Degradable temporary plugging agent for workover and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

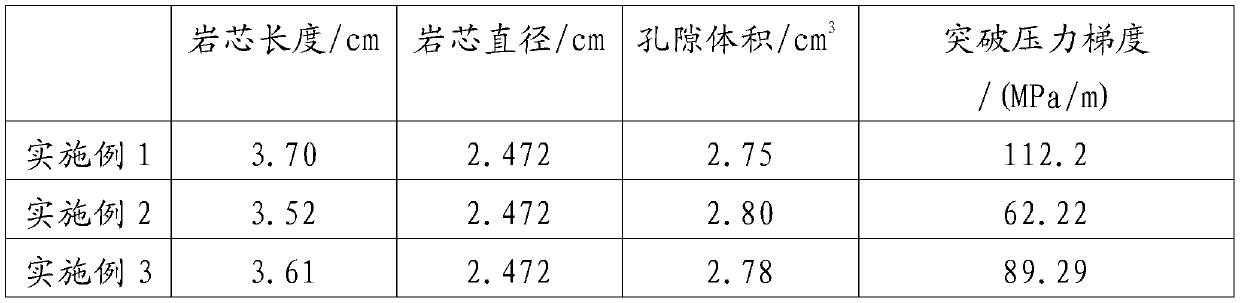

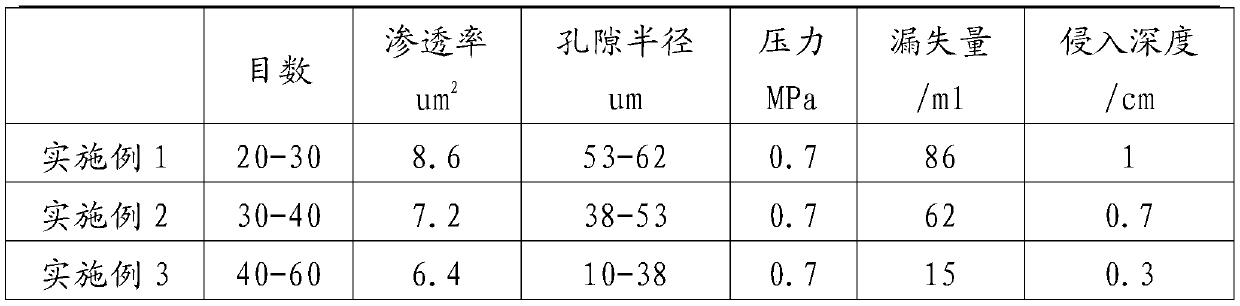

Embodiment 1

[0023] (1) Weigh 15g of corn flour and add it to 134.756g of distilled water, stir at 65°C for 30min to make it gelatinized;

[0024] (2) Keep the temperature of the solution at 20°C, add 10 g of acrylic acid and 30 g of acrylamide in sequence, adjust the pH value to 6.5-7 with 10% sodium hydroxide solution, and stir for 20 minutes to obtain intermediate solution 1;

[0025] (3) Weigh 12g of sodium alginate, 0.004g of hydroquinone, and 10g of bentonite into intermediate liquid 1, stir for 30 minutes to obtain a uniform solution, and obtain intermediate liquid 2;

[0026] (4) Weigh 0.04g of polyethylene glycol diacrylate and add it to intermediate liquid 2, and pass it through nitrogen for protection for 30-50min to obtain intermediate liquid 3;

[0027] (5) Adjust the temperature of the solution to 50°C, weigh 0.6g of ammonium persulfate and 0.6g of sodium bisulfite and add them to the intermediate liquid 3, continue to pass nitrogen for 30min, then let the reaction stand for ...

Embodiment 2

[0029] (1) Weigh 20g of corn flour and add it to 37.79g of distilled water, and stir for 30min at 65°C to make it gelatinized;

[0030] (2) Keep the temperature of the solution at 20°C, add 14g of acrylic acid and 42g of acrylamide in sequence, adjust the pH value to 6.5-7 with 10% sodium hydroxide solution, and stir for 20 minutes to obtain intermediate solution 1;

[0031] (3) Weigh 24g of sodium alginate, 0.01g of hydroquinone, and 30g of nanoclay into intermediate solution 1, stir for 30 minutes to obtain a uniform solution, and obtain intermediate solution 2;

[0032] (4) Weigh 0.2 g of polyethylene glycol diacrylate and add it to intermediate liquid 2, and pass through nitrogen for protection for 30-50 minutes to obtain intermediate liquid 3;

[0033] (5) Adjust the temperature of the solution to 50°C, weigh 1.0g of ammonium persulfate and 1.0g of sodium bisulfite and add them to the intermediate liquid 3, continue to pass nitrogen for 30min, then let the reaction stand ...

Embodiment 3

[0035] (1) Weigh 18g of corn flour and add it to 96.272g of distilled water, stir at 65°C for 30min to make it gelatinized;

[0036] (2) Keep the temperature of the solution at 20° C., add 12 g of acrylic acid and 36 g of acrylamide in sequence, adjust the pH value to 6.5-7 with 10% sodium hydroxide solution, and stir for 20 minutes to obtain intermediate solution 1;

[0037] (3) Weigh 16g of sodium alginate, 0.008g of hydroquinone, 10g of bentonite and 10g of nanoclay and add them to intermediate solution 1, stir for 30 minutes to obtain a uniform solution, and obtain intermediate solution 2;

[0038] (4) Weigh 0.12 g of polyethylene glycol diacrylate and add it to intermediate liquid 2, and pass it through nitrogen for protection for 30-50 minutes to obtain intermediate liquid 3;

[0039] (5) Adjust the temperature of the solution to 50°C, weigh 0.8g of ammonium persulfate and 0.8g of sodium bisulfite and add them to the intermediate liquid 3, continue to pass nitrogen for 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com