Method for preparing propene by catalytic cracking

A catalytic cracking and propylene technology, applied in chemical instruments and methods, hydrocarbon cracking to produce hydrocarbons, molecular sieve catalysts, etc., can solve the problems of accelerated catalyst aging and long-term unfavorable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

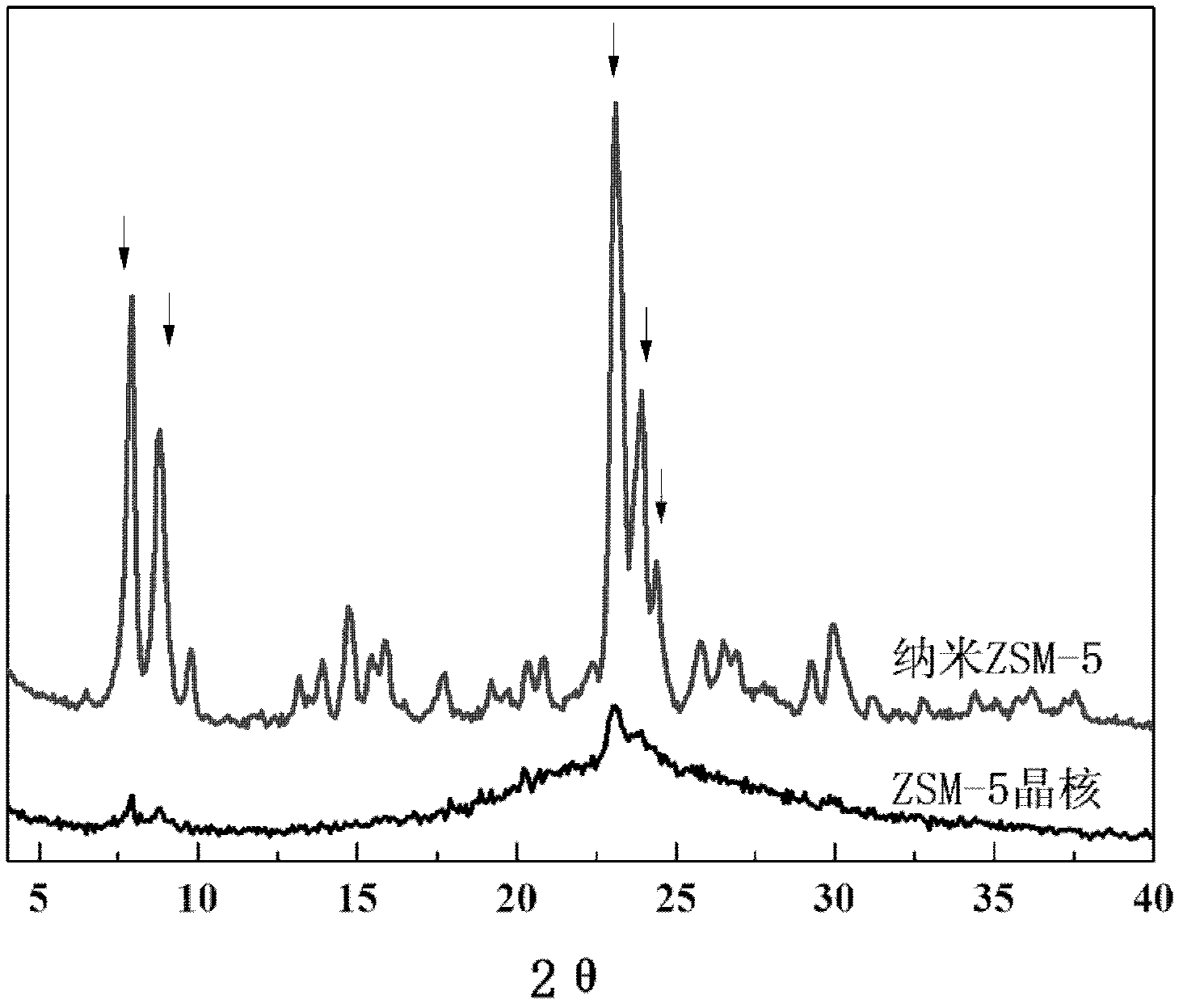

[0110] That is, water glass, seed crystal, n-butylamine and deionized water are formulated into glue A, and then aluminum sulfate solution, deionized water and H 2 SO 4 solution, stirred evenly to form solution B, and then slowly added solution B to solution A under strong stirring to form a mixture gel. The molar ratio of each component in the gel according to its oxide is: Al 2 o 3 : SiO 2 :Na 2 O: n-C 4 h 9 NH 2 :H 2 O=1.0:36.2:2.0:12.2:850, the amount of seed crystal added is 10.0% of the total weight of the mixture gel dry basis. The reaction mixture gel was added into the reaction kettle, and the temperature was gradually raised to 110° C. under stirring, and maintained for 24 hours. Then lower it to normal temperature, filter, separate the mother liquor, and wash the reactant with water, dry and roast to obtain a white powder product. As measured by X-ray diffraction (XRD), it has the diffraction characteristic peak of ZSM-5 molecular sieve, but its intensity ...

Embodiment 2

[0116] Repeat Example 1, but change the crystallization temperature to 120°C and 170°C, and the corresponding crystallization time is 18h and 0.5h. Then ZSM-5 crystal nucleus catalysts A-3 and A-4 are obtained. The reaction pressure is normal pressure, the reaction temperature is 470°C, and WHSV=3.5h -1 Under certain conditions, the butene conversion rates were 82.71% and 81.54%, the propylene yields were 27.60% and 26.48%, and the isobutene yields were 12.01% and 14.60%.

Embodiment 3~5

[0118] Repeat Example 1, but change the crystallization time to 20h, 10h, 5h, respectively. Then ZSM-5 crystal nucleus catalysts A-5, A-6 and A-7 were obtained. The butene conversion rates are 69.51%, 65.65% and 66.47%, the propylene yields are 33.40%, 32.60% and 30.26%, and the isobutene yields are 10.45%, 9.75% and 11.03%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com