One-step synthesis process of producing biodegradable high-hydroscopicity resin directly with corn powder

A technology of superabsorbent resin and synthesis method, which is applied in the field of synthetic resin production, can solve problems such as the difficulty of large-scale production, and achieve the effects of environmental protection, soil structure improvement, and volatilization reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

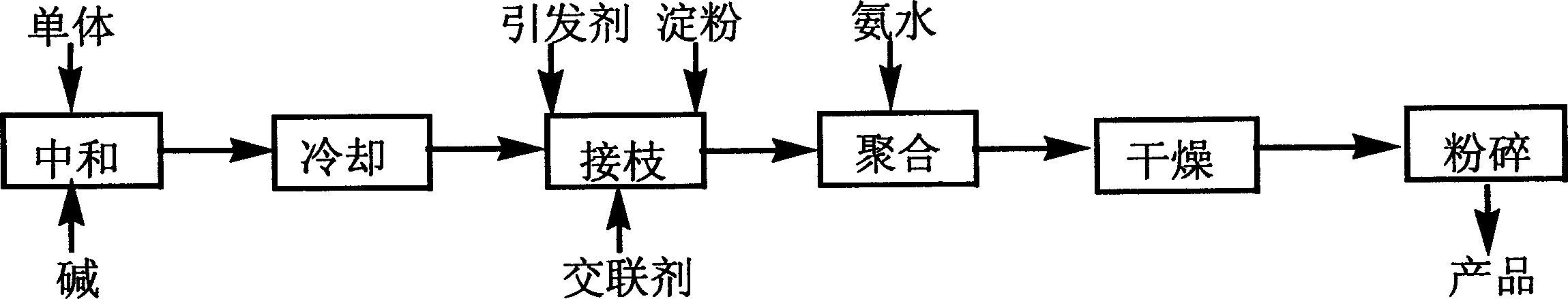

Method used

Image

Examples

Embodiment Construction

[0032] The best embodiment of the present invention is: at normal temperature, prepare 85ml of sodium hydroxide solution with a concentration of 26%, slowly add it into 60g of propylene-based monomer after cooling to room temperature, and keep stirring to complete the reaction. Cool to 35°C. Under the condition of constant stirring, 11g of corn flour and 1g of peat powder were successively added to make the corn flour and peat powder evenly dispersed, and the mixture was stirred at constant temperature for 30 minutes. Then slowly add 0.7 g of initiator and 0.2 g of cross-linking agent in sequence, and stir for 2 hours at constant temperature. Add 17ml of ammonia water, and the reaction system will react to completion after standing for 10 minutes. The obtained product is dried at 120°C, crushed and pulverized to obtain a light yellow powder product, which is the final product with an average water absorption rate of 800-1000 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com