Heat-resistant agent, high-temperature-resistant silicone rubber and preparation method thereof

A high-temperature-resistant silicone rubber and heat-resistant agent technology, which is applied in the field of silicone rubber, can solve the problems of poor compatibility between heat-resistant agent and silicone rubber, adverse effects on mechanical properties such as hardness, and easy loss of high-temperature elasticity, etc. Modulus, good elasticity and mechanical properties, and the effect of improving processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

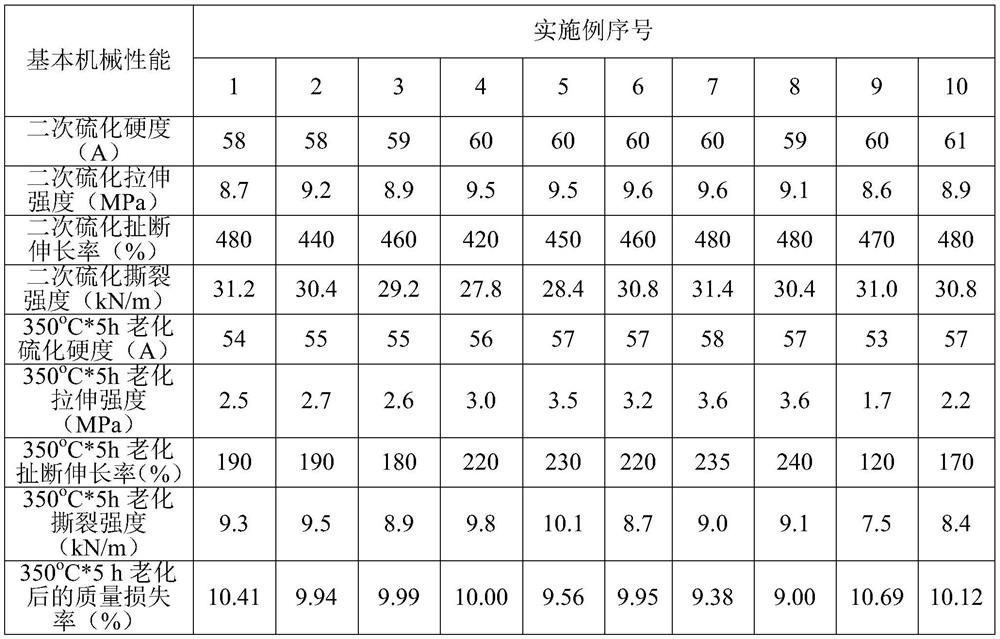

Embodiment 1

[0044] The average molecular weight is 689,000, and the average vinyl content is 100 parts of methyl vinyl silicone rubber raw rubber of 0.168mol% (wherein the molecular weight is 700,000 vinyl content of 0.05mol% methyl vinyl silicone rubber raw rubber 65 33 parts of methyl vinyl silicone rubber with a molecular weight of 680,000 and a vinyl content of 0.23 mol%, 2 parts of a methyl vinyl silicone rubber with a molecular weight of 500,000 and a vinyl content of 3 mol%, 47 parts of fumed silica (XHG-300, Zhejiang Kaihua Synthetic Materials Co., Ltd.), 2.0 parts of hydroxyl silicone oil (viscosity of 25mm at 25°C 2 / s, hydroxyl content is 8.5wt%), 1.5 parts of hexamethyldisilazane (content ≥ 99%), 1.5 parts of vinyl hydroxy silicone oil ((viscosity (25 ° C), mm 2 / s: 35, hydroxyl content: (mol%) 6.0, vinyl content: (mol%) 7.0)), 1.0 parts of methylphenyldimethoxysilane (HY-PS-9116, Hangyu Technology Product Center) , 0.1 part of zinc stearate (Hangzhou Oleochemical Co., Ltd.), ...

Embodiment 2

[0048] The average molecular weight is 682,000, and the average vinyl content is 100 parts of methyl vinyl silicone rubber raw rubber of 0.226mol% (wherein the molecular weight is 680,000 vinyl content of 0.08mol% methyl vinyl silicone rubber raw rubber 50 parts 48.2 parts of methyl vinyl silicone rubber with a molecular weight of 700,000 and a vinyl content of 0.20 mol%, 1.8 parts of a methyl vinyl silicone rubber with a vinyl content of 5 mol% and a molecular weight of 500,000), 40 parts of fumed silica (HL-200, Yichang Huifu Silicon Material Co., Ltd.), 0.5 parts of hydroxyl silicone oil (viscosity at 25 °C is 25mm 2 / s, hydroxyl content is 8.5wt%), 0.6 parts of hexamethyldisilazane (content ≥ 99%), 2.0 parts of vinyl hydroxy silicone oil ((viscosity (25 ° C), mm 2 / s: 35, hydroxyl content: (mol%) 6.0, vinyl content: (mol%) 7.0)), 2.0 parts of methylphenyldiethoxysilane (Hubei Xinghengye Technology Co., Ltd.), 0.08 parts of hard Fatty acid (Hangzhou Oil Chemical Co., Ltd.)...

Embodiment 3

[0052] The average molecular weight is 685,000, and the average vinyl content is 100 parts of methyl vinyl silicone rubber raw rubber of 0.235mol% (wherein the molecular weight is 700,000 vinyl content of 0.05mol% methyl vinyl silicone rubber raw rubber 59 37 parts of methyl vinyl silicone rubber with a molecular weight of 680,000 and a vinyl content of 0.23 mol%, 4 parts of a methyl vinyl silicone rubber with a molecular weight of 500,000 and a vinyl content of 3 mol%, 42 parts of fumed silica (Tokuyama QS-25, Japan Tokuyama Co., Ltd.), 1.0 parts of hydroxyl silicone oil (viscosity at 25°C is 25mm 2 / s, hydroxyl content is 8.5wt%), 0.9 parts of hexamethyldisilazane (content ≥ 99%), 1.0 parts of vinyl hydroxy silicone oil ((viscosity (25 ° C), mm 2 / s: 35, hydroxyl content: (mol%) 6.0, vinyl content in mole percent: (mol%) 7.0)), 1.5 parts of methylphenyldimethoxysilane (HY-PS-9116, Hang Yu Science and Technology Product Center), 0.1 part of calcium stearate (Hangzhou Oil Che...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com