Soil conditioning agent, and preparation method and applications thereof

A technology of soil conditioner and crop straw, which is applied in the field of soil pollution restoration and improvement, which can solve the problems of soil quality decline, soil nutrient loss and loss due to the use of chemical fertilizers, and achieve the effects of increasing food production, promoting biodegradation, and reducing residual pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

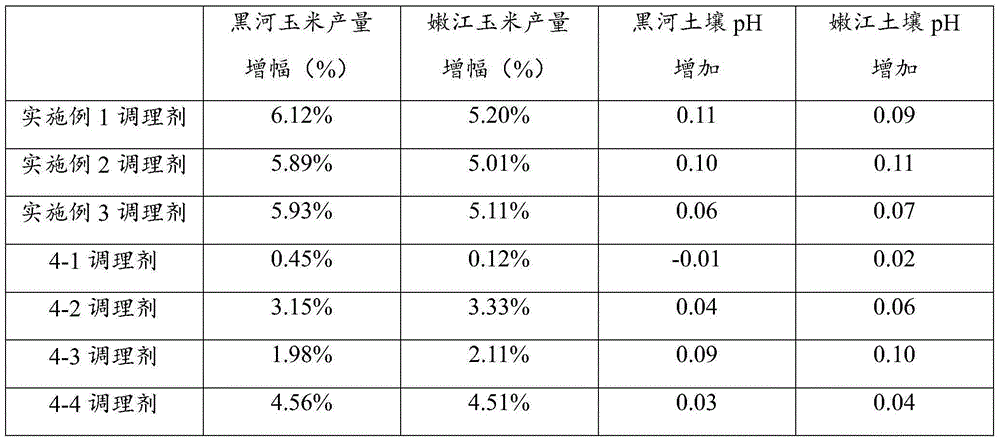

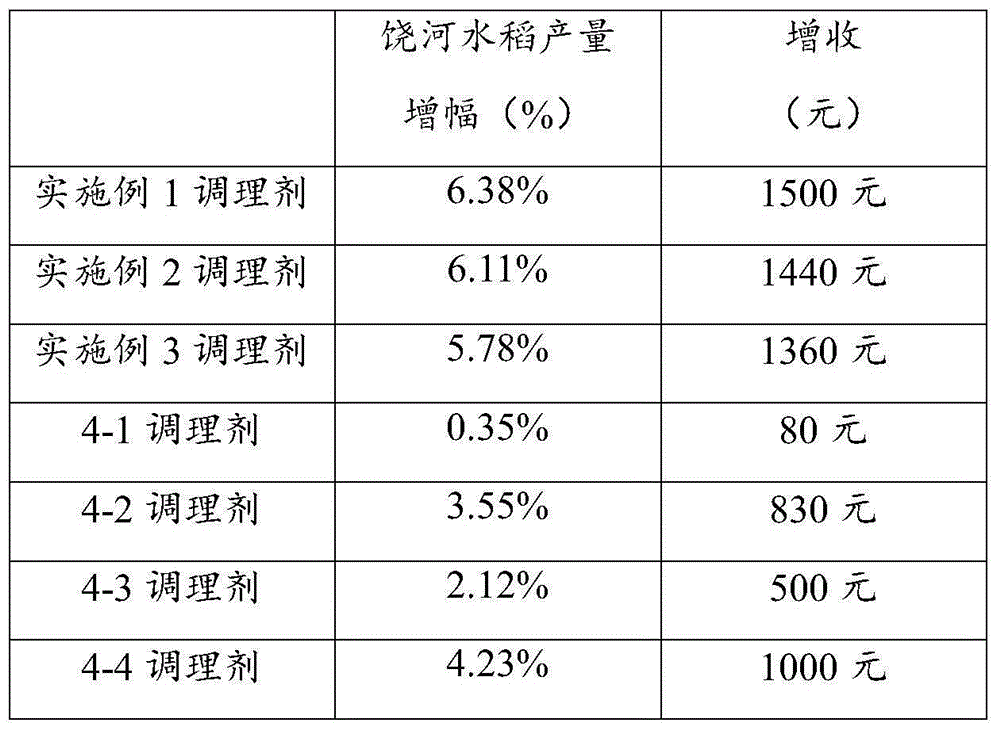

Examples

Embodiment 1

[0030] The present embodiment provides a soil conditioner and preparation method thereof, the specific process is as follows:

[0031] 1) Send corn and rice straw low-temperature carbide, organic fertilizer, and humic acid to the pulverizer according to the ratio of biochar: organic fertilizer: humic acid = 5:3:1, and pulverize until the particle size is 1.0- 4.0mm, to obtain pulverized materials; among them, low temperature carbides of corn and rice straw, corn straw and rice straw are mixed according to the same quality, after mixing, anaerobic carbonization treatment is carried out in a carbonization furnace at 300 ° C for 4-5 hours.

[0032] 2) Mix the pulverized material and clay obtained in step 1), send the EM bacterial agent into the extrusion granulator or disc granulator through the spraying device according to the formula ratio, and perform preliminary molding to obtain preliminary shaped granules , the number of viable bacteria in the EM bacterial agent used is 2×1...

Embodiment 2

[0036] This embodiment provides a soil conditioner. The difference between the soil conditioner and Example 1 is that low-temperature carbide of straw, organic fertilizer, and humic acid are formulated according to biochar:organic fertilizer:humic acid=6:2: The ratio of 1 is sent to the pulverizer for pulverization. Finally, in the soil conditioner, in terms of mass percentage, corn and rice straw low-temperature carbide accounted for about 60%, organic fertilizer 20%, humic acid 10%, clay 5%, and EM bacterial agent 5%.

Embodiment 3

[0038] The present embodiment provides a kind of soil conditioning agent, and the difference of this soil conditioning agent and embodiment 1 is:

[0039] Straw low-temperature carbide, organic fertilizer, and humic acid are sent to the grinder for crushing according to the ratio of biochar: organic fertilizer: humic acid = 9:7:4. Finally, in the soil conditioner, in terms of mass percentage, corn and rice straw low-temperature carbide accounted for about 45%, organic fertilizer 35%, humic acid 20%, clay 10%, and EM bacterial agent 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com