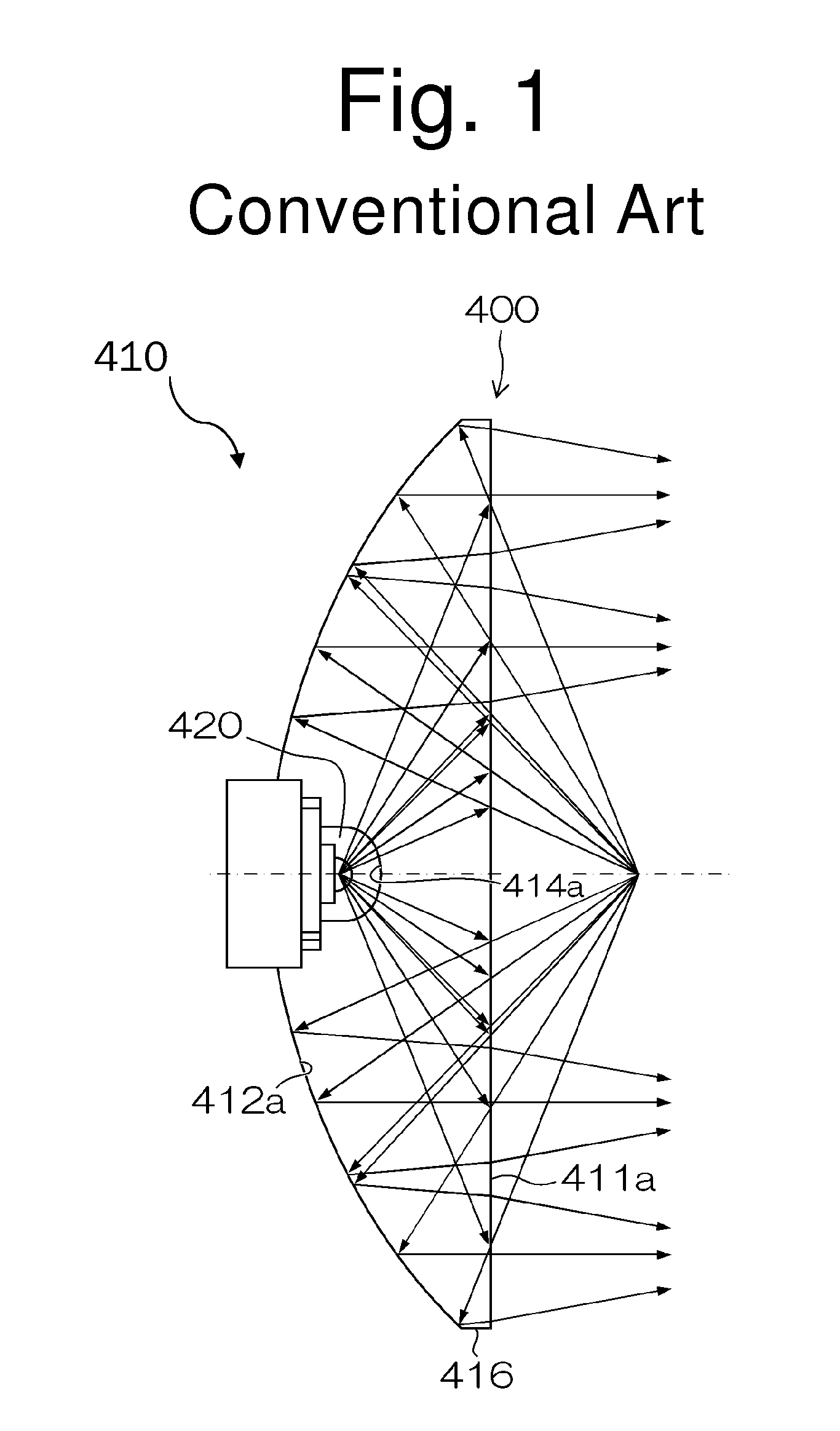

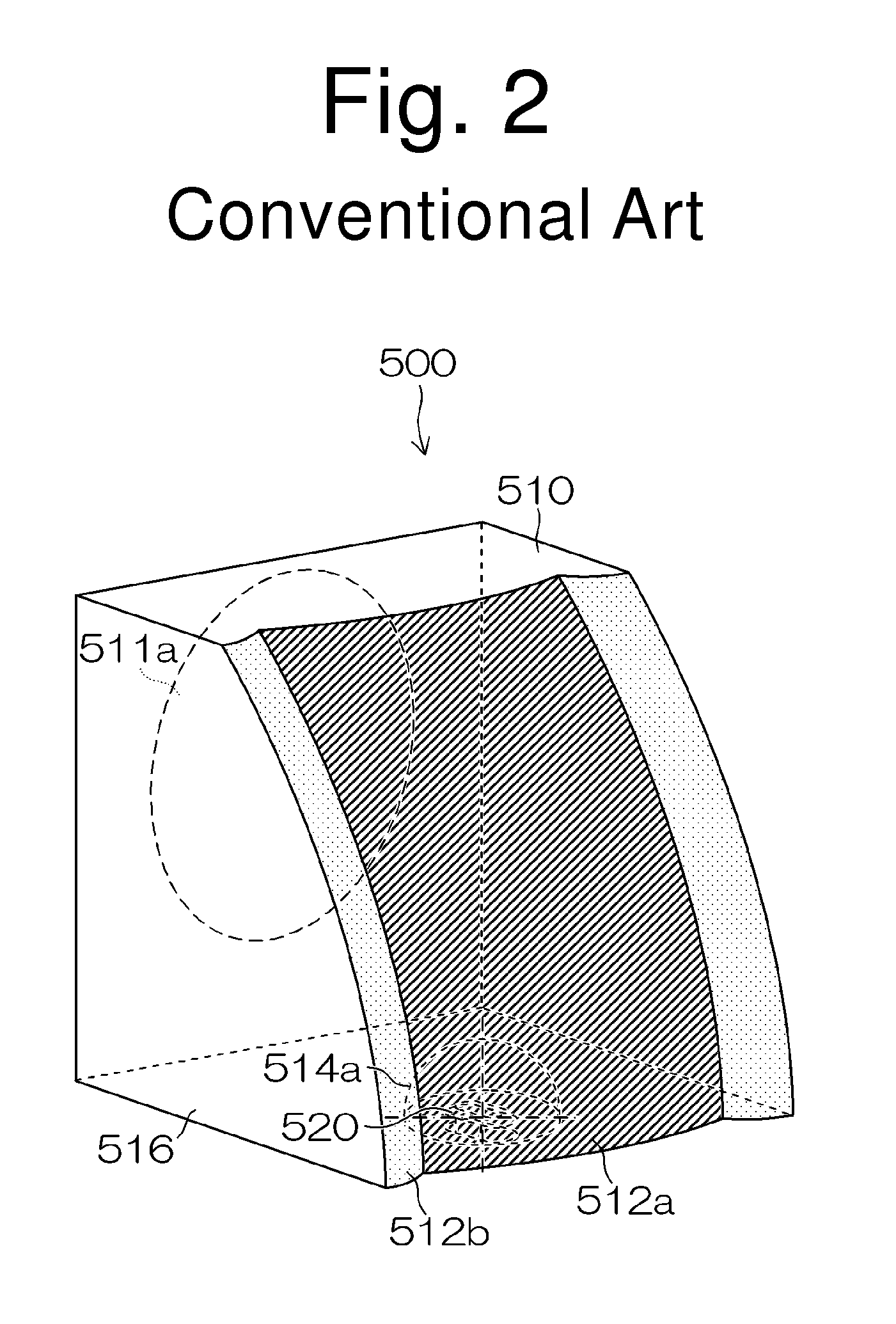

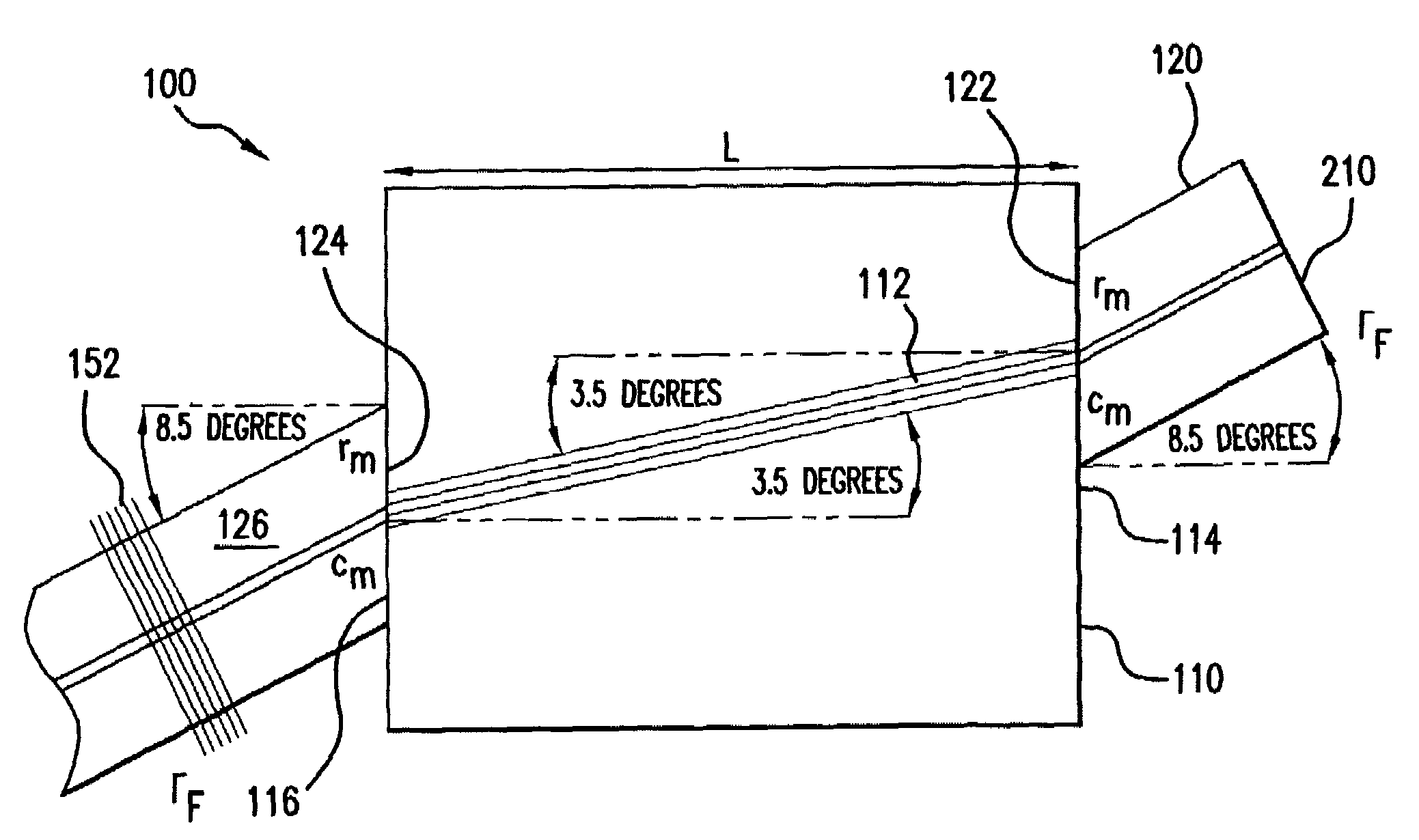

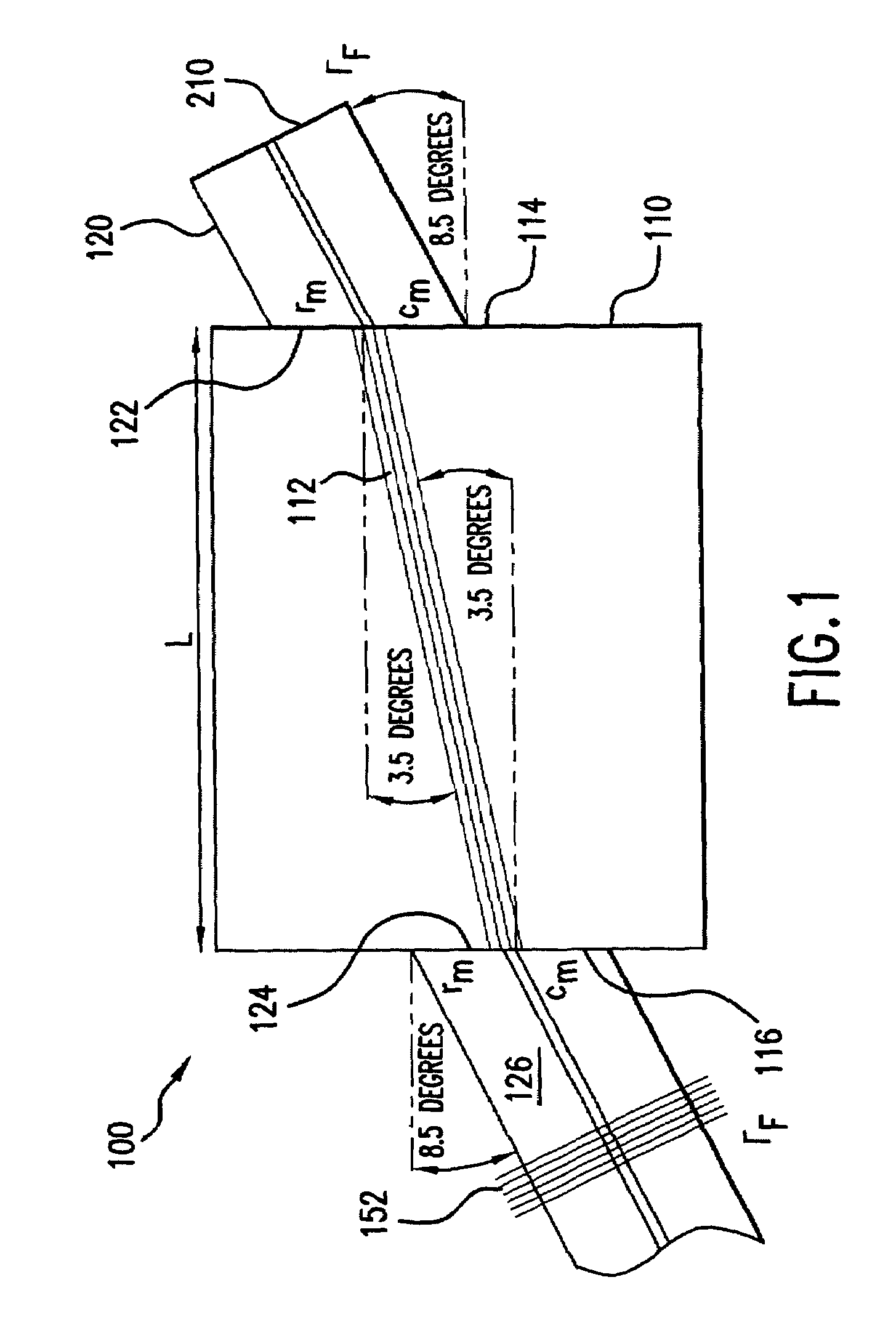

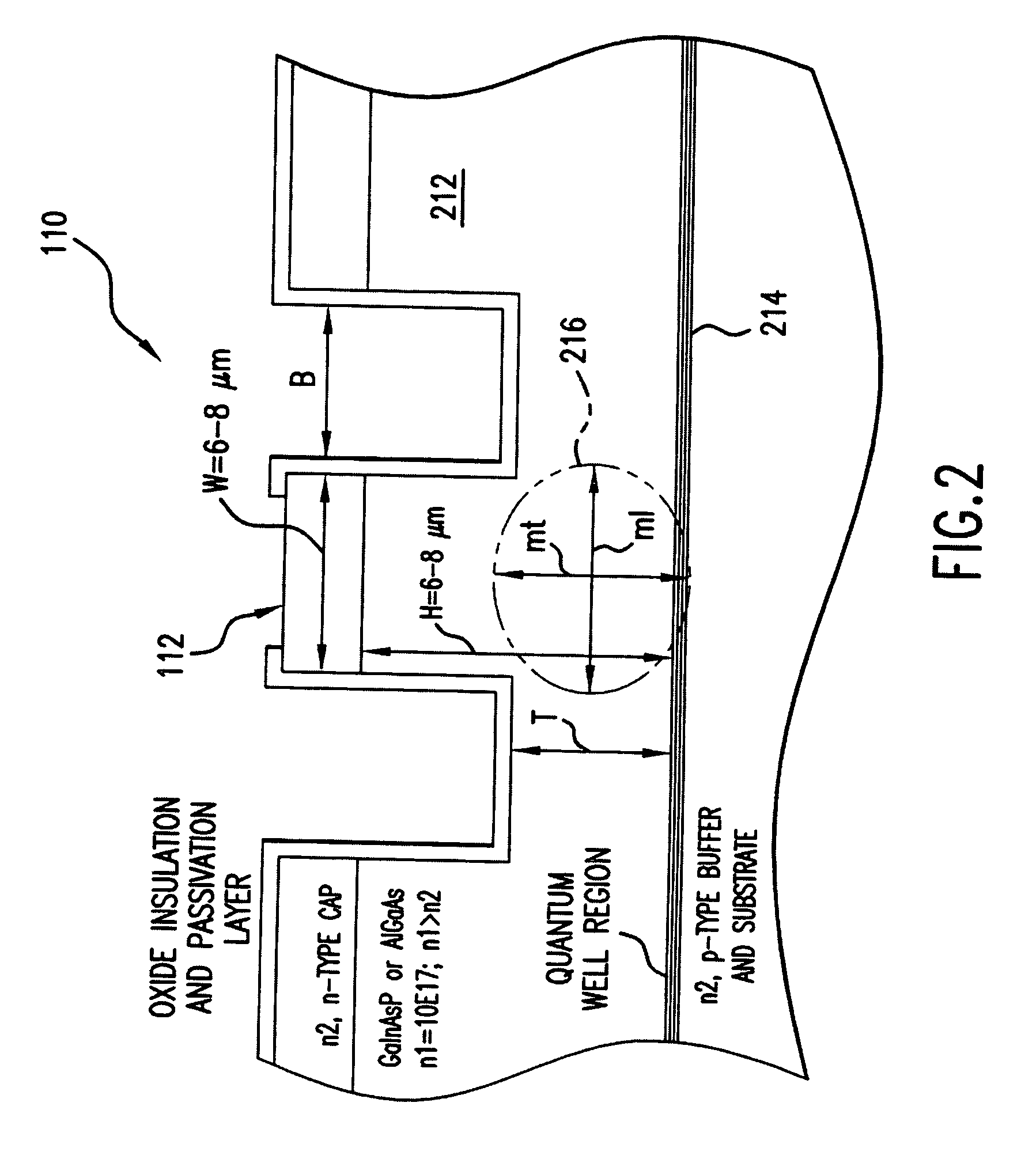

Large modal volume semiconductor laser system with spatial mode filter

InactiveUS7106773B1Reduce numerical apertureLarge mode sizeLaser detailsLaser optical resonator constructionSemiconductor waveguidesSelf-oscillation

A semiconductor optical amplification system that uses a single-mode fiber angle-coupled to a semiconductor wave-guide medium with optical gain. This design is particularly simple and relevant to optical fiber systems, but it may be generalized to include other implementations as well, in which other spatial mode filters are employed. A chip design is employed in which lowest order mode has a size greater than about 5 micrometers (μm). Thus, much smaller facet angles can be employed while still avoiding self-oscillation. More specifically, according to some aspects of the invention, facet angles of less than 4 to 5 degrees are utilized.

Owner:WALPOLE JAMES N +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com