Magnesium oxychloride cement paste, preparation method and application thereof in prevention of oil base drilling fluid loss

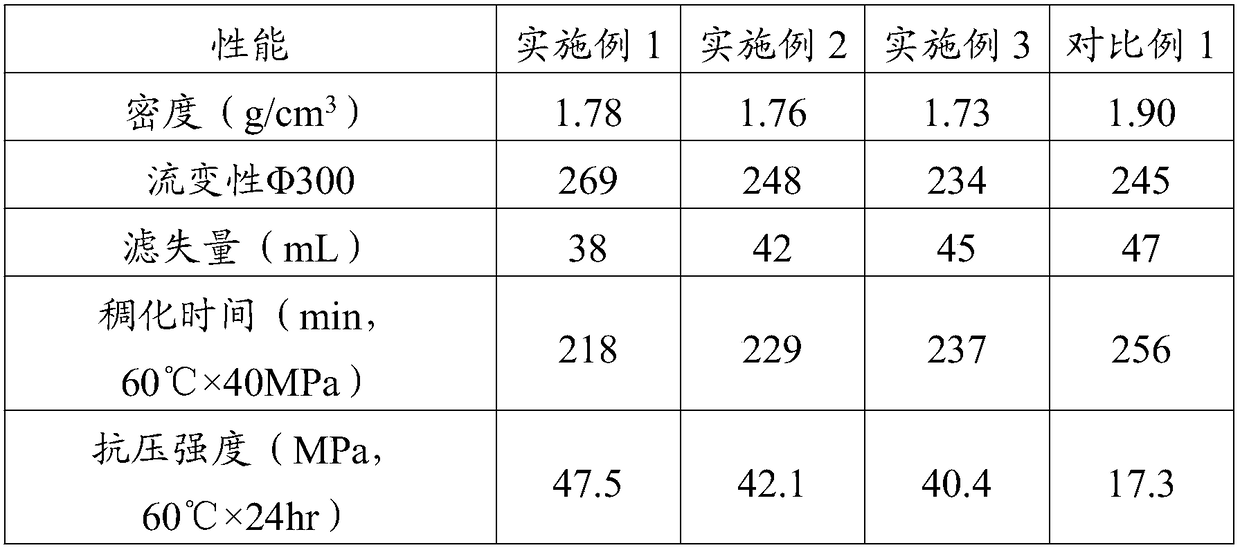

A technology of magnesium oxychloride cement and oil-based drilling fluid, applied in the directions of drilling compositions, chemical instruments and methods, reagents, etc., can solve problems such as failure to meet the requirements of plugging strength, and achieve the effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

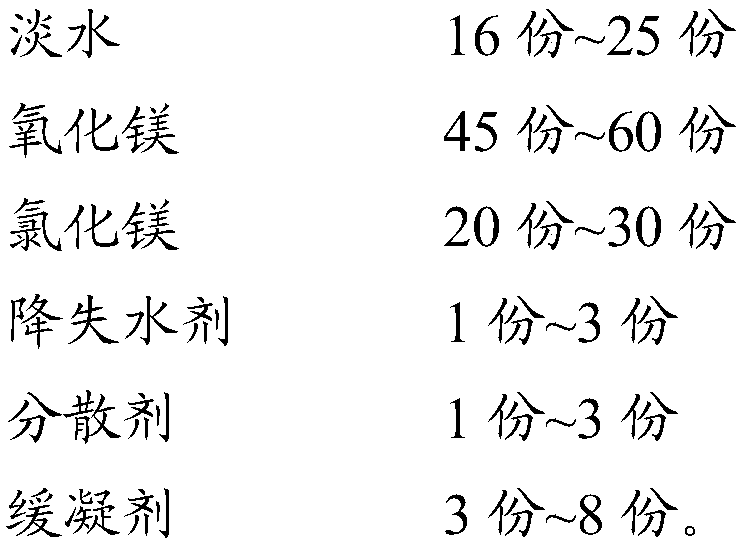

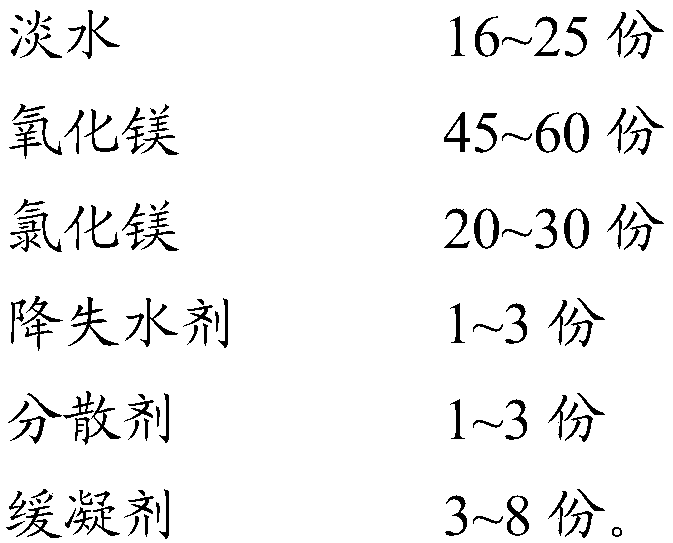

[0030] The present invention also provides the preparation method of magnesium oxychloride cement slurry described in above-mentioned technical scheme, comprises the following steps:

[0031] (1) Magnesium oxide, fluid loss reducer, dispersant and retarder are mixed to obtain dry powder;

[0032] (2) fresh water and magnesium chloride are mixed to obtain a magnesium chloride solution;

[0033] (3) The dry powder obtained in the step (1) is mixed with the magnesium chloride solution obtained in the step (2) to obtain the magnesium oxychloride cement slurry.

[0034] In the present invention, magnesium oxide, fluid loss reducer, dispersant and retarder are preferably mixed to obtain dry powder.

[0035] In the present invention, there is no special limitation on the mixing method of the magnesium oxide, the fluid loss reducer, the dispersant and the setting retarder, and the mixing method commonly used by those skilled in the art can be adopted.

[0036] The present invention ...

Embodiment 1

[0048] Weigh 56 parts by weight of magnesium oxide, 1 part by weight of water loss reducer, 2 parts by weight of dispersant, and 5 parts by weight of retarder and mix them evenly into dry powder; measure 16 parts by weight of fresh water and weigh 20 parts by weight Mix the magnesium chloride with fresh water to obtain a magnesium chloride solution, stir the magnesium chloride solution at a speed of 4000r / min, after the magnesium chloride is fully dissolved, add the mixed dry powder within 15 seconds, and continue stirring for 35 seconds at a speed of 12000r / min , to obtain the magnesium oxychloride cement slurry used for oil-based drilling fluid plugging according to the present invention.

Embodiment 2

[0050] Weigh 50 parts by weight of magnesium oxide, 1 part by weight of water loss reducer, 1 part by weight of dispersant, and 6 parts by weight of retarder and mix them uniformly to form a dry powder; measure 20 parts by weight of fresh water in a mixing cup, Take by weighing 22 parts by weight of magnesium chloride and mix it with fresh water to obtain a magnesium chloride solution, stir the magnesium chloride solution at a speed of 4500r / min, after the magnesium chloride is fully dissolved, add the mixed dry powder within 10 seconds, cover the stirrer lid, and Stirring is continued for 35 seconds at a rotating speed of 12500r / min, and the magnesium oxychloride cement slurry for oil-based drilling fluid plugging of the present invention is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com