Method and device for measuring anti-dirty performance of material surface based on weight method

A measuring device and measuring method technology, applied in the direction of using material absorption and weighing, etc., can solve the problems of selecting an economical and applicable anti-scale surface, long detection time, time-consuming and laborious, etc., and achieve fast evaluation, simple operation, and accurate testing high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Now in conjunction with accompanying drawing and specific embodiment the present invention is further described as follows:

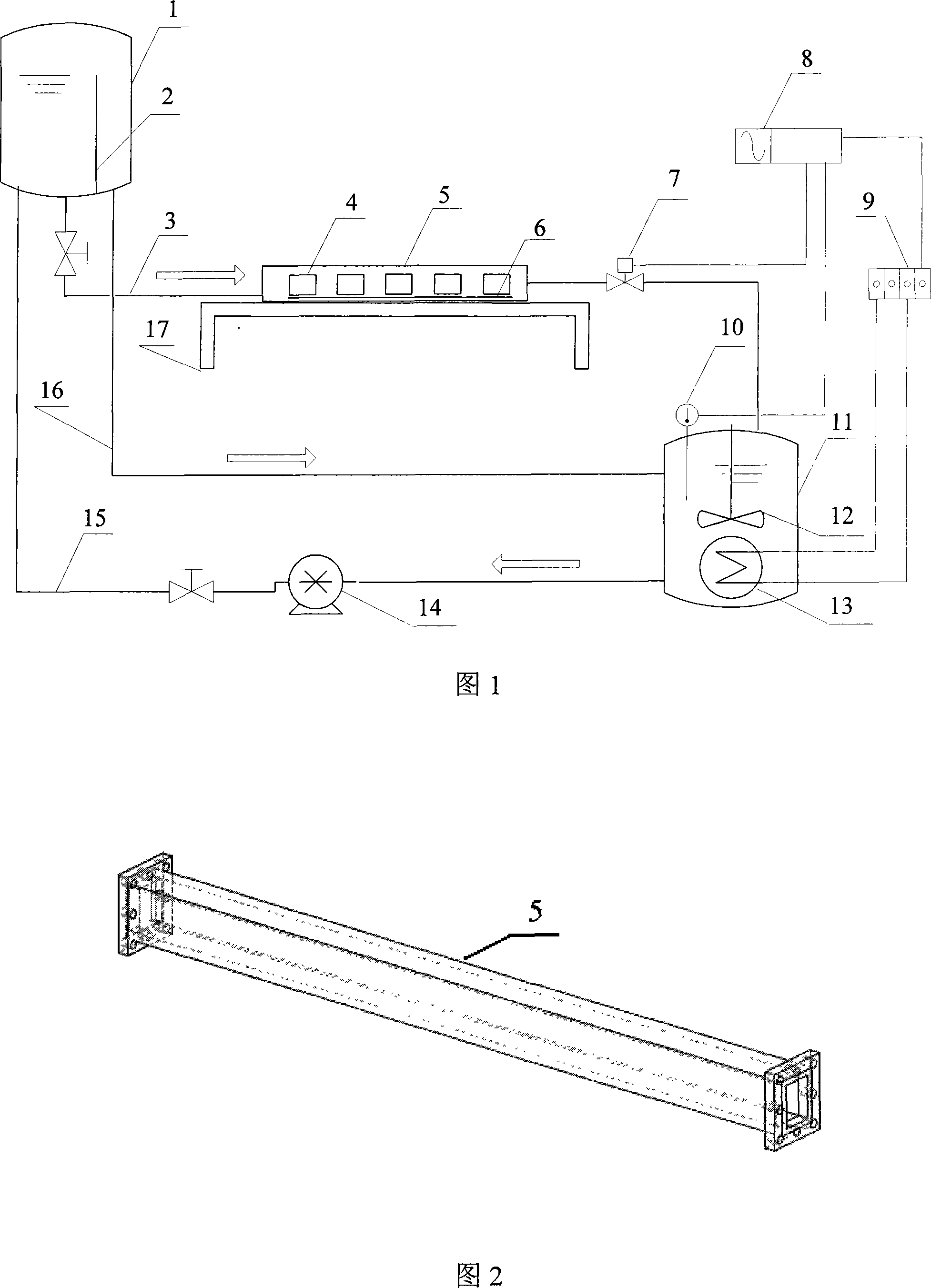

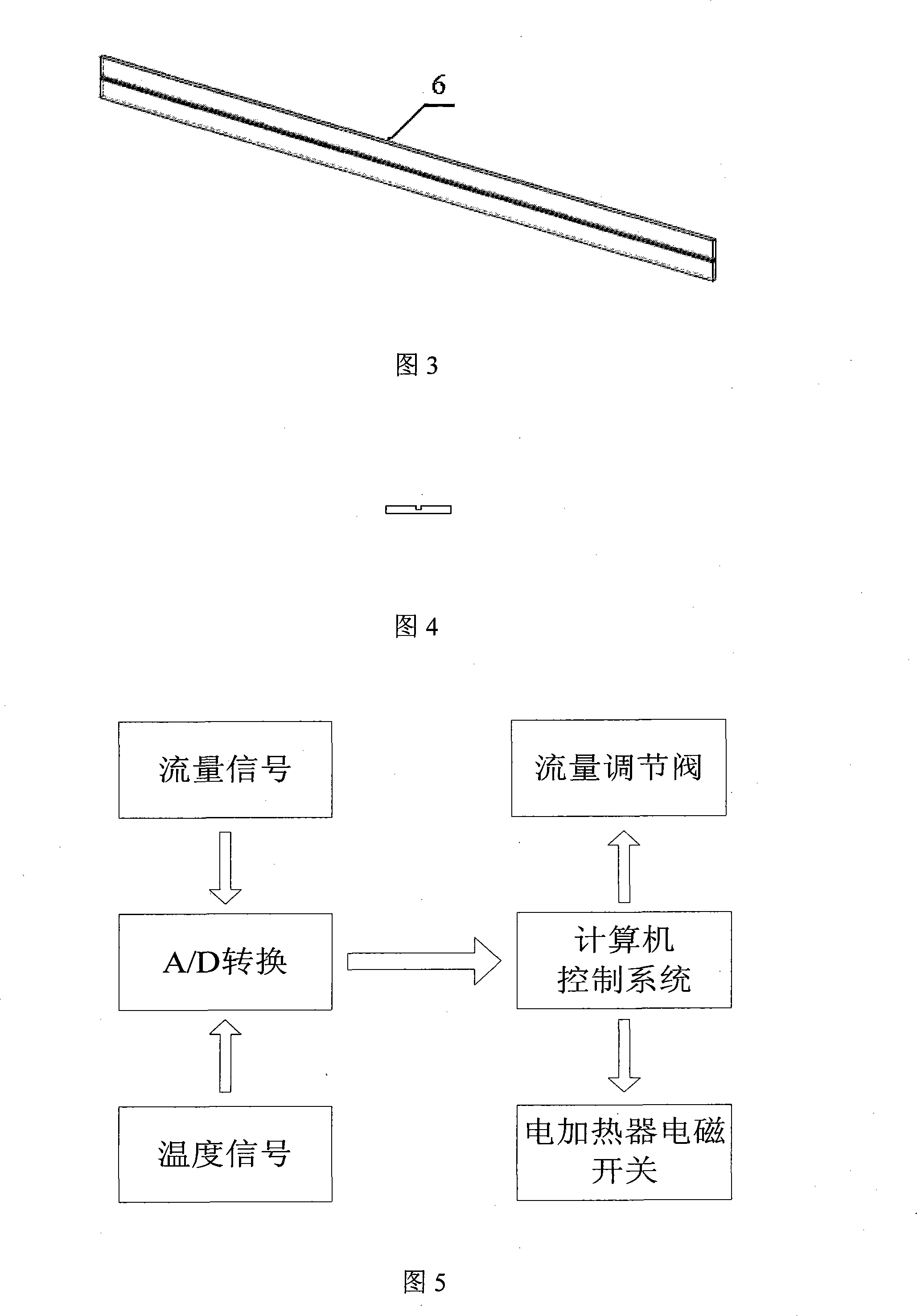

[0051] As shown in Figure 1, a kind of measuring device based on weighing method to evaluate the antiscaling performance of material surface, it is made up of upper water tank 1, overflow plate 2, downpipe 3, test piece 4, test box 5, test piece frame 6 , a flow regulating valve 7, a computer data acquisition card 8, a power supply 9, a thermal resistance 10, a lower water tank 11, an agitator 12, an electric heater 13, a circulating pump 14, an upper water pipe 15, an overflow pipe 16, and a test bench 17; The upper water tank 1 is equipped with an overflow plate 2, and the upper water tank 1 is connected to the side upper part of the lower water tank 11 through the overflow pipe 16 at the bottom; The lower part of the side is connected; the lower water tank 11 is connected to the bottom of the upper water tank 1 through the upper water pipe 15 ...

Embodiment 2

[0059] As can be seen from Fig. 1, a kind of measuring method based on weighing method evaluation material surface antiscaling performance of the present invention is made up of following steps:

[0060] Install the numbered surface material test pieces to be tested in the working medium channel of the experimental box of the material surface scale inhibition performance measurement device;

[0061] Inject the working medium into the lower water tank in the measuring device, heat it to a set temperature value with an electric heater installed in the lower water tank, start the agitator and adjust its rotating speed, and wait for the temperature to stabilize;

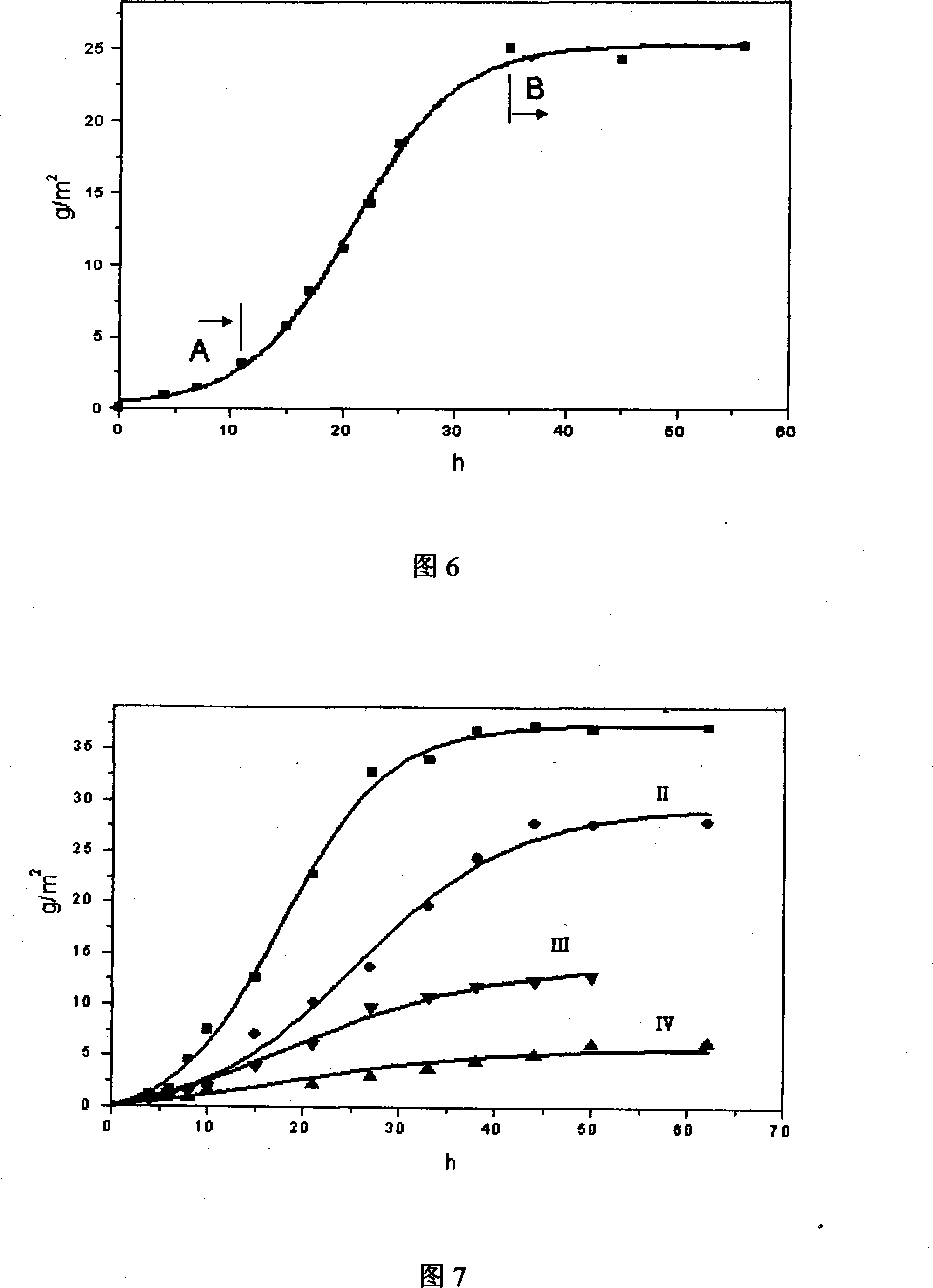

[0062] Turn on the circulation pump in the working circulation loop of the above-mentioned measuring device to circulate the working medium; adjust the opening of the flow regulating valve to the required flow, and start timing, until the asymptotic value appears, stop the circulation pump;

[0063] Record the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com