Preparation method of cationic silicon-fluorine thinning agent for drilling fluid

A cation and diluent technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of oil and gas formation damage, large processing capacity, unstable dilution effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] As the best embodiment of the present invention, it discloses a preparation method of cationic silicon fluorine diluent for drilling fluid, the steps are as follows:

[0021] 1) Add 50ml of methyl methacrylate and 100ml of butyl acrylate in 500ml of distilled water in sequence, stir evenly, add 7.5ml of Span 80, stir for 1 hour, and form a monomer pre-emulsion;

[0022] 2) Take out the pre-emulsion, add 35ml of hexafluorobutyl methacrylate, 25ml of dodecafluoroheptyl methacrylate, 25ml of γ-methacryloxypropyl trimethoxysilane, vinyl trimethoxysilane 40ml, disperse by ultrasonic vibration for 10min;

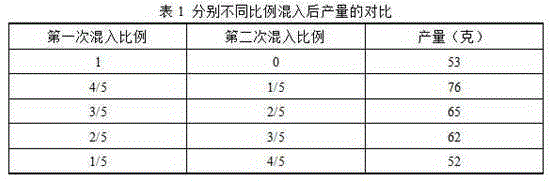

[0023] 3) Take 1 / 5 of the ultrasonically oscillated emulsion and add 3g of ammonium persulfate, add it into the flask and heat it in a water bath, and then add 3g of ammonium persulfate and distilled water after reaching the reaction temperature;

[0024] 4) After the emulsion has a blue light, add the remaining 4 / 5 emulsion dropwise within 15 minutes, then add 3g of ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com