Low-temperature-resistant silicon rubber and preparation process thereof

A preparation process and low temperature resistance technology, applied in the field of low temperature resistant silicone rubber and its preparation, can solve the problems of poor mechanical properties of low temperature resistant rubber, limited application scope, poor mechanical properties, etc., achieve strong low temperature resistance performance, improve mechanical properties, The effect of short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

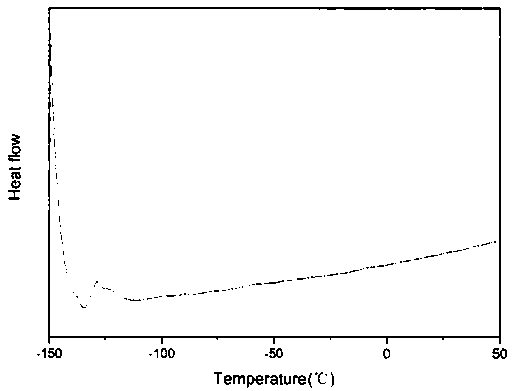

Image

Examples

Embodiment 1

[0030] Preparation of modified methyl vinyl silica gel: Weigh 5g of methyl vinyl silica gel into a 150ml Erlenmeyer flask, add 50ml of tetrahydrofuran, stir until fully dissolved, add mercaptopropionic acid at a ratio of vinyl to mercapto molar ratio of 1:1.3, At the same time, 1wt% photocatalyst DMPA was added, stirred until fully mixed, and then placed under ultraviolet light to initiate a mercapto-ene click chemical reaction. After the reaction was completed, tetrahydrofuran was rotary evaporated to obtain a modified methyl vinyl group.

Embodiment 2

[0032] Preparation of low temperature resistant rubber:

[0033] S1. Kneading: Knead 80g of modified methyl vinyl silica gel and 1g of zinc stearate as a release agent in a vacuum kneader for 3-5 minutes, first add 5g of graphene oxide into the organic solvent tetrahydrofuran, and ultrasonicate for 5 minutes to form Uniform and stable dispersion, then add the dispersion to the kneaded silica gel, continue ultrasonic stirring, the modified methyl vinyl silica gel will gather into the graphene oxide sheet structure in the form of intercalation, and the solvent molecules will continue to desorb The form ensures the entropy balance of the system, and finally forms a stable intercalation structure. The solvent is removed by rotary evaporation to obtain a graphene oxide / rubber composite material, and 40g of white carbon black, 3g of white oil, 0.1g of zinc oxide, 0.2g of 2 -Mercaptobenzimidazole, 0.1g dioctyl adipate, 10-50 rpm, stir and mix evenly, heat treatment at 60-90°C for 10-...

Embodiment 3

[0037] Preparation of low temperature resistant rubber:

[0038] S1. Kneading: Knead 100g of modified methyl vinyl silica gel and 3g of zinc stearate as a release agent in a vacuum kneader for 3-5 minutes, first add 10g of graphene oxide into the organic solvent tetrahydrofuran, and ultrasonicate for 5 minutes to form Uniform and stable dispersion, then add the dispersion to the kneaded silica gel, continue ultrasonic stirring, the modified methyl vinyl silica gel will gather into the graphene oxide sheet structure in the form of intercalation, and the solvent molecules will continue to desorb The form ensures the entropy balance of the system, and finally forms a stable intercalation structure. The solvent is removed by rotary evaporation to obtain a graphene oxide / rubber composite material, and 50g of white carbon black, 5g of white oil, 0.2g of zinc oxide, 0.4g of 2 -Mercaptobenzimidazole, 0.4g dioctyl adipate, 10-50 rpm, stir and mix evenly, heat treatment at 60-90°C for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com