Hydroxyapatite forming method, hydroxyapatite and application of hydroxyapatite

A technology of hydroxyapatite and molding methods, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of easy swelling, low mechanical strength, and cannot be used dry, and achieve high sphericity and high adsorption performance , the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

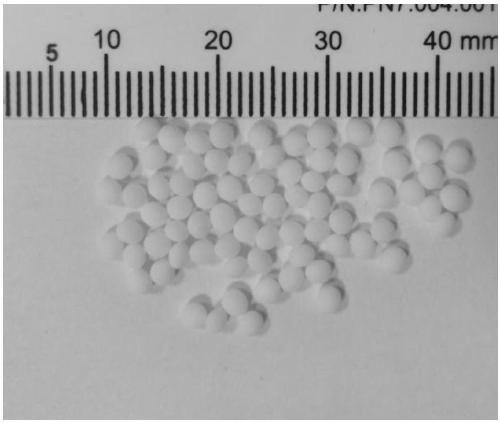

[0028] Take 74.8 g of anhydrous calcium chloride and 52.8 g of ammonium dihydrogen phosphate and dissolve them in 1600 mL of water respectively, mix the calcium chloride solution and ammonium dihydrogen phosphate solution under mechanical stirring, and adjust the pH value of the solution to 10.4 with ammonia water. Continue to stir for 15 minutes, put it into a 90°C water bath, continue to stir and heat for 2 hours, cool at room temperature and let it stand for aging for 12 hours, and filter the obtained precipitate with a Buchner funnel under reduced pressure. 6.69 g of the precipitate was dissolved in 15.61 g of deionized water to obtain 22.3 g of a 30% hydroxyapatite dispersion. Add the dispersion liquid to 20 g of 3% sodium alginate solution, and disperse with magnetic stirring for 30 min to obtain a suspension of hydroxyapatite. Take the above suspension and drop it into 300mL 0.2M calcium nitrate aqueous solution, after aging in the calcium nitrate solution for 2 hours, ...

Embodiment 2

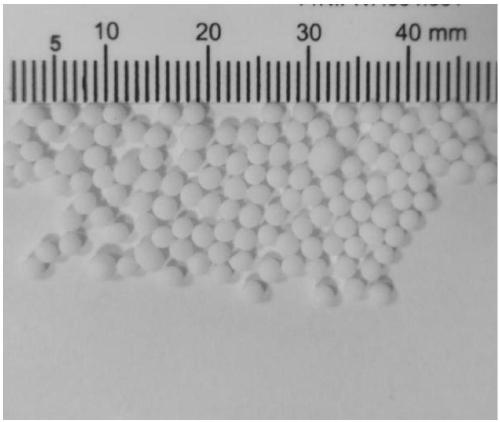

[0030] The preparation steps of hydroxyapatite are the same as in Example 1, except that 8 g of hydroxyapatite precipitate is added to 40 g of 1% sodium alginate solution, stirred and dispersed for 30 minutes to obtain a suspension of hydroxyapatite. Take the suspension above and drop it into 300mL of 0.5M calcium nitrate solution. After aging in the calcium nitrate solution for 10 hours, take it out and dry it at 60°C for 24h at room temperature, and then roast it at 500°C for 3h to obtain spherical hydroxyapatite with a diameter of 2.5mm. real photo see figure 2 . It can be seen from the figure that the outer surface of the pellets is smooth, spherical, and the particle size is uniform. The mechanical strength is measured by a DL III-500 strength tester, and the average mechanical strength can reach 148N / piece.

Embodiment 3

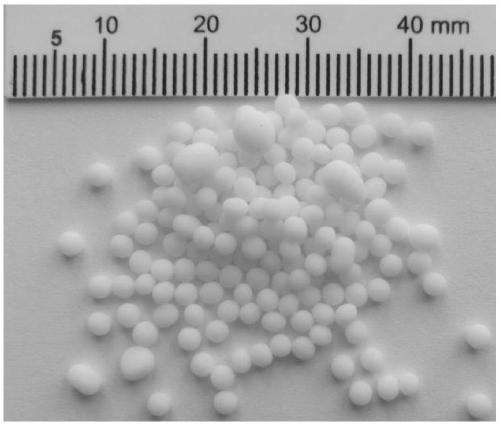

[0032] The preparation steps of hydroxyapatite are the same as those in Example 1, except that 6 g of hydroxyapatite precipitate is added to 30 g of 2% sodium alginate solution, stirred and dispersed for 180 min to obtain a suspension of hydroxyapatite. Take the above suspension and drop it into 300mL 2M calcium nitrate solution, age in the calcium nitrate solution for 1 hour, take it out and dry it at room temperature at 120°C for 8 hours, then roast it at 700°C for 1 hour to obtain spherical hydroxyapatite with a diameter of 2-5mm , real photos such as image 3 . It can be seen from the figure that the outer surface of the small ball is smooth, the small particle is in the shape of a sphere, and the large particle is in the shape of an ellipse. The mechanical strength is measured by a DL III-500 strength tester, and the average mechanical strength can reach 162N / piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com