Water-based drilling fluid and preparing method thereof

A technology of water-based drilling fluid and smectite, applied in the field of drilling fluid, can solve problems such as abnormal drilling operations, difficult adjustment of rheological properties, and increased filtration volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

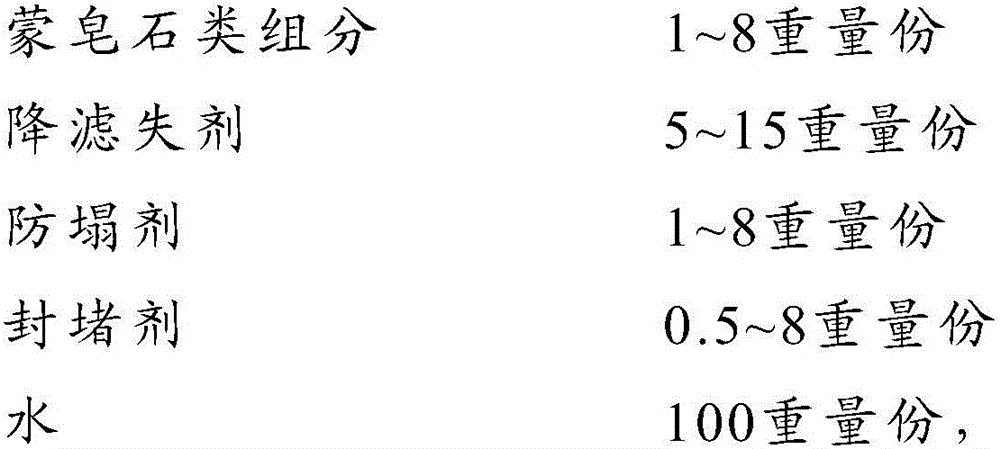

[0093] (1) Water-based drilling fluid contains the following components:

[0094]

[0095] (2) Preparation method: add 10g of synthetic laponite to 400mL of water, stir at high speed for 20 minutes, and hydrate at room temperature for 16 hours to obtain the base slurry; add lignite into the high stirring cup containing the base slurry according to the formula under high-speed stirring Resin SPNH, fluid loss reducer KJAN, anti-slump agent and plugging agent, finally add barite to increase the density of drilling fluid to 1.2g / cm 3 , and continue to stir for 20 minutes to prepare water-based drilling fluid.

[0096] (3) The prepared drilling fluid performance is tested:

[0097] (a) The rheological properties and medium-pressure fluid loss of the high-temperature-resistant synthetic laponite water-based drilling fluid prepared at room temperature were tested with a six-speed rotational viscometer and a medium-pressure fluid loss meter.

[0098] (b) Put the water-based drill...

Embodiment 2

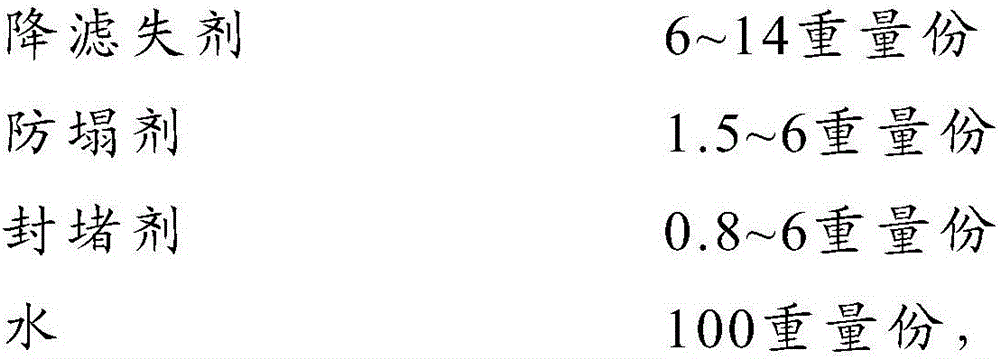

[0104] (1) Water-based drilling fluid contains the following components:

[0105]

[0106] (2) Preparation method: Add 14g of synthetic laponite to 400mL of water, stir at high speed for 20 minutes, and hydrate at room temperature for 16 hours to obtain the base slurry; add sulfur into the high stirring cup containing the base slurry according to the formula under high-speed stirring Lignite SMC, sulfonated phenolic resin SMP-I, anti-slump agent and plugging agent, finally add barite to increase the density of drilling fluid to 1.4g / cm 3, and continue stirring for 20 minutes to obtain a water-based drilling fluid.

[0107] (3) The prepared drilling fluid performance is tested:

[0108] (a) The rheological properties and medium pressure fluid loss of the newly prepared high temperature resistant synthetic laponite water-based drilling fluid were tested at room temperature using a six-speed rotational viscometer and a medium pressure fluid loss tester.

[0109] (b) Put the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com